Massey Ferguson 575 buying

Posted by Chris Graham on 20th September 2020

Dan Harris offers some practical advice on all aspects of buying and maintaining the popular Massey Ferguson 575.

Massey Ferguson 575: Launched in the summer of 1976, the MF 575 replaced the MF 168 with square styling and a ‘Q’ cab.

Massey Ferguson launched the highly successful 100 series in December 1964, and revised the range in 1971. When the majority of tractors for the UK market had to be fitted with a ‘Q’ cab by 1977, Massey Ferguson responded by developing the 500 series.

The initial model of the range to be launched was the largest, the MF 595, in 1974, which provided a world preview of what was to come from Massey Ferguson. However, it would be two years later, in the summer of 1976 – at the Royal Show at Stoneleigh – before the four, smaller models were introduced. The full range at this time consisted of the MF 550, 565, 575, 590 and the 595, replacing the 148, 165, 168, 188 and 1080 models respectively.

It’s clear that the MF 575 has its heritage in the MF 168, which it replaced on the UK market, while the MF 168 was still available for export. The major mechanical items largely remained unchanged, but a number of key advancements internally and externally in the way of operator comfort were introduced, which we shall discuss in detail later. Like the MF 168, the 575 was assembled at both the Coventry and Beauvais factories.

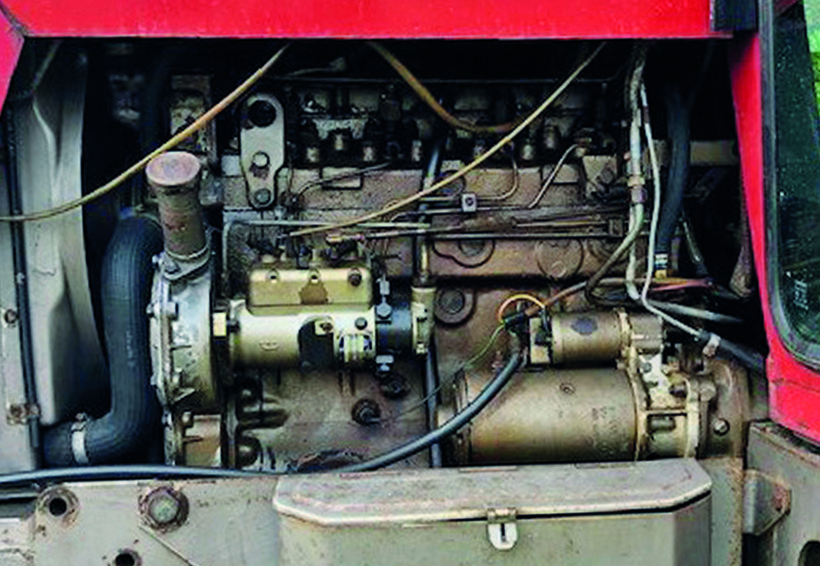

Engine

For the MF 575, the Perkins A4.236 engine was specified. Launched with the MF 175 in late 1964, it’s regarded as one of the best tractor engines available of the period, and had a 30-year production run in models from the 175 through 168, 575, 275, 675, 3050 and 375, ending in 1997. This alone tells you that it was one of the best-performing Perkins engines of all time – even if it did have some tweaks, such as metrification, along the way!

Left-hand side of the engine with engine oil filler location and standard toolbox.

With a bore of 98.4mm and that all-important, long 127mm stroke, the engine develops a respectable 66PS and 255Nm of torque at 2,000rpm and 1,250rpm respectively. The engine isn’t known to have any specific issues, and is fitted with a Lanchester balancer in the sump, which keeps vibration of this long-stroke engine to a minimum.

With careful maintenance (engine service interval 250hrs), 8,000-10,000 hours of operation can be expected before a major rebuild is required. If looking to purchase, try to witness the engine starting from cold, and expect it to go on the first attempt unless in sub-zero temperatures.

Clutch

Two options of clutch were fitted to the MF 575, either a dual-clutch with 12-inch primary and 10-inch secondary plates, or split-torque clutch with 12-inch main plate. Most will be familiar with the dual-clutch arrangement, whereby partially depressing the clutch stops forward motion and depressing fully stops drive to the hydraulics and PTO. The split torque unit means that drive is uninterrupted to the hydraulics and PTO, the latter being engaged by a hydraulically-actuated clutch instead.

