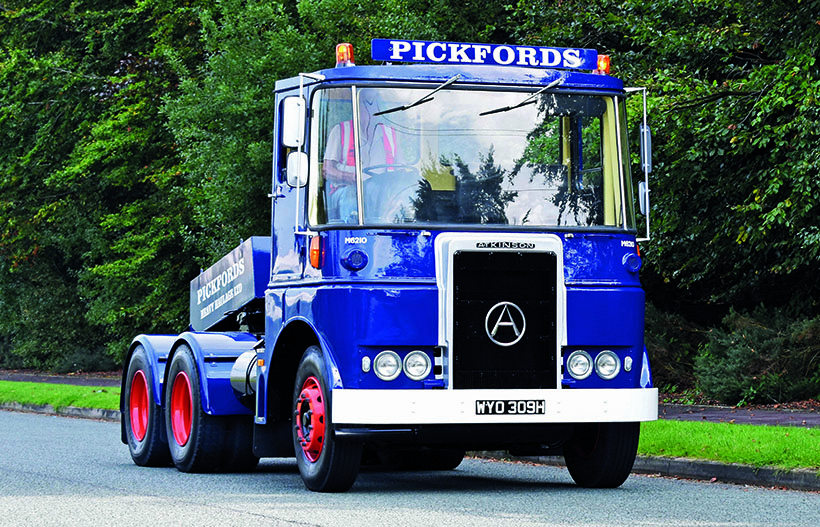

Beautifully-restored 1970 Atkinson Viewline

Posted by Chris Graham on 5th December 2020

Semi-retired engineer David Batty’s Atkinson Viewline has taken a long time to come good, but it’s been well worth the wait, as Peter Simpson discovers.

David Batty has been meticulous with the restoration of his 1970 Atkinson Viewline, and the superb results speak for themselves.

It’s not exactly hard to see the ‘Unique Selling Point’ of an Atkinson Viewline. If the appearance doesn’t give the game away, then the name will surely do so! It was all about visibility and, as well as much-improved forward vision, an increased glass area low down at the sides was intended to eliminate the customary blind spots on each side of the cab.

Clearly, all-round visibility is an important factor for heavy-haulage work. It’s also probably fair to say that a state-owned operation might attach more importance to a safety-related factor than a private, profit-led concern; safety is important of course, but it’s not generally a big selling point.

Two batches

Anyway, Pickfords took two batches of six Viewlines. One batch, including WYO 309H, comprised 6×4 tractor units rated at 45tons. The other six were 4×2 ballast boxes, with Allison automatic transmission and rated at 65tons, though this was pulling or pushing rather than carrying.

An interesting, period photograph showing the Atkinson Viewline in service with Pickfords, although the date and location are unknown.

There were, though, few other takers for the Viewline. ICI operated some from its chemical works at Billingham, and BP also had some. But most other Viewline sales were one-offs, or small batches of two or three sold to existing, Atkinson operators. None, unfortunately, were sufficiently enthusiastic for it to remain in production.

One particular problem was that the large areas of glass could lead to an uncomfortably hot cab in summer. Additionally, the side-glass which allowed the driver to see out of the cab, also allowed others to see into it. Consequently, production lasted just two years – from 1968 to 1970 – and it’s thought that less than 200 were made.

The Viewline shortly after it arrived with David, from the scrapyard. Further information about Neville EMV would be very welcome.

Now in his early seventies, David Batty has worked in road transport for over 50 years. A former fleet engineer, he’s now ‘semi-retired’ but still spends two days a week as a consultant engineer for tanker transport specialist, Abbey Logistics. As he puts it: “I still work to fund my toys.” These comprise another Atkinson lorry, a rare, Searcher six-wheel rigid he’s had for 30 years and which came from Bagshaws Grain and Corn, plus a couple of classic cars. The cars are a ‘chalk and cheese’ pair – a 1979 Rolls-Royce Silver Shadow originally owned by Manchester City and England footballer, Francis Lee, and a surprisingly rare, 1989 150hp ‘red top’ Vauxhall Cavalier GSI.

However, the ‘toy’ we’re looking at here is David’s ex-Pickfords 1970 Viewline, the restoration of which has just been finished after 17 years. He spotted it in a Stoke-on-Trent scrapyard back in 2003 and, as he has something of a thing for unusual Atkinsons, he decided to take it on, even though it was clearly going to be a major project. He describes its condition at the time of purchase as ‘running, but that was about it.’ The length of time taken to complete the project was, however, as much a reflection of the high quality restoration David has carried out, as of the Viewline’s condition when purchased.

Steel cab rear lower panel was renewed.

Missing history

In terms of the vehicle’s history, David knows some, but there are gaps which he’d like to fill. Somewhat unusually, it’s the more recent stuff that’s a bit of a mystery, and any further information would be very welcome. In particular, he’d like to know a bit more about Nottinghamshire-based Neville EMV, which appears to have been the Viewline’s last operator. As you can see in the restoration photographs, its name was sign-witten on the cab doors when the lorry was bought.

