Superb 1970s Volvo F88

Posted by Chris Graham on 11th April 2023

Ian Shaw reports on how Swedish manufacture Volvo successfully burst onto the UK commercial vehicle market with the F88 during the 1970s.

Swedish design code was embodied by the Volvo F88.

There had been a few European lorries getting a foothold in the UK truck market throughout the 1960s. Volvo was neither the first one nor only one. There had been other Volvos before this model too, but it was the F88 more than any other single truck, which was to change the balance of Britain’s truck market forever. This was the start; the thin end of the wedge, the beginning of the end.

It was a quiet revolution in every sense. Imported to the UK by Ailsa Trucks, the F86 had established a beach-head for the larger F88 to come ashore and both were renowned for their low noise levels. Independent tests in the early 1970s declared F86 and F88 in-cab noise to be ‘more akin to a saloon car than a lorry’ with just 74dBA in the cab at 2,400rpm the findings reported. The external figures on the test varied from 84.2 dBA on the upwind side to 85.8 on the downwind. The results compared with contemporary UK limits of 92 dBA for new vehicles at the F88’s power, and 89 dBA for the F86 type respectively.

Sleeper cab visually disguises the tractor’s long wheelbase.

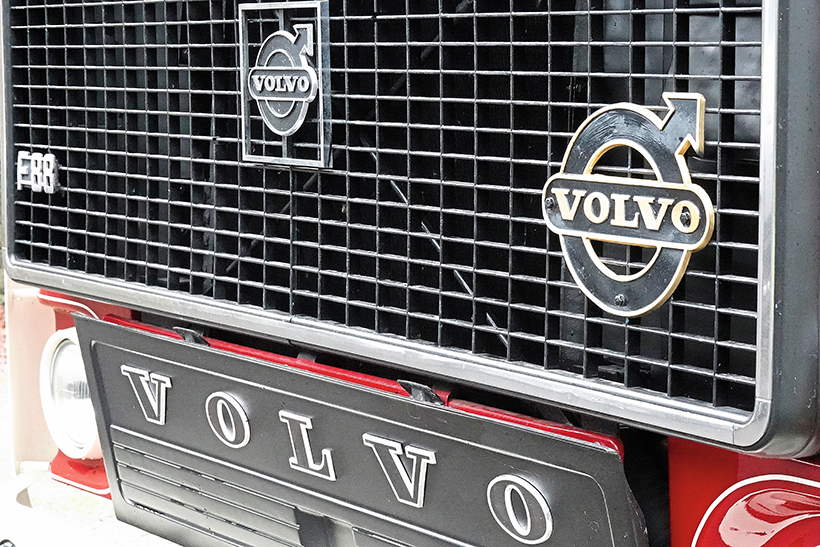

This one is certainly quiet. Owner Maurice Fearn has it idling in the yard, that much I can tell from a Gardner-esque blue-grey exhaust haze on idle, but I cannot hear it until I open my cab door. It’s a 1975 Volvo F88-290, originally rated for a total of 38 tonnes but plated and operated at 32 tons for the UK and fully restored into that specification; witness the wheel sizes. In its current condition, rest assured you will not have seen it in print, but in a former life it did appear in our sister title Trucking, when operated by owner-from-new LM Allan. The year after this one was built, at the Earl’s Court Commercial Vehicle Show in October 1976, Volvo launched the down-rated 250bhp F88 to plug the gap between the 201bhp F86 and the near 300-horse F88.

The 290’s larger grille is the visual difference but as Maurice Fearn points out many post-’76 owner-driver 250s were retro-fitted with the large grille. At 32 tons 250bhp was deemed to be sufficient, competing head-on with Cummins-engined ERFs and Seddon-Atkinsons while DAF had recently launched its 2300 (230bhp) tractor unit. Therefore, Volvo reasoned, a 250bhp truck would gain a slice of the distribution fleet sector without affecting sales of either the F86 or 290bhp F88. Essentially the F88 290bhp was more intended for 38 tonnes operation, but many operators just liked the extra power and torque. A Volvo spokesman at the time was quoted as saying; “Some operators need more power than the F86 can provide but don’t like the idea of letting their drivers loose in a truck which has got nearly 300bhp under its belt”. We wonder what he would say today, with fleets running flagship FH16s with 750bhp at only 12 tonnes more!

Period ‘custom’ details keynote this great restoration.

The Volvo engine was noteworthy for many reasons, but chief of these has to be its use of turbocharging. Where conventional wisdom would dictate a naturally-aspirated diesel of around 11-litres would be required for reliable operation at 200bhp – a Leyland .0680 for example – and Cummins offering up to 14 litres to reach 250bhp, the F88 sweeps less than 10-litres of cylinder volume. The TD100-series six-cylinder unit boasted direct injection, with conventional enough internal dimensions having a bore of 120mm (4.75in) and a stroke of 140.0mm (5.51in) giving a capacity of 9.6 litres (685 cu.in) If that stroke looks a little short, the reason is a relatively low static compression ratio of just 15:1. However, the maximum output began in 1968 with 260bhp at 2,400 rpm allied to net torque of 694 lbs.ft at 1,400 rpm. By the mid-1970s these figures would rise to 290bhp and over 750 lbs.ft.

