Buying the giant MF 1200!

Posted by Chris Graham on 9th September 2022

Chris Graham chats with experienced Massey Ferguson specialist Doug Mottershead about buying and living with the giant MF 1200.

The chassis and all panel work was extremely thick on the MF 1200, so it lasts well. Any rust found is likely to be surface-only. The cab wasn’t built by Massey Ferguson and the paint quality wasn’t as good as the factory achieved.

If you fancy a large, 1970s classic tractor, they don’t come any bigger than the articulated MF 1200. This is a beast of a machine that, having been developed in America, was built by Massey Ferguson at its industrial works in Barton Dock Road, Manchester, between 1971 and 1979.

This massive, articulate tractor followed the design footsteps of the more powerful, American 1500 and 1800 models, and featured the same, ‘hard-nosed’ style of bonnet with side-mounted air intake stalk and pre-cleaner element, plus a very square-looking cab. The pivot for the 1200’s articulated steering set-up was also similar but, at the rear, an integrated three-point hitch was developed to provide the sort of implement versatility needed for the European market.

Power a plenty!

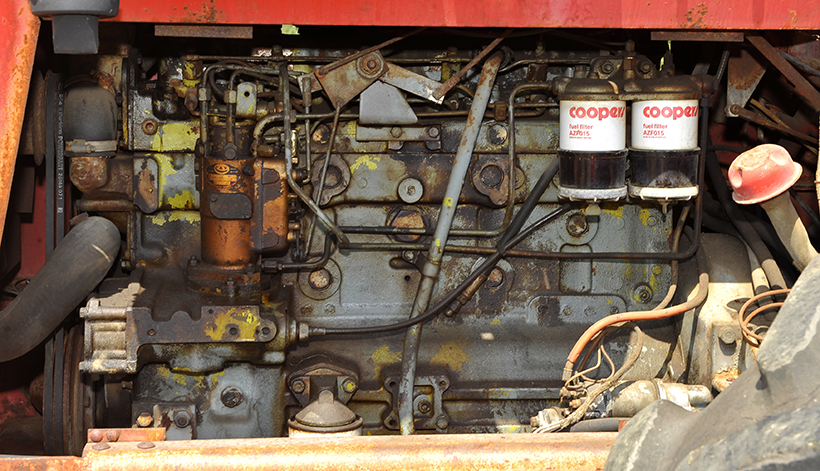

Power was delivered by a Perkins A6.354, 5.8-litre, six-cylinder diesel engine producing 105hp at 2,400rpm which, back in the early 1970s, was right at the top of the scale here on the home market. The engine’s output was transmitted to the wheels via a 12-speed Multi-Power transmission, or an optional, eight-speed gearbox.

The MF 1200 had been designed from the outset as a 4WD tractor, and it rode on large, equal-sized wheels that ensured plenty of ground clearance. These were bolted onto a pair of axles taken from the MF 188, and the tractor’s central articulation allowed the front and rear wheels to tilt independently, enhancing rough ground performance. A powerful hydraulic ram turned the machine around its central pivot, with the engine and cab on the front half allowing the driver to face forwards at all times, while the rear wheels followed in the tracks of the fronts.

A 318-litre fuel tank was mounted high up behind the cab, and large, easy-to-remove panels on either side of the engine provided access for routine maintenance. The dry element air cleaner was mounted to the side of the bonnet and the battery was housed under the cab, on the offside, with a swinging door giving easy access. Overall, the amount of attention to detail lavished on the 1200’s layout at the design stage resulted in a very user-friendly tractor that was easy to live with, service and maintain.

The MF 1200 was the UK’s first articulated, 4WD tractor. The 70-gallon fuel tank is built into the back of the cab, and checking the level requires a bit of climbing! Massey Ferguson bought the wheels from a third party supplier so, like the can, they tend not to be as durable as the rest of the tractor. Standard equipment was 12×38 tyres, but most are fitted with the optional 14x34s. Check for loose, welded-up rim lugs.

Driver benefits

A big selling point for the MF 1200 was the quality of its cab. Although it may have looked simple and boxy from the outside, it offered the driver plenty of space, comfort, visibility and refinement. It conformed to the very latest safety regulations and would support the weight of the tractor in the event of a roll-over.

