JD 50 Series buying guide

Posted by Chris Graham on 23rd July 2020

If you fancy a classic John Deere offering performance and reliability, here’s our JD 50 Series buying guide to assist prospective purchasers.

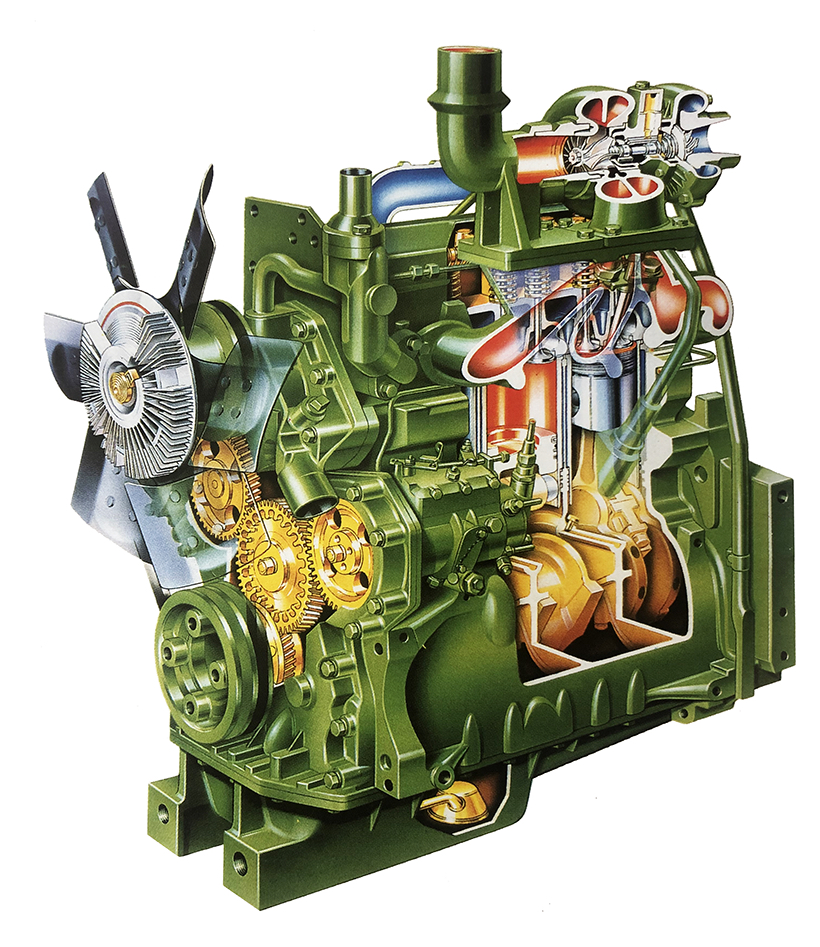

JD 50 Series buying guide: With the addition of a turbocharger to the 5,883cc, six-cylinder engine, the range-topping 3650 produced 114hp. (Photo: Scott Lambert)

John Deere’s popular 50 Series was introduced in 1986, to replace the company’s well-liked 40 Series models. Customers could choose from a wide spread of horsepower – from 38-114hp – meaning that new range offered something suitable for virtually every operation. Built in Europe, the new tractors were heavily based on the outgoing models, but with subtle improvements.

In this buyer’s guide, we concentrate on the most popular tractors as far as the UK and Irish markets are concerned, and aim to explain why these machines remain as desirable now as they were in they heyday.

‘Constant power’ engines

The crux of John Deere’s design was commonality of parts – with all models sharing the same bore and stroke dimensions, of 106.5mm and 110mm, respectively. This one-litre-per-cylinder displacement, the company said, enabled the John Deere ‘Constant Power’ engine to develop equal power without strain, compared to competitive engines with smaller displacements.

