Superb Anson Engine Museum end-of-season event

Posted by Chris Graham on 21st February 2023

Barry Job reports from the successful, end-of-the-season event at Anson Engine Museum at Poynton, in Cheshire.

Anson Engine Museum: Geoff Challinor, museum curator, stands beside the recently-acquired and significant 1892 6hp Hornsby-Akroyd, s/n 101.

The last weekend in October always marks the end of the season for the Anson Engine Museum at Poynton, in Cheshire. At the museum the fascinating craft section draws the public to watch displays of wood-turning and metal-working.

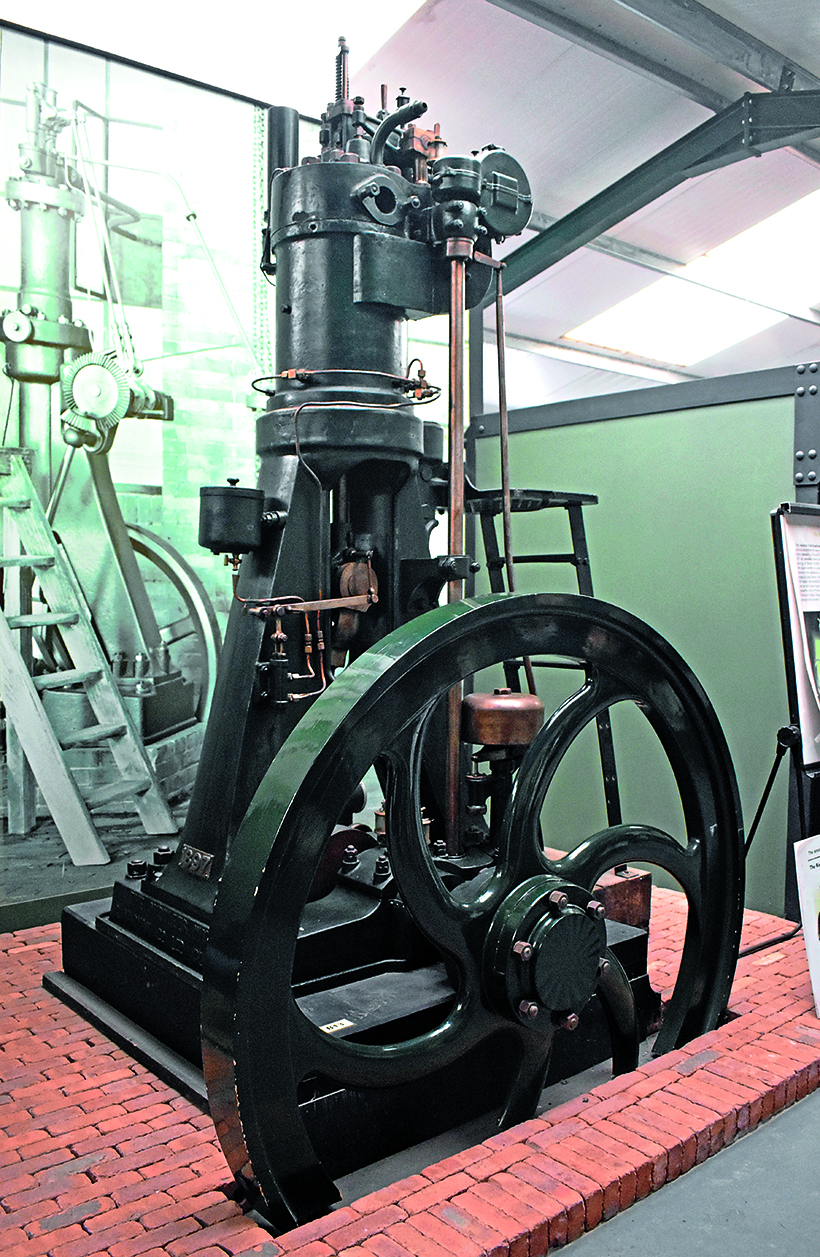

The excellent steam section is based around the 1903 S Stott cross-compound mill engine, which is the largest stationary steam engine in Cheshire. But the section also includes many early steam engines, such as the ‘Bingfield’ engine of 1840, and an 1825 double-acting ‘A’ frame engine which came from Adlington Hall in Cheshire.

