The world’s largest motor graders!

Posted by Chris Graham on 9th June 2023

Keith Haddock takes a look at some of the world’s largest motor graders, most of which are now relegated to the history books.

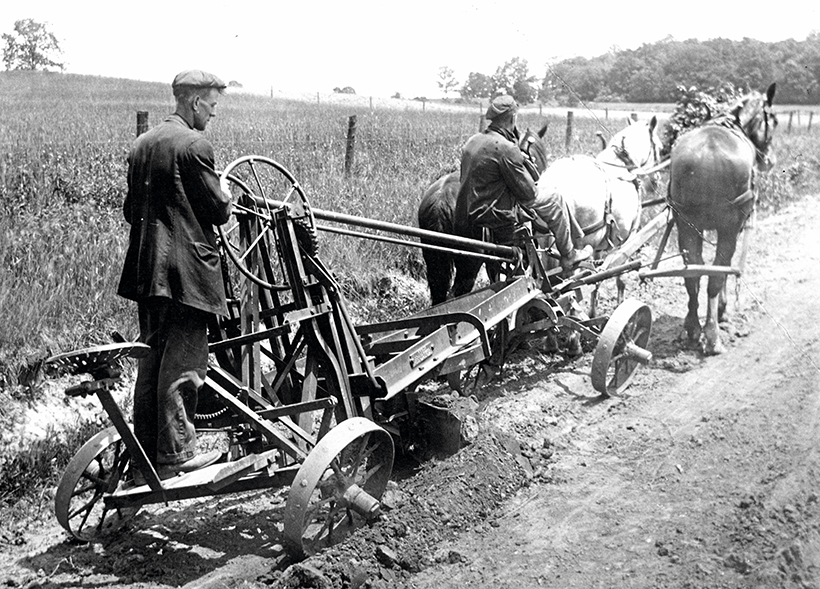

In the early days, all graders were pulled by horses. In 1885 JD Adams invented the leaning wheel principle to offset the side thrust of the angled blade, as shown here.

Graders originated way back in the horse-drawn era, as a simple board mounted on a wheeled frame. In 1885, entrepreneur JD Adams made the grader’s wheels adjustable so they could be cranked to lean against the sideways thrust of the angled blade. This leaning-wheel principle changed the way graders were designed and remains a feature in all graders today.

In the early part of the 20th century, steam traction engines gradually replaced animal power to pull graders then, in the 1920s, tractors with internal combustion engines took over. By that time, pull-type graders were a familiar sight maintaining the thousands of miles of gravel roads in North America. In 1919, the Russell Grader Manufacturing Company introduced a self-propelled machine which set the stage for Russell and other manufacturers to improve on the self-propelled idea. Eventually, all grader makers offered self-propelled models in their lines, even though some continued selling pull-types as late as the 1950s.

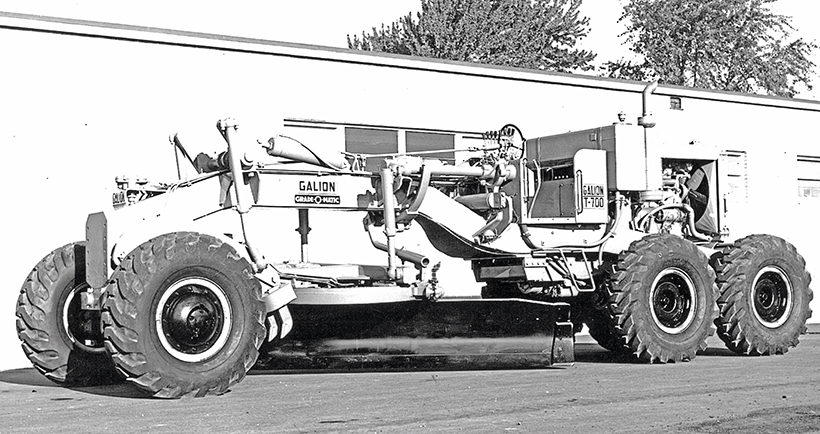

The era of big motor graders began in 1955, when the Galion Iron Works launched the T-700 with an operating weight of 40,000lb.