The MF 575 features a nearly flat floor with pendant-style clutch and brake pedals.

To determine which clutch is fitted, depress the clutch and engage the PTO: if the tractor is a dual-clutch model, the PTO won’t rotate until the clutch pedal is released. If it’s a split-torque type, then the PTO will start rotating immediately. If the PTO is difficult to engage, with gears grating, then the secondary plate on the dual-clutch model is out of adjustment, which may be rectified via the inspection plate under the bell housing.

Check for primary plate slip by driving in a low gear in high range and applying the brakes momentarily; the engine should die away quickly. A failing release bearing can usually be detected by listening for rumbles when the clutch pedal is depressed. Secondary plate slip, which is unusual, would only be detectable by trying to operate a power-hungry PTO implement, such as a rotavator. If a problem is suspected with the clutch, then the tractor would have to be split to repair.

Gearbox

Two options of gearbox were generally available, either a newly-developed two-range, eight-speed with synchromesh on third and fourth gear in each range, or the 12-speed Multi-Power unit carried over from the MF 168. The eight-speed gearbox is known to have some reliability issues with the synchromesh unit but, generally, most perform without fault. Engage all gears and a tractor that struggles to engage between third and fourth on the move requires attention.

Visibility from the seat is good thanks to the fully glazed doors; this eight-speed model features a very long main gearstick.

Multi-Power models are generally reliable and offer an extended range of gears, plus an on-the-move clutchless change between high and low ratio in each of the six basic gears. They do, however, have the quirk of lack of engine braking in low, and cannot be tow started. The Multi-Power lever should change gear decisively when operated; also drive the tractor uphill in Multi-Power high, then depress the clutch through the first stage, whereby the tractor should ‘hill hold’ and not roll back.

A third gearbox option, consisting of the three-stick, 12-speed synchro unit more commonly found in the MF 600 series, may be found on some of the very last MF 575 examples. This is a great gearbox in terms of ratios and reliability, but finding one thus fitted will be challenging. Whichever gearbox is fitted, it’s important to make sure it does everything as expected, as repairs will be expensive.

