Ferguson TED-20 buyer’s guide

Posted by Chris Graham on 12th November 2020

The Ferguson TED-20 is an appealing tractor that’s perfect for anyone interested in getting involved in the preservation scene.

A Ferguson TED-20, with Ferguson dung-spreader attached, make an ideal combination for restoring and showing.

With so many having been manufactured by the Standard Motor Company factory at Banner Lane in Coventry, there are certainly plenty of examples to choose from today. In this buyer’s guide, we describe the features, what to look out for when viewing a Ferguson TED-20, and offer some ideas about some of the ‘toys’ you can pull behind your newly-acquired Fergie.

The designation ‘TED-20’ denotes that the tractor is designed and built to be started on petrol and run on tractor vaporising oil (TVO) once warm. TVO isn’t a commercially-available fuel, but can be approximated by mixing petrol and 28-second heating oil (kerosene). HMRC requires that anyone mixing TVO holds a valid licence to do so, which is best obtained from a relevant club, such as Friends of Ferguson Heritage. Organisations like this will also give guidance on the proportions of constituents which should be used.

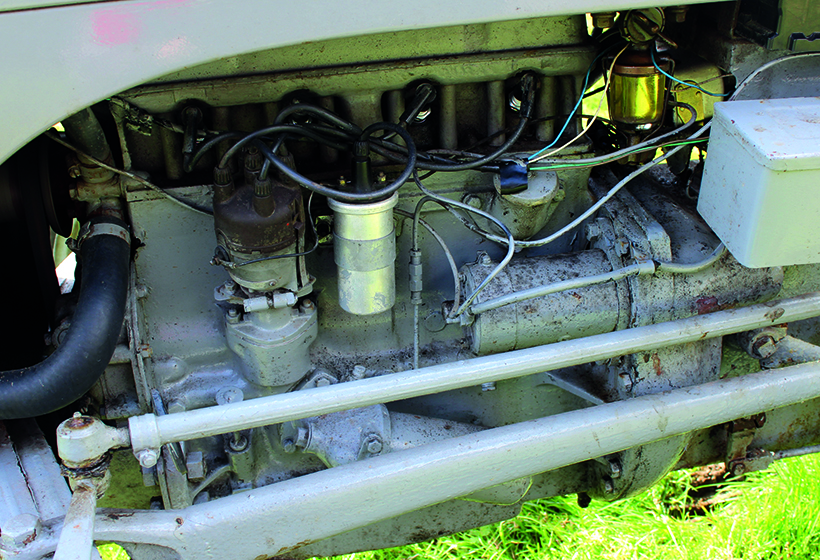

Left-hand side of the engine, displaying the electrical equipment; early tractors are 6V, later models, 12V.

The 2,088cc engine was manufactured by the Standard Motor Company, and features a cylinder bore diameter 85mm as opposed to the 80mm bore of the original, petrol-only engine, while retaining the same 92mm stroke. The increase in bore was necessary to counteract the power loss of running a lower compression cylinder head, to prevent pre-ignition of the fuel. Initially, a compression ratio of 4.8:1 up to and including engine number S170,173E produced 23.9hp, but later engines featured a compression ratio of 5.1:1, with a correspondingly useful increase in power to 25.4hp.

The engine is a strong unit having its heritage in Triumph sports cars, but it’s not interchangeable with those due to differences in block design and bore diameter. The ‘stressed’ block to carry the front axle being achieved by a deeper block casting and shallower sump.

The right-hand side of the engine features the Zenith 24T carburettor and vaporiser manifold heat shield.

The Achilles heel of the engine is the fact that oil dilution could occur if the tractor was switched over from petrol before being sufficiently hot enough. The result was premature wear of all the major engine bearings, which gives a clue to why the service intervals on TVO tractors are very short.