Rated speed was either 2,300rpm or 2,400rpm which, Deere said, was just one of a number of features that gave the 50 Series engines a telling measure of reliability and life expectancy. The piston speed of 8.4m/s fared well against industry norms of between 9m/s and 11m/s, equating to reduced vibration, quieter operation and a long service life, as well as better fuel economy.

The engines feature wet-sleeve cylinder liners, which are easy to replace, and dissipate engine heat into the surrounding coolant efficiently, improving engine life. Another interesting feature is piston spray cooling. Filtered oil is sprayed against the underside of each piston, in the form of a jet, which cools the cylinder and keeps the pistons and liners lubricated.

Nick Young, managing director at John Deere specialist Nick Young Tractor Parts, told T&M: “The European 50 Series tractors were an upgrade on the very successful 40 Series. They are mechanically very similar, in that the engines have the same capacity, but the 50 Series have different pistons and a viscous fan that gave improved fuel economy.”

Easier starting

The Constant Power engine features a low-friction piston design for reduced drag on the cylinder walls, which means greater fuel economy and less wear. What’s more, the high ring position reduces the so-called ‘dead area’ around the top of the piston for tighter compression, better combustion and easier starting in cold conditions.

The 1950, higher-spec, four-cylinder tractors, and all three six-cylinder models, feature a viscous fan and, whether they have three, four or six cylinders and are naturally aspirated or turbocharged, these engines are famed for their reliability. The porous liners that affected reliability in the early days of the 40 Series, aren’t a problem associated with the 50 Series, and so you can expect the hour meter to be in the region of five figures or more, before major work is required.

Commonality of parts was a theme across the range and, as a result, you can expect the same reliability whether you plump for a three-, four- or six-cylinder model – naturally-aspirated or turbocharged. The turbocharged, four-cylinder model pictured was fitted to the 2650 and 2850. (Image taken from promotional literature)

Tough transmission

A dry-disc clutch was standard across the board, with hydraulic actuation on the larger, SG2-cabbed models. With the right operator and good working conditions, you can expect to get 7,000-8,000 hours out of the clutch before it needs overhauling, which can be an expensive process.

Also available throughout the range, with the exception of the range-topping 3650, were three transmission options. The tried-and-tested ‘Power Synchron’ transmission was carried over from the 40 Series, and offers 16 forward and eight reverse gears. An ‘H-pattern’ shift features gears one to four, while a second lever allows the selection of low, high and reverse ranges.

A ‘shuttle-shift’ integrated reverser (reverse opposite low range), coupled with 50% faster reverse speeds, shortens cycle times. On-the-go shifting from either a dash-mounted lever or the right-hand console – depending on model and cab fitted – enables the most suitable speed for the job to be achieved.

For those that didn’t plump for the optional Power Synchron transmission, there was a choice of the standard, eight-by-four Synchron, or the 12-by-eight Synchron + Creeper. It’s also worth noting that the 3650 was only available with the Power Synchron transmission.

The transmission is another very strong point and, although it’s not indestructible, problems are few and far between. Issues usually occur from wear in the selectors, which can be replaced, and it’s worth listening out for strange noises. The bearings on the lower range shaft can fail and cause problems, but this isn’t particularly common.

If top speed is an important factor in your purchase, it’s worth seeking out a 40kph example. Later-build 50 Series models, equipped with four-wheel-drive, had the option of a 40kph transmission including, contrary to popular belief, all of the three-cylinder tractors.

All but the 1350, 1550 and 3650 models were available to purchase in two- or four-wheel-drive configuration, as the two smallest models were two-wheel-drive only, and the largest four-wheel-drive.

The 50hp 1750 was the smallest tractor in the range to be offered with the option of four-wheel-drive. (Image taken from promotional literature)

Front-wheel lean

There is little to go wrong with the two-wheel-drive models, but look out for the usual pivot pin and king pin wear – particularly if the tractor has ever had a loader fitted.