The keys to the interior refinement lay in the fact that the cab – together with the engine, gearbox and transfer box – was supported on rubber mounts, and that state-of-the-art insulation had been included, both of which helped minimise the transmission of sound and vibration into the driving compartment. The cab also featured a flat floor, fully adjustable seat, hydro-mechanical controls and a heater/blower to provide the driver with rudimentary ‘climate control’.

Above all, though, the MF 1200 had been conceived as a heavy-duty tractor; it was sturdily built, durable and big enough to take the operation of large implements – power harrows, forage harvesters and rotavators etc – in its stride. Plenty of thought had also gone into the vital aspect of weight distribution and, when properly set up, the 1200 could out-pull the best of the rest.

However, with the newest of the MF 1200s now being 43 years old, and the model only having been build in limited numbers – by the standards of most mainstream tractor models – examples on the secondhand market these days are few and far between. But that ‘rarity value’, of course, has the effect of making the MF 1200 even more desirable to enthusiasts in search of what truly is the big daddy of the Red Giants 100 Series range.

Buying advice

One such enthusiast is Derbyshire-based, self-employed Massey Ferguson mechanic and parts specialist, Doug Mottershead. He’s worked on the MF 1200 professionally, both as a Massey Ferguson dealer employee and, over the past 34 years, as an independent repair specialist. So he’s ideally placed to comment on the ins ands outs of both buying and owning one of these giant machines.

I visited Doug’s Ashbourne home on what turned out to be the hottest UK day in living memory – July 19th – and, as we sheltered in his cool farmhouse kitchen before the photo session, I asked him to begin by explaining the potential problems that an MF 1200 buyer should be aware of.

However you look at it, the MF 1200 is a large and imposing machine. Massey Ferguson red paint from this era typically fades to the pink seen here on Doug Mottershead’s original example.

He started by stressing the importance of establishing that the tractor you’re interested in is as original as possible. “Make sure you are able to see a set of decent photographs before you set off for a viewing,” he advised. “Plenty of 1200s have been modified over the years, and lots have been used for tough work, such as forestry. I’d avoid any that have been worked in that sort of environment. I’d also steer clear of those that have been fitted with a Hiab crane on the back, or chopped around in other ways; these models are usually beyond viable restoration, in my view.

“Restoring one of these tractors properly is undoubtedly a big and involved job, and the number of unique parts used on the model mean that sourcing correct spares nowadays can be a real struggle.”

Practical pointers

“The superb Perkins 6.354 engine is secured to the chassis by four, rubber, anti-vibration mountings. It should be a good starter and can be a bit smokey until it’s warmed. Early models can smoke a lot under load, which is a sign of an injection pump timing fault. Some will have been retro-fitted with a Opico turbo to boost power. The externally-mounted air cleaners suffer badly with corrosion, and you’ll often find that exhaust system will have been repaired or modified.

“There’s never a problem with the chassis because it was made from such thick steel; just about the only thing that can rust seriously is the battery tray (under the cab). At the front, check the axle input seal for weeping fluid loss, and the outer seals near the wheels for leakage. You might also find split brake adjuster rod rubber cup seals, which will be leaking.

“Check the engine-to-gearbox shaft, as the metal/elastic rubber bushes tend to perish and, if you notice a rattle during tick-over, it could be the splined pulley and shaft wear. This pulley also drives two hydraulic pumps, via two pairs of belts. Assess the clutch for thrust bearing noise and slippage as a clutch overhaul will entail getting the whole unit reconditioned. The 13in drive plate is accessed through cab floor.

Well-equipped dash offered theMF 1200 driver plenty of information, apart from fuel level. However, a simple sight glass was provided elsewhere in the cab.

“Check the operation of the gearbox, listening for excessive noise or a tendency to jump out of gear. Also watch out for excessive play in the gear-lever, and oil leaks from the cotter pin. Be warned that most internal components used in the Multi-Power gearbox were unique to the 1200, so finding affordable replacements is very difficult now.

“The transfer box shares oil with both the steering pump and gearbox, and the level can be checked by removing the square-headed bung at the back. Also check for drive shaft seal leaks. To carry out any internal work on either the gearbox or the transfer box, they’ll need to be lifted and extracted through cab door!”

