Interesting Massey Ferguson prototypes

Posted by Chris Graham on 6th August 2021

John Farnworth spotlights a selection of the most notable and interesting Massey Ferguson prototypes from down the ages.

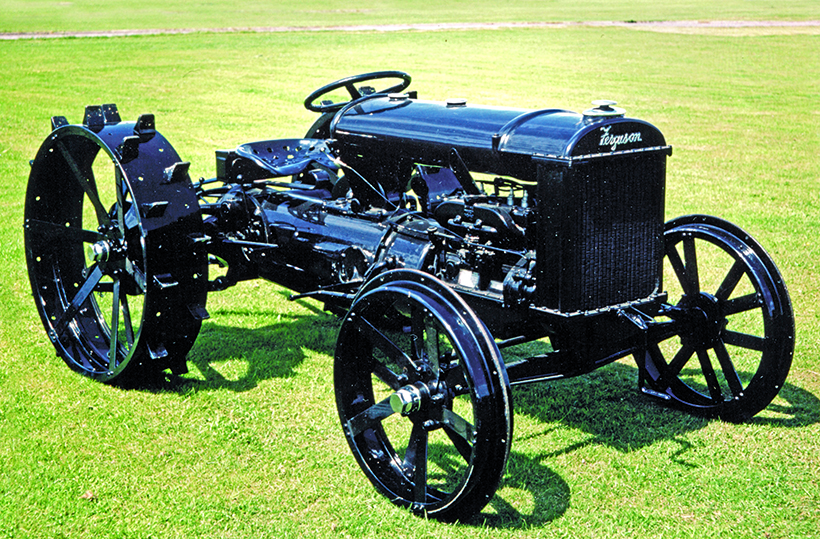

Interesting Massey Ferguson prototypes: The iconic, Ferguson Black Tractor photographed at the Massey Ferguson Training Centre in Stoneleigh, Warwickshire, which was originally founded by Harry Ferguson.

The purpose of a prototype is to develop a designer’s ideas from a concept to an actuality, and to allow some field testing as well as evaluation by marketing and the sales teams. This inevitably leads to further ideas and suggestions for improvements, the best of which can then be worked into the design before the final production version enters production. On the flipside, if a prototype proves to be unfit for purpose or market, then the whole project is generally scrapped, with only a few examples surviving this fate.

Important assessment

Certainly, Massey Ferguson UK Engineering would have given model numbers to prototypes, for marketing to assess the likely appeal and possible pricing. Although sometimes sales, marketing and product planning would draw up a base specification for engineering to develop a prototype for testing. Of course, the demand – particularly for a contract in a particular country – could soon evaporate.

Perhaps the most significant, surviving agricultural prototype machine is the iconic Ferguson Black Tractor. This tractor revolutionised tractor design because of its light weight, three-point implement linkage system, automatic, hydraulically-controlled implement depth control and automatic weight transfer from implement to tractor. This ‘Ferguson System’ concept has been adopted by all modern tractors, in some or other way, ever since.

While the prototypes I’ve included in this feature are all interesting, it’s not an exhaustive list and I’m sure there are many other yet to be tracked down. Also, those here are listed in no particular order, although the iconic Ferguson Black Tractor seemed the obvious place to start, simply because of its long-term impact on agricultural mechanisation.

Only a few other agricultural machinery inventions – such as the invention of sickle bar mowers, reapers, binders, and seed drills – warrant similar acclaim. But maybe we are forgetting the plough?

Ferguson Black Tractor

This tractor, built in Belfast, was the prototype for the Ferguson Model A tractor, that’s more commonly known as the ‘Ferguson-Brown’. One example was made and, today, is to be found in the Science Museum, in London. This tractor resulted from genius engineer Harry Ferguson’s desire to transform the inefficient operations of the tractors of the day.

Although only about 1,350 model As were produced, they proved the workability of the ‘Ferguson System’ concept in a range of farming environments. This model was subsequently developed into the Ford-Ferguson tractors of the Second World War period which, in turn, were followed by the now world-renowned grey Ferguson TE and TO series models. Development continued, resulting in the Ferguson 35s, Massey-Harris 50 and Ferguson 40s then, following these, Massey Ferguson tractors such as the MF 35 and 65, and many besides.

