1980s six-cylinder Ford 30 Series

Posted by Chris Graham on 27th April 2022

Chris Graham spotlights the 1980s six-cylinder Ford 30 Series, which offered tractor users a whole new world of operational convenience.

Tractors from the Ford 30 Series had a tough, no-nonsense look about them. It’s hard to believe this example is 30 years old!

The 30 Series, which Ford introduced 33 years ago in 1989, built on the sales success and operational popularity of the well-established TW range. Some skilful cosmetic changes – which essentially boiled down to black-painted radiator grille and mudguards, plus the addition of a Super Q cab and some fresh new graphics – were enough to give the three new 30 Series models a fresh new look, and disguise the fact that, beneath the surface, the engine and running gear remained much about the same.

However, it was the new Power Shift transmission that grabbed all the headlines, and rightly so. Ford had opted to specify an advanced, 18-speed, single-lever-controlled transmission from America, and it’s fair to say that that decision proved little short of revolutionary for both the brand and the practical usability of its tractors in the field.

Three-model launch

Three models were made available at the launch, neatly replacing the TW15, TW25 and TW35; these were the 8630, the 8730 and the range-topping 8830, producing 132, 154 and 186hp, respectively. Gone were the spindly, floor-mounted gear change levers found in the TW machines and, in their place, was a single, stubby control lever used to select both forward and reverse as well as individual gear ratios, all without the need to operate the clutch pedal.

The lever was mounted conveniently on the driver’s right-hand side and could be operated with minimal effort. The direction of travel was selected logically be moving the lever either forwards or backwards, while the individual gears (18 forward and 9 reverse ratios), could be cycled through by knocking the lever to one side or the other. At all times, the gear selected was displayed clearly on the digital dash panel, and the system proved an instant hit with customers.

If you even have cause to remove the rear wheels, you’ll have to deal with the collets that secure them. These can be a real struggle to remove, especially if the wheels haven’t been off for many years. You’ll need patience, plenty of penetrating spray and some controlled force – there is a risk of breaking them if you’re not careful.

Just to be on the safe side, Ford continued to offer a more conventional, Dual Power transmission alternative for all three 30 Series models, but few of these were sold on the home market as most farmers rushed to the convenience of hand-controlled, clutchless tractor control. Now, three decades later, the Dual Power models are rare to find, which makes them of interest to an increasing number of Ford tractor enthusiasts and collectors.

In many respects, it’s hard to believe that what appears outwardly to be such a modern-looking tractor has been around for so long – even the youngest 30 Series model is nearly 30 years old now. Production finally ended in 1994, which means that these still capable machines are now knocking on the ‘classic status’ door, and values are starting to increase as a result.

Buying advice

For some practical feedback on 30 Series tractor ownership and buying, I visited rural Kent to meet 8630 owner Jim Aikman and Ford-trained tractor technician and restoration specialist, Nick Wright. Both are admirers of the 30 Series, although Jim’s tidy example is a relatively new addition to his 30-tractor collection; he bought it about four years ago. While it still works for its living, it’s not involved in hard graft and spends much of its time cutting grass.

Nevertheless, Jim has used it enough to fully appreciate the benefits that Power Shift brings and, as Nick aptly put it: “It’s a tractor that you can use for a day and then walk away from quite comfortably afterwards, without the sort of clutch pedal-related leg fatigue you get with so many others!”

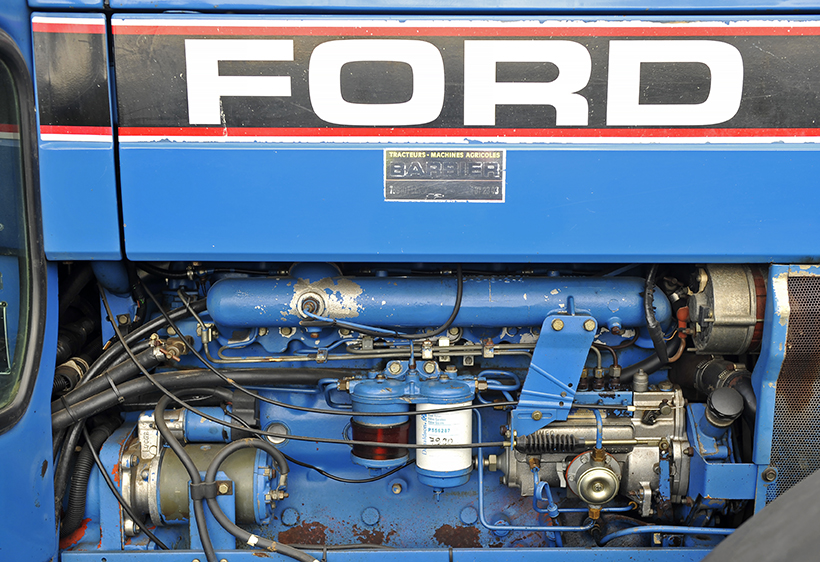

The Ford 6.6-litre, turbocharged diesel engine that powers the six-cylinder 30 Series models is a willing and durable worker. Expect a smokey exhaust on start-up, and when it’s working hard.

Nick, having worked in the workshops at a Ford/New Holland dealership for many years, is perfectly positioned to comment on the 30 Series’ mechanical manners and, as far as he’s concerned, he has nothing but praise for the machines. He considers that it was a solid tractor with good levels of inherent reliability, assuming proper levels of maintenance and servicing, of course.