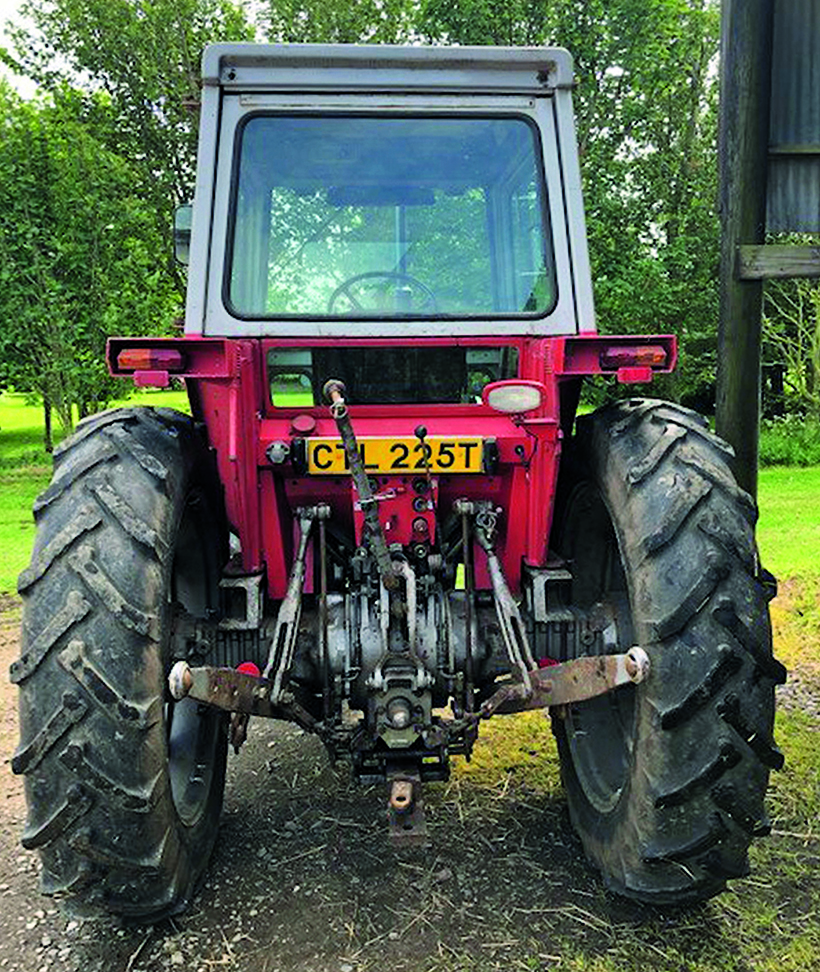

Rear axle and PTO

The rear axle incorporating a multiplate wet brake arrangement was inherited from the MF 168. However, the brakes are hydraulically-actuated and are, therefore, self-adjusting for balance. Drive the tractor at a moderate speed and check to make sure it stops in a straight line when the brakes are applied. The axle, incorporating a pedal-operated differential lock, is a strong unit and problems aren’t to be expected. But do check the rear hub seals to make sure they aren’t leaking as replacement is an involved operation.

The rear axle, linkage and pickup hitch inherited from its MF 168 predecessor.

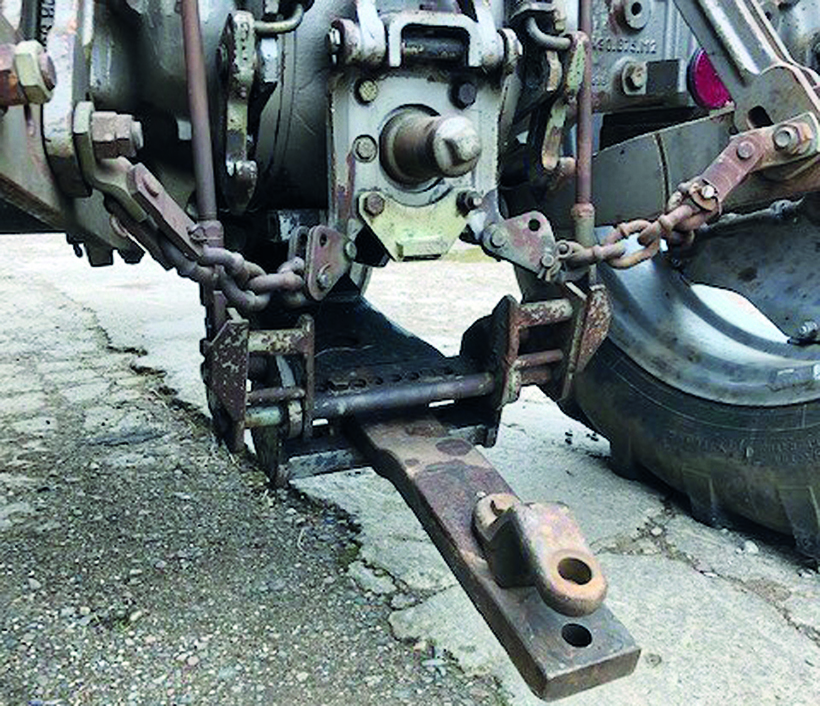

Slung beneath the rear axle is the standard MF pick-up hitch and swinging drawbar arrangement, which can quickly be fitted with either the pick-up hitch crook or a heavy-duty clevis drawbar. Fortunately, and unlike the previous MF 168, the pick-up hitch is operated by rods rather than chains, which have a tendency to stretch and require periodic adjustment. Actuation of the release handle does, however, require the operator to lean out of the rear window.