Massey-Harris 744D tractor

The British Society for Research in Agricultural Engineering report of December 24th, 1949, reports the testing of a Massey-Harris 744D tractor prototype by the National Institute for Agricultural Engineering and Scottish Machinery Testing Station.

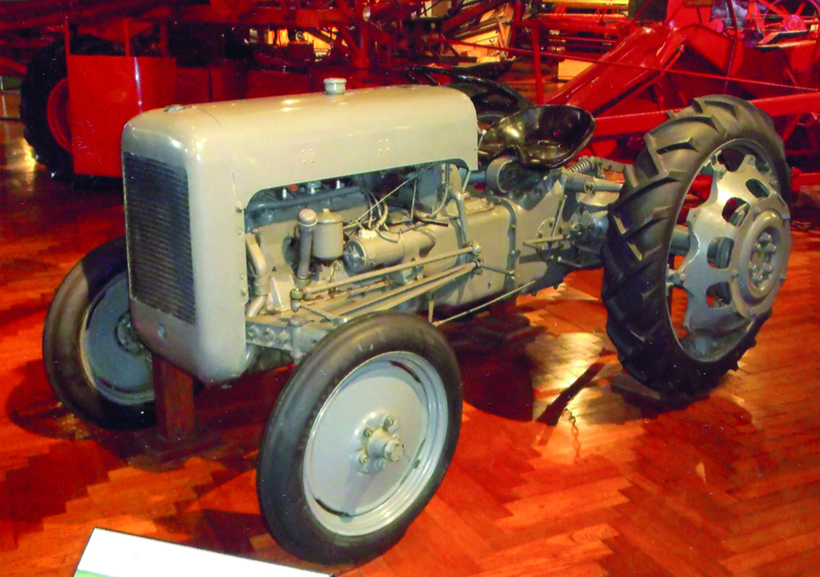

The prototype Massey-Harris 744D tractor strangely had the serial number ‘972’.

It is comprehensive with many technical details and field tests but, in summary, states that: fuel tank capacity insufficient; Ki-gass pump should draw fuel from the engine-side of the filter, thermostat does not work satisfactorily; faulty oil seal on a half shaft; no toolbox; drawbar only located by one bolt per side; several clutch pedal adjustments required while under test; wheel weights awkward to remove and fit; driver’s seat and field of vision good.

M-H commented that required changes would be considered and made and that some defects were due to an outside supplier problem. It’s interesting to note that the tractor serial number was 972 – well into the commercial production run. Could this have been the first tractor that was held back for testing and inserted later into the serial numbers?

Massey Ferguson 290 tractor

In an endeavour to reduce driver fatigue, this MF 290 was designed with the engine positioned in reverse to its normal placement. The aim was apparently to reduce noise and vibration. The experiment probably failed. The MF 290 model was made between 1983 and 1986.

The smart-looking MF 290 reverse-fitted engine tractor, which never saw production.

Ford-Ferguson

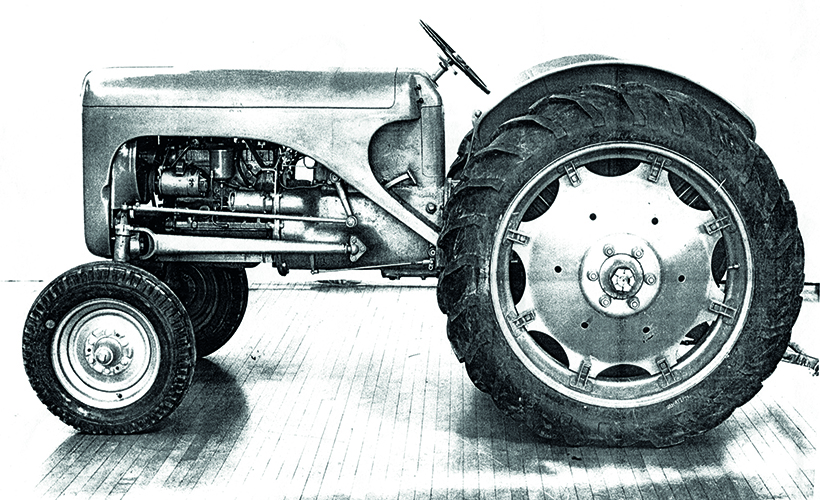

Housed in the Ford museum in Dearborn, Michigan, is the prototype Ford 9N tractor. This was the first Ford tractor to be developed with the Ferguson System. Henry Ford turned the first furrow with this in April 1939, on his own farm at Dearborn. The tractor weighed 2,100lb. It was a considerable design advance on the Ferguson-Brown tractor (the production version of the Ferguson Black) and, after the war, followed by the ubiquitous TE and TO series of grey Fergusons.