This was to become the turbo-era for mainstream trucks and somewhat in error, the general consensus is that the European makers were in the vanguard. Turbocharging was of course nothing new, Renault had produced a turbo-supercharged petrol engine before the First World War, but most British developments had been in the more conventional engine-driven supercharger, creating icons such as the 1920s ‘blower’ Bentley and Rolls-Royce Merlin. Where on earth would the Merlin be, without its three-stage supercharger? Well actually, in a tank, since that’s what the Centurion’s Rolls-Royce Meteor engine was, but you’re with me in principle.

Business end, great details and greased fifth-wheel in readiness.

The combination of diesel engine and turbocharger is the engineering holy grail of something for nothing. A crank-driven supercharger takes a little power for itself, a turbocharged petrol engine, brings its own set of problems, specifically in cylinder temperatures but the turbo-diesel runs several hundred degrees cooler and being of compression-ignition design has no issues with pre-ignition which the petrol unit does. A look at the output figures reveals its minus point however. Those crankshaft speeds of 2,400rpm and 1,400rpm for peak outputs would make a Gardner or Leyland engineer cry into his mug of tea, and although at its peak, the actual cylinder compression ratio far exceeds the naturally-aspirated engine, that only happens once the turbo’s compressor is providing full boost.

Hence, we must embrace the spectre of turbo-lag. It can take a couple of seconds for that tiny turbine to reach its near-100,000 rpm peak and its opposite number to compress the incoming air, making up for, then exceeding, the lower inherent compression in the cylinders, while the driver waits, foot to the floor. Despite this characteristic, the gains are real and two-fold. A much higher specific output and hence power to weight ratio of the engine itself allied to better overall fuel consumption. These are tempered with a reduction in engine braking effect due to the lower static compression ratio. Moreover, the slowing of the exhaust gases also helps to act as an additional silencer, further improving refinement. In fairness, British trucks – mainly at the more specialised end of the market – had embraced turbocharging already, but their widespread use in ‘normal’ trucks, was just one more aspect that bolstered the Swedish and German makers’ reputation for advancement.

The Volvo F88 and Merriworth low-loader are used to transport other restorations.

The higher revving nature of a more powerful engine was a characteristic that British truck makers were all too familiar with however. Both the Foden two-stroke and Cummins V6 had suffered from operator prejudice because of it and Foden’s 12-speed (triple-range) transmission (Heritage Commercials May 2022) was a most noteworthy solution, while Guy’s Big J had embraced the Cummins V6’s desire to rev, with something of a compromise. Here a David Brown six-speed overdrive main transmission was combined with an underdrive splitter and lower final drive ratio. Most Big J operators still plumped for a Gardner 180 and six-speed combination. (Heritage Commercials August 2022).

Volvo’s solution to the nature of its turbocharged 9.6-litre unit was to become the norm for the rest of the manual-transmission’s lifespan. An eight-speed range-change synchromesh offered ease of driving thanks to synchronised changes and a logical four-plus-four H-gate with simple Lo/Hi switch on the side of the gear knob. The optional splitter – primarily intended for higher weights in Europe – was the only further development from then on and would create the 16-speed affairs which would later become the mainstay in UK 41-44 tonnes operations. This Volvo 860 gearbox utilised a hefty 16.5in single-plate clutch while at the other end its direct drive (1:1) 8th gear sent the torque to a relatively high 4.9:1 final drive ratio. It was this combination which was to create Volvo’s reputation for refined motorway cruising manners and enviable fuel economy, something for which its current FH-series of trucks is still amassing accolades.

Ready to work at 32 tons GCW.

With an eye on the SMMT accepting the recommendations to move up to 38 tonnes, in 1975 some back to back comparisons were conducted with the F88 290 two-axle tractor operating with a three-axle Tasker artic trailer at both 32 and 38 tonnes. The fuel figures proved most interesting. At 32 tons the F88 returned 6.5mpg only dropping to 5.8mpg at the higher weight. An increase of 11 percent in fuel usage against a 28 percent gain in payload.

Braking was entirely conventional for the period with a Westinghouse dual-circuit air pressure system and cam-operated leading-and-trailing shoe units at all wheels. A combination of double diaphragm chambers on the front axle’s 16.25in diameter drums, and ‘Maxibrake’ spring-diaphragm actuators on the 15.5in diameter rear drums. Shoe widths were a generous 5in at the front and 7in at the rear, while ZF power steering completed the picture.