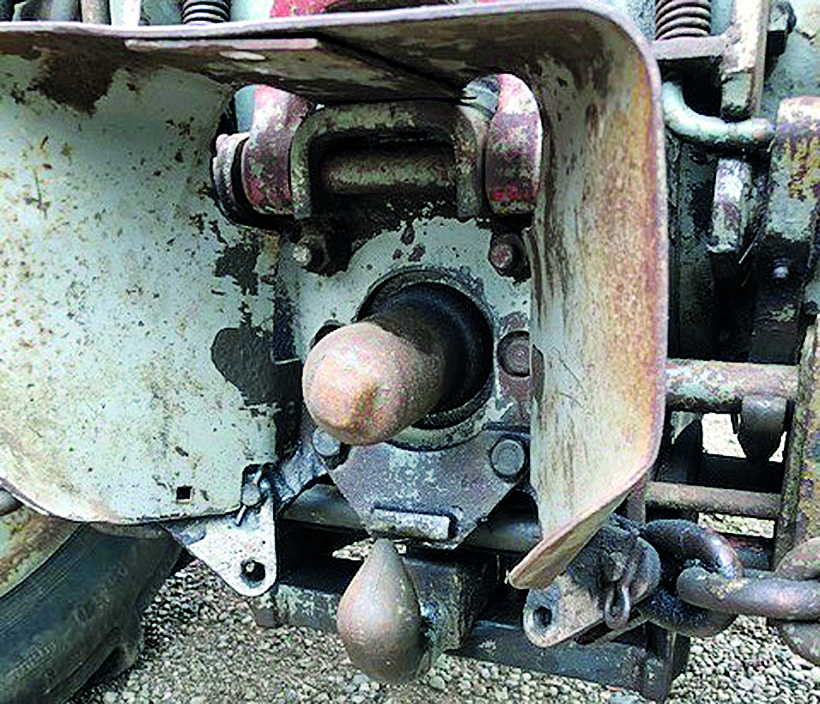

The PTO is the one area on the MF 500 series where the greatest mechanical development, compared to the outgoing 100 series, was made. It was possible to specify a new MF 575 with the ability to interchange between standard 540 and 1,000rpm PTO output speeds. It is necessary to swap the PTO output shaft between six-spline and 21-spline types, by removing the retaining circlip with raised prongs at the base of the PTO shaft. Models without the circlip with raised prongs will be 540rpm-only machines.

The most significant mechanical advancement over the MF 168, was the provision of optional, 1,000rpm PTO.

Interestingly, there were a number of PTO combination options possible, and I’ve been unable to source a definitive list but, essentially, the basic eight-speed gearbox model would typically be fitted with a dual-clutch and 540rpm/proportional ground speed PTO arrangement. A Multi-Power gearbox tractor is likely to have a split torque clutch, iPTO and either a 540rpm-only or 540/1,000rpm PTO provision. ‘iPTO’ is independent PTO, meaning that the PTO is actuated by a hydraulic clutch, without interrupting forward motion.

It is possible, however, that some dual-clutch machines were also fitted with 540/1,000rpm PTOs. Proportional ground drive speed PTO was not available in combination with the 540/1,000rpm option. The PTO lever, which can be found to the lower left of the driver, has either two or three positions, depending on the PTO option installed; three-position models denote the provision of ground speed PTO.

On iPTO-equipped models, make sure the PTO shaft engagement is smooth and, if possible, check this with a PTO-powered implement attached. When a machine isn’t attached, the PTO shaft shouldn’t be rotating; if it is then the iPTO hydraulic clutch pack brake has failed, with repair necessitating a complete strip-down of the rear end to replace the brake pad or, even worse, the iPTO clutch housing, which is expensive.

Hydraulics

The Ferguson system with draft, position and pressure control, was specified with the linkage pump being driven at the higher PTO speed on 1,000rpm-equipped models, resulting in an output of 27.5l/min (6 gal/min) at 210bar (3,000psi). Standard lift capacity is an adequate 1,796kg, which is sufficient for the implements the tractor was designed to pull. Lower links feature interchangeable balls to enable both category one and two implements to be used.

The linkage pump is complemented by an auxiliary pump on Multi-Power-equipped models, which provides priority services for Multi-Power and iPTO, where fitted. A flow of 36l/min (7.9 gal/min) at 172 bar can be used independently, or combined with the linkage pump to provide hydraulic flow to up to three, double-acting spool valves, via the in-cab selector valve. Auxiliary spool valve levers are found to the lower right of the driver, and it’s usual to find two double-acting services fitted.

