Cleaning your classic tractor

Posted by Chris Graham on 23rd November 2021

We evaluate two interesting products from Bilt-Hamber that could revolutionise cleaning your classic tractor. Chris Graham reports.

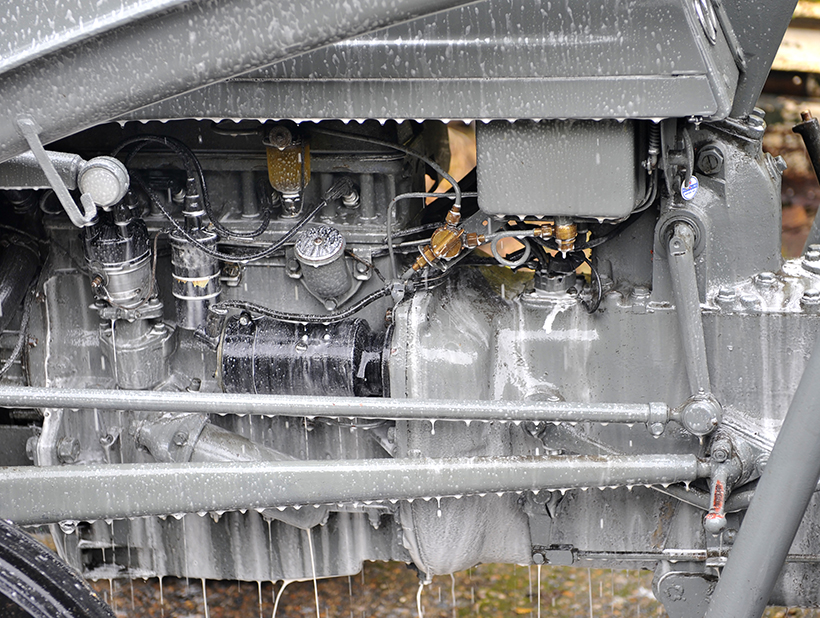

Cleaning your classic tractor: Gary’s superbly-restored grey Fergie wasn’t as dirty as we’d have liked for this product test, but is probably representative of most cherished tractors.

How do you clean your tractor and how regularly do you do it? It’s unlikely to be as often as you clean your car I’d wager but, if you’re a regular on the tractor show circuit and have a restored machine that’s in decent nick, then I imagine that you do your best to keep it looking its best. The problem, of course, is that cleaning your classic tractor effectively is both difficult and awkward to do. Unlike a car, most of a tractor’s working parts are exposed for all to see, especially on those machines from the vintage and classic eras. So, anyone wishing to clean their machine thoroughly is faced with an awkward array of sponge-snagging pipes, sharp-edged fixings and bothersome bolt heads. As a result, getting into all the nooks and crannies can be a knuckle-bashing nightmare, and this is surely why many owners are put off even trying.

Henry applying Bilt-Hamber’s Touch-less. We were somewhat hampered by the jet washer not being able to froth the product into the desired ‘snow foam’ layer that could then dwell on the tractor for several minutes while doing its work.

Painless solution?

The much easier – and less painful – solution is simply to do your best with a hose pipe on all the awkward bits, then run a sponge over the tinwork to remove the worst of any dust or mud that might be clinging. I’m sure that there are plenty of owners who adopt this approach, and never bother with specialised cleaning products to make initial dirt removal more effective, or to enhance the final finish of painted surfaces.

However, the automotive valeting products industry is nothing if not innovative, and one of the more recent technological developments has seen the introduction of ‘touchless’ cleaning products, which are designed to do their work without the need for physical agitation.

Nevertheless, it was still clear that the product we applied was quickly able to soften and loosen the grease, dirt and oil deposits found in all those awkward-to-get-at places.