In the 1940s, the number of grader manufacturers shrank to a small number of internationally-known names producing the bulk of the output. In North America, famous grader makers Adams, Austin-Western, Galion, Huber and Champion dominated, along with full-line manufacturers Allis-Chalmers and Caterpillar, who offered graders as part of their product lines. In Great Britain, graders were imported from America, especially Caterpillar and Allis-Chalmers, but many were also made on home ground by firms such as Blaw-Knox, Aveling-Barford (Austin-Western under license) and British Jeffrey-Diamond Ltd (Wakefield brand under license from Galion).

The massive industrial developments of the 1950s – dams, highways, steelworks, etc – demanded graders much larger than those previously built. In addition, opencast mining was rapidly expanding world-wide, and larger haul trucks needed larger graders to maintain their haul roads. Since the 1950s, average off-highway hauler sizes have gradually increased from 15 tons up to today’s 400-ton monsters. But, because graders with sufficient power to maintain their haul roads sold in comparatively small numbers, manufacturers tended to discontinue production of the largest graders after a relatively short production run.

Now let’s take a look at some of the companies that designed and built outsize graders since the 1950s.

Galion

The first, super-sized grader was the Galion T-700, introduced by the Galion Iron Works & Manufacturing Company in 1955. Larger than any grader yet built, it developed 190hp and boasted an operating weight of over 40,000 pounds. The T-700 also utilised a torque converter, output shaft governor and power-shift transmission called the Galion Grade-O-Matic drive, which allowed simple, two-lever control of speed and direction. Moldboard (blade) length was 14 feet. Galion became a division of Dresser Industries Inc in 1974. Then, in 1988, the Komatsu Dresser Company joint venture was established. Today’s graders with a Galion heritage are sold under the Komatsu name, and have been renumbered to comply with Komatsu’s GD-series nomenclature.

Huber

At 195hp, the big 5D-190 grader made by the Huber Manufacturing Company between 1955 and 1957 was billed as the world’s most powerful motor grader. Although weighing less, at 30,000 pounds, it competed with the biggest graders of the day, such as the Galion T-700. It also carried a 14-foot moldboard.

In 1957, the Huber Manufacturing Company claimed its model 5D-190 as the world’s most powerful grader, at 195hp.

CMI

Some of the very largest graders weren’t made by the most familiar grader manufacturers. CMI Corporation (famous for its automated profiling and paving equipment), brought out a giant grader in 1969. Named the ‘Autoblade’, the 40-foot long double-articulated unit had a power module at both ends, each consisting of a 225hp diesel engine driving four wheels through hydrostatic drive. The eight-wheel-drive machine featured a centrally-mounted cab which could swing 180° to face in either direction. This, coupled with the ability to rotate the blade through 360 degrees, eliminated the need to back up over the grade to make another pass. In other words, the machine worked efficiently in either direction. CMI also promoted the 65,000lb Autoblade as a precision grader, suitable for fine grading in paving operations.

This 40-foot long, double articulated grader boasted a 225hp power unit at each end. It was built in 1969 by CMI Corporation.

RayGo

RayGo Inc, famous for compactors, also ventured into the ‘super grader’ field with a grader known as the ‘Giant’, which certainly lived up to its name! Like the CMI Autoblade, it was double-articulated, and had a power unit at both ends. But at 106,000 pounds, the RayGo was more than 50% heavier! The power units at each end were GM 318hp diesel engines, each driving a single axle. The RayGo Giant was suitable for heavy-duty levelling and reclamation of surface mines but, unlike most other graders, its blade was fixed to the central frame instead of the usual circle mounting.

