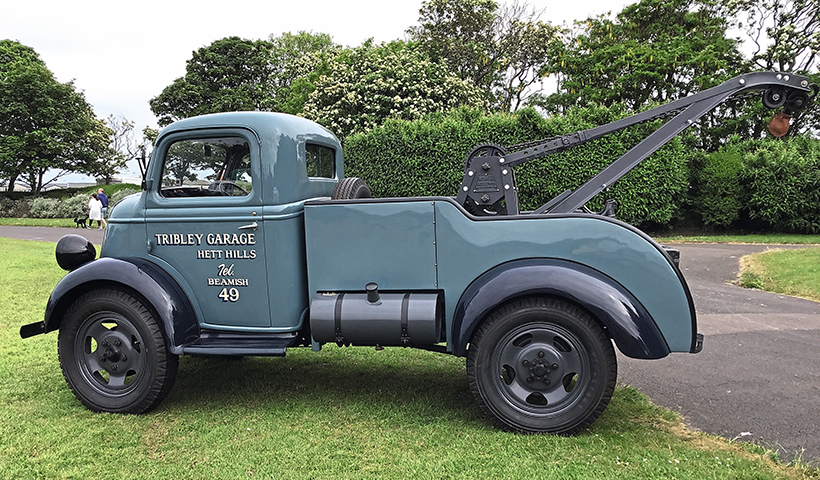

This 1936 Fordson breakdown truck is simply superb!

Posted by Chris Graham on 23rd April 2024

Brian Culpan tells the story of this 1936 Fordson breakdown truck and the restoration that’s brought it to its present superb condition.