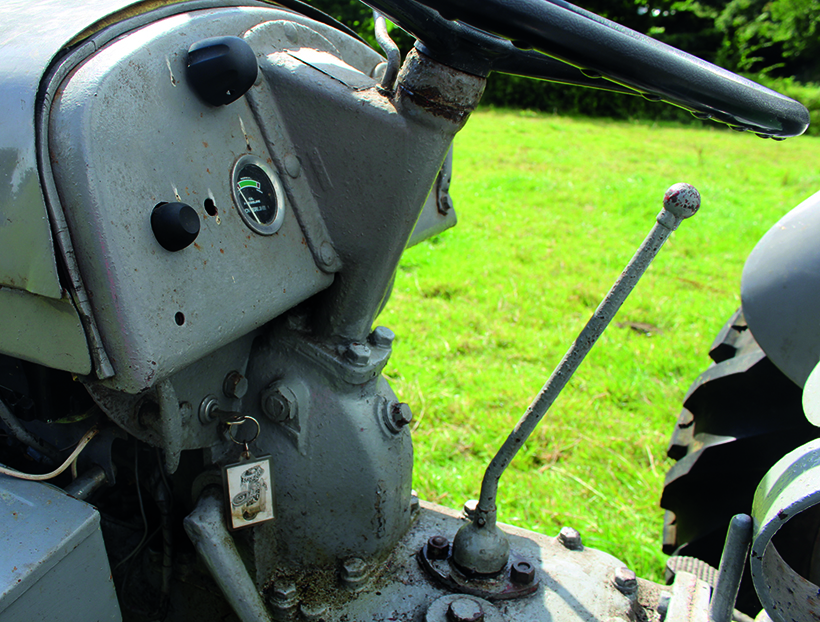

When viewing a potential purchase, assuming that the tractor is a runner, ask to see the tractor started from cold, and then left running until it’s fully warmed up. Starting from cold will greatly assist in determining the correct operation of the carburettor under choke conditions, the choke control being found to the lower right of the dashboard. A novel safety feature of the Ferguson TE range is that the gear lever pushed to the upper right acts as the starter switch, once the ignition key is switched.

A running tractor in fine fettle should start quickly and instantly display good oil pressure, even at idle. Petrol tractors shouldn’t smoke so, if they do, then something’s very wrong. However, a cold tractor will, of course, be puffing visible water vapor as the combustion products condense on a cold exhaust pipe. The tractor should be allowed to warm up at a fast idle before any attempt is made to switch from petrol to a TVO equivalent mixed fuel. Incidentally, the change-over tap is found under the left-hand rear of the fuel tank.

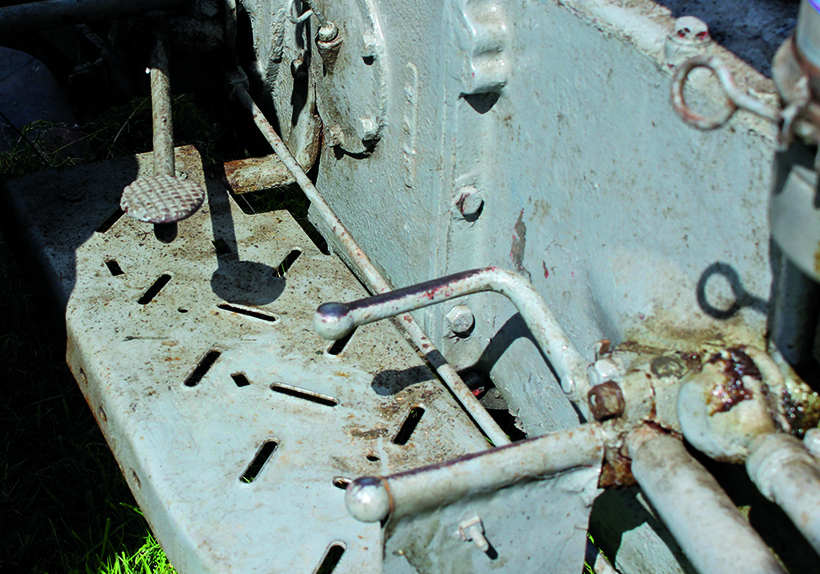

Clutch pedal to the lower left, PTO lever the upper centre with the LH independent brake pedal below.

Clutch

The TED-20 is fitted with a single-plate clutch measuring 229mm (9in), which means there’s no live drive to the PTO or hydraulics. Consequently, everything stops when the clutch pedal is depressed. For anyone used to driving more modern tractors, going backwards, technologically-speaking, takes some getting used to. There is, however, one advantage in that it’s rare for the clutch to go out of adjustment, but do check that the pedal has free movement at the top of its travel.