Beginning in 1969, RayGo Inc built this double articulated grader called the ‘Giant.’ It was the world’s largest at the time, with an operating weight of 106,000lb

The operator’s cab was mounted on the rear frame, and suspended over the rear articulated joint, giving the operator a panoramic view of the blade and front power unit. RayGo began manufacturing the Giant in 1969 after it had been developed and tested several years earlier by Ken Harris, a South Dakota contractor. RayGo went out of existence in 1985 when CMI Corporation purchased the company. Rights to the RayGo products passed to Caterpillar Inc in 1987, but no more were produced.

Another view of the Raygo Giant in action, with its General Motors’ 318hp engines front and rear.

Champion

Long-time grader specialist Dominion Road Machinery Company (Champion Road Machinery Ltd. from 1977) took a bold step with the introduction of the world’s largest production grader in 1975. The Champion 80-T (which later became the 100-T) had an operating weight of some 202,000 pounds and carried a 24-foot blade. Designed for use in surface mining operations to maintain roads for the largest haulers, or to reclaim vast areas of land, this machine was equipped with a 700hp Cummins engine. In 1989, Champion sold the manufacturing rights of the 100-T to Dom-Ex Corporation of Hibbing, Minnesota. Volvo took over the remaining Champion grader business in 1997 and continued grader production under the Volvo name.

The Champion 100-T looked just like a normal grader, except it was much bigger! Built by the Dominion Road Machinery Co, beginning in 1975, it claimed to be the world’s largest production grader with its 24-foot blade and operating weight of 202,000lb.

Acco

The largest grader ever built was the one-of-a-kind monster built by Italian contractor Umberto Acco in 1980, for use on a major contract in Libya. Its 33-foot blade, front and rear engines totaling 1,700hp and running on 12 large tires, ensured the ACCO overshadowed everything else built to date in the grader field. Its estimated weight was around 400,000 pounds! But this grader hardly qualifies for the grader ‘hall of fame’ because the job for which it was designed never materialised and, as far as we know, the machine never actually accomplished any productive work.

The largest grader ever built was this monster put together by Italian contractor Umberto Acco in 1980. Its front and rear engines produced a total of 1,700hp, while its blade was 33 feet long!

O&K

In Germany, Orenstein & Koppel (O&K) made a full line of motor graders for world-wide distribution. In 1980, the company launched a huge mining grader known as the G-350, with an operating weight of over 90,000 pounds. It was the largest grader in production during the time it was built. It boasted all the blade movements of its smaller brothers, and found use in large mining applications where haul trucks were rapidly increasing in size. O&K sold 34 G-350s to many different countries, including to Northern Strip Mining Ltd in the United Kingdom, but discontinued its production in 1986.

German manufacturer O&K produced a range of graders topped by the 90,000-pound model G-350 in 1980. This one maintained haul roads at Northern Strip Mining’s Godkin opencast coal site, in Derbyshire, where 170-ton Wabco haul trucks – the largest in the UK – were operated.

Komatsu

Komatsu launched its flagship grader, the GD825A, at the Conexpo 87 equipment show in Las Vegas, Nevada. With its 16-foot blade, 280hp engine and 58,250lb operating weight, it remains Komatsu’s largest grader. It features an articulated frame and a load-sensing system which automatically adjusts the amount of oil to the hydraulic cylinders to suit the work at hand. The GD825A has been sold in respectable numbers as a surface mining product along with the Komatsu’s haul trucks and mining-size excavators.

Komatsu launched its flagship grader in 1987. The GD825A operated with a 16-foot blade and was in the 58,000-pound weight class.