The one thing we know for sure, though, is that this Viewline is a genuine, ex-Pickfords tractor unit, and was first registered in February, 1972. Thanks to Atkinson expert/archivist Paul Allen, David now has a copy of the original build-sheet, which indicates an original specification including a 14-litre Cummins, 250hp, non-turbo engine attached to a six-speed ZF gearbox. Both are still fitted to the vehicle.

The fully rebuilt engine, as it was received back from Cummins.

The build sheet also, however, lists three-piece 10.00×20 rims. These, apparently, were a standard Pickfords item and the same size was used across a wide range of heavy haulage tractors and trailers to ensure maximum interchangeability. They had, however, been replaced with 11×22.5 tubeless wheels and tyres by the time David acquired the Viewline.

Two other differences

When bought, the lorry also differed from its build specification in two other respects. Firstly, the chassis had been extended by the usual ‘cut and shut’ technique, letting a new section into the middle. David thinks this modification dates from the early 1980s, when he believes it was used as a breakdown/recovery vehicle with an operator (possibly Highway Recovery) based near the bottom-end of the M1. Again, any further information would be appreciated.

This side view highlights the slightly extended chassis – note the distance between the fuel tank and the first rear axle.

The second mystery surrounds something not on the build-sheet, but which nonetheless appears to have been fitted from new, or almost-new. The Viewline has two fuel tanks. Crucially, though, both tanks are genuine OE Atkinson items, and the second tank has clearly been fitted properly, and if not a factory-fit, it’s indistinguishable from what the factory would have done.

David’s been told that this might be because his Viewline was used on long-distance, international work including – it’s been suggested – transporting large Concorde components from the French factory in Toulouse, to the British assembly plant at Filton, near Bristol. But he’s also been told that it was based in Sheffield, and someone else says he saw it several times at the Leicester depot, where a ballast box was fitted and removed as required. Although these locations seem far apart, there’s no reason at all why all these sightings shouldn’t be true as, while the Pickfords heavy-haulage fleet was well-known, it was also relatively small, and vehicles would go wherever in the country they were needed.

The Viewline’s shassis after shortening, with newly-made replacement ballast box in position.

The restoration

As I say, this was a long and painstaking job, though rather than actually working on the vehicle, a lot of time was spent finding new parts; David wasn’t in a massive hurry, but he did want the finished lorry to be as right as possible.

Given his many years of experience in the haulage industry around the north west, David has built up a wide range of contacts. So, he put the word out and, as it spread, the offers of parts came in from far and wide. A few real gems were uncovered; he was able, for example to assemble a complete set of new (brand new, not refurbished or reset) springs and, perhaps most remarkably of all, a complete set of new hubs, complete with bearings and still in their factory grease-paper wrapping. David estimates that the restoration parts bill alone came to about £20,000.

The cab being painted. New glassfibre panels were made where needed, using the original, Atkinson factory moulds.

Though it looks very different from the standard Atkinson offering, the Viewline cab is totally traditional Atkinson, in terms of construction; ie an ash-frame with glassfibre panels attached. While this was definitely old-fashioned by 1968, Atkinson stuck with it as its customers were used to – and liked having – cabs that could be repaired quickly and easily in-house, and by unskilled or semi-skilled staff. In this case the frame, unsurprisingly, needed total renewal; ash was obtained from a local timber merchant and a local ‘chippy’ used the remains of the original offside components to make new ones. When it came to the nearside, however, David made the components himself, creating mirror-images of the ones that had been made professionally.

New panels

Most of the panelwork was also renewed; fortunately, all the original glassfibre cab moulds were saved when the Atkinson factory closed, and are now in the possession of Blackburn-based enthusiast, Kevin Battersby, who made them available for the construction of replacements. The steel cab floor was also renewed, together with the steel rear panel and all windscreen surrounds/rubbers. A trimmer in Liverpool did a good job of making new seat covers.

While certainly offering improved visibility out of the cab, the deep windscreen led to some complaints that drivers felt as though they were in a goldfish bowl.

The cab was painted in the original and familiar Pickfords Oxford Blue, using Dupont Elite two-pack. The paintwork was done by RNB Commercials, of Skelmersdale, while the signwriting was carried out by a Liverpool-based father and son team who replicated the original, simple yet highly distinctive, Clarendon font.

As already noted, the main issue with the chassis was that it had been lengthened. Chassis work – even reversing a previous modification as was needed here – has to be 100% accurate; chalk marks on the floor aren’t good enough! Here, too, David’s network of contacts came to the fore, and he used someone with appropriate jigging facilities to ‘cut and shut’ the chassis, removing the extension and re-joining the front and back so that the alignment was right. Elsewhere, all the hubs were, as previously noted, renewed, along with the brake shoes and chambers, springs, shackles and track-rod ends. New rear wings and period-style mudguards completed the chassis.

Classic Atkinson cab interior; very period but sadly this view of a lorry made in 1970 demonstrates perfectly why the likes of Volvo were able to establish a foothold in the UK market.