Axles and steering

“Check the driveshaft universal points for signs of wear, and listen for knocking under braking – this can be caused by play in the top and bottom spherical bearings. If there’s no oil showing on the rear dipstick, then it’s probably the lip seal in the oscillating part of rear axle that’s letting the fluid leak out.

“The power steering is fed off the same belt-driven pump as the Multi-Power system, and it takes oil from bottom of transfer box through a replaceable, suction filter. The power steering gets priority over Mult-Power so, if there’s no assistance, then there’s probably insufficient oil in the transfer box. If the steering becomes very heavy when Multi-Power is set in ‘high’, then there’s probably a major leak in the supply to the Mult-Power, through the input shafts to the gearbox.

“The centre housing contains the Scotch yoke hydraulic pump for the lift arms, PTO and diff-lock pump and clutch pack. A hydraulic quadrant is bolted to the side of the driver’s seat, and two operating cables run from this, through a canvas tube, to the hydraulic top cover. An assistor ram is used, via linkage, to give a greater lift capacity of 3,402kg (7,500lb). These cables often seize up, but the hydraulic systems themselves seldom give trouble.

Engines were often modified of swapped o the 1200. This one is from a Claas combine harvester.

“To assess the PTO, note how easy it is to turn the shaft by hand (with the engine switched off). If it’s really hard or impossible, this could be an indicator of warped plates inside the clutch pack. Again, it’s not unusual for the cable to be seized up. It’s also quite normal for the shaft to turn when the oil is cold, and when there’s no implement attached. However, if it neither drives nor stops, there’s probably no output from the pump, due to worn internal splines.”

Diff locks and spool valves

“The diff locks on both axles are operated by a cab floor-mounted pedal, and there’s a white engagement light on the dash panel. There are some steel and rubber oil pipes in this system which can corroded away or perish.

Two single/double-acting spool valves are fitted as standard, and operated by two levers to the right of the dash panel. Another belt-driven pump sucks oil from a steel tank under the LH side of the cab, through a changeable filter. Four rubber, high-pressure pipes run under the cab floor, and through the canvas tube to four, quick-release couplings at the rear.

This auxiliary tank has a dipstick on top plus a filter tube in the left-hand side of the engine bay. Standard fitment is a 2,500psi system which pumps at 4.3 gallons per minute at 1,500 revs. An optional, hi-flow system was available, delivering 2,000psi and 10 gallons per minute.

“The tractor’s brakes are fluid-operated via a pedal, with a reservoir under the bonnet flap containing dot 4 fluid. A master cylinder supplies four slave cylinders, two on each axle. The handbrake works mechanically on the front axle only. Later tractors had a longer lever. Check for seized-up or sticking cylinders, usually caused by moisture in the fluid, corroded pipes, perished flexi hoses or rubber cup seal failure.”

The 1200 featured an extremely heavy-duty drawbar, but no pick-up hitch. Hydraulics are generally reliable. Rear light clusters on stalks were vulnerable, so are often broken or missing.

Further thoughts

Of course, finding and buying an MF 1200 is one thing; having the space to store, live with and use one is quite another. Weighing in at well over five tonnes, it’s not a tractor that you can pop on a trailer and tow around with your Discovery. In reality, moving one of these will require a sizeable low-loader or a big trailer towed behind a powerful, modern tractor. And, at just over nine-and-a-half feet high, you’ll need a serious shed for proper storage, too.

Nevertheless, Doug is convinced that this Red Giant is becoming more collectable all the time, and he thinks that most owners tend to hang on to their machines. Those examples that do get moved on are often the ones that have been abused, so buyers need to be careful. Renovating one of these machines properly will require a thorough, nut-and-bolt restoration. It’s a big, heavy job if you’re going to do it right and, with the shortage of parts that now exists, useful contacts and the help of other owners will be essential.

With such things in mind, Doug advises that you buy the best you can. “In my view,” he told me, “you’re always better off paying a higher price in the first place, and getting a tractor that’s pretty much sorted, rather than buying something that, although cheap, will require a fortune to be spent to get it right. Having said that, I can understand the attraction. An increasing number of people are realising what the MF 1200 can offer, and the important place it occupies in the Massey Ferguson tractor development story.