Four-wheel-drive Deeres of this era are famed for the ‘John Deere-invented, 12-degree Castor Angle’, which allows the front wheels to ‘lean’ when turning. With the pivot axis of the steering knuckle tilted 12° to the rear, purportedly more than twice that of the nearest competitor, a 50° steering angle could be achieved – even with large tyres at standard tread settings.

The axle can be engaged on the move, under load, thanks to an oil-cooled, multi-disc clutch – by way of a dash-mounted rocker switch. A self-locking differential is also a feature of the driven front axle – locking automatically at the first sign of slip.

Although introduced well into the 1980s, when power steering systems were the norm, be sure to check that the tractor you’re intending to purchase has such a ‘luxury’, as the smallest models didn’t have power steering as standard – particularly if they were destined for a market where basic tractors were still desirable.

Deere’s braking system design shouldn’t cause any problems, but look out for insufficient stopping power on high-hour tractors. The inboard disc brakes incorporate a ‘cling-resistant surface’ and retraction springs to aid disc separation following braking, and are fed by cooled, filtered oil to aid heat dissipation.

The ‘H-pattern’ shift on the SG2-cabbed models is nice to use, but look out for changes that aren’t as crisp as they should be. This could point to a worn selector. (Photo: Howard Sherren)

Hydraulics & PTO

John Deere marketed its hitch system as ‘Liquid Lightning’ – employing a closed-centre hydraulic system throughout the range, in partnership with lower link-sensing.

The crux of the idea is a special hydraulic pump, costing in the region of £500 +VAT, that ‘rests’ when there’s no demand from hydraulic functions. Pressure inside the pump builds and forces the pistons away from the cam drive, so that there’s no overheating or parasitic power wastage. Meanwhile, oil in the hydraulic lines is held at standby pressure.

Once hydraulic power is called for, the pressure inside the pump is relieved, and springs force the pistons on to the cam drive so that it can deliver the flow of oil required, which is shared by the transmission – simplifying maintenance and reducing expenditure. Pump output across the range was 45 litres per minute, with pressure at 190 bar.

Nick Young was quick to point out the problems associated with this type of hydraulic system. “The unique, JD closed-centre hydraulic system can be an issue,” he said. “I think this is mainly due to the age of the tractors. The output of the internal-mounted transmission pump, that feeds the front-mounted high-pressure pump, as well as the Hi-Lo and PTO clutches, reduces over time – causing a range of hydraulic problems.

“The 50 Series tractors use a common oil supply for the transmission and hydraulics and, therefore, worn-out brake discs can contaminate the system, causing premature pump wear. It’s quite a labour-intensive job to repair the internal hydraulics, as the cab needs removing and the tractor splitting. New, genuine and replacement parts are available.”

If you’re looking for something less common, a two-wheel-drive, six-cylinder model makes for an interesting talking point. All models, with the exception of the flagship, could be specified in two-wheel-drive configuration. (Photo: Howard Sherren)

The lower link-sensed element of the system is great for uniform tillage – with the system providing sharp response and subsequent signals to the rockshaft, but look out for weeping/leaking at the lower link attachment points on high-hour tractors, and/or those that have undertaken a lot of draft work.

Over time, the shaft gets grooves worn into it and this, combined with age-hardened seals, leads to oil leakage. Thankfully, this is a relatively straightforward fix, and the parts needed to rectify the problem – namely a replacement shaft and seal – can be obtained for about £100 +VAT.

Prohytronic electronic linkage control was offered on later, six-cylinder tractors, but it’s rare to find a tractor fitted with the system – as many deemed it too complicated for such a ‘basic’ tractor.

A ‘High Lift’ linkage became available as an option on the larger four- and six-cylinder models, offering an increased range of movement for the lower links, and an increased lift capacity. Tractors equipped with High Lift (often abbreviated to ‘HL’ in classified advertisements) are worth seeking out.

“All 3650s were High Lift, and the 3050 and 3350 High Lift models had a different front axle, engine cylinder block and transmission castings compared to the standard lift models,” Nick explained.