A Ford Ferguson prototype in the Ford museum at Dearborn, in the USA.

Massey Ferguson Whole Crop Harvester

This ‘new concept in harvesting’, as MF called it, was designed essentially as a simple combine harvester but, in addition to harvesting the grain, it also produced finely broken straw. Barley and wheat straw as such is particularly valued in North Africa and other regions for livestock feed. It was evaluated in the 1988 and 1989 seasons, and was suited to tractors with a linkage lift capacity of 1,400kg.

The MF Whole Crop Harvester, designed for areas of the world where cereal straw was especially valued as livestock feed. It could have been less expensive than a self-propelled combine harvester.

The broken straw could be collected in bags or blown into a trailer with a density of about 80kg/m3. The combine could also be used for stationary threshing. It could be fitted with 1.4 or 2m width tables, and be transported within the width of the tractor. As far as can be established, the combine never went into commercial production.

Massey-Harris Pitt tractor

With the advent of the Ferguson tractors, Massey-Harris became desperate for a similar tractor. Its small tractor of the day – the Pony – hadn’t gone down too well in North America, although it did in France, where farms were smaller and less advanced.

The Pitt Tractor was Massey-Harris’s doomed attempt at designing a tractor to compete with the grey Ferguson ‘menace’!

Their research department was contemplating the development of a two-plough tractor, equipped with enclosed Bendix hydraulics. Professor Arnold Pitt headed the department, and was in charge of the prototype made, but the project was a design failure and abandoned.

This prototype did, however, stand in M-H’s showroom in Toronto for a while, but it appears that no technical details of it have survived. It had very neat lines, somewhat comparable to a Ford-Ferguson.

Ford 4P tractor

Ford and Ferguson worked with their separate engineering teams to design a successor and larger tractor to the Ford-Ferguson tractor. Five prototypes were made and evaluated in the US and UK. However, it never went into production, with Ford and Ferguson soon going their separate ways.

The Ford 4P tractor was a joint Ferguson-Ford endeavour to design a successor to the Ford Ferguson. But the two companies ultimately went their separate ways in tractor design.

Massey Ferguson 598 tractor

This MF 598 tractor is presumed to have been a development of the MF 595 Mark 2-style of tractor. However, it’s uncertain whether it was a one-off engineering prototype or whether it was produced for small French or Belgian domestic markets, because certain parts suppliers’ websites come up with parts for an MF 598 tractor with Perkins AD4.318 engine. The front axle is by Landini, and its pressed steel wheels contrast with the cast wheels of the MF 595s.

The Massey Ferguson 598 prototype tractor.

Massey-Harris 735 combine harvester

An interesting article in the July 1951 issue of M-H’s Growth magazine, reports on a new 6.5ft cut combine for 1952 delivery, with photos and specifications. However, a small emergency insert between the pages says M-H regret to announce that, due to material shortages and other factors beyond their control, the No. 735 combine will not be available in 1952!

The photos show the 735 combine to be very similar in appearance – but smaller – to the very popular M-H 726 combine of the day. It was to have a Morris engine, and smaller wheels and only three straw walkers with, of course, a 2ft narrower cutting width.

The prototype Massey-Harris 735 combine was, in essence, a smaller version of the larger, highly successful M-H 726 combine. But it was abandoned in favour of a very much redesigned and smaller machine.

In the event, the 735 was redesigned as a 6ft cut, with a very different overall appearance that was easily distinguishable from the 726. It was finally introduced in 1956.

