Miniature steam collection

Posted by Chris Graham on 20th March 2023

Designer and engineer James Stanley is busily expanding his miniature steam collection, as Sally Clifford discovers.

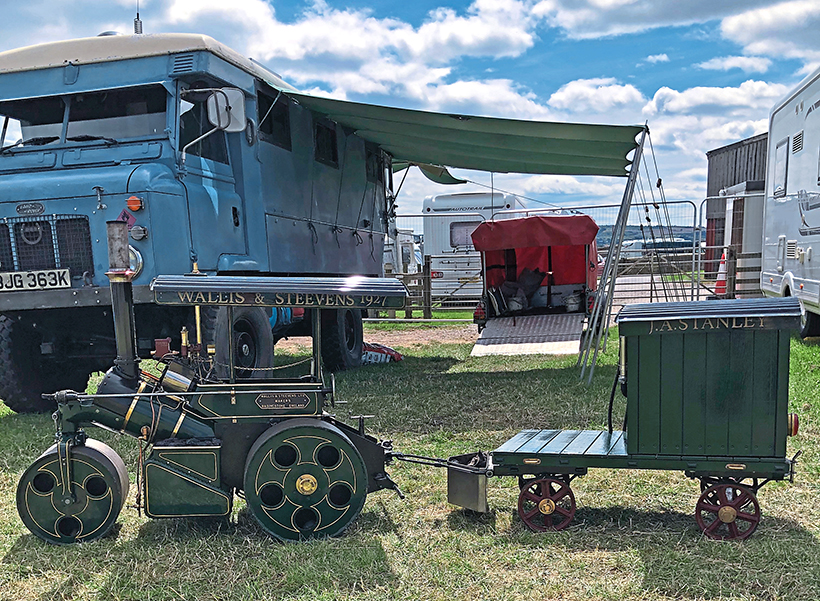

miniature steam collection: James Stanley with Arthur, his Wallis & Steevens Simplicity roller. (Pic: Sally Clifford)

Developing a skill demands plenty of time and patience. Spending hours perfecting a piece to slot into that all important place to make the engine run and, perhaps more importantly, steam, is par for the course for both kit and scratch-build miniature makers.

Befitting of someone who doesn’t stand still and who is very much hands-on, even during our conversation James Stanley announces “I am standing here now filing a part for it!”

The Wallis easily pulls James and this trailer – plenty of power there! (Pic: Sally Clifford)

For James, and his fellow enthusiasts who spend many a pleasurable hour in workshops and garages up and down the country after tasking themselves with the challenge of building a steam engine in miniature, time is precious and every second counts!

So there is a justifiable eagerness to complete his latest project – a six inch version of his very first miniature steam engine – a four inch scale Wallis & Steevens Simplicity roller. “I’ve been a mechanical engineer since I left school. I’ve always been building vehicles. I’ve built custom cars, motorbikes all my life and I’ve been exhibiting vintage vehicles at shows for the last ten years,” explains James. “While at the shows when I was exhibiting I have always been fascinated by steam and anything mechanical.”

Everything is carefully made to scale on James’ Simplicity. (Pic: Sally Clifford)

Always on the go, James was easily bored after strolling around the rallies and wasn’t content just standing by his exhibits. Unsurprisingly, the miniature traction engines attracted his attention. “I thought if I got into steam it occupies your time – more than I realised – it takes up your time!” laughs James. “But I love the aspect of being busy, and the design aspect of it, and how it evolved with technology.”

“So about six years ago I started hunting to get one and I started talking to other steam people – they are a fantastic community and I love it now that I am part of it. It is just amazing how it has still got that traditional community culture, it has not become digitised and modernised.”