A front linkage and PTO was available for four- and six-cylinder tractors, with a frame running alongside the engine to strengthen the chassis. The front PTO was a further option, and transmits power from the crankshaft, through an oil-cooled clutch, to a reduction gearbox between the lift cylinders. It is actuated by a cab-mounted switch, but can be disengaged completely by a lever on the aforementioned gearbox.

Look out for tractors fitted with a genuine Deere front linkage. Aftermarket options, such as the Farm Force linkage, are much more prevalent than factory-fitted examples. (Image taken from promotional literature)

Nick Young told us that investigating the state of the pick-up hitch is worthwhile, as it could lead to additional expense. “The pick-up hitches are now often worn,” he explained. “The range of new parts to repair the factory-fitted Axla hitch is now very limited. Good, used hitches and parts are almost impossible to find. The best solution is to fit a new, aftermarket pick-up hitch.”

An oil-cooled, multi-disc clutch, independently and hydraulically actuated, was a feature across the range, but the speeds offered and method of switching between 540rpm and 1,000rpm speeds (where applicable) differed, according to the model and cab fitted.

There are no major problems associated with the power take-off system, but look out for a PTO shaft that doesn’t stop turning. This is often due to failure of the friction plate – either the friction material or the splines that lock it to the shaft.

The High Lift linkage fitted as an option on later models is definitely worth having. Look out for a worn pick-up hitch, as it can prove to be an expensive fix. (Photo: Scott Lambert)

Cab choice

The 50 Series, like its predecessor, is famed for its SG2 cab – but this was not available for all models in the range. The smallest, three-cylinder models could only be purchased, depending on the market, with an open station or MC1/CC2 cab, but the 1950 was not available with an option station.

The 2250, 2450, 2650 and 2850 had the option of SG2 or MC1/CC2, while the six-cylinder tractors were only available with the SG2.

Some dislike the SG2 for its novel design, single door and unusual method of entry, but the fact remains that it was one of the leaders of its day – with noise levels lower than 80dB(A). Look out for later examples with a wider step and handrail assembly – which made a vast improvement.

The controls, switchgear and analogue instrumentation are pretty robust, but electrical gremlins have been known to occur with faults emanating from the fuse box. “Due to the tractors’ age, the right-hand side of the dashboard can have electrical problems,” Nick Young told us. “The terminals on the fuse card and printed circuit get corroded, and cause electrical connection issues. New, genuine parts are available, though.”

Look out for electrical gremlins with both the analogue and digital (fitted from 1992) displays. Problems can often be traced back to the fuse box or printed circuit board. (Photos: Howard Sherren)

There’s little to go wrong in terms of gear levers, hydraulic and PTO controls, as it’s all very ‘hands on’. But, as time goes on, the interior trim of the SG2 can start to look a little unloved. Cladding kits are available, but time and patience is required to get an SG2 back to looking its best.

The alternative – the MC1/CC2 – was covered in detail in the July issue of T&M but, in short, it offered an ‘economy’ alternative to the SG2, with two-door entry, an openable front screen and lower overall height.

Available from the off, the MC1 had mid-mounted gear levers, and didn’t have the luxury of pendant-style pedals, but the CC2 (introduced in 1990/91) saw the gear levers repositioned to the right-hand console.

If overall height is a concern, or if access to the SG2 is likely to cause you a problem, a 50 Series tractor with an MC1/CC2 could be a viable alternative. Plus, if you’re going to be in and out of the tractor a lot, negotiating the steps and dash panel every time you climb aboard or alight the SG2, may prove tiresome. Look out for broken doors on the MC1/CC2, as the edge of the glass is particularly vulnerable and the steel frame can be damaged, too.

Once inside both cabs, the comfort level is good, but with better mechanical ventilation, the SG2 makes for a better bet in hot weather. Think about what you’ll be doing with the tractor, as visibility is very different according to which cab is fitted. If you can, find an example of both to ascertain which will be best for you.

