Fordson Super Dexta rebuild: Part 1

Posted by Chris Graham on 29th January 2020

Ben Phillips introduces his new restoration project, a 1964 Fordson Super Dexta, and gets cracking with an overall condition assessment

This is how the 1964 Fordson Super Dexta arrived with me, from its owners in Wales. I’ve always loved the style of this model

I’ve always loved the style of the Fordson Super Dexta; it was the last incarnation of a successful range of small tractors that come out of Ford’s Dagenham factory. So, when I was approached by John Goreing from Crickhowell, in Wales, to restore his family-owned example, I simply couldn’t wait to get started on it.

Before taking delivery of the tractor I’d seen a few photographs in emails that John had sent me, so I knew vaguely what to expect. However, when it arrived it soon became apparent that the machine had endured a hard life.

Damage assessment

The first thing I noticed was the front wheel rim, which had rusted around the tyre bead, and had given way due to the metal being so thin. Obviously, the tyre was flat so moving the tractor was difficult and my first job was to replace the rusty wheel with a good, secondhand one so that the tractor could be rolled more freely.

Then, with a long, straight bar and another tractor, we carefully pushed the old Fordson towards my workshop, and into an area where there was space to have a proper look at it. At the front the cowl was dented and twisted in many places and, even though part of one light was fitted, it was clear that replacement grilles and lights would be needed. Down the sides, I found the usual areas of rust in all the familiar places and, if this couldn’t be repaired economically, then new panels would be needed; they are available, but it was too early to make the final decision on that.

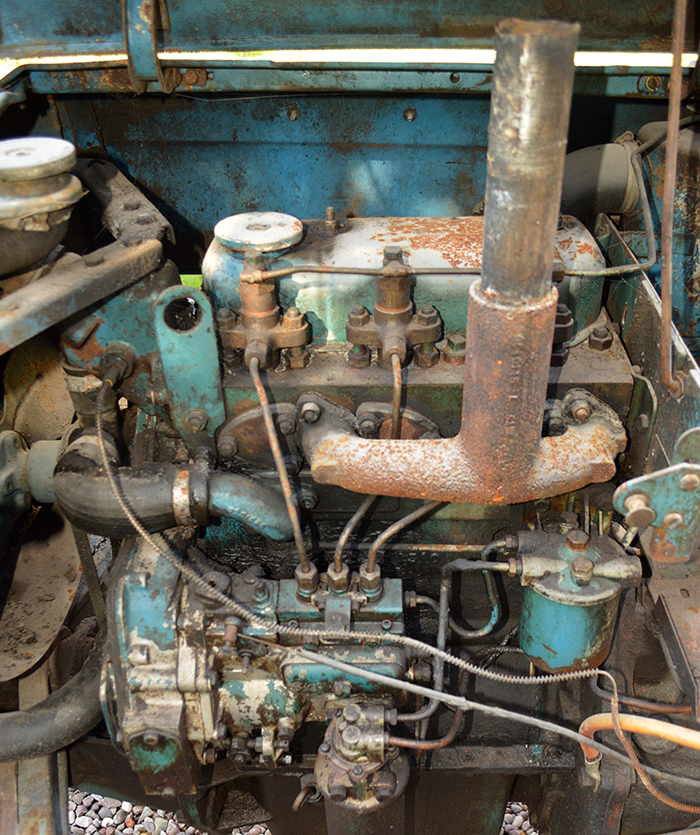

However, the main bonnet was in good condition compared to the rest of the tinwork, and featured the original badges. I found one small dent on the top section, but it was clear that that that wouldn’t take a great deal to straighten out. Under the bonnet was the familiar Perkins, three-cylinder diesel engine – quite a similar unit to the engine found in the MF35 but, as there’s no fuel tank perched on the top, it looks a lot smaller.

I don’t know when this engine was last started, and I didn’t attempt to do so as it had already been agreed that the motor was to receive a comprehensive rebuild. But, judging by the overall condition of the rest of the tractor, I assumed that the engine had been similarly well used.

