Electric-powered Ferguson TE-A 20

Posted by Chris Graham on 15th June 2023

David Reed visits Keith Atkinson to discover how he converted his recently-purchased 1949 Ferguson TE-A 20 to electric power.

Keith Atkinson on his 1949 Ferguson TE-A 20 that’s now powered by an electric motor. He’s now designated the tractor as a ‘T 20 E’.

Keith Atkinson has been involved with tractors all his life, in one way or another, and has always been keen on experimenting when he can. So, when he saw a television programme about converting vehicles to electric power, he thought about how he could convert a tractor.

“I’d watched Vintage Voltage, a series that followed Richard ‘Moggy’ Morgan and a team of electric car experts who converted and restored classic cars to be powered by electricity,” Keith said, impressed with the conversions. “They have worked on all sorts of vehicles using Tesla motors,” he said. “The Land Rover 2A went really well!”

Keith was also fascinated with the team’s efforts to convert a two-stroke, single-cylinder BMW Isetta ‘bubble car’. He explained: “They wanted to use it in London, but didn’t feel comfortable driving it around, as it was slow and difficult to change gear. When it was converted to electric power it was much better. They also adapted a Volkswagen Beetle and a VW camper van,” he added.

After considering sourcing an electric motor from a forklift or an old milk float, this airport tug provided the necessary components to convert the tractor.

About a year ago, Keith set about converting a tractor to run on electricity. Before long he came across a suitable tractor not too far from home – a 1949 Ferguson TE-A 20 that had worked on market gardens in the Tarleton area, south of Preston, in Lancashire.

It was a bit rusty when bought, and not in the best of condition – although it had been partly restored.

Keith has always liked experimenting with tractors and he told T&M: “Years ago I was the first man to put a diesel engine into a Fordson Standard N, so I saw converting a tractor to run on electric power as a bit of a challenge. I wanted to do some ploughing with it!”

Lift the bonnet and some of the batteries can be seen. Those that would be easily visible are covered by a box.

The first thing that Keith had to do was to find a suitable motor that would both fit the Ferguson and provide enough power. He had an idea where to find one, though. “I had thought about using the motor from a mobility scooter, but realised that it would be too small to power a tractor,” he said.

The project was temporarily at a standstill, but Keith approached Yvonne Helm from Essential Industrial Services of Preston, who delivered bearings. She suggested that Keith got into contact with Gary and Lee Clark of AC Forklifts Ltd, to see if a motor from a forklift would be suitable. “When I talked to them, they didn’t think that solution would work,” Keith said. “Instead, they talked about using a motor from an old electric milk float, or something similar.

“They then suggested that I got a motor from an airport tug that had been used to pull a train of luggage containers to planes at an airport,” he added. It was a breakthrough moment, so Keith approached Beech Forklifts of Cockerham, near Lancaster, who had a couple of tugs for sale, and went to have a look. It turned out to be just what he wanted.

The motor partly is housed in the engine’s sump, under some of the batteries.

“I bought a Peterborough-built, 2012 Bradshaw T5, 48-volt tug in May last year,” Keith explained. “I converted the tractor over the summer, and the project was finished just in time to do some ploughing matches.”

Work begins

So exactly how was the conversion carried out? The first thing to do was to remove the motor from the tug, which proved to be a bit of a problem. “The motor was actually part of the back axle of the tug,” Keith explained, “So when the motor was removed from the axle, there was no end plate on it.”

Once again, a solution had to be found. “The answer was to fabricate a new end plate, which was carried out by Edwin Santley of ESL Electromech Ltd, of Runcorn,” Keith added. “As for the motor itself, it works in three phases, starting in DC, then converting to three-phase AC for controllability. The throttle lever from the conventional tractor can also control the speed.”