The rod-operated swinging drawbar and pick-up hitch came fitted with a crook and heavy-duty clevis hitch.

The world-renowned Ferguson system is reliable but, where possible, check the output from the system lifting an appropriate implement or a pressure gauge. Should the linkage be jerky in operation, then this is an indicator of either a low transmission oil level from where the pump gets its feed, or a blocked inlet strainer, which is accessed from underneath the centre casing, behind the gearbox.

Front axle, steering and wheels

Most tractors are 2WD, however a 4WD variant was assembled at Beauvais, in France, with these models generally regarded as underpowered. The front axle on 2WD variants is the same, heavy-duty version as on the MF 168 – the model it replaced – and features gussets between the beam and the kingposts. The front track is adjustable in four-inch increments, between 52 and 68in (1.32-1.73m), which is useful for row crop operations.

Hydrostatic power steering was fitted as standard, making the steering very light, as with all hydrostatic steering models of the period, any wear in the orbital unit will make it difficult to keep the tractor in a straight line on the road. Check the system for leaks, especially around the steering hydraulic cylinder behind the grill door.

This example features its original tinted cab glass throughout; note the provision of double wing mirrors.

The steering system will have been subjected to heavy loads and is prone to wear, ball joints are easy to check by operating the steering and observing any play. Kingpins are best checked with the tractor jacked up, allowing the wheels to be rocked to detect any movement; a check of wheel bearings can be made at the same time. Wear in the steering shaft, which passes through the axle support, will exacerbate any steering wander, due to a worn, orbital steering unit.

Standard wheel equipment included 13.6/12×36 rear and 6.00×19 front tyres on pressed-steel rims. However, most will be found with 7.50-16 front tyres instead. Rear wheel options included 13.6/12-38 and 16.9/14-30 pressed-steel type, and all rear wheels could be specified as cast centred PAVT versions if required. The cast centre PAVT rear wheels offer track adjustment of 54-90in, but rim condition is important, as new ones aren’t available. Check that the lugs and clamps are in good order, paying attention to the rim rails for cracked welds.

Cab

The Q cab was first introduced with the MF 595 and, although it’s not quiet by today’s standards, it was a welcome upgrade from the relatively open MF Sirocco safety cab that preceded it. It’s adequately specified with an adjustable spring suspension seat and pendant-style pedals, although the single access door of the original model didn’t appeal to all operators. Later cabs are fitted with two doors, which are worth seeking out if this is important to you.

Cab access is adequate through the single LH side, rear-hinged door on early models.

The original livery of the cab was a red lower half with a silver top half, which I personally think is more attractive than the later, nearly all red model with silver roof only. The cab does feature ventilation and heating, but the option of air conditioning would only arrive with the later MF 600 series. On single-door models, the rigid side features a swing-out window, while two-door models have a sliding window instead.

These cabs are made from pressed steel, spot-welded together like a car body and, as such, they naturally have a significant number of condensation traps, which rot. Doors and windows can be repaired, but the frame of the cab shouldn’t be welded if the tractor is to remain operational in agricultural duties. Check the cab carefully; a tractor with a tidy cab is by far the most attractive option, and will generally command a premium.

Conclusion

The MF 575 is a great tractor for lighter duties on an agricultural unit, and is an ideal tool for this purpose with a MF 80 power loader fitted. With the last ones being sold in 1983, any model is now nearly 40 years old and, as such, fits straight in on the classic preservation scene. Due to the complexity of restoring a cab, they aren’t for everyone, but certainly make a comfortable steed on which to complete a winter road run.

The MF 575 was also available in a four-wheel drive version, which is relatively rare and considered sluggish by users.

What to pay

Prices will be variable, depending on a number of factors, but the condition of the cab will be pivotal. Off-farm models will be found for about £3,000, low hours original models in good condition go up to £9,000. Restored models range from £6,000 to £12,000 for concours show examples, with everything in between.

Many thanks to Steven Mair for taking photographs of his tractors, and making this article possible during lockdown.

For a money-saving subscription to Classic Massey & Ferguson Enthusiast magazine, simply click here