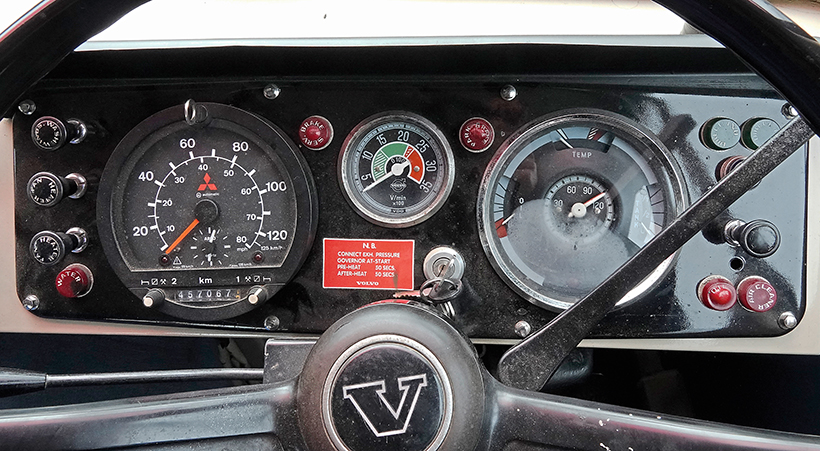

Cab is spacious with clean layout, Radiomobile plays Abba’s Dancing Queen!

However, it was the F88’s cab which was to endear it most of all to drivers of the period. It was entirely conventional in its design, indeed by the late ‘70s the split windscreen was looking dated but despite this, wind noise was always reported as low. The thick A-pillars were a corollary of more stringent Swedish impact regulations and slightly limited the visibility, certainly compared to earlier British cabs with a more pronounced wraparound glass house like an LAD or Foden ‘Mickey Mouse’. The interior space – particularly with the sleeper design – was appreciated by owner drivers in particularly and the logical and clear instrumentation and switchgear was to become something of a Volvo hallmark.

Comprehensive instruments and switchgear, tachograph shows 283,000 miles.

Maurice Fearn’s example certainly ticks all those boxes and just two days (but three years!) after jumping out of a ‘72 Foden S39 and into the F88, the difference is vivid. Despite the actual dimensions – sleeper requirements aside – being similar, it just feels so much more spacious with light coloured materials obviously playing their part and little touches like the storage tray on top of the engine cover and the switchgear in logical rows or banks for similar functions. Like all the best ergonomic designs, it’s not obvious, but it just works so easily. This one also benefits from improvements to the F86 and F88 ranges announced at the Brussels Show in January 1973, including the extensive use of energy-absorbent materials for dashboard and door trims designed to protect the driver and passenger.

Paint quality is fantastic, similar shade to original livery.

On the F88 a new two-spoke steering wheel was incorporated to allow a better view of instruments and controls, while the windscreen wiper motors were repositioned in the dashboard with wipers then pivoting from the bottom instead of the top of the windscreen. On the outside of the cab two new grab handles were added and non-slip steps fitted in the bumper to facilitate the cleaning of the windscreen. The black radiator grille hails from that time too, while fabric seat coverings replaced the previous pvc. All of this combined to make the F88 very driver-friendly and so many contemporary reports liken it to driving a car rather than a truck while its overall gearing and low engine noise contributed to its refinement levels. In this period, commercial vehicle magazine journalists were having to explain why their usual test of pulling along from 10mph in a direct drive top gear had to be abandoned! The F88’s tall final drive meaning that at 10mph its direct drive 8th gear would equate to an engine speed some 300rpm less than tick-over while 20mph only accounted for 800rpm and it had to be acknowledged that the turbocharged unit would not begin to generate usable torque until 1,100 revs. A range-change indeed!

Details abound on this restoration and it shouts ‘1975 owner-driver’.

Not that such considerations bother Arthur Spendlow as he drives the F88 he spent 12 months restoring with owner Maurice Fearn, through the picturesque manifold valley, en route to collect a 1972 Merriworth 40ft low loader trailer. This Volvo embodies the owner-driver specification and accessorising that was so common to F88 at the time. The windscreen sun visor, the air-deflectors on the cab corners and slightly different front bumper treatment, all are period perfect. Having spent a long time idle, quite a bit of sheet metal work was required around the cab – essentially a rebuild – before painting and the finer details, particularly those relating to its 32-ton specification.

Err, who did you say made it, again?

The low ‘Susie bridge’ for the trailer lines, aluminium catwalk and original Jost fifth wheel coupling are all bang-on, only the Hankook tyres identify as being more recent and in period for the UK, it would most likely have been shod with Michelins. The rest is in keeping with the level of customisation applied at the time, additional Volvo badges and decals, lettering of the air intake snorkel and the showman-style coach lining. At the time in Sweden, there were heavy American influences on the truck customising scene too, very similar in tone to Maurice’s F88. It all adds a nice contrast to the very clean and uncluttered interior treatment, notwithstanding the very high quality of trim and upholstery, replicating the move to cloth covering for the Bostrom suspension seats at the time.

Owner Maurice Fearn (left) and Arthur Spendlow with the superb Volvo F88.

The F88 was to serve Volvo well, it was still using essentially the same engine 25 years later in the FL10, while the design code of the F88 carries through to this day and the quest for fuel economy which it embodied, now has a deep green tone applied to it. The F88 then, was not the beginning of the end. It was the start of the future.

The author wishes to thank, owner Maurice Fearn for all his help including finding photographic locations, Arthur Spendlow for driving the F88 and Commercial Motor for access to its Volvo archives.

This features comes from the latest issue of Heritage Commercials, and you can get a money-saving subscription to this magazine simply by clicking HERE