1934 Leyland Cub

Posted by Chris Graham on 7th July 2020

Incredible though it may seem, less than four years ago this 1934 Leyland Cub was a very incomplete wreck, and had already been used as a parts donor. Peter Simpson tells its story.

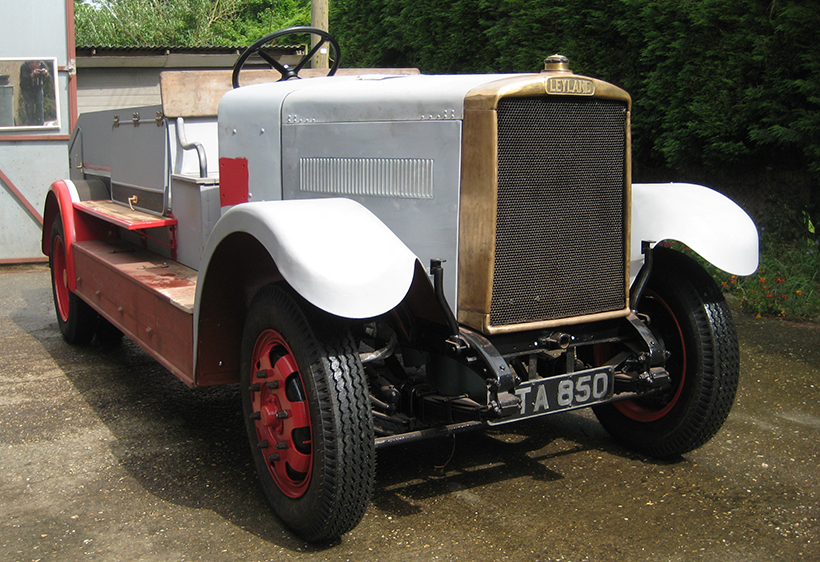

1934 Leyland Cub: Thanks to the efforts of two dedicated restorers, this is now a fully-operational fire engine.

It’s far from unusual for a rough vehicle to be described as ‘suitable for spares’. Sometimes, against all the odds, such vehicles end up being restored. This 1934 Leyland Cub, however, takes that whole concept one stage further, as it wasn’t just suitable for spares when acquired by restorers Roger Turpin and Charles Pateman. It had already been used as a parts donor, and what the restorers started with was the picked-over remains!

There’s more. Obviously, this meant a lot of parts were missing. More to the point, much of what was missing was the uber-rare stuff that’s impossible to find. So, make no mistake about it, this was a massively brave rebuild; however skilled and experienced you are, if you can’t get the parts, you’re basically stuffed. Unless, of course, you employ some lateral thinking…

The men responsible for this fine restoration; Those responsible; Charles Pateman (left) and Roger Turpin.

Two by two…

We’ll come back to all that in a moment. First, though, a little about this particular appliance’s history. It was supplied new to Plympton Fire Brigade, and is thought to have spent its entire working life in Devon. When its firefighting days were over, it eventually ended up at the famous Winkleigh West of England Transport Collection. How it got there, though, isn’t certain, but what is known is that while at Winkleigh it ‘met’ another Leyland Cub of similar vintage. The two were placed together on the basis that one good one could be made from the pair. However, the Plympton appliance – registration BTA850 – being the worst of the two, was always considered the parts donor.

Post-Winkleigh, the pair stayed together but moved about a bit. The history trail goes a little cold at this point, but they’re thought to have spent some time in Surrey, before being acquired by well-know fire appliance enthusiast/restorer Rick Loudon, based near Grimsby. Here the anticipated restoration took place, with BTA850 donating many original components. A high-quality and, in terms of specification, highly original restoration resulted, and we understand the other appliance remains with Rick.

Stripped-out

After this, the remains of BTA850 moved on, finishing up in John Arnold’s yard, near Doncaster, where it was parked in a ‘shed’ constructed from scaffold-poles. By this point, the appliance had no engine, gearbox or pump, and the only brass component remaining was the large brass radiator shell which, for understandable reasons, was stored separately.

What was present was the chassis and running gear, a bonnet and front wings – all in poor condition – the remains of the water tank and wooden rear bodywork, plus the scuttle, windscreen and windscreen surround. One other important part of the vehicle was also present – an up-to-date V5c, with the original registration number. Additionally, though the vehicle was clearly very incomplete, enough of the original survived for any restoration to retain entitlement to said number.

First sighting of the remains, in John Arnold’s yard.

Anyway, in 2016, restorers Charlie and Roger visited John’s yard to collect a replacement engine for another vehicle. While there, they spotted the remains of the appliance and were, shall we say, ‘intrigued’. Clearly it was a major project, but they could see its potential, and as they were skilled and experienced restorers, the actual work didn’t phase the pair. The missing parts were, however, another matter.