Clutches do wear, of course, but it’s unlikely to have been abused as a loader tractor. Nonetheless, always check for clutch slip by driving in third gear then applying the brakes momentarily, at which the engine should die away quickly. This is assuming that the brakes are working effectively! Also, check for any nasty noises from the thrust bearing when the clutch pedal is depressed. Any work on the clutch will necessitate splitting the tractor, although this is a straightforward procedure due to the tractor’s basic specification.

Gearbox

It’s no surprise that the TED-20 was only available with one gearbox option limited to four forward ratios and a single reverse. In general, first and second gears are ploughing gears, third is for light draft work (such as harrowing) and fourth is intended for transport. There’s no synchromesh so care is needed when changing gears – the original handbook advises bringing the tractor to a standstill before doing so. Maximum transport speed is approximately 12mph, which is adequate.

The single gear lever is well positioned on top of the transmission housing, the ignition switch is found below the dashboard.

The standard TED-20 is unable to tackle rotavating due to the lack of low gear ratios and, therefore, Howard rotavators offered its own reduction gearbox to fit inside the standard TED-20 transmission, to solve this problem. A tractor with such a gearbox fitted will have a gear lever on the right-hand side of the transmission housing. These reduction gearboxes must never be used to increase tractive effort, as the transmission components aren’t designed for such abuse.

The standard gearbox is a robust unit, and trouble shouldn’t be expected in this area. If viewing a potential purchase, drive the tractor in each gear to check that all can be engaged, and don’t make any nasty noises. They’re not known to be particularly noisy so suspect something is amiss if a tractor is noticeably ‘whiny’.

Rear axle and PTO

The rear axle of the TED-20 is the building block on which several generations of MF rear axles were produced, over a 50-year period. It’s unlikely that any trouble will be encountered in this area other than, perhaps, a failed half-shaft grease seal. Unlike subsequent generations, the axle also features greasable axle hubs, so expect to find 70 odd years-worth of caked grease upon a full strip down.

The PTO shaft and trailer tip pipe are found to the lower section of the rear axle.

At the end of the half-shafts you’ll find the 14in drum brakes, which are sufficient for the size of tractor. This is an area were many tractors will have been neglected, with brakes shoes often worn and out of adjustment. The brakes are operated together by the single, master footbrake, or independently by the two pedals behind the operator’s heels. A parking latch is provided on the master brake pedal.

This rear axle and linkage design remained little changed for 50 years on MF’s small tractors.

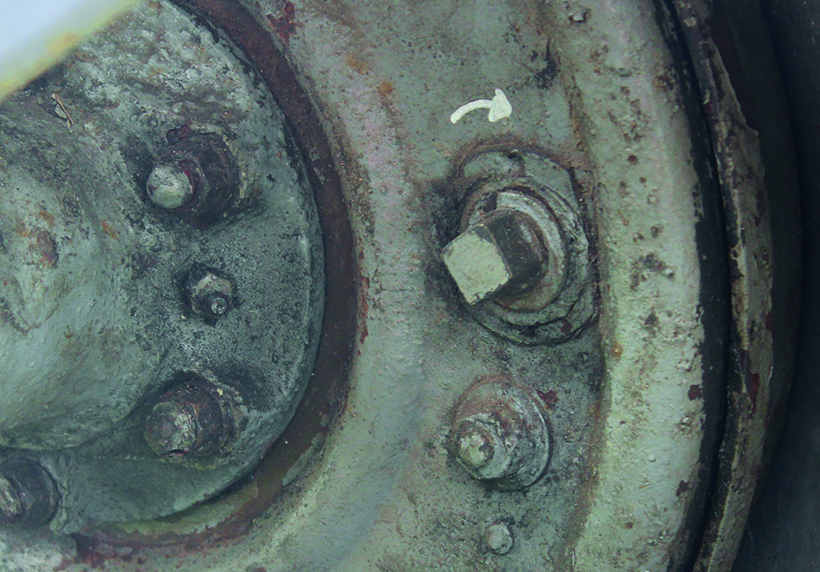

The brakes can easily be tested together or independently, to establish their condition. If their performance is poor, the brakes may simply need adjusting using the screw on the brake backplate or, more likely, the shoes will need to be replaced, and the drums skimmed or replaced.