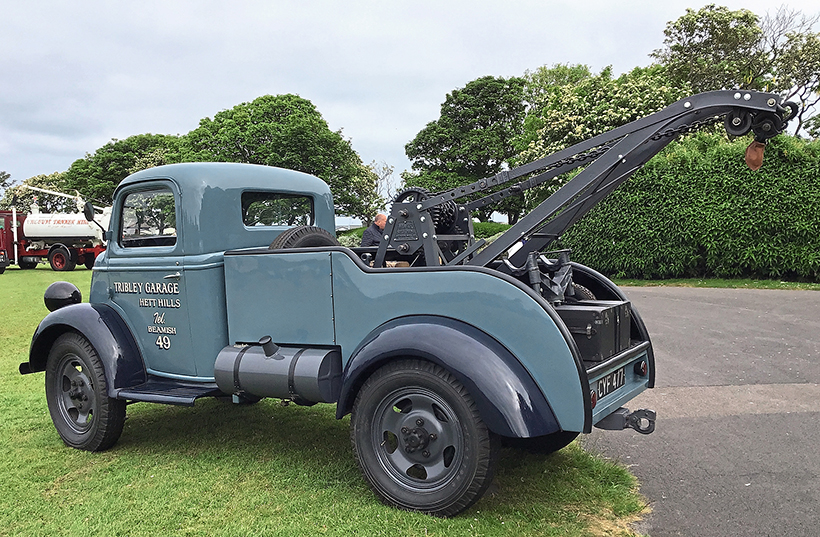

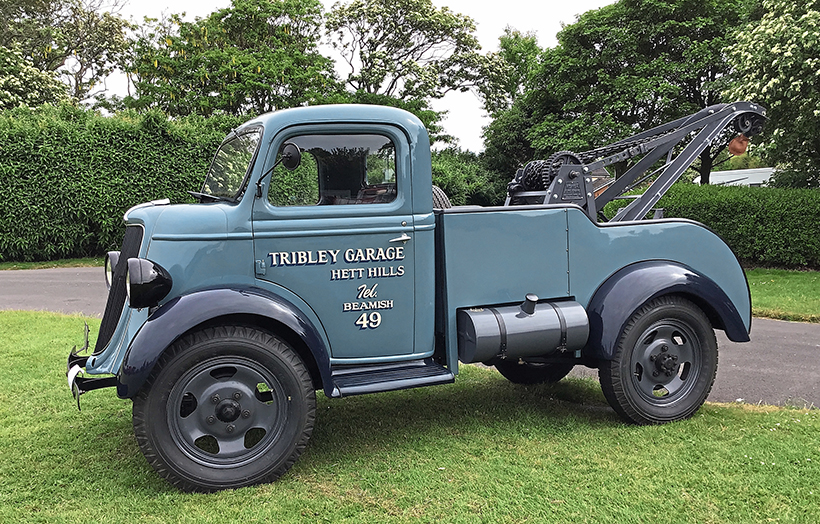

Russell Storey’s superbly-restored 1936 Fordson breakdoiwn truck

This very smart Fordson breakdown truck was an entrant in the 2022 HCVS Tyne-Tees Run but didn’t appear at the finish in Bents Park, South Shields. I was disappointed not to have seen it. Unfortunately, the rivets holding the cooling fan to its hub had worked loose creating a noticeable row, at the half-way stop its owner thought it best to not continue and drove cautiously home (not far away). However, it entered again on the 2023 run it did make it to the finish that time.

Admired by many at the HCVS Tyne-Tees Run.

When new, in 1936, this vehicle left Dagenham as a Ford Model 61 with the small-bore V8 engine, it now has the later, straight four-cylinder engine that Ford fitted from late-1937 for the 1938 model year. So, technically it is now a Fordson E88W (Ford also changed the brand name at the same time for small commercials under two-tons). However, it has been totally converted to be an E88W; wearing a Fordson badge, a fixed bonnet side and top structure with removable radiator grille, so, it is, and looks, absolutely correct for the Model it has become.

Almost finished as a running chassis.

Confused? There’s more, another change has been its bodywork; when new it was a fire appliance and worked through the Blitz; it left the factory as a chassis/front end to be bodied as a fire appliance by a bodybuilder. Finally registered as CYF 477 with London County Council in May 1936.

Cab as it was returned from the soda blasters.

Since production for the civilian market didn’t start until June that year; despite being announced in October the previous year. So, this is a very early example; coming off the production line before those destined for the public, preference being given to the fire service. At some time later it became a flatbed, and finally, now is a chariot style breakdown truck. The back is fitted with a hand-powered Weaver Auto crane for vehicle recovery work. The truck is owned by Russell Storey of Chester-le-Street, in County Durham.

Cab in its chosen gloss paint.

Bought in September 2013 as lot 88; from a John Mould Paradise Collection auction organised by Thimbleby & Shorland in Reading. It came as a chassis/cab with no paperwork or records apart from the statement that John Mould had got it from a farmer in Essex, hoped to restore it but never got around to it. The cab was in two different primer shades. Also bought at the same time was another, similar Fordson (lot 75), a former fire engine (now a dropside truck).

Cracked cylinder head.

Russell decided to restore the worst vehicle first. He had done several restoration projects before for himself (and taken in more modern damaged bodywork for clients in his everyday job as a bodywork repair specialist). It appeared that some restoration work had been started, the cab was painted in two shades of primer, but that would prove to be poor workmanship; covering up many faults with vast amounts of filler.

E88W cab in primer.

Soon a start was made, but other work meant that the Fordson restoration stopped for four years, and then would take a further four to complete (in 2022). The chassis/cab was taken completely apart and soda blasted; the friend entrusted to do this was on the verge of falling out with Russell as the cab was well and truly plastered with stubborn filler.

A close-up of massive head crack.

The chassis proved to be good, the cab structure was riddled with pinhole corrosion spots – resembling a colander, also uncovered were several illegal brazed patches. These were painstakingly removed and replaced by welded ones.

Curiously, the offset hole doesn’t line up with the starting dog.

When the time came to fit the ‘new’ bonnet structure that came with the vehicle as part of the sale, it wouldn’t fit – clearly 4in too wide! It had to be taken apart and made to the correct size. Petrol tank was bad; its top surface had many tiny top surface perforations due to condensation (rather than rot on the inside on the bottom), repairs were carried out.