John Arnold was keen that the remains should have at least a chance of a new life, so quoted a price which, in Roger’s words, “wasn’t cheap but wasn’t expensive.” Basically, he asked, and the pair agreed to pay, the (not inconsiderable) value of the brass radiator surround, plus the current scrap metal price for the rest. It subsequently emerged that the yard needed clearing anyway, a scrapman with cutting gear was ready and waiting, and had Charlie and Roger attempted to haggle the asking price down, John wouldn’t have let them buy it. As an additional ‘sweetener’, John threw in six original Leyland wheelrims of the correct pattern.

On the transporter, ready for the journey down to Lincolnshire.

The restoration

Once the remains had been delivered to their base in South Lincolnshire, Charlie and Roger assessed what they had. The biggest issue, as they’d expected, was obtaining the missing parts – a replacement engine and gearbox, especially. The gearbox was a particular problem as it has a power take-off (PTO) for the pump and, realistically, the only likely source of any of these was going to be another pre-war fire appliance that was being broken – clearly unlikely in the extreme to be available. It was, therefore, accepted from the word go that deviation from the original, mechanical specification would be needed.

Undercover, ready for the restoration work to start.

As regards the rest of the missing stuff, the fire appliance preservation world is a fairly close-knit and co-operative one and, once word got around, leads and offers of help soon started arriving. By lucky coincidence, at about the same time as the project started, the National Fire Service Preservation Group at Weedon Bec, Northamptonshire, was having a sale of surplus items. Charlie and Roger visited and, in Roger’s words, “we came back with 35ft Ajax ladder and a pre-war Dennis No2 2 trailer pump, which could be adapted to fit on the Leyland relatively easily.”

However, the problem of how to drive said pump remained. The original Leyland sidevalve unit had an unusually shallow oil sump, meaning very little clearance between the sump and the front axle beam. Initial thoughts were that a Bedford 28hp engine could be used, as these are still relatively plentiful, but one of these just couldn’t be made to fit under the bonnet.

Alternative power

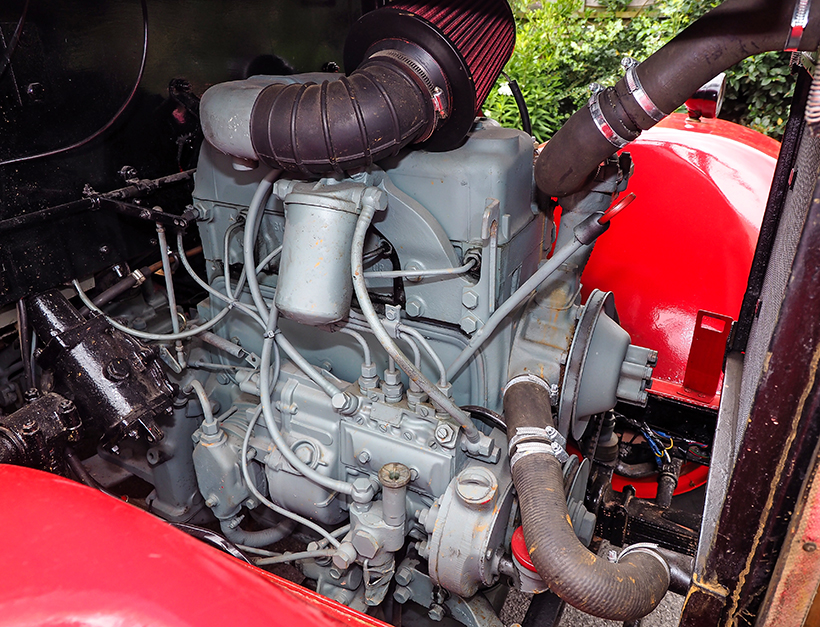

In the end, a rather ingenious solution was found, one which we’re sure won’t meet with universal approval, but which actually works extremely well and was key to a basically no-hope vehicle returning to the road. The PTO is supplied by a transfer box taken from a 1950s Leyland Martian military lorry. Then, for the engine and gearbox, the restorers used a four-cylinder diesel engine and matching gearbox from a 1970s Mercedes 7 1/2tonner. Being shorter than the original unit, this sits behind the front crossmember rather than on top of it, meaning there are no clearance issues. The gearbox is also compact enough for the transfer box to be bolted up behind, via a custom-made adaptor and, of course, the Leyland now has a hydraulic clutch.

The replacement, 1970s Mercedes-Benz engine is position.

This arrangement, though clearly nothing like original, does actually work very well indeed and, while rivet-counters may disapprove, this has allowed a 1934 vehicle to return to the road. It also, of course, makes the appliance more driveable and useable. “To the average on-looker, it’s still a 1934 fire engine, though” as Roger puts it.

The transfer box is from a Leyland, albeit a 1950s Martian military vehicle.