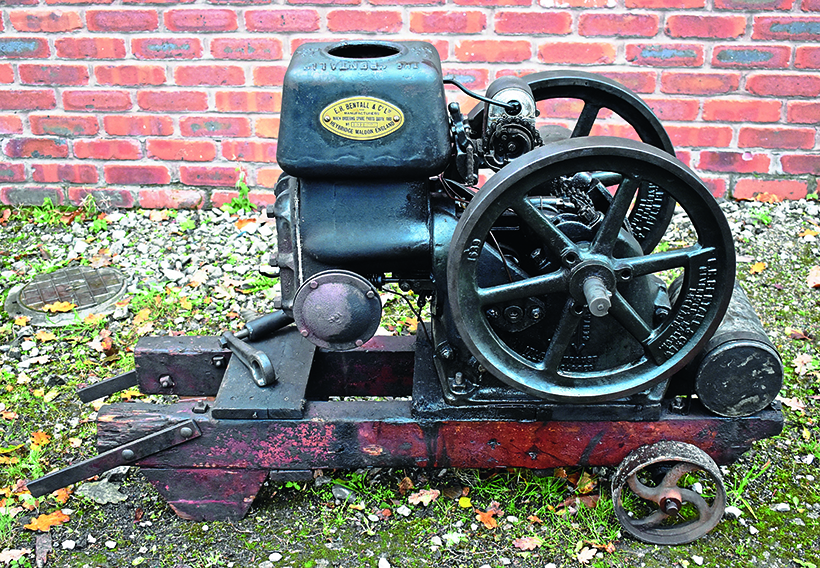

Phil Potts’ 1913 Bentall Pioneer, s/n 131120, 1½hp to 2½hp looked splendid on its original trolley.

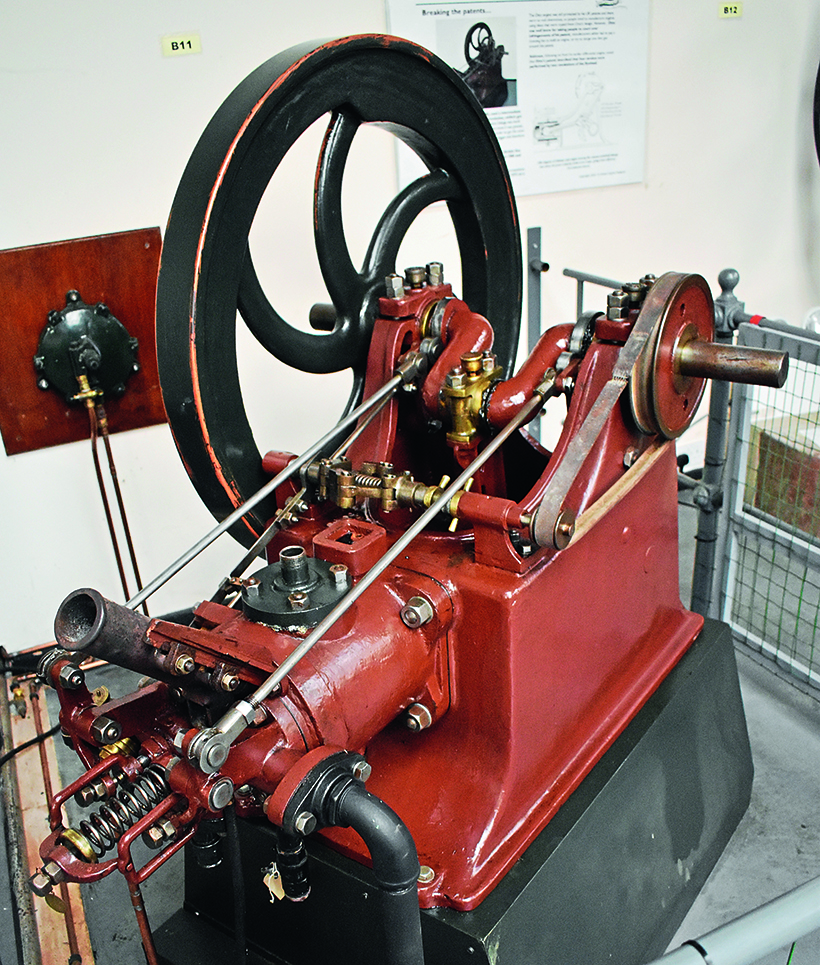

At the heart of the museum is its collection of stationary engines; with well over 250 examples, it’s the largest in Europe. New visitors will be amazed at the range of exhibits. For example, any museum would be pleased to have one, single-cylinder hot-air engine, but here there is a line of them, of increasing size. There are a number of very rare engines to enjoy, too, with a particular favourite of mine being the c1890 Atkinson, that was devised by James Atkinson in 1882. It’s an eight-stroke engine that was designed to get around the Otto four-stroke patent. Unfortunately, the extra-heavy linkage reduced the rated power output, although it did achieve some success.