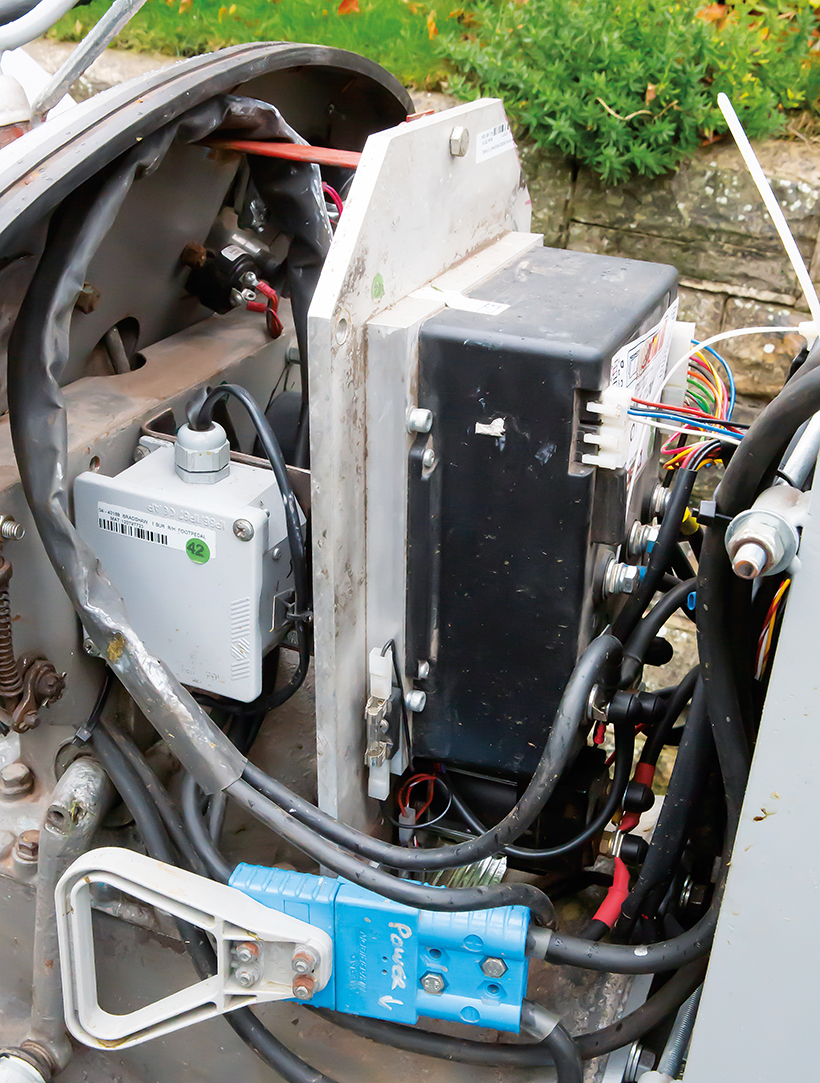

The controller is situated between the dash panel and the batteries under the bonnet.

With the tractor’s original engine removed, the idea was to replace the engine block by partly fitting the motor into the sump. “That then became part of the chassis,” Keith added. “It left just enough room to get some of the batteries under the bonnet.

“It was difficult getting everything lined up,” he admitted. Unfortunately, when the new motor was fitted into the Ferguson, Keith couldn’t get it to run. “I messed about with it and eventually got it sorted,” he said. “The problem centred on the forward and reverse switch from the tug.”

Luckily, Keith received a lot of help with this process. “I am very grateful to my friends who helped me with this, such as David Gardner – who helped with the electric side of things,” he continued.

The rear of the Ferguson is as you would expect, save for the batteries on the footplates, reminiscent of a TE-F 20.

As for the clutch and the gearbox, they are original, although the question had been whether to keep the clutch or not. “I had been told that one would not be needed,” Keith said. “I thought that the clutch and gearing would control the forward and reverse speed and be an alternative for ploughing, which I prefer doing.”

The clutch is also needed to operate the hydraulics. “When lifting the plough, the gears knot up a bit if I don’t use the clutch,” Keith explained. As for the gearing, though, that turned out to be just about right. “It is just about as it was on a conventional tractor,” Keith added.

Another concern was that the torque from the motor would not be enough to get the Ferguson moving, but in the end, there was no need to worry. “The torque was good when setting off and would be fine for ploughing,” Keith said.