Master brake pedal and RH independent brake pedal are on the right-hand side of the transmission casing.

The Ferguson TED-20 features a PTO but, due to the single clutch, both the forward motion and PTO start at the same time. The shaft size is also only 1 1/8in, which is non-standard which necessitates the use of an adapter to operate equipment fitted with the standard 1 3/8in size. Replacement conversion PTO shafts are available, should you wish for a more robust solution.

When using the TED-20 for towing, it would have originally been supplied with the Ferguson nine-hole drawbar and stay arrangement. This is a cumbersome set-up, but was suitable for most trailed implements of the time. It’s possible to fit a swinging drawbar assembly, and these are now readily available as a remanufactured item.

Brake adjustment is effected by rotating the square-headed adjustment screw on the brake backplate.

Hydraulics

The Ferguson System is at the heart of the TED-20 tractor and, although cutting-edge at the time, it’s an extremely simple system offering basic top link-sensed draft control only. It’s possible to approximately stop the lower links at any height by finding the neutral position on the control quadrant, to the right of the driver but, ultimately, there’s no internal control for holding a particular position.

One quirk of the system is that the PTO lever must be engaged to drive the hydraulic pump; great for saving energy and wear in not driving the pump continuously, but frustrating when operating PTO equipment as the PTO has to be turning just to raise and lower an implement. So it’s important to keep the PTO cap on as the shaft is rotating whenever the hydraulics are operating.

The hydraulic control quadrant, to the right of the driver’s seat, offers draft control only.

As this is a small tractor, the linkage features category one only, and can muster a lift capacity of about 450kg, which is enough to lift all the Ferguson equipment the tractor was designed to be used with. The system is in its element for ploughing and cultivating, but items requiring position-control – such as hay tedders and like – are a little challenging, if not impossible, to operate.

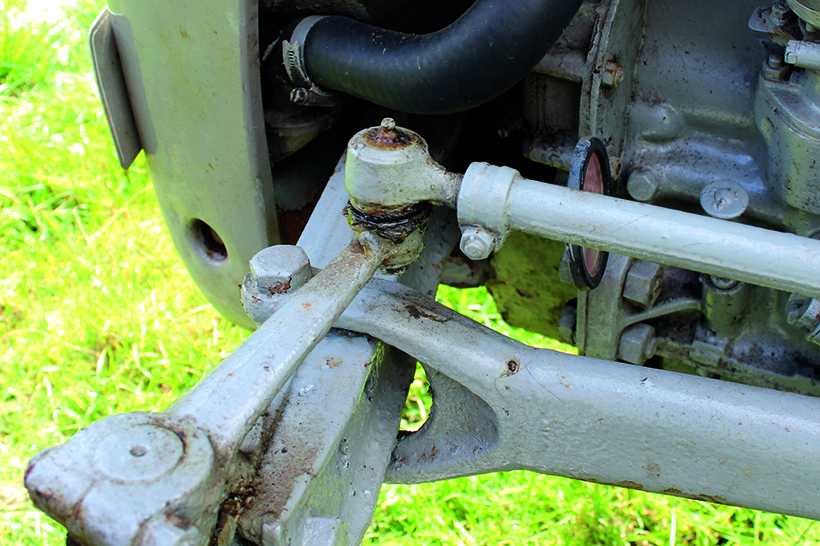

It’s category one only lower links for this little tractor, so expect to find plenty of wear in the linkage components.

When checking over a tractor, wear will be expected in the linkage joints, which typically can only be rectified by replacing components. It’s vital to check are the studs which protrude from the trumpet housing to hold the bottom-ends of the lower links; if worn, the trumpet housings will need to be removed if replacement is desirable. The levelling box is also prone to excessive wear and, although aftermarket replacements are available, original items in good order are scarce.

The hydraulic system is ideal for operating a two-furrow plough, such as this 12in furrow model.

Front axle, steering and wheel equipment

The tractor features a three-piece front axle, which was originally specified on the Ford Ferguson 9N models, and allows the track width to be adjusted while keeping the Ackerman angle in the steering geometry approximately correct. This is necessary to ensure that the inner and outer wheels on the steering axle during a turn act on differing track radii, to avoid scrubbing the tyres.