The L Gardner No. 6 single-cylinder, 5/8hp, hot-air engine was made pre-1900 under licence from A & H Robinson.

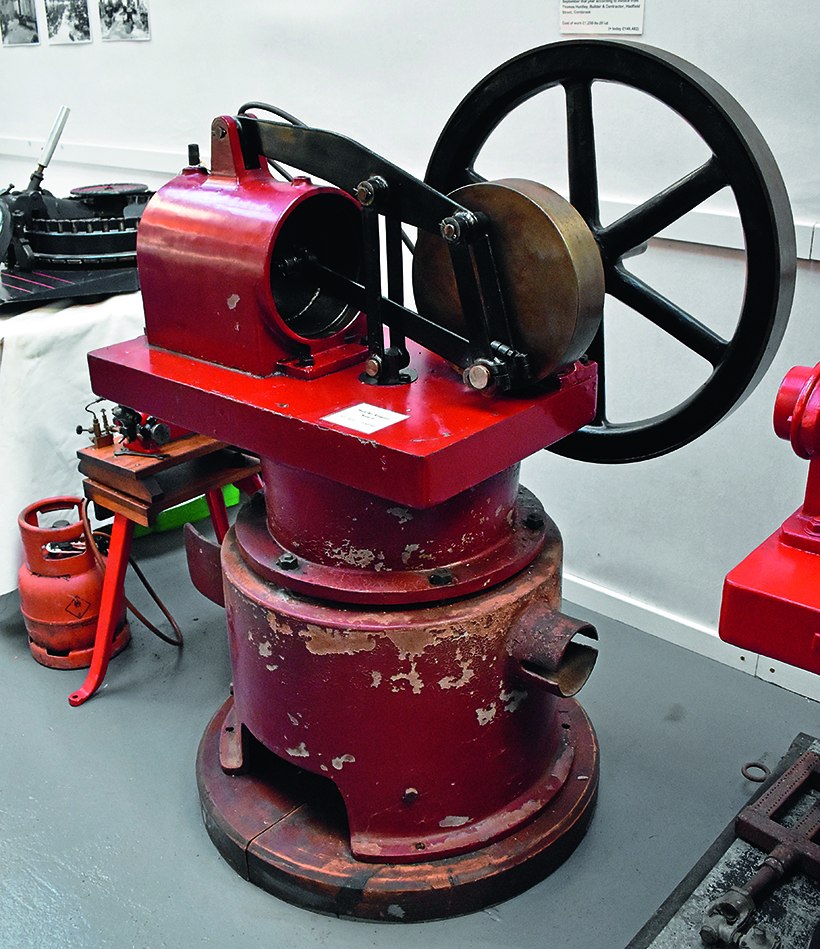

Seen running was another rare engine; the Bisschop non-compression gas engine. Designed to run on Town Gas, the different volatility of propane required careful adjustment of the gas supply. As an atmospheric engine, it developed little power, indeed it’s rated at two manpower, not horsepower. Over 2,000 were produced locally under license by JEH Andrew of Stockport, between 1878 to 1893 and, because they were so quiet, the majority were reputedly used for driving church organs.

Here’s the Bisschop non-compression gas engine being started; it requires ignition from a continuous flame drawn into the cylinder.

A significant and unique engine – and a major coup for the museum – is the acquisition of the July 1892 Hornsby-Akroyd (serial number 101), which was the first production compression ignition engine in the world. It has been secured after many years of negotiation by museum curator Geoff Challinor MBE, with many false hopes along the way.

This is the single-cylinder 20hp, four-stroke, air-injection diesel engine that was made by Mirrlees in 1897.

Indeed, at one time it was thought to have gone to join the MAN Diesel collection in Germany, but now it’s safe in Poynton. This is a seminal engine in the development of compression ignition, and a comprehensive history of 101 will appear shortly. It played a role in the argument about who ‘invented’ the first engine to rely on compression for ignition. A discussion on the relative merits of the two major protagonists, Herbert Akroyd Stuart and Rudolph Diesel, has appeared in this magazine (see Oil Engine Rivals, by Barry Job, issue 278, April 1997).

