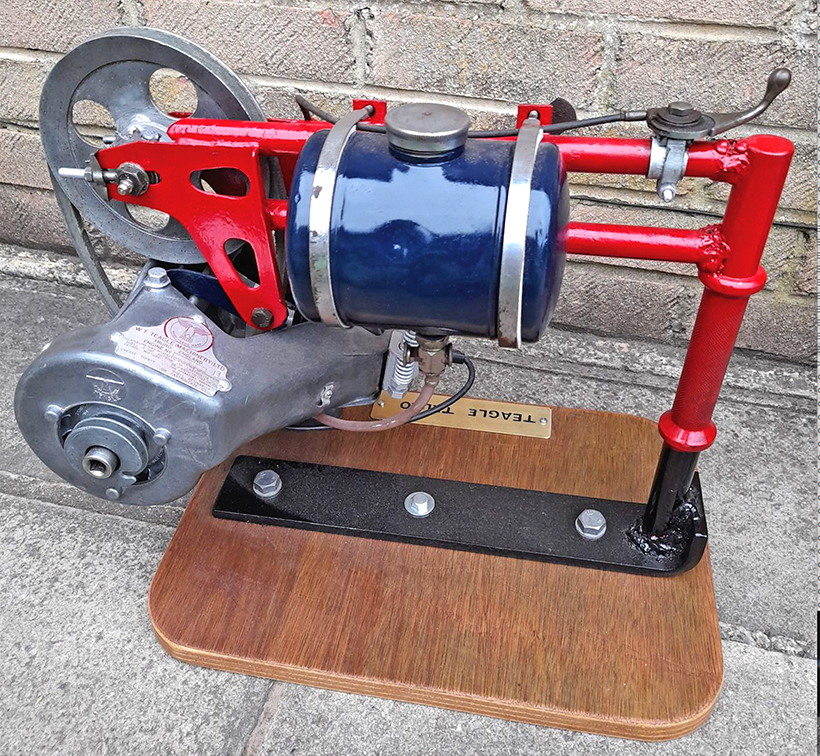

Teagle hedge trimmer engine

Posted by Chris Graham on 15th November 2021

Steve Stuart reports on a recent lockdown project; the restoration of a long-neglected Teagle hedge trimmer engine.

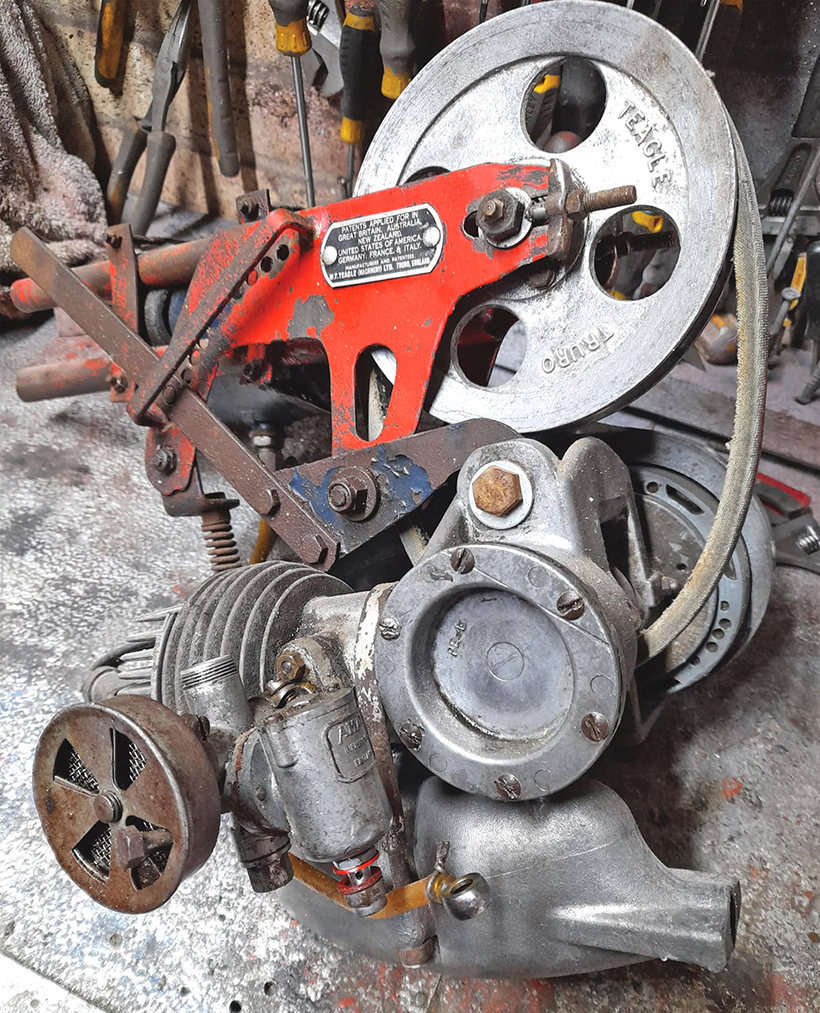

Teagle hedge trimmer engine: The little two-stroke motor, while still attached to the remains of the hedge trimmer.