I’m sure you’ll all have noticed how car paint deteriorates with age; a process that can be greatly accelerated by careless treatment of the surface. Just stroll through any supermarket carpark on a bright, sunny day and you’ll see many horror stories; bonnet, roof and boot lid panels that are covered in unsightly, swirly patterns. This undesirable effect is most noticeable on dark paint colours, and results from the accumulation of thousands of tiny scratches that are unceremoniously cut into the clear lacquer top coat, either by automatic roller-based car washers, or poor hand-washing techniques.

Touchless cleaning products have been introduced in a bid to do away with the need to have any physical contact with a car’s delicate, painted panels, and thus remove swirl-inducing sponges, brushes and dirty old rags from the paint cleaning equation.

So, I thought it would be interesting to see if this sort of technology could be usefully applied to the tractor world, and was delighted when Gary Anderson, who is the Ferguson Club’s website co-ordinator, offered one of his superbly restored TE-20s as a Guinea pig.

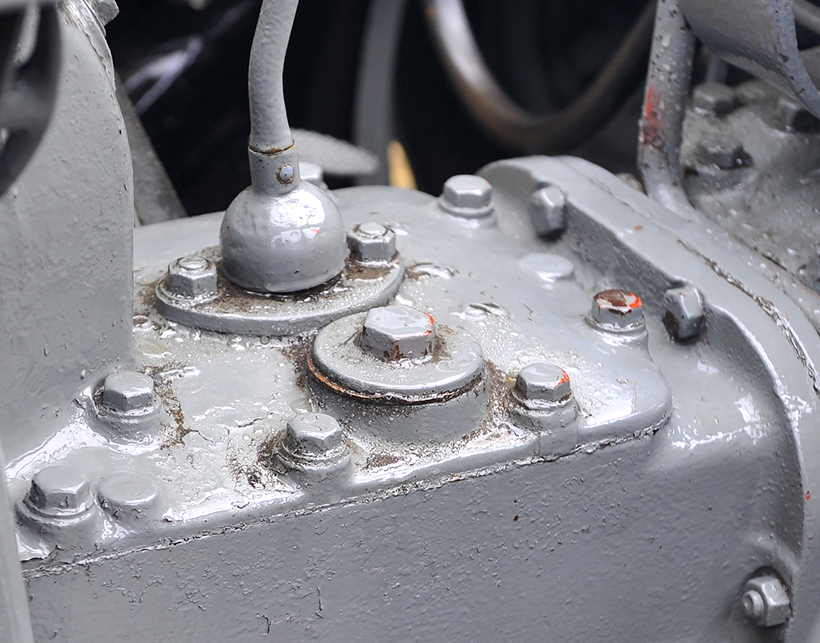

The top of the gearbox casing was obviously quite grubby before we started…

… but the Touch-less cleaning process made a big improvement.

Product choice

For some advice about which products might be best suited for use on a grubby tractor, I approached the experts at Chelmsford-based cleaning product manufacturer, Bilt-Hamber Laboratories. After some discussion, the company agreed to donate a five-litre bottle of Touch-less, plus some sachets of a new paint protection product called Touch-on, for which we were extremely grateful.

When I arrived at Gary’s Buckinghamshire home with products and camera in hand, he and son Henry were ready and waiting to help. The pair set to work shunting tractors in and out of sheds to release the ‘grubbiest’ example from Gary’s impressive collection – a 1950 TE-A 20, complete with banana loader. Admittedly, it wasn’t very dirty, but there was appreciable grease and grime build-up on the engine and gearbox castings, and on the rear axle/linkage assemblies, so it was going to be interesting to see how Touch-less coped with that.

The rear axle was another of the dirtier areas on this tractor but, once again…

the cleaning power of Bilt-Hamber’s Touch-less is obvious.

The straightforward application methods for the two products are detailed in the separate panel, but we soon ran into a bit of a practical problem. Gary’s pressure washer was unable to generate the layer of snow foam that’s ideally needed to enable the product to sit on the vehicle for the required dwell time. Even the machine kindly lent by a helpful neighbor also failed to deliver the foamy goods, so we just had to do the best we could.