Detail issues

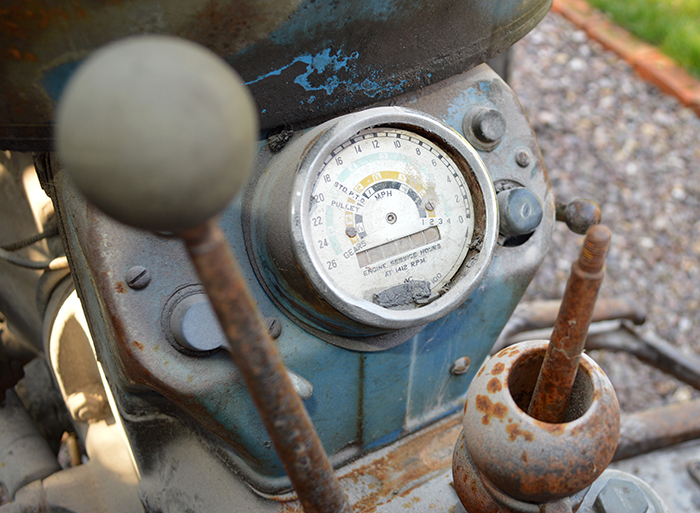

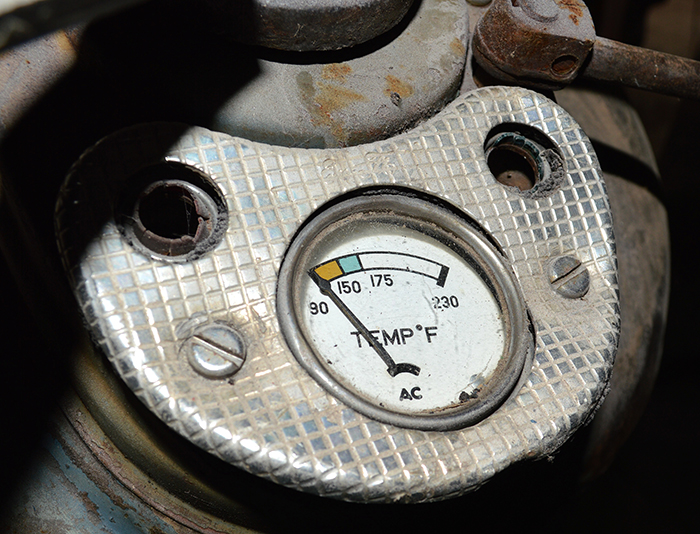

It was clear from my initial inspection that the tractor was lacking a lot of little items, very noticeably on the lower dash. The main tractormeter was missing its glass and had no needle, and it was obvious that the rest of the switches and buttons around it would all need to be replaced. On the upper dash, the water temperature gauge was complete, but the red and green warning lights on either side of it were broken. Just above this dash, the steering wheel was worn right down to its metal frame, and moving it revealed a lot of free play.

I can’t stand excessive steering box play so that’s another aspect that would need to be sorted out. Thankfully, looking through the Agriline Products catalogue, I could see a number of the parts needed to service these boxes were listed. However, if I’d been disappointed by the amount of steering play, that turned out to be nothing compared to what I found on the clutch pedal. This could literally be moved every way possible, and the root of the problem seemed to be at the pivot so, at this early stage, my hope was that the wear was confined to the bush in the pedal, and that the pin which bolts to the tractor wasn’t affected, as this part is no longer available as a new replacement.

However, one of the most obvious parts on the tractor in need of replacement was the seat cushion. In true farming style, a plastic feed sack covered what had remained of the original cushion set.

Roll bar removal

Before I got the tractor safely undercover, I wanted to remove the roll bar. Getting this off meant removing the wings which, judging by the movement in them, wasn’t going to be difficult! Years of trapped, damp mud had promoted serious corrosion, and I found that they were only being held in place by the three bolts on the footplates. Once these had been undone/cut off, the whole lot simply fell off!

Slightly more tricky was removing the roll bar’s two main 5/8in bolts which, in this case, had rusted into the tractor’s castings. As I’d taken the remains of the wings off, I had half an inch in which to strike the top, once I’d trimmed around the hexagonal head with the grinder. Hitting it hard with a sledgehammer might seem brutal but, nine times out of 10, it starts to shift it, allowing me to push the complete roll bar off the tractor backwards. This then gave me more exposed bolt on which to beat down further and, together with the application of plenty of WD-40, they were soon tapped out.

As I started to remove the rest of the tinwork, it exposed all the years of dirt and grime that had collected in various places. The radiator was full of rubbish, and was showing some damage to the fins but, as the engine didn’t have much coolant fluid in it, it was hard to tell if it was still watertight. The engine was caked with oil which, in many places, was literally inches thick. A lot of this needed to be scraped off by hand before the sand-blasting stage. Leaving it on there would mean the blasting medium would simply bounce ineffectively off the surface.