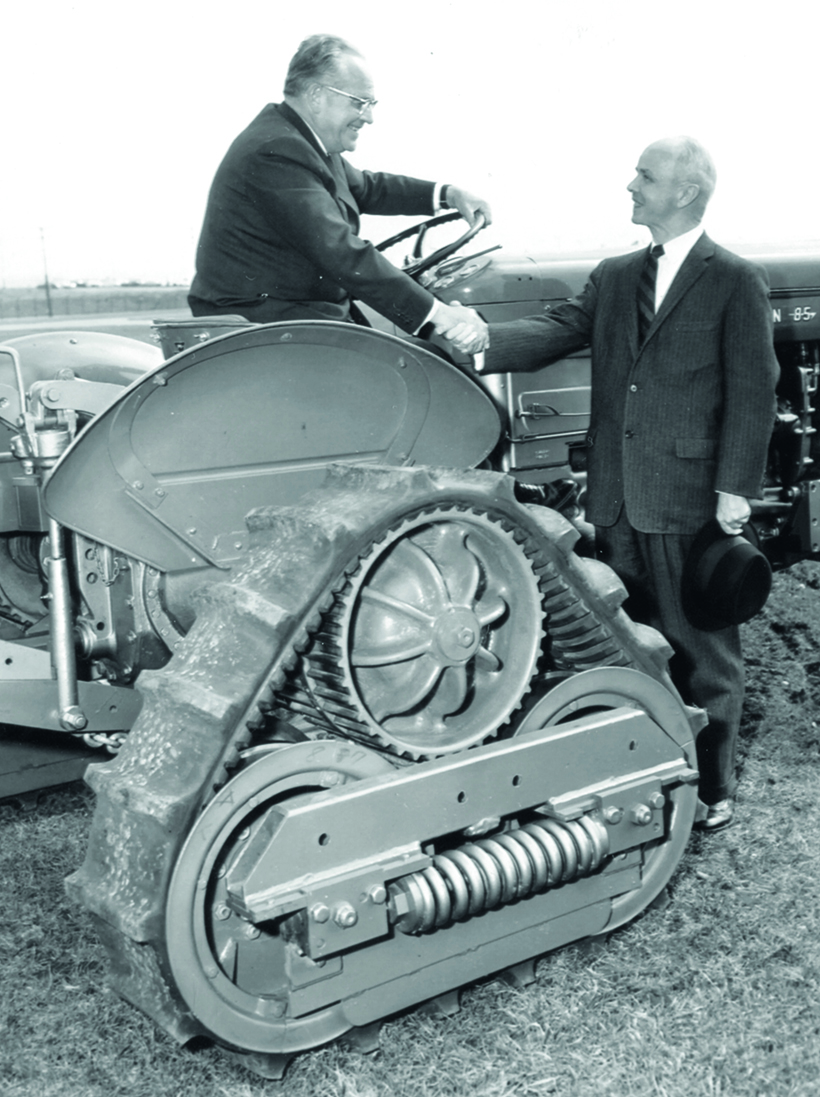

Half-tracks for the MF 98 tractor

As far as can be traced, Massey Ferguson never produced half-track tractors, whereas Massey-Harris and Ferguson did offer them. Seated on the Massey Ferguson 85 tractor is Hermann Klemm, who was Harry Ferguson’s chief engineer in Detroit and then, subsequently, for Massey Ferguson.

Half-tracks on an MF 98 tractor. They are of unknown origin, but MF’s chief designer in the US, Hermann Klemm, is in the driving seat. They look to be robustly-designed and very functional, having rubber tracks – probably very advanced for their day.

It’s not known whether these half-tracks were conceived and built in-house, or whether they were sourced from an outside supplier. Whatever, they’re an impressive, robust piece of engineering and advanced for their day in having rubber tracks.