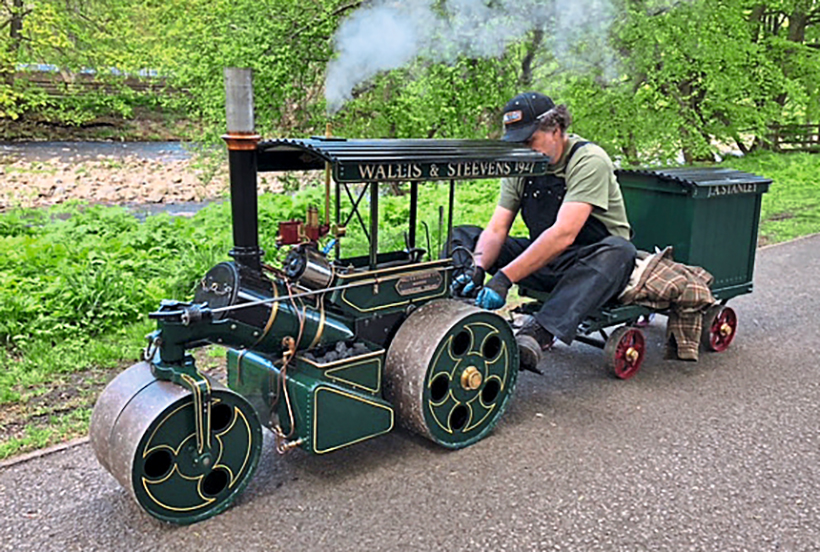

James at the wheel of Arthur, his Wallis & Steevens Simplicity roller. (Pic: James Stanley)

James eventually found his first miniature steam engine through Facebook. “But it was in Brighton and I live just outside Newcastle.” Undeterred, the journey was made and the four inch scale Wallis & Steevens Simplicity roller began its new life in Gateshead.

Based on the 1927 version and dating back to the early 90s, the engine needed plenty of TLC. “It was a project but I like projects,” says James. After acquiring a set of original drawings for the engine from Plastow, James spent a year working on it. “It needed painting, a new canopy, it needed a lot of motion components and some of the gears were broken. Because I restore vehicles I did the restoration of it, the re-painting and machined all the parts,” explains James.

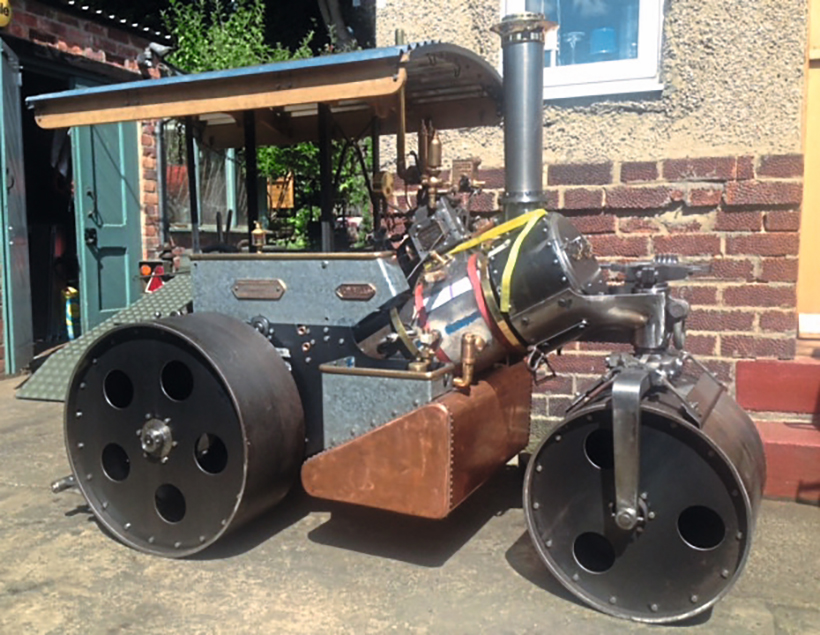

James with little Arthur and his scratch-built 6in version, which looks capable of doing a day’s work! (Pic: James Stanley)

Perhaps the most complex part was learning how to fire it and run it. James learned from others that the Simplicity in particular can be challenging to fire. “I couldn’t get it to work, to move around the field, but it was OK on Tarmac.” James was able to draw on his design, engineering and pattern making skills to modify some of the parts and improve the engine’s performance.