As a result, much of the product ran off too quickly, so the full effects of the up to five-minute dwell time recommended, weren’t available to us, which was a shame. Nevertheless, both Gary and Henry agreed that the cleaning effects achieved were impressive.

It’s important to give the tractor a thorough rinse after applying Touch-less and allowing it to work. This is the stage that removes the already loosened dirt and grime, as well as any excess product. Touch-less is fully biodegradable and caustic chemical-free, so you need have no concerns about it polluting the environment.

Effective performance

Dirt and grease was softened and loosened by the product, making it easy to remove with the subsequent fresh water jet wash rinse. Afterwards, the whole tractor looked immeasurably cleaner and, better still, there wasn’t a bruised knuckle or scratched forearm in the house!

The follow-up Touch-On paint finish enhancer can be applied with either a jet wash or a more traditional bucket and cloth, so we adopted the latter. It contains a modern, ceramic formulation which bonds to the surface and is designed not only to enhance the shine, but also to make subsequent washing easier as the smoother surface it creates makes it more difficult for contaminants to stick.

Bilt-Hamber’s surface enhancer, Touch-on, can also be applied using a jet washer, but we chose the ‘old school’ approach with warm water in a bucket and a sponge.

Obviously, the true worth of that side of its performance will take several further washes to evaluate, but Bilt-Hamber recommends that its use is restricted to once a month. Consequently, we couldn’t assess its long-term benefits but, in terms of instant results, it certainly gave the Ferguson’s painted surfaces a discernable, extra shine. Water-beading was also much in evidence.

Whether or not the results come across adequately in the photographs once they’re printed in the magazine remains to be seen, but those of us there on the day can attest to the impressive effects these two products delivered. So, when you add in the facts that both are easy, quick and convenient to use, caustic chemical-free, environmentally-friendly and actively fight corrosion, these two Bilt-Hamber products get a hearty thumbs-up from us!

Touch-on needs to be thoroughly rinsed off with clean water following application, and then the surface must be dried. Leaving it to air-dry can result in water spotting.

APPLICATION METHOD SUMMARY

Bilt-Hamber Touch-less

This bio-degradable, sugar-based product contains no phosphates, solvents, NTA or caustic soda. It can be applied with trigger spray, pump spray, pressure washer or snow foam lance. The minimum recommended dilution rate should be 2% PIR (Panel Impact Ratio), and up to 5% for very dirty vehicles. Follow the manufacturer’s instructions for achieving the desired PIR.

- Working out of direct sunlight, apply a thick, foamy layer of Touch-less to the entire vehicle.

- Allow to soak for between one and five minutes (but never allow it to dry on the surface).

- Power-wash off throroughly.

Bilt-Hamber’s Touch-less is sold in a five-litre container costing £19.95.

Bilt-Hamber Touch-on

This is a durable, hydrophobic ceramic paint protection treatment that additionally has low-foaming, powerful detergency for most second-stage bucket washes, allowing further cleaning of the paint. Once applied it has dirt-releasing properties that works in conjunction with Touch-less in subsequent wash routines, to produce superior contactless results.

- Empty contents of a one-dose, 30ml sachet into a power washer or lance reservoir, then top-up with clean water and apply at low pressure.

- Alternatively, empty 30ml sachet into a 15-litre bucket of warm water, then apply to vehicle using ‘noodle’ wash mitt.

- After application, rinse whole vehicle with clean water from a pressure washer.

- Dry with a clean, microfibre cloth.

Note: The vehicle must not be allowed to air-dry as water spotting may occur.

Touch-on surface enhancer is supplied in a 30ml, one-shot sachet. Each costs £1.19, and they’re available in packs of 10.

FIND OUT MORE

Bilt-Hamber Laboratories

Swift House

18 Hoffmanns Way

Chelmsford

Essex CM1 1GU

tel: 01277 658899

email: technical@bilthamber.com

Gary was delighted with the finished job; this Bilt-Hamber product combination certainly gave his grey Fergie a real visual lift.

For a money-saving subscription to Classic Massey & Ferguson Enthusiast magazine, simply click here