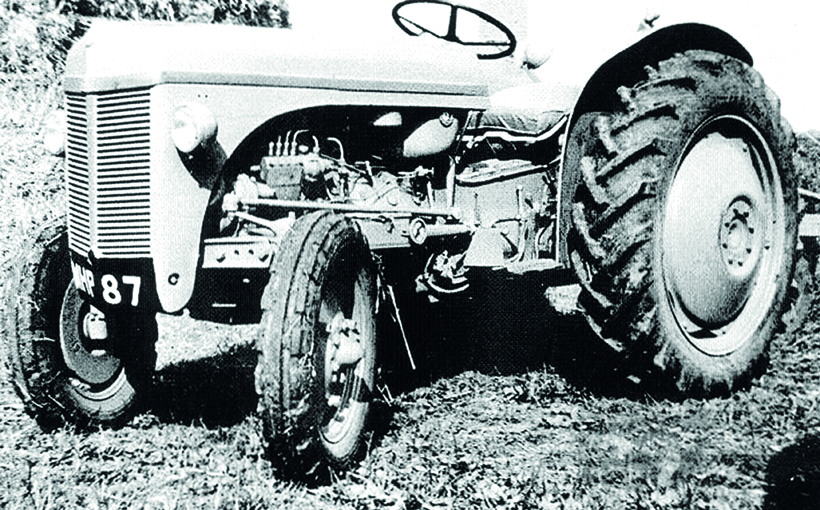

Ferguson LTX tractor

The Ferguson LTX tractor (Large Tractor Experimental) was one of Harry Ferguson’s two attempts to design a more powerful and larger tractor to replace the ageing, grey Fergusons. Development of this was undertaken in the UK while, in his Detroit, US, facilities he had chief engineer Hermann Klemm come up with the Ferguson 35 and win the day. While the LTX was considered a very good tractor performance-wise, the Ferguson 35 reached the ‘ready for production stage’ before the LTX.

One of the prototype Ferguson LTX tractors. This model was Harry Ferguson’s UK engineering endeavour to produce a higher-powered tractor than the Ferguson TE-20. But his design team in the US was to produce the Ferguson 35, which signalled the end of the LTX project.

Several prototypes of the LTX were made but, sadly, none survive. They were ordered to be scrapped as at the point Massey-Harris had merged with Ferguson, and the new company was desperate for a larger tractor. It was a dark day for Ferguson loyalists in the UK. The LTX had been under development for longer than the Ferguson 35, but decisions had to be made.

The LTX had no provision for front-mounted implements, such as corn pickers, as required by the North American market, and there wasn’t a readily available, mass-produced engine for it – Ferguson had been developing his own range of different sized engines. Another decisive factor was that the 35 design provided the basic concept for future, larger tractors such as the MF 65, as well as the development of a worldwide tractor range.

MF rear-mounted, Reverse Drive Forage Harvester

Conceived and made by MF in Germany, the origins and design objectives of this forage harvester are uncertain. Could it have been that it makes for a more compact unit than a trailed forward working machine and thereby, perhaps, making it more convenient in small fields and on headlands?

It was designed to fit MF 2000 Series tractors, so it would have been a high-capacity machine. However, it would have been somewhat inconvenient for the driver having to look alternately back and forwards to observe both the cutting, and the filling of the trailer.

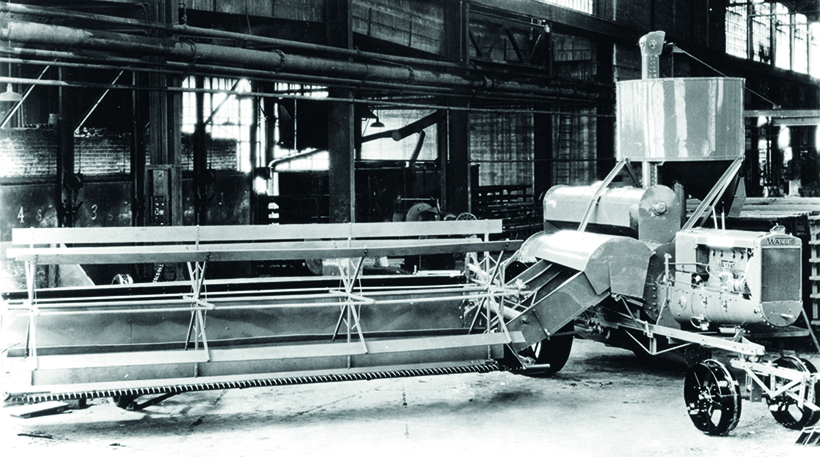

Wallis Combine Harvester

In 1928, Massey-Harris bought the JI Case Plow company, of Racine, Wisconsin, primarily to acquire the successful Wallis tractors which it produced. In with the deal came a trailed Wallis prototype centrifugal combine. The photo shown here is dated 1929, but the project was abandoned. The combine is shown to be powered by a Wallis tractor engine as, fitted to the model 20-30 tractors.

This is the only known photograph of the prototype Wallis trailed, engine-driven combine harvester. Massey-Harris took over the company to gain its Wallis tractors, but were themselves already well established in the trailed combine market.