Once complete, he was able to showcase it at local rallies and shows where he enjoys answering questions about what he regards as its unique boiler. “A lot of people ask why the boiler is at an angle.” James says despite his thirst for knowledge in hunting down the answers, it remains a grey area although, he ponders the conceivable possibility that, being a roller going backwards, forwards, upwards and downwards, the design may be to prevent the water in the boiler from sloshing over the firebox.

The scratch-built 6in Simplicity is very much a work in progress at present. (Pic: James Stanley)

“I would think that is why it is called ‘Simplicity.’ They are a very simple engine but when you come to make one they are very complex.”

It was at Whitby Traction Engine Rally in August where I met James and Arthur, the miniature that subsequently inspired the creation of its 6in replica. Currently a work in progress, James hopes to have the 6in Wallis & Steevens Simplicity roller up and running by next summer to showcase it alongside Arthur.

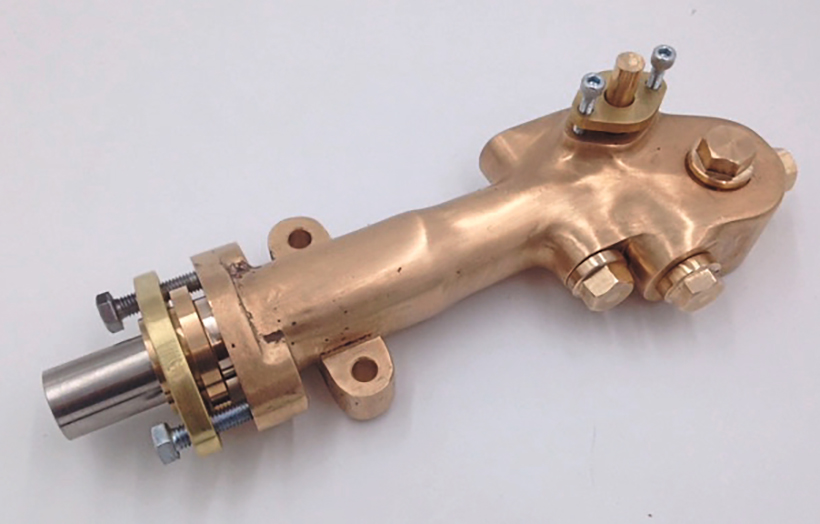

The wooden pattern created for making the roller’s water pump. (Pic: James Stanley)

At two metres in length, 1½ metres high and weighing 700kg, James’ latest engine, to be christened Joy Bells after his mum, is an up-scaled version of his original Plastow engine, but has been built to his own drawings. “No-one has seen it yet,” says James.

“I think people like to see it in raw steel – the painting, lining and the polish is another aspect to it. It’s like a process of going from a design, an engineering drawing, to selecting the materials to manufacture. Putting on the parts and finishing it is the core of what I am about.”

The rough casting is ready for machining to produce a working pump. (Pic: James Stanley)

Undertaking his own scratch-built version, on a bigger scale, wasn’t just a challenge for James – it also gives him a greater understanding and an insight into how generations before have tackled the intricacy of such small-scale projects.

“One of the reasons why I wanted to make a bigger version is I wanted to experience all of the manufacturing process, what the people had to go through in the time they were building them. “I teach people how to make things and I have made a lot of stuff in my time, but there are certain aspects of traditional making I have not experienced before that I have had to read and learn about, and I can share that with younger generations,” says James, a technician at Northumbria University.

Machining the casting took some time to complete. (Pic: James Stanley)

He is also conscious that embarking on such projects, as many miniature steam enthusiasts do, he is helping to preserve heritage and, hopefully, fire the imaginations of the next generation.

He talks of others, like him, working by day and spending hours in their workshops at night. “Repairing and keeping heritage alive which is common ground for me – I can share that with other people,” says James. “I love the challenge of learning new skills, understanding and perfecting, becoming a craftsman at something, and you can only do that if you put 20,000-30,000 hours into it, not just do it for five minutes.”

James’s finished and assembled water pump looks a real treat. (Pic: James Stanley)

The feature comes from the latest issue of Old Glory, and you can get a money-saving subscription to this magazine simply by clicking HERE

Previous Post

Fantastically original 1956 Land Rover Station Wagon

Next Post

Newark Vintage Tractor & Heritage Show