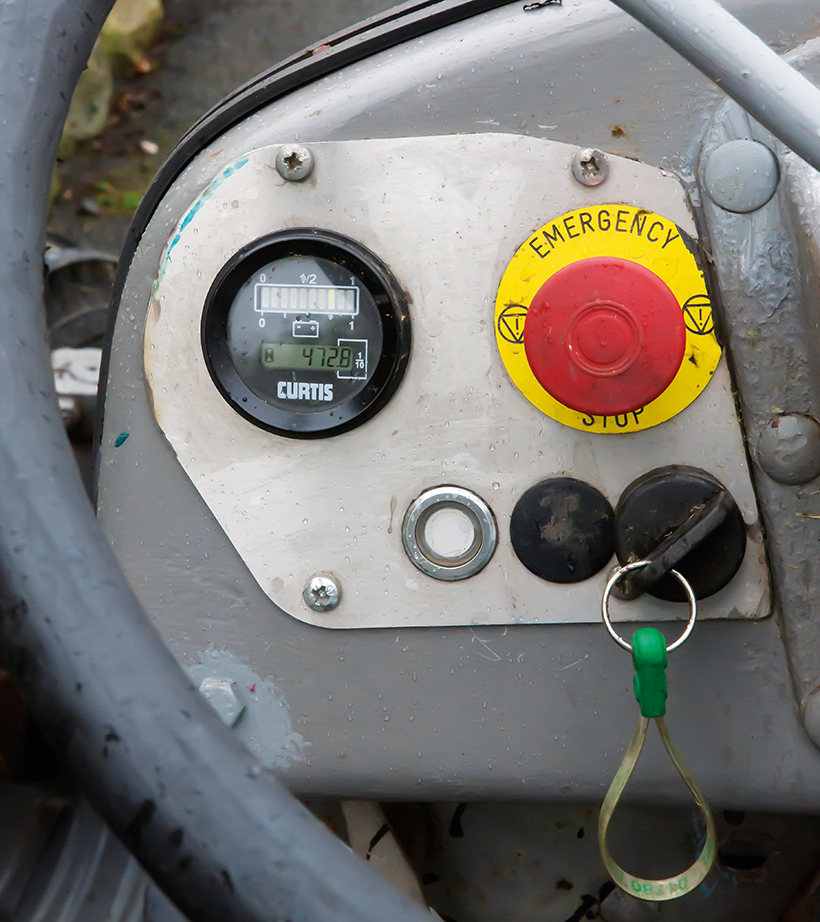

The tug’s controls and instrumentation are now fitted within the original dash panel.

All through the conversion, Keith had tried to make the Ferguson look as original as he could, but this isn’t an easy task when the tractor carries 24 two-volt batteries, producing the 48 volts needed to power the motor.

There is still some work to do, according to Keith. The rear housing needs to be taken apart and painted, now that he knows that the electric concept works, and he also wants to build more battery covers to make the tractor appear to be in original condition.

As for Keith himself, he attended technical college learning engineering skills and started work during the 1960s, at the age of 17, as an agricultural blacksmith. One of his jobs was to convert horse machinery so that it could be drawn behind a tractor. “I worked there for around 10 years,” he explained. “It was always on machinery, I never repaired tractors.”

The hand throttle remains and acts as a speed controller.

Keith enjoyed his work, and cycled the three miles there every day, passing a garage on the way. “On the way home, I used to stop there to see what was going on,” he said. “I would go back at night to help them out, learning a lot about cars in the process.”

After carrying on working at the smithy for a while, Keith then moved on to work for Massey Ferguson dealer Gibson Brothers of Garstang, as a mechanic. “It was fantastic working there,” he said. “In my opinion, there was nothing to compete with the Ferguson System.”

It was there that Keith became seriously interested in tractors, and he went on courses to learn all about them, along with balers and combines. He worked at Gibson Brothers for about 15 years, then went to work for Jim Hall, at Porter’s Farm at Inskip, near Preston, where he started repairing Ferguson tractors. “I was there for 10 years, and worked on 135s, 148s and 590s,” Keith explained.

The foot pedals on the tractor work as on a standard Ferguson.