I can’t remember where – or, indeed, when – I purchased this Teagle of Truro hedge trimmer; it has been lurking at the back of the shed for a long time. However, with all things being shut over the past 18 months or so due to the Covid-19 pandemic I, like many other stationary engine enthusiasts, have been making good use of the time by working my way steadily through all my unfinished projects. During that process I eventually reached the back of the shed, at which point it was the turn of the Teagle!

Here we see the engine dismantled; what a lot of parts for such a small motor.

The hedge trimmer itself was long past restoring, being badly bent and with a number of parts missing, but the engine was complete and so I checked it over to see if it was a viable restoration project. It wasn’t seized, so that was a good omen. The points were cleaned and the carburettor flushed out and, after some fiddling, I managed to get it running.

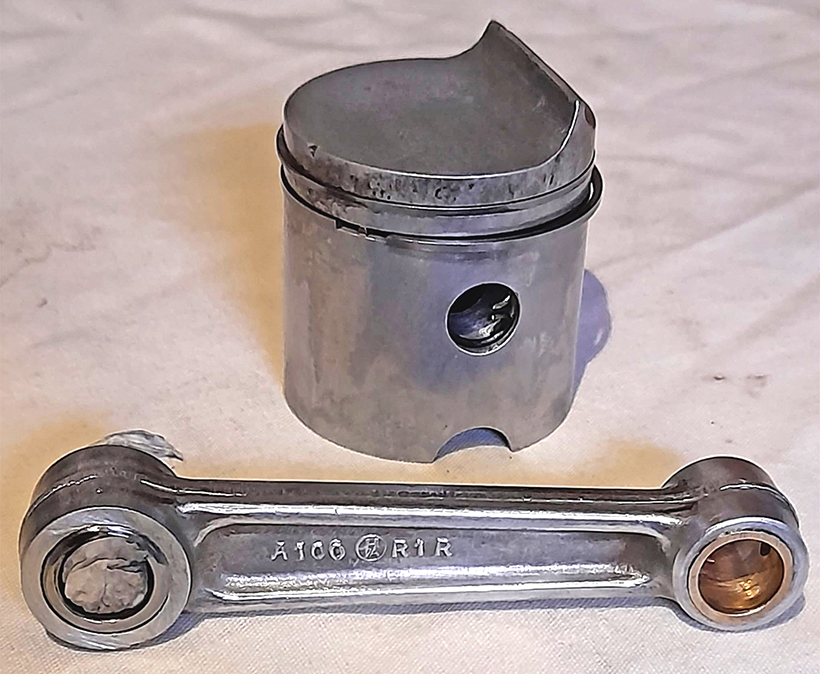

The piston and con-rod.

All sounded OK so I ran it for 10 minutes, after which I decided to completely strip it down and clean the individual parts before reassembling it again. No wear was found, which was also good news. I did, however, notice that the top piston ring was pegged as it’s in the middle of the capped port that you remove the gudgeon pin through.

