Superb Ford Force 5000 DIY restoration

Posted by Chris Graham on 24th June 2024

Chris Graham meets John Vowell to have a chat about the painstaking but excellent restoration of his 1971 Ford Force 5000.

John Vowell’s superbly restored 1971 Ford Force 5000 has been something of a stop/start project, but very much worth it in the end.

Sentimentality plays an enormous part in most enthusiasts’ involvement with classic tractors. More often than not, speak to an owner and you’ll discover that the machine they treasure has a poignant link to a loved family member or simply happy childhood memories.

This is certainly true for John Vowell, who spent his formative years growing up on a Kentish farm where his tractor-driving father worked at the wheels of various Fordson and Ford models. As a result, John feels a connection to tractors from the 1960s and ’70s that’s so strong that it’s driven him to painstakingly re-create his favourite from that era.

Earliest memories

“My dad, having started his working life on an arable farm in Northumberland, came to London during the Second World War where he met and married my mother,” John explained. “The couple then settled on a farm at Stanford North, in Kent, and that’s where I was born. Dad was the farm’s main tractor driver, and my earliest memories are of him using a pair of Nuffields. The farm then switched to Fordson Majors and, in 1958, one of those was exchanged for a County crawler, which took on the heavy work.”

The rear linkage is fitted with an assister ram, which was the final item to be restored. John intends to start using the tractor for competitive match ploughing.

As time passed the farm’s tractor fleet progressed through Super Majors then New Performance versions of that model before, to much excitement from the young John, a brand new Ford 5000 arrived. “Dad used that tractor exclusively and it remains vivid in my memory to this day. Then, at 13 years old, I got a part-time job on a nearby farm, where I started driving a Fordson Major and a NP Super Major, helping at harvest time and doing a bit of rolling and harrowing. I simply loved every minute of that work but, being a tractor-mad teenager, all I really wanted was to drive a 5000. But I was never allowed to do that.”

John’s father was adamant that he shouldn’t become a farmer. He didn’t see much future in that, and wanted him to do an apprenticeship and learn a trade, so he’d always have something to fall back on. “The idea was for me to go to Invicta Motors in Canterbury,” John remembers, “but that didn’t happen. The family moved away from the original farm to a house near Canterbury and, when I left school at 15, I heard about a tractor-driving job back on the farm where we’d been before. I cycled back there to see if I could get it, and the farmer agreed to take me on, but only if my dad came and gave his permission.”

First 5000 experience

“Reluctantly Dad agreed although, secretly, I think he thought the novelty would soon wear off, especially as I’d be cycling five miles to and from the farm each day throughout the coming winter. However, I stuck to it and had a fantastic time driving my dream tractor, a Ford 5000. I did all the winter ploughing then helped with the planting for the following season. It was a great experience.

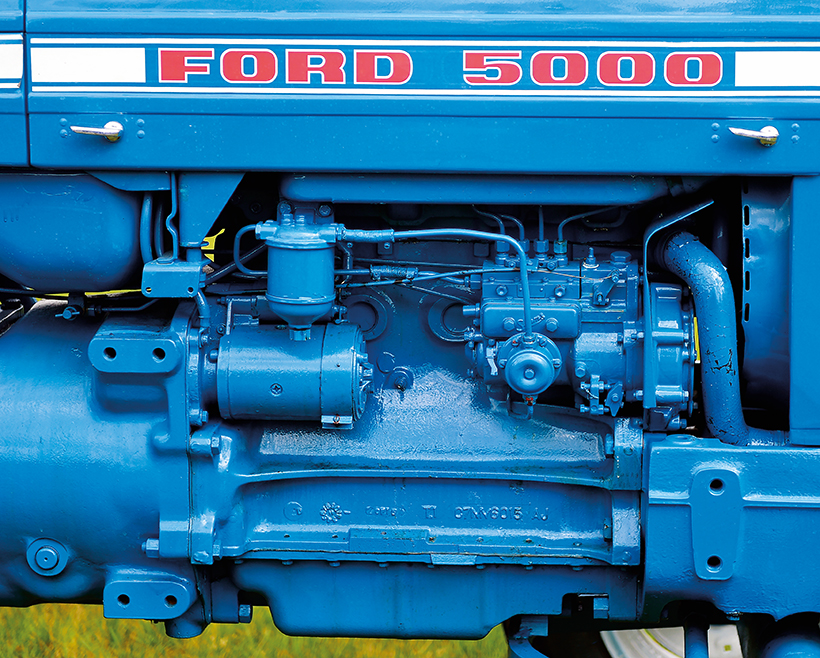

John is a big fan of the sensible, 1000 Series design, and finds tractors like this 5000 easy and straightforward to work on.