The height of the SG2 gives a commanding position, but all-round vision is quite different to that of the MC1/CC2. Criticisms of the SG2, aside from entry/exit, include the hand-operated differential lock fitted to tractors built from 1991 onwards, and the lack of storage space for a lunch bag, tools and the like.

Nick Young said: “The SG2 cab, although being quite small, is regarded as a nice place to work. The cab steps can be a bit of a challenge, although the wide step on later, six-cylinder models was better.

“We are constantly being asked for good, SG2 cabs but, unfortunately, demand far exceeds supply. Most of the tractors we now get in for dismantling often have rusty cabs. Finding good, used cab doors and seats is a particular problem. There is a range of aftermarket cab glass, mudguards and interior cab cladding available.”

The later-type, wide step made for much better access. (Photo: Scott Lambert)

Final thoughts

John Deere’s 50 Series is renowned for its simplicity and reliability – the pinnacle of evolution based on this design. It built on the success of the 40 Series and, in recent years, has become one of the most popular ranges of classic tractors, coveted by die-hard Deere fans and general enthusiasts alike.

No tractor is perfect and although the SG2 has always been a ‘Marmite’ cab, there’s a lot to be said for its levels of comfort. If you can’t get over the aesthetics and ergonomics of the unit, then perhaps a 50 Series Deere is not for you.

An MC1/CC2-cabbed tractor can be hard to find, but if it’s more likely to suit your needs it’s definitely worth persevering with your hunt for one.

Prices remain strong, particularly for the 2650, 2850, 3050, 3350 and 3650, but you may be able to find a three-cylinder model at a reasonable price. Our search (July 2020) revealed the following tractors: JD 1950, two-wheel-drive, creeper gears, 5,500 hours, tidy, CC2 cab: £9,950 +VAT. JD 2650, four-wheel-drive, Power Synchron, 40kph, 10,500 hours, average, front linkage, SG2 cab: £10,500 +VAT. JD 3350, four-wheel-drive, Power Synchron, 40kph, wide step, High Lift, 7,500 hours, £12,500 +VAT.

As time goes on, the popularity of these tractors is sure to increase. With new tractors heavily reliant on electronics, the simplicity of the 50 Series is likely to become more appealing to those who want to undertake their own maintenance and repair.

Nick Young concluded by saying: “50 Series tractors are now seen as usable classics and, therefore, prices have risen accordingly. However, owners and prospective purchasers should remember that these tractors are 30 years old. Most, but not all, parts are still available but, because of the age of the tractors, some will be expensive.

Many thanks to Nick and James Young at Nick Young Tractor Parts for their technical input and for providing parts prices.

| Parts prices: John Deere 2850 | |

| Engine oil filter | £4.48 |

| Fuel filter | £10 |

| Hydraulic filter | £6.32 |

| Inner air filter | £12.34 |

| Outer air filter | £14.66 |

| Fan belt | £12.76 |

| Clutch plate (OEM: LUK) | £232 |

| Head gasket | £23.29 |

| Starter motor | £120 |

| Alternator | £130 |

| Water pump repair kit | £38.17 |

| Water pump | £118.73 |

| Hydraulic pump | £495 |

| Exhaust silencer | £125 |

| Door mirror (OEM: Hella) | £32 |

| SG2 base trim kit | £230 |

| SG2 mudguards (pair) | £395 |

| SG2 wide mudguards (pair) | £420 |

Note: All prices +VAT (July 2020) from Nick Young Tractor Parts.

Useful contacts

Alwyn Thomas Used Tractor Sales

Gwynedd

Tel: 01248 670643

alwynthomastractors.co.uk

Used classic tractors

Crickley Hill Tractors

Gloucestershire

Tel: 01452 862232

crickleyhilltractors.co.uk

Used classic tractors

JF Agricultural Engineering Ltd.