Caterpillar

If you want a big grader today you would have to go to Caterpillar, the only company to persist with large grader production over several decades. Although building motor graders since 1928 following purchase of the Russell Grader Manufacturing Company, Caterpillar’s large grader story began in 1963 with the introduction of the No.16. At 225hp and an initial weight of 46,500lb, it represented a big jump in size for Caterpillar and was, in fact, the largest grader on the market at that time. With its 14-foot blade, this grader was designed on similar principles to Caterpillar’s smaller graders of the time – the 112E, 12E, and 14D – weighing up to 30,300 pounds. Utilising hydraulic-actuated mechanical controls, the rigid-framed No.16 was powered by a Caterpillar D343 turbo-charged engine. It enjoyed a production run of 10 years and, by then, upgrades had increased its weight to 49,600lb.

Several early Caterpillar graders were designed to mount on standard Caterpillar tractors. This Motor Patrol No.25, with hand-operated controls, was designed to mount on Caterpillar 25 tractors in the 1930s.

In 1973, Caterpillar replaced the 16 with the 16G when launching its new G-series articulated graders. Outmoded mechanical controls were replaced with state-of-the-art hydraulic controls; it was one of the last major grader manufacturers to do so. The big 16G quickly became the standard for haul road maintenance at surface mining and heavy construction projects. Its weight topped out at just over 60,000 pounds when equipped with ripper, and a power increase to 250 flywheel horsepower over the former model enabled the 16G to handle a 16-foot wide blade. After another increase to 275hp, the 16G enjoyed a remarkable production run of 22 years.

Caterpillar’s big grader production began in 1963, with the introduction of the 225hp No.16 at 46,500lb operating weight.

In 1995, Caterpillar announced its H-series graders which included the upgraded 16H to replace the 16G. New features included an operator’s cab with improved forward vision, and electronically-controlled transmissions. It retained the same power and weight ratings as the former model, but held the distinction of being the largest grader on the market at that time.

Caterpillar took over the Russell Grader Manufacturing Co in 1928, adding graders to its already established tractor line. One of the first motor graders to carry the Caterpillar name was this No.7 Auto Patrol.

Caterpillar broke its own size record for graders when the giant 24H appeared in 1996, allowing the company to dominate the big grader market. As the world’s largest production grader, the 24H boasted a Caterpillar 3412E engine rated at 500hp, and an operating weight of 131,000 pounds. The 24H sold extremely well to the world’s largest surface mines, where it was ideally suited to the new breed of haul trucks with capacities up to 400 tons.

In 1996, Caterpillar announced the 500hp 24H grader with 131,000lb weight. At that time, all other giant graders had been discontinued, so the 24H claimed title to the world’s largest.

Moving forward, Caterpillar launched its M-series graders in 2007 to replace former models. These included the 290hp 16M weighing 60,700 pounds, and the 533hp 24M tipping the scales at 138,300 pounds. The most notable new feature of the M-series was the introduction of push-button controls in conjunction with joystick levers, to activate all grader blade movements including steering. This system quickly caught on with young drivers in the industry, but was definitely not preferred by the older, well-seasoned operators!

Caterpillar’s M-series graders, brought out in 2007, included the 16M. This one worked for UK Coal at its Lodge House opencast coal site in Derbyshire.

Today, Caterpillar continues to retain its dominance in giant graders. In 2015, the 16M and 24M were upgraded to the M3 series, and a new size – the 18M3 – was introduced. At the 2020 Conexpo equipment convention held in Las Vegas, Caterpillar announced a new format to reference most models in its entire line of earthmoving equipment, by abandoning the letter suffix. Its top three largest graders, now current, are the 16 at 290hp and weighing 71,454lbs, the 18 at 304hp and 74,324lbs and the 24 at 535hp at 164,392lbs – a weight more than double that of the next smaller model 18, and by far the heaviest and most powerful machine in the industry.

Sales targets for the Caterpillar 24M are large surface mines. This one operates in the oil sands industry in Alberta, Canada, where several dozen of this size can be found hard at work.

This feature comes from a recent issue of Old Glory, and you can get a money-saving subscription to this magazine simply by clicking HERE

Previous Post

A pre-war Scammell lorry that’s covered 1.2 million miles!

Next Post

Steam engines in Serbia