“Everything was going really well until, out of the blue, Dad announced that he’d found me a job at a local garage, where I could train as a car mechanic. This wasn’t great news for me as I had little interest in cars. Fortunately, though, the garage also operated an agricultural contracting business so there was some interesting machinery to be dealt with, too. I remember they ran a Massey Ferguson 780 combine, a Fordson Major, and a New Holland 268 baler.”

As soon as John revealed that he had some baling experience, he was put to work on that side of the operation, but that didn’t last. “The contracting business was sold off and I found myself back in the workshop, working on front-wheel drive Minis. But it was a regular income and I ended up working for that same garage for the next 44 years! As it turned out, it gave me a fantastic grounding in all aspects of the business.”

A mix-up regarding a crankshaft ‘re-grind’ led to worryingly low oil pressure when the engine was first used after the rebuild. Thankfully, no internal damage was done.

Nevertheless, John still hankered after some practical involvement with tractors and, when he heard about a nearby dairy farm needing a hand, he jumped at the opportunity. “The farm operated a couple of Muir-Hills, a large Case and a five-furrow reversible plough, and I started working there on my spare Saturdays, helping with the ploughing and drilling work.”

Then, in about 1999, John finally managed to buy his first tractor – a 1959 Fordson Power Major, and he still owns that machine today. “Although it’s never been fully restored, I’ve done quite a lot of work on it over the years. When I got it, it was fitted with JCB rear wheels, the wrong wheels on the front and a very tired engine. So I did what I needed to do to start match ploughing with it and, today, it’s a nice, straight example.”

Chance encounter

“In 2005 I came across a Ford 4000, abandoned under a hawthorn bush. It had a glass-less cab, a front loader, Super Major rear wheels and had ended its working life as a lowly yard scraper. I managed to buy it for little more than its scrap value, and immediately began a full restoration. That was a good project and certainly whetted my appetite for more of the same. Then the big opportunity arose.

The Ford 1000 Series dash is simplicity itself. The instrument panel is the original.

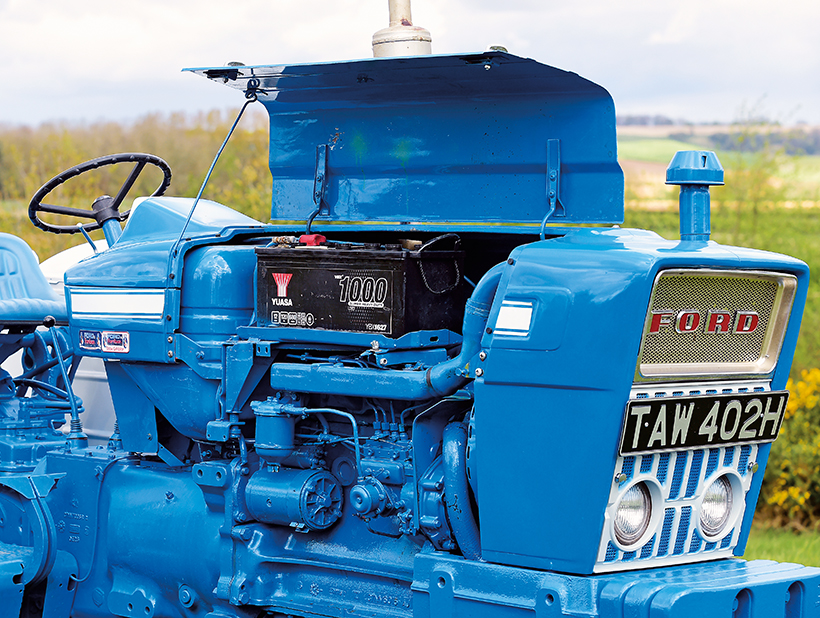

“I bought the Ford 5000 in 2009, having found it on the outskirts of Dover after being told about it by a friend. It belonged to a contractor but obviously hadn’t been used for years. In fact, it had been parked under a tree and left. It stood there, untouched, for at least seven years. Amazingly, though, it only took me an hour or two on a Saturday afternoon to get the engine running. Nothing was seized and, having fitted a new battery, it sprang into life almost immediately. Although the engine actually ran pretty well, my plan from day one had been to go through it with a fine-toothed comb.

“I always like to know what’s going on inside an engine, and the only way you can be sure about that is to take it to pieces. I soon discovered that the block had been fitted with new steel liners, so I assume it was one of the engines that had suffered with the famous porous block problem, which afflicted so many Ford 1000 Series tractors back in the day.