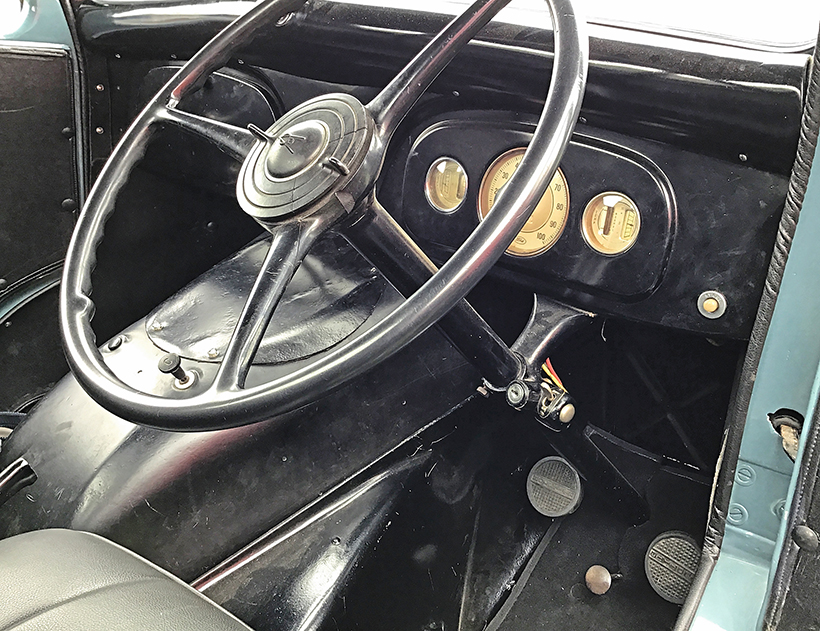

Enormous steering wheel and, behind, a comprehensive dash.

Russell’s workshop has a very useful English wheeling machine that can roll flat sheet steel in both directions creating a double curved bowl-shape – such as a wing. Using the machine, a pair of rear wings were made from scratch, styled to match the front ones. Also, one front wing was beyond saving, so a new one had to be fabricated from scratch, and extensive reconstruction was needed to the offside inner front wing.

Nice door cards and wind-up windows.

Curiously, a piece of Perspex was fitted as a make-shift driver’s window, but no cab glass came with the Fordson, accurate templates were made by a fellow enthusiast from his Fordson to give to the supplier with the order. I was fascinated to see that the window winder first moves the glass slightly rearwards before lowering it.

Kismet Duplex footpump.

The Fordson had had several bodies in its life, Russell had definite plans for it; as a chariot breakdown truck. The rear bodywork was first made as a wooden mock-up to get the proportions and dimensions correct. Then a frame made of 2in square steel tube, then steel sheet side panels made, very cleverly Russell, a master craftsman, gave these a very slight convex shape to add rigidity, and make them look ‘right’ and flat.

Macho image fits in well.

This is an ancient technique used by Greeks who gave their temple tall supporting columns a very slight barrel shape to deceive the eye with an optical illusion of straightness and consistent diameter. Black rubber half-round topping to the chariot bodywork came from a boat yard supplier, it is rubbing strip as used on small boats.

Perfection in every detail.

The mechanical parts of these Fordsons are pretty tough, the driveline from gearbox through to the rear axle was stripped but found serviceable. The cylinder-head had a massive crack (due to frost damage) so, a replacement was sourced, the rest of the top end did require some work including new valves and timing gears.

Fictitious name and address made up of real paces.

The resplendent Fordson has been liveried out as: ‘Tribley Garage, Hett Hills, Beamish’ – a fictitious address but made up of real, local places! Russell’s parents owned Tribley Farm and its phone number was Beamish 49. Later, Russell lived in Tribley Cottage, and when he started his bodyshop business, he called it Tribley Coachworks.

Large headlamps with ribbed lenses.

However, when the time came for sign-writing on the Fordson that business name was just too long to fit across the narrow cab doors. Not wanting to reduce the size of the font; the decision was taken to adopt the name Tribley Garage!

Petrol tank neatly absorbed into the bodywork and yet easily accessible.