With regard to the remaining restoration, the front wings and bonnet are the originals but both needed extensive restoration. The bonnet looked like it had been driven over at some point according to Roger. He also said: “I would like to say that there’s no filler in them, but I’d be lying.” Though the impressive brass radiator surround is original, the radiator itself needed a full, professional rebuild.

Scuttle repairs underway and engine repainted.

Too far gone!

The rear bodywork, and the water tank underneath, are both new constructions; the originals were too far gone to be restored, but could be used as patterns. The body replicates the original construction of plywood over a wooden frame, with the whole lot covered with tinplate. Replacement side panels were also fabricated from scratch, and a replacement hose reel was sourced on eBay.

The Dennis water pump was originally trailer-mounted, and came from the Fire Service Preservation Trust.

Fortunately, all the original ladder supports came with the vehicle but, needless to say, all the original brasswork and other fittings were long-gone. So it was basically a case of finding what could be found and, for the rest, “modelling in 12in to the foot, using photos and, if it looked right, it was right.”

In some places, what was originally brass has been replaced in aluminium for reasons of cost – for example the treadplate metals were originally brass, but it costs £75 a metre, and over 20 metres were needed. So, by using aluminium instead, they saved around £1,500.

At this stage, Roger happened to attend the Lincoln Steam & Vintage Show where he met Rick Lowden – who, remember, had used the engine for spares, to restore another. Of course, the photo album came out and Roger showed Rick what they’d achieved so far. At the end of the conversation, Rick invited Roger to “come over and see me” with the suggestion that he might have something a bit special that would make a good finishing touch. That turned out to be the Francis spotlight, which is thought to have been with BTA850 when it was new. A deal was agreed, and the spotlight is now back where it belongs.

Looking like a fire appliance again, even though it had yet to receive any red paint.

The chassis was cleaned up and refinished. Most of the running gear – springs, kingpins, steering joints etc – was, apparently, in surprisingly good condition, and could also be cleaned up for reuse. The brake hydraulics, however, were fully refurbished with new rubbers and the cylinders refurbished or renewed, as required. Parts for this were supplied by Past Parts, of Bury St Edmunds.

Sixteen coats

The superb paint finish was, as it would have been originally, applied by hand, though using rollers rather than brushes. Traditional coach paint was supplied by Black Country Paints, and T Class 4in rollers were used, which Roger describes as “not cheap but magnificent.” In all, 16 coats were applied – it was supposed to be 15 but, typically, just after the 15th and supposedly final coat had been applied, some unexpected gusts of wind covered the surface with dust, necessitating an careful rub-back and additional coat. The impressive signwriting was done by a local professional, using some original Leyland photos obtained with the vehicle, as a guide.

Sixteen coats of red paint were applied by roller, each being rubbed down before the next one went on.

The all-important sign-writing, applied in the traditional way.

A little over two years after work started, the project was completed. This is a remarkably short turnaround for what was clearly a very major project, and the result looks superb. Despite Charles and Roger doing pretty-much everything themselves, it wasn’t especially cheap either. However, the results speak for themselves, and it’s a super job. It went to a number of events in 2018/19, including the Lincoln Show where Rick Lowden – and “quite a few” other people – were able to take the completed appliance for a spin. It’s also completed a 199-mile round trip to a show in Hertfordshire; something that’s a lot more practical with the current power unit than it would have been with the original, Leyland sidevalve.

My conclusions

Despite the somewhat unconventional approach to the mechanical aspects, this is a fully-operational, 1934 fire engine. All the fire-fighting stuff – ladder, pump, hoses etc., are fully functional, and it certainly looks the part. It’s also arguable that the various mechanical changes are precisely the sort of thing that would have been done if, for some reason, this engine had been retained as, say, a factory fire appliance, or in some other emergency role for which dependable operation was vital. There’s also no getting away from the fact that, without these changes, it’s highly unlikely that this impressive machine could have been restored at all.

The original, brass radiator surround encloses a re-cored radiator. The ladder came from a National Fire Preservation Group clearance sale.

Since our photo-session, the Leyland has changed hands; a friend of Roger’s named Alex Scott was keen to own it and offering a good home, and the restorers have other projects to keep them occupied, including a Mack MM6 military recovery vehicle and, from the ‘other side’, a ZIL131. It now lives in Suffolk where Alex has since made a number of further improvements to the machine including, we understand, a set of period brass headlights. As Roger put it: “We were sorry to see it go in many ways, but we had taken it to one stage, and Alex is now taking it to the next.”

The original Francis Spotlight is now back in position.

Charles at the wheel. With the current engine and gearbox it will, apparently, cruise at 38-40mph.

This 1934 Leyland Cub fire appliance is now powered by 1970s, four-cylinder Mercedes-Benz engine.

For a money-saving subscription to Classic & Vintage Commercials magazine, simply click here