“Unfortunately, because the exhaust hadn’t been covered while the tractor was standing outside, water had got down into No.2 cylinder and etched into the surface of the liner. At that point I decided to get new liners fitted and a new set of pistons. The block went away for that work to be done as I don’t have the necessary equipment for that, and the crankshaft was sent for re-grinding, too.”

This is the polytunnel that John uses as his spray shop, where he applies modern, two-pack primer and top coat paint finishes. A space heater is sometimes needed to boost the ambient temperature.

No faults found

While the engine block was away, John sorted out the tinwork, stripped and refurbished the brakes, dismantled the rear axle, fitted new half-shaft seals and carefully checked the gearbox internals. “While it was clear that the tractor had led a reasonably hard working life – front loader fitted and an assister ram on the back – I didn’t come across any serious mechanical problems,” he said, “which made the mechanical side of the rebuild pretty straightforward.

“Once the block returned I was able to reassemble the engine although, unbeknown to me, there was trouble brewing. I think all that the specialist did with the crank was to polish it, which led to problems further down the line… much further, as things turned out. After I’d reassembled the engine, the restoration ground to a complete halt as other aspects of life got in the way. In fact, the tractor sat in this part-restored state for the best part of a decade, and it was only about three years ago that I finally had the time to resurrect the project.”

This was John’s first outing last year at Spilsby with the newly restored 5000 and his Ransomes TS 59 two-furrow, 14in plough.

John added: “Fortunately, I’d stored it well over that period and there had been no appreciable deterioration in overall condition. I arranged for the skid unit to be sand-blasted clean, then I primed and painted it. I do all my own spray work, and opted to finish the tractor in a two-pack paint. I know there’s lots of debate about the use of modern products on classic tractors, but my take on it is that the synthetic finishes that lots of people use look OK for about six months, but then dull right off.

“A lot of work goes into the restoration of a tractor like this 5000, and I don’t want to have to be doing jobs twice. Two-pack paints hold their shine best of all, especially the ‘high solids’ type I use. I lay this down on a high-build, two-pack primer, and am very happy with the results. Breathing apparatus is required due to the toxic, iso-cyanate content, but the paint air-dries perfectly well given a warm ambient temperature. I do all my spraying in a polytunnel, which works really well as a controlled environment.”

Final stages

After the painting was finished, John moved on to the final stages of the restoration. “I fitted a new wiring loom, new instruments and dash switches, a new set of tyres and re-assembled everything else. Soon after that I moved to Lincolnshire and, with the tractor in its new home, was keen to put it to work. I’d bought a chain harrow to use on the fields we have here, and I thought having a run out with that would be the perfect way to give the rebuilt engine a useful shake-down test.

Here’s John arriving at Lincolnshire Aviation for the start of this year’s 43-mile, Easter Carrington Road Run. His granddaughter, Madi, follows behind at the wheel of her Nuffield 10/42.

“Well, I was part-way along my second run with the harrow when I noticed that the oil light had come on. I knew that the level was correct and, in the past, I’ve had trouble with oil pressure switches, so my first thought was that that was the most likely cause. The engine sounded absolutely fine so I did another couple of runs but, as the light was still on, I decided to stop and check things more carefully with my oil pressure gauge. The correct oil pressure on this engine should sit between 80 and 90psi but when I connected my gauge I discovered, to my horror, that it was just 12psi!

“So, with the tractor back in the workshop, I removed the sump, took out the oil pressure switch and, using a syringe, pressured oil into the system. Looking up, I could see it leaking out from around the main bearings. This seemed mysterious given everything that had been done to the engine, so my only option was to remove the engine and extract the crankshaft for a closer look. As it turned out, the big ends were 20thou undersized and the mains were 30, which came as a shock to me. I’d never come across such a thing in all the engines I’d rebuilt over the years, but some subsequent research did reveal that Ford did do this.

The 5000 (left)beside an earlier project; John’s Ford Force 4000. Both have been restored to the same, exacting standards.

“Of course, with the engine specialist not having re-ground the crank and not mentioning to me anything about the unequal bearing sizes, I’d gone ahead and fitted the wrong size shell bearings, hence the oil leak and low pressure. Luckily, no damage had been done and, once I’d checked the measurements and fitted the correctly-sized shells, everything worked perfectly.”

This feature comes from the latest issue of Tractor & Machinery, and you can get a money-saving subscription to this magazine simply by clicking HERE

Previous Post

Collectable Ford and Fordson BBE and 7V models

Next Post

London to Brighton in a 1927 steam wagon