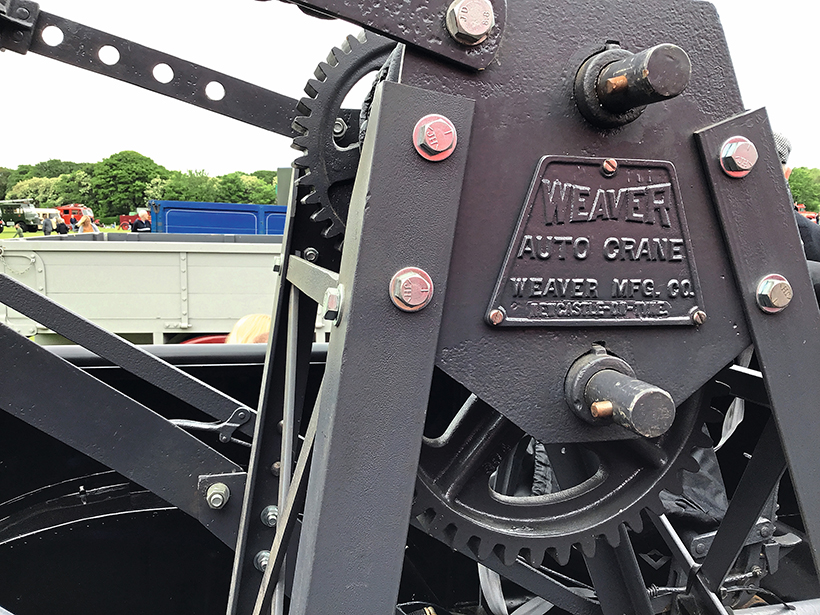

The Weaver Auto Crane was made in Springfield, Illinois, America by Weaver Manufacturing Co. and first came to the market in 1915. Their advertising claimed that this crane could convert a truck (or large car) into a tow truck, it could be powered by a ‘donkey’ petrol engine, or like this example, hand cranked. Lifting capacity was initially two-ton; soon raised to 2.5 then three. Associated equipment offered were: an ambulance (two-wheeled dolly and a tow pole) an alternative to the more usual suspended tow from a chain and hook – with a dangling old tyre to cushion any nudges from the casualty vehicle.

Quick-lift wheeled jack.

Suspended towing is now forbidden; because a heavy load on the crane’s jib pivoting about the truck’s rear axle gives sufficient leverage to lighten its front axle affecting steering, also sway of the towed vehicle cannot be controlled. Using a wheeled dolly and tow pole, or a spectacle extended ram is acceptable, but the safest method of recovering a light vehicle is to ‘piggy-back’ on a transporter. However, seeing this old method of recovery brings back memories of everyday life to many older enthusiasts.

Weaver Auto Crane from 1926.

The crane dates to the mid-1920s (the truck some 10 years later), it came from Arthur Newton of Lanchester, a well-known supplier of period vehicles to TV and film companies working in the North. It was lying in a ditch; Arthur was reluctant to part with as it was of sentimental value. Eventually he agreed to sell and also supplied the towing dolly.

Space is limited in the driver’s footwell.

The crane was in bad shape – all four angle-iron uprights were severely corroded; they were replaced and Russell also skillfully laid down a long run of weld to strengthen the jib members – this restored the fillet radii and is almost undetectable.

Russell Storey of Chester-le-Street, master craftsman.

Displayed in the back is a single lift lever jack, which is ideal for a quick lift – a similar design is used by pit crew of F1 racing teams as part of the two-second pit stop wheel change action. Also, strapped down is a Kismet Duplex foot pump; its two barrels give a large capacity and high pressure (good for 300p.s.i.). Every wartime Spitfire pilot had a similar Kismet pump onboard to recharge the air reservoir in case an emergency engine re-start.

Well balanced front and rear overhangs.

The Kismet brand (named after the musical show) was owned by William Turner and brother in Sheffield, they were pneumatic engineers, starting up in the early 1930s. In 1949, Weaver Engineering was setup in Bedford to make (under licence) the American garage equipment.

By 1959, both had been bought up and merged by the Cape Asbestos Group, I spent time at both factories as part of my apprenticeship with the group, seeing these items was very nostalgic. So, it is fitting that Russell has collected these examples and displays them on the truck – they would have been invaluable.

Suspended tow trucks need minimal rear overhang.

Russell did every job needed during the restoration; except the seat upholstery and sign-writing. My very sincere thanks to Russell and Ann for their help with this article and supplying many photographs of the work as it progressed. For those who are interested the chassis no. is GLC1219NE, engine no. the same.

This feature comes from the latest issue of Heritage Commercials, and you can get a money-saving subscription to this magazine simply by clicking HERE

Previous Post

This 1903 Mercedes just sold for an incredible £9.5 million!

Next Post

David Brown 996 saved and beautifully restored