Keith eventually decided to branch out on his own, and started contract ploughing with a Marshall tractor that was fitted with a three-furrow reversible plough. “I then progressed to using a Massey Ferguson 3080 and a 3085 tractor, before buying a 30ft rake to fulfil a contract. I continued ploughing but ended up raking some 2,000 acres a year with an MF 3095 and a 6180,” he added.

There was no letting up as Keith approached the age of 70. “I took up hedge-cutting, as well as continuing with ploughing and raking,” he said. Although he enjoyed his working life, when he was approaching his mid-70s, Keith decided to cut back a bit. “I gave up ploughing and raking, but kept on hedge-cutting until I was about 75,” he said.

Now retired, Keith keeps his hand in with ploughing. “I compete in matches,” he said. “I really do enjoy that.”

His electric Ferguson, which he calls a T 20 E, isn’t his only tractor. “I also have a TE-F 20, and a 1957 FE 35, a very smart MF 35 and a 148 from 1972, which is in equally good order,” he added.

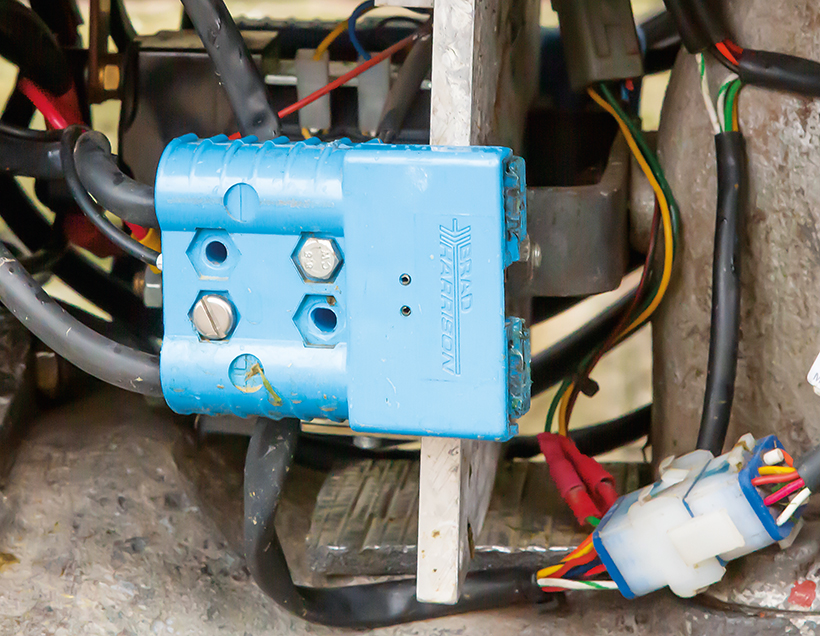

This blue plug is used to connect the tractor to a battery charger.

Despite these nice examples, it is his Ferguson conversion that is in the spotlight at present. “It hasn’t been done for any profitable reason, I just wanted to see if I could do it,” Keith said. He has completed some demonstrations with it already, and explained that was the reason why he wanted to keep it looking as original as possible.

Keith is always on the lookout for ways to improve the look of the tractor. “I would like to fit a Ferguson combined epicyclic gearbox and live PTO unit,” he said. “It would mean that I could fit a battery at the back, and with more weight there it would lighten the steering. It would also give me more room for my feet!”

If you know where Keith could purchase one, please get in contact with the editor in the first instance, by email to: tm.ed@kelsey.co.uk.

The seat is standard, but the batteries at each side make things rather cramped for the operator’s legs.

Interestingly, Keith does think that the future will be electric. “I do think that electric tractors will come in eventually,” he said. “There will be motors in every wheel, and the tractor will be computer-controlled. Everything will be completely different!”

Time will tell on that idea, but it is a thought. Whatever the future holds, Keith has demonstrated that the concept works, and a standard Ferguson tractor can be converted to run on electricity successfully. Now, I wonder what Harry Ferguson would have to say about that?

Keith has plans to work on the tractor over the winter months.

This feature comes from a recent issue of Tractor & Machinery, and you can get a money-saving subscription to this magazine simply by clicking HERE