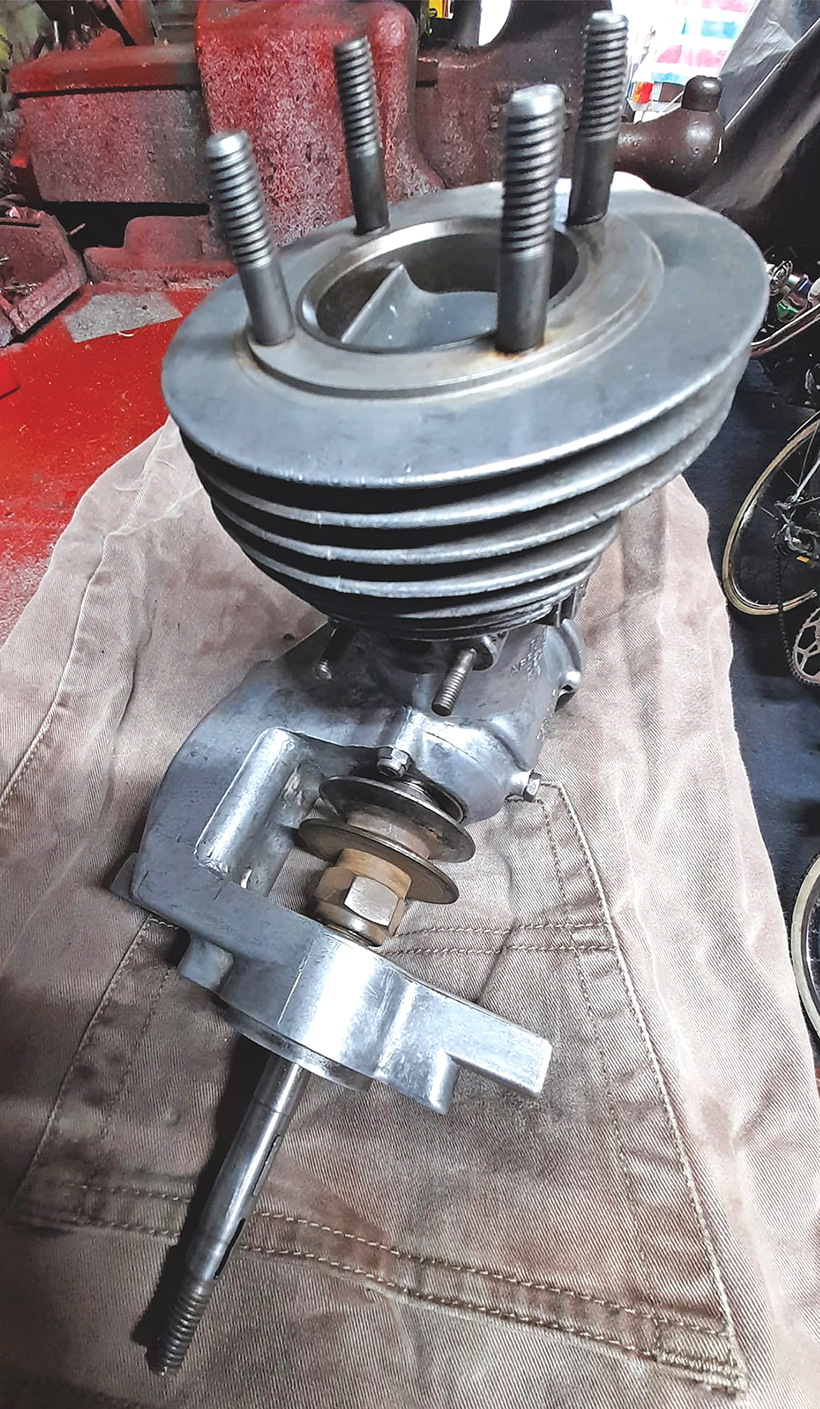

Some of the main castings, cleaned and polished.

I’ve worked on many two-stroke engines over the years, from Japanese motorcycle engines to Villiers and JAP units etc, and I know that it was common practice to set the rings so that they didn’t interfere with the ports, so avoiding snagging and breakages.

A feature I’d not encountered before; the top piston ring was pegged so it’s in the middle of the capped port that you remove the gudgeon pin through.

At first I thought this might be a factory mistake, but my son has a Teagle in his collection of small engines, so I removed the cover on his engine and discovered that it was the same on that, so it looks like that’s how they were. However, I can’t see why it couldn’t have been fitted to avoid the ports, as there is room around the bore.

Looking down the bore.

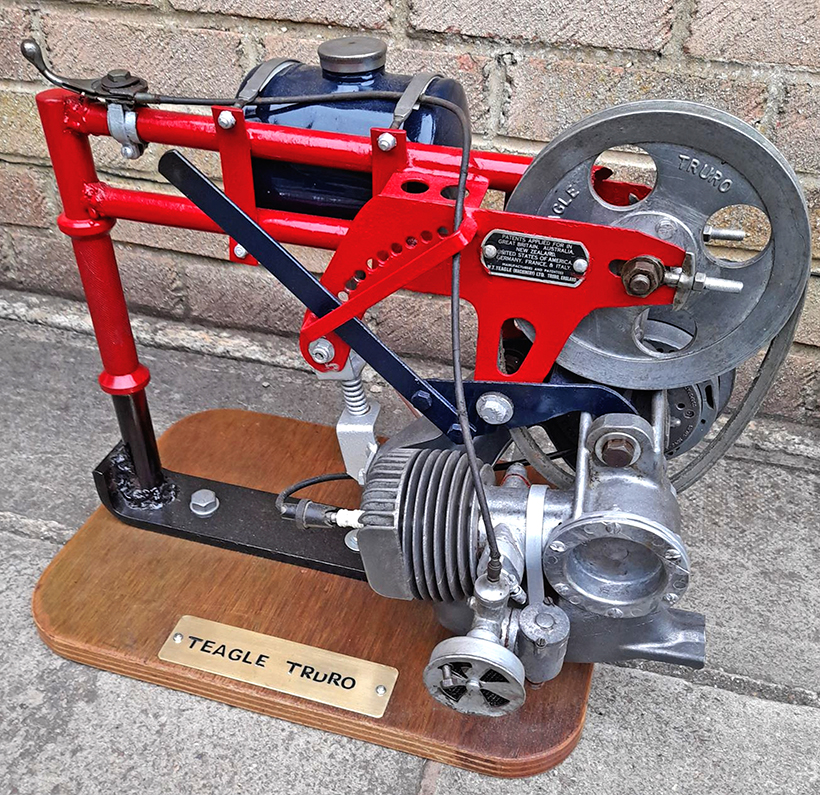

Anyway all went back together with no problems and it’s now on the shelf with others, patiently awaiting its first outing.

I’m very pleased with the finished project.

Here’s another view of the finished engine, viewed from the other side.

For a money-saving subscription to Stationary Engine magazine, simply click here