Buckinghamshire

Tel: 01525 370477

jfsales.co.uk

Used John Deere tractors

Nick Young Tractor Parts

Lincolnshire

Tel: 01673 828883

nytractorparts.co.uk

New and used parts

Oakfields

Hertfordshire

Tel: 01763 780440

oakfields-ag.com

Used classic tractors

| Specifications: John Deere 50 Series | |||||||||||

| Model | 1550 | 1750 | 1850 | 1950 | 2250 | 2450 | 2650 | 2850 | 3050 | 3350 | 3650 |

| Power | 44hp | 50hp | 56hp | 65hp | 62hp | 70hp | 78hp | 86hp | 92hp | 100hp | 114hp |

| Cylinders | 3 | 3T | 4 | 4T | 6 | 6 | 6T | ||||

| Bore | 106.5mm | ||||||||||

| Stroke | 110mm | ||||||||||

| Displacement | 2,940cc | 3,920cc | 5,883cc | ||||||||

| Rated speed | 2,300rpm | 2,400rpm | 2,300rpm | 2,400rpm | |||||||

| Torque | 152Nm | 185Nm | 195Nm | 245Nm | 230Nm | 255Nm | 285Nm | 315Nm | 340Nm | 370Nm | 431Nm |

| Fuel capacity | 72 litres | 84 litres | 86 litres | 136 litres | 173 litres | 177 litres | 170 litres | ||||

| Transmission | Synchron (8 fwd, 4 rev), Power Synchron (16 fwd, 8 rev) or Synchron + Creeper (12 fwd, 8 rev) | Power Synchron 16 fwd, 8 rev | |||||||||

| Lift capacity* | 1,825kg | 2,267kg | Standard: 2,670kg

High Lift: 3,568kg |

Standard: 3,517kg

High Lift: 4,526kg |

5,270kg | ||||||

| Turning radius** | 2WD: 3,280mm | 2WD: 3,280mm

4WD: 3,900mm |

2WD: 3,500mm

4WD: 4,000mm |

2WD: 3,658mm

4WD: 4,100mm |

2WD: 3,800mm

4WD: 4,200mm |

2WD: 4,500mm

4WD: 4,300mm |

4,700mm | ||||

| Length | 3,754mm | 3,764mm | 4,193mm | 4,243mm | 4,787mm | ||||||

| Wheelbase | 2WD: 2,050mm | 2WD: 2,050mm

4WD: 2,057mm |

2WD: 2,151mm

4WD: 2,159mm |

2WD: 2,266mm

4WD: 2,287mm |

2WD: 2,551mm

4WD: 2,582mm |

2,582mm | |||||

| Weight | 2,640kg*** | 2WD: 2,510kg***

4WD: 2,819kg*** |

2WD: 2,545kg****

4WD: 2,849kg**** |

2WD: 2,790kg****

4WD: 3,105kg**** |

2WD: 3,210kg***

4WD: 3,510kg*** |

2WD: 3,490kg*****

4WD: 3,800kg***** |

2WD: 3,625kg*****

4WD: 3,935kg***** |

2WD: 4,150kg*****

4WD: 4,475kg***** |

5,125kg***** | ||

| Front tyres | 2WD: 6.50-16 | 2WD: 7.50-16

4WD: 11.2-24 |

2WD: 6.50-16

4WD: 9.5 R24 |

2WD: 7.50-16

4WD: 11.2-24 |

2WD: 10-16

4WD: 11.2-28 |

2WD: 10-16

4WD: 12.4-28 |

2WD: 10-16

4WD: 13.6-28 |

14.9-26 | |||

| Rear tyres | 12.4-28 | 12.4-32 | 13.6-36 | 16.9 R28 | 13.6-36 | 13.6-38 | 16.9 R38 | 18.4-38 | 18.4-38 | ||

Note: Range also featured the 1350 model.

* Lower links horizontal

** Without brakes

*** With MC1 cab

**** With CC2 cab

***** With SG2

For a money-saving subscription to Tractor & Machinery magazine, simply click here