“This is a tractor that was a trend-setter in its day, and was a very accomplished performer. In some respects it was ahead of its time, with the emphasis in placed on driver comfort and safety, plus the ground-breaking marriage between engine power and well-engineered four-wheel-drive.”

Despite being the first articulated 4WD model available to farmers in the UK, the MF 1200 was never a great seller; perhaps it was just a step too far for the conservative British market at the time. A proportion of the 2,200 or so 1200s that left the Manchester factory were exported to Australia, Denmark and Holland, where the larger fields may have suited the tractor’s skill set better. The model was superseded by the improved and slightly more powerful 1250 version in 1979 but, despite that machine’s practical benefits, only about 320 were sold, and production came to an end in 1982.

Storing an MF 1200 requires plenty of space, but the tractor’s articulated layout makes it easier to back into spaces than you might imagine.

Today, the MF 1200’s lack of sales popularity is a distant memory, and of little concern to collectors who now see the model as interesting and even quirky. It’s a physically impressive machine that never fails to turn heads, and seeing one out and about – or at a show – is always a rare treat.

Owner’s view: Doug Mottershead

“I was attracted to the MF 1200 because of its sheer size, and the fact that it makes everyone smile when they see it! It’s also very useful at shows if the conditions get wet and slippery; I’ve often used mine to tow stranded lorries off a muddy show field.

“This tractor was advertised as having a perfect, 50:50 weight distribution with an implement on the back and, in that guise, it’s my view that nothing from that era could pull like a 1200. I’ve owned my late example for about 15 years, but have never done any serious work with the tractor. However, I have bought a couple of ploughs for it, although both are in need of complete restoration.

“I have to admit that I haven’t done much mechanical or restoration work on it over the years; working with Massey Ferguson tractors for my day job, tends to mean that my own machines get put on the back burner. Consequently, it’s in the same condition now as when I bought it. All the paint is original and, due to the characteristic, age-related loss of pigment, it’s faded to pink.

“I’d love to be able to find the time to restore it properly but, as things stand, it’s the paying jobs that have to take priority. Nevertheless, I still get a thrill from driving the 1200. It’s not a fast machine on the road (I’ve never taken part in a road run in it), but there’s a real sense of occasion every time I use it. The refinement in the cab really does match the claims made by Massey Ferguson in its marketing material.

Doug Mottershead has owned his MF 1200 for 15 years, and hopes to get around to restoring it one of these days. He also now supplies various new brake parts, seals and complete sticker sets for the 1200. You can call him on: 01335 348889 (evenings only).

“It’s such a shame that so many got cut about and modified for purposes other than working in the fields. I know that one specialist firm used to reverse the cab, fit a large bucket and sell them as dumpers! I’ve seen others permanently fitted with sprayers, and I know that a number ended up as tugs for trailering boats in and out of the sea which, of course, is a death sentence for any tractor.”

WHAT TO PAY?

The rarity of the MF 1200 makes accurate valuation tricky as sales are few and far between. However, as a guide, you’re unlikely to be able to buy any example (even a non-runner) for less than £7,500, these days. That appears to be the entry level.

For a good, original example, you should expect to pay around £20,000 while, for an example that’s been well restored, prices are likely to start at £25,000.

MF 1200 SPECIFICATIONS

| Production period | 1971-1979 |

| Produced at | Manchester, England |

| Engine | Perkins A6.354, 5.8-litre, six-cylinder diesel |

| Bore/stroke | 98x127mm |

| Compression ratio | 16:1 |

| Max power | 105hp |

| Transmission | 12 fwd, 4 rev Multi-Speed

8 fwd, 2 rev |

| Dimensions | Length: 199.5in

Height: 114.6in Width: 59.8in |

| Weight | 11,370lb (5,157kg) |

This feature comes from the latest issue of Classic Massey & Ferguson Enthusiast, and you can get a money-saving subscription to this magazine simply by clicking HERE

Previous Post

1975 former Sealink ferry now operating in Greece

Next Post

Exciting new classic tractor models