The swept front axle is of a three-piece design, to correctly preserve steering geometry for differing track widths.

All steering systems feature many ball joints and bearings, and the TED-20 is no exception. If possible when viewing a tractor, jack-up the front end to check the amount of wear in the front axle pivot bush, before moving to the rest of the steering joints and kingpin bushes. Play in the steering box is likely to require replacement of the column bearings before correctly adjusting the locknut. All parts to overhaul the system are readily available.

The four ball joints and the axle pivot pin need close inspection; replacement parts are cheap and readily available.

Only one size of front and rear wheels were offered, these being 4.00-19 fronts and 11.2/10-28 rears. Some tractors may have been retro fitted with larger 6.00-16 and 12.4/11-28 tyres but this is a personal preference. If originality in restoration is your end goal then try and find a tractor with Goodyear diamond front tyres in good condition as new tyres of this type are not available to match the 11.2/10-28 Goodyear sure grip rear tyres still currently available.

Jack-up the front end to assess wear in the components; the king pin bushes are the most difficult item to replace.

Operator platform

The standard operator platform is basic; these tractors weren’t fitted with foot plates, only foot rests. But, many tractors have been retro-fitted with foot plates, which not only adds the benefit of an alternative foot position, but also adds safety when climbing aboard. Once aboard, you’re greeted with a tin seat mounted on a spring steel arm with no cushion (they are available nowadays).

All the controls are to hand, with an oil pressure and water temperature gauge to monitor the engine. The clutch pedal and steering are light in operation, with the well placed gearstick making manoeuvring easy. The operating position is a perfect place to be on a dry day but, driving a tractor without a cab is no fun in the wind and rain!

View from the driver’s seat; completely uncluttered. A wing mirror is a useful addition for road runs. An oil pressure and water temperature gauge, plus ignition light, feature on the dashboard.

It’s possible to obtain period cabs for the TED-20, such as the type manufactured by Scottish Aviation, but these aren’t safety cabs, so can be used for show and rally purposes only, rather than on a working tractor. It is, however, possible to fit a Lambourne cab – more commonly found on MF35s – to the TED-20, which is a safety cab with two easy access doors, making it ideal for work or play.

Optional equipment

There were a number of optional items available for the TED-20, one of the most popular of which was the automatic hitch, enabling trailed implements to be attached from the tractor seat. A lighting kit was also offered; the first incarnation featured a single, bonnet-mounted headlight, two bonnet-mounted side lights and a single, combined rear/number plate marker and a plough lamp. This style of lighting kit is commonly referred to as the ‘Cyclops lighting kit’.

Towards the end of production, the later kit included two headlights mounted on arms that projected from the side of the bonnet, in combination with two rear marker lights, one also acting to illuminate the number plate. Some tractors will have been retrofitted with a lighting kit of the style more commonly found on a MF35X, such as the tractor featured in this article.

A must-have accessory is the automatic hitch, with this being a later MF style, with improved latch.

Other options included a belt pulley attachment, tachometer and hour recorder, tractor jack, vertical exhaust instead of the standard, rear exit-type, to name a few. Besides the options, there’s the range of Ferguson equipment to collect, and most will be satisfied with a two-furrow plough. If you want something a little different, then seek out an original, 30cwt trailer, or a Ferguson dung-spreader, but these items aren’t cheap, especially the former!

Current prices

Expect to pay £300-400 for a grade one non-runner, moving upwards towards £900 for a grade two running project, which will need a few jobs doing to it, plus a cosmetic overhaul. Grade 4, older restoration tractors will fetch the best part of £2,000, while a freshly-restored tractor will typically cost £4,250.

Show tractors will edge towards £5,000 with original parts and correct detailing, such as chrome- and zinc-plating in all the right places. The most coveted models are the grade 3, original, never-repainted examples, which are unlikely to give you very much change from £5,000.

The Ferguson 30cwt trailer is one of the more expensive implements to collect, but sits nicely behind the TED-20.

Many thanks to Percival Harris for allowing me to photograph his tractor and implements.

For a money-saving subscription to Classic Massey & Ferguson Enthusiast magazine, simply click here