Ferguson tractor-mounted combines

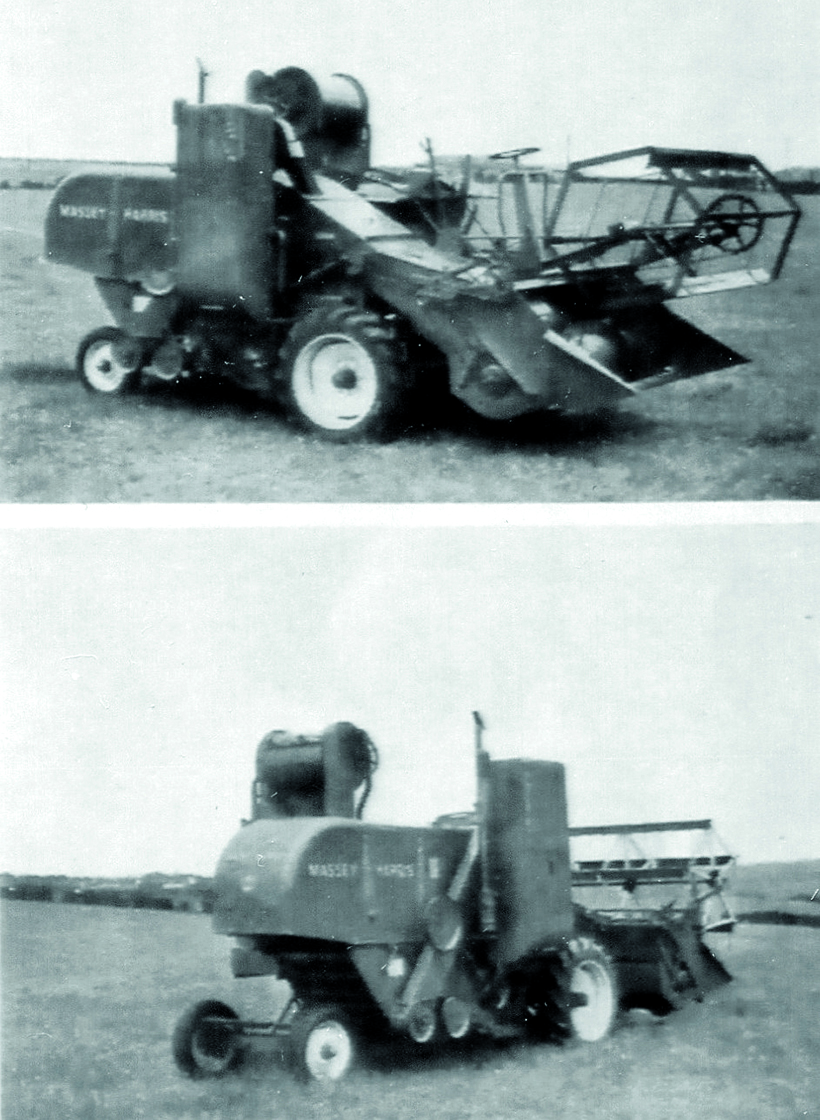

Just as Harry Ferguson had two, larger tractor development programmes being undertaken on each side of the Atlantic, he also had two tractor-mounted combine development initiatives. They were headed by his chief engineers respectively in Coventry and Detroit. Each programme produced and field-tested several prototypes of different cut widths.

An example of the US-designed, tractor-mounted combine with auxiliary Ferguson engine fitted…

… and one of the prototype, UK-designed mounted Ferguson combines. Both the US and UK designs were abandoned.

The mounting of the combines on the grey Ferguson TE and TO tractors was quite different. The UK version was time-consuming and involved fitting an extended rear axle, while the US design had a clever, quick-hitch side-mount facility. Additionally, for the US design, an auxiliary engine could be fitted to power the combine being attached to the rear, and simply lifted into place using an engine fitted out with a three-point linkage. A grain bulk tank was also offered for the US version. Both suffered from poor driver visibility and dust from the table.

Ferguson also designed an epicyclic reduction gearbox to enable slower tractor speeds. This gearbox was subsequently fitted to the Ferguson tractors used on the South Pole Antarctica Expedition. The UK version had the advantage of being able to open-up a field without running down the crop on the outside. Upon the takeover of Ferguson by Massey-Harris, these combines were abandoned, recognising the superiority of Massey-Harris designs and their world lead in this field of harvest mechanisation.

Acknowledgements

I’m very grateful to the following for the provision of some photographs and points of information: Chris Clack, Mark Channell, Mike Thorne, Julie Browning and Peter Smith, David Lory, Bob Gilchrist, Malcolm Robinson, Ted Everett of AGCO and the late Nigel Liney.

For a money-saving subscription to Tractor & Farming Heritage magazine, simply click here