Finally, something else that needed to be removed at this early stage was the mouse nest I found behind the dash. It was amazing to think that a small rodent had carried so much material so far into this tractor. I guess that this Super Dexta had been sitting in a shed, unused, for a good many years, which had given our little four-legged friend plenty of time to get established.

The front cowl on the Super Dexta had certainly seen better days; it was bent, twisted and rotten. It was also missing a grille and, effectively, both lights

This area of rot on the cowl was in a familiar place; about halfway down, on the side

The bonnet, on the other hand, was relatively straight and had the Fordson badges still fitted and in good condition. A small dent found on the top will be easy to deal with

This Perkins engine is destined for a full rebuild. Considering it uses a very similar block and cylinder head to the engine in a MF35, it looks tiny in comparison

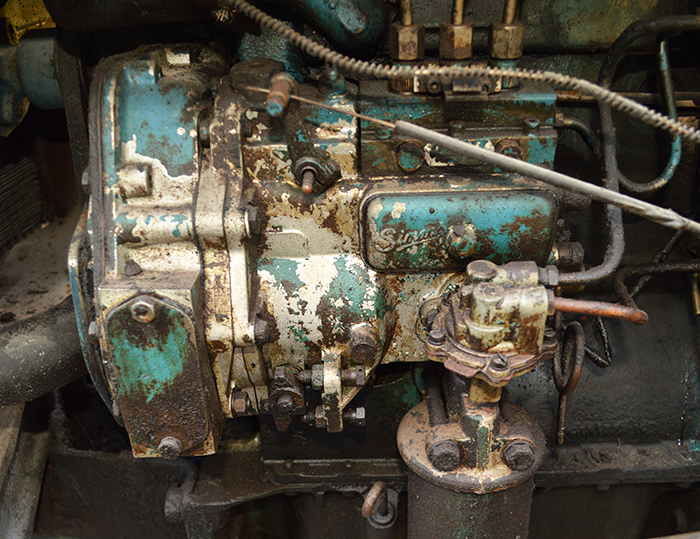

In the 1950s and 1960s, Fordson tractors were fitted with Simms fuel injector pumps. This one will be serviced at Dieselec at Ditton Priors, Shropshire

The Super Dexta is fitted with a small dash, and it’s quite low down. This one will need most of its components replacing as neatly everything was damaged

The water temperature gauge was in reasonable condition on the upper dash, just below the steering wheel, but the two warning lights were both broken

Steering wheels on tractors of this age are nearly always worn out, and this one was no exception. It was down to the metal all over

I suppose that a plastic feed sack on what was left of the sponge cushion provided some protection, but it did look a bit of a mess

Alongside the seat, the handbrake and ratchet needed several new parts to get it working properly again. Fortunately, everything needed is available to buy new

Just under the handbrake, the clutch pedal was showing signs of extreme play, so will need a new bush and perhaps some welding to the pivot pin. A new set of footplates will also be needed

I found a bent and twisted number plate bracket still attached to the oil and grime-coated Fordson. As the tractor came with a registration number, this bracket will be replaced to provide a firm mounting for the refurbished number plate

At the rear of the tractor, the wings were loose due to severe rusting, the hydraulic arms had excessive play and the roll bar needed to be removed – one of my first jobs

The rear tyres didn’t match (different manufacturers) and the tread on this one was quite low. A set of new ones will transform this tractor

This 6.00/16 front wheel and its tyre were total scrap. The tractor had arrived on the trailer with this still fitted, so I wasted little time replacing it with a good wheel with inflated tyre, so that the vehicle was easier to move about

Behind the front cowl, I found that the radiator was in poor condition. It was badly clogged with all sorts of debris so it’s cooling ability would have been compromised

As with all my restorations, new hoses would replace these old ones. A lot of the hose clips I found were so corroded that they had to be cut off

Several areas of the tractor were caked in thick, black oil and dirt but, not surprisingly, it was the engine that was worst affected. All this would have to be scraped off by hand in preparation for sandblasting

Once the dash had been removed, a mouse nest was uncovered. This no doubt got built during the many years the tractor had been standing inactive

It’s not hard to see why wings corrode so badly along their lower edges when you see how much rubbish collects on the mounting plate

As you can see, the wings weren’t held on with much in this case. In fact, it was just the half-inch bolts connecting them to the footplates that were left holding them more or less in place

To subscribe to Ford & Fordson Tractors, click here