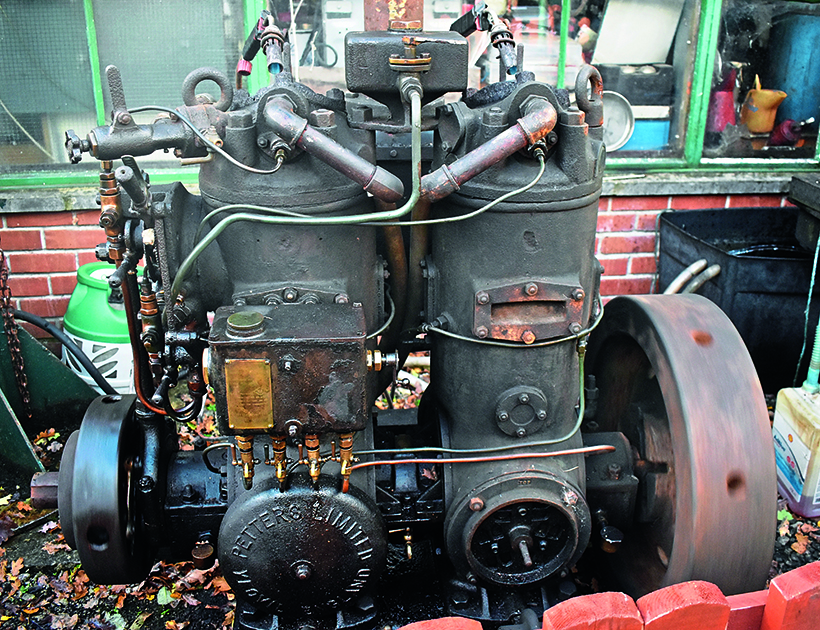

This Petter S2 semi-diesel two-stroke was obtained from the Beamish Museum, and created a lot of interest.

Suffice to say here that Akroyd Stuart had filed patents and produced working engines years before Diesel’s first patent in 1893, for an engine which actually used powdered coal dust for fuel. Although the unassuming Akroyd Stuart achieved some success in conjunction with Hornsbys, with 32,417 engines produced, it was the flamboyant extrovert Diesel who, on his wife’s suggestion, gave his engine his own name and unfairly gained world-wide fame. For comparison, the museum also has on display the important 1897 Mirrlees diesel engine, which was the third production diesel engine in the world.

Recent developments at the museum include the completion of the Chris Bowden Memorial building. This houses a number of large engines including the 1928 air-start Crossley OE128, the restoration of which is continuing apace. Other items are under restoration by the dedicated band of volunteers, but the most recent is a bit different; an axial-flow water turbine. Unfortunately, this must remain a static exhibit as there’s insufficient head of water on site to run it.

The Brotherhood R63/8 500hp sleeve-valve engine was originally installed in the Kirkstall Brewery, Leeds.

One of the many running engines which created a lot of interest over the weekend was the two-stroke Petter semi-diesel S2. Its details are obscure but, using crankcase pressure to drive the lubrication ratchet puts the build date in the 1920s. Another impressive exhibit is the Peter Brotherhood eight-cylinder diesel of 1943. After a talk on sleeve-valve engines, this was started by Ian Summerfield, a stalwart volunteer and former Mirrlees employee.

I have commented previously on Bentall Pioneer engines, which were relatively common in the early days of rallies. I’ve also said that I haven’t seen one for some time, yet the first exhibit I saw on arrival was guest engine, Phil Potts’ 1913 Pioneer, which looked splendid on its original trolley.

The Atkinson eight-stroke hot-tube ignition engine was made by the British Gas Engine & Engineering Company in about 1890.

The weather was relatively good for the weekend and the public attendance was excellent, indeed so good that there were parking problems. The museum is currently closed for the winter, but will reopen next May. You can visit its website at enginemuseum.org for the 2023 dates. Do come and see Hornsby-Akroyd 101 and the Mirrlees diesel, in the meantime look out for the article on the history of the very important engine 101.

This story comes from the latest issue of Stationary Engine, and you can benefit from a money-saving subscription to this magazine simply by clicking HERE

Previous Post

1946 paddle steamer Waverley enjoys a busy season

Next Post

Collectable Austin A55 and A60 models