Major mechanicals

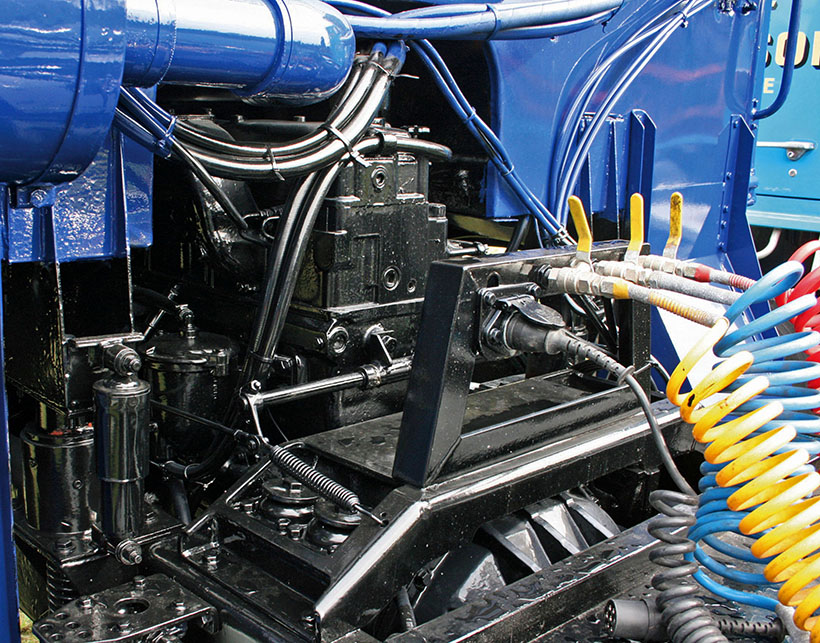

With restoration stories of this kind, we often say that the major mechanical components needed little if any work. David states that this was definitely not the case here; he tells us that the only remaining original part of the engine is the block! Everything else, including both cylinder heads and the crank, plus all the usual renewals such as pistons, valves, bearings and so on, are brand new. The engine rebuild, apparently cost about £6,800 in total. This work was undertaken by Cummins at its plant in Worsley, Greater Manchester. Also renewed were the clutch and flywheel, plus the starter ring-gear.

The gearbox and differentials were also fully rebuilt, this time by a specialist in Oldham which, sadly, is no longer in business. Both fuel tanks were rebuilt by a local Serck Marston branch, which also restored and re-cored the radiator and header tank, while ATS at Stoke-on-Trent was able to obtain a set of new tyres. Serck and ATS are both well-known names in the current parts-supply industry, and it’s sometimes surprising just what can be obtained from companies like this in terms of parts and services, though a lot depends on the attitude and willingness to help of local branch staff. Being a long-term customer helps, too, of course.

The engine rebuild alone cost £6,800; the block is original, but not much else survives.

The ballast box that the lorry currently wears is a new-build from photographs of an original, and contains about four tons of concrete.

The lorry was finally finished earlier this year. Unfortunately, and for reasons that we’re all aware of, show appearances haven’t happened this year. David has, however, driven the lorry about a bit and, unsurprisingly, it “always attracts a lot of interest.” This interest has included some from a slightly unexpected source; the current managing director of Pickfords, Mark Taylor, who said: “This is an amazing piece of work, so much care has been taken to restore the vehicle faithfully and it’s a credit to David’s hard work and commitment.”

What to do?

However, having completed the restoration, David found himself facing a bit of a dilemma. As already noted, he owns other vehicles including the Atkinson Searcher which, after 30 years with him, clearly isn’t going anywhere. It would also probably be fair to say that, as an engineer, his primary interest is repairing and restoring. Then, earlier this year, he was faced with the possibility of losing some of his storage space.

A view of the rear. The ballast box is just that, and weighs around four tons.

Accordingly, the Viewline was, reluctantly, offered for sale as one of the guest entries in the recent Kevin Dennis auction. However, it didn’t reach its reserve, so David collected it. Most of the journey home from Lincolnshire was by low-loader, but David drove the Viewline on the final stretch from Sheffield over the Pennines. It drove absolutely superbly and, apparently, “flew over the Woodhead Pass at 30mph, in fifth!” Based on this, and the fact that the anticipated loss of storage never happened, he’s decided to keep it.

One final thought. As those of you still in the industry – or who follow it – will know, new Direct Vision Standards for London are coming; they were due in from October 1st, but have now been put back to March 2021. Basically, to take a lorry into London – and in some places the enforcement zone almost reaches the M25 – you need a permit and, to get one of those, your vehicle needs to meet minimum visibility standards to prevent pedestrians close to the lorry – be they in front or to the side – from being invisible.

Nowadays, this involves the use of camera-technology, but the problem is precisely the same as the one as the Viewline was intended to counter, more than half a century ago.

For a money-saving subscription to Classic & Vintage Commercials magazine, simply click here