“The Power Shift transmission system was made in America, by Funk,” he explained, “and has certainly stood the test of time, as far as I’m concerned. Just about the only disadvantage came with the early units, which used straight-cut gears that were noisy in operation. In 1993, the manufacturer switched to ore expensive, helical-cut gears, which quietened its operation significantly. But both gear type function equally well, and there’s no difference between them in reliability terms.”

As far as the engine is concerned, Nick went on to explain that: “All three models use the same, six-cylinder, turbocharged, 6.6-litre Ford diesel unit, and the power differences arise from tweaks made to the fuel injection, the turbos and the compression ratio. It’s essentially the same unit that was used in the TW Series machines, so is all tried and trusted. There was also the option of two-wheel-drive across the 30 Series range, but this was something that was for more popular in America than here.

“The Super Q cab offered 30 Series drivers a better working environment than was available on the TW,” Nick continued, “with more space, a better, more efficient heating and ventilation system, easier access to the air filters and a fully digital dash. Elsewhere, the hydraulic system was beefed-up to a degree but, if you’re being hyper-critical, this was probably one of the model’s very few weaknesses.”

One of this model’s very few weaknesses concerns the hydraulic linkage arrangement at the back; wears does occur and is very expensive to put right.

Overal condition?

With that last point in mind, Nick’s first piece of pre-purchase advice was to begin any tractor inspection at the back. “Pay close attention to the condition of the hydraulics and rear linkages. Check the link arms for wear by testing for play. There’s a torsion tube that runs across the bottom which is splined on either end, and it’s these splines that wear.

You can assess condition simply by pulling back and forth on the arm and, if there’s obvious movement at the bottom anchor point, then the system is badly worn and effective draft control ability will be lost.” Of course, this might not be a desperate problem if you’re not intending to work the tractor but it’s important to note that if you want to put such wear right, the parts needed are hard to find and expensive when you locate them.

More generally, Nick also made the point that first impressions are always important, too. “General appearance is an important consideration, as always. If a tractor looks right, and is free from obvious damage, then the omens for its overall condition will be good. Machines that are covered in dents and scratches, and fitted with dirty oil filters that obviously haven’t been changed for ages, should set the alarm bells ringing in terms of how they’ve been cared for. A decent service record is an important aspect with this sort of tractor. If the cab interior is scruffy, as well – perhaps with missing trim and a neglected seat that’s badly worn – then these are also tell-tale signs of a tractor that’s probably been poorly maintained overall.

Smooth changes?

Ideally, you’ll want to test drive the tractor before you decide to buy it and, during that, one aspect that’s essential to assess is the operation of the Power Shift transmission. Nick explained: “This gearbox needs to be periodically calibrated and, while this isn’t a complicated thing to do, it is important that it’s carried out at the required intervals to keep everything running correctly and smoothly. The procedure for doing this is included in the owner’s manual, and involves a simple sequence of ignition switching and gears lever operation, and checking the resultant figures displayed on the dashboard as the calibration proceeds.

The Super Q cab is comfortable and spacious. Check for damaged/missing trim when buying, and listen out for an annoyingly loud fan in the roof – the bearings do fail.

“What you’re doing in this process is calibrating the three clutch packs, by triggering the system to electronically measure the time taken for the clutches to bite, and then adjust the pressure of oil being supplied to compensate for any wear. If the procedure isn’t carried out routinely, the gear changes will become progressively more sluggish and harsh. However, there isn’t a specific warning light on the dash to indicate that calibration is required, so it’s a job that owners just have to remember to do. Normally, the gear change should be smooth so, if you come across one that feels harsh and jerky, then it’s likely that calibration is required.”

As this is a relatively sophisticated tractor, in terms of its electronic control systems, problems can arise. However, Nick says that, more often than not, these sorts of fault are induced by operator error. “By and large, the electronic system used on this generation of tractor are inherently reliable so, if problems do strike, then they’re sometimes triggered by something external. Careless electronic welding, for example, can deliver an electronic spike that’s sufficient to cause processor damage.

Alternatively, the fault may lie with chafed or broken wire that’s causing a short circuit, and problems like this will typically occur under the cab, where the damage will be most difficult to detect and then get at! On the plus side, though, there are independent specialists around nowadays who can help with electronic processor module repair.”

Self-diagnosis

Nick continued: “The electronics on 30 Series tractors will perform a self-check procedure when the ignition is switched on; all the warning lights illuminate while the electronic checks are made, then are extinguished if no issues are detected. As on a modern car, warning lights that remain on indicate a problem, and will require further investigation. There’s no electronic service tool available for this tractor, so it’s not possible to interrogate the control systems to identify the nature of any recorded faults. Dealing with electronic issues effectively involves the use of a multimeter, and isn’t really a DIY prospect unless you have the relevant experience.”

The Power Shift transmission was the big selling point with this tractor, enabling forward and reverse as well as gear selection to be controlled by this single lever, without the need to operate a clutch pedal. It’s a well-engineered and durable system, according to Nick Wright.

The engine should start easily, and Jim confirmed that his example starts on the button, even in cold weather. He did admit that it’s a bit smokey on start-up, though – and when the engine is being worked hard – but that’s just a characteristic of these six-cylinder diesels.

It’s also worth noting that the transmission valve chest is located on the side of the transmission on this tractor, and that some of the valves inside can be prone to sticking if the oil isn’t kept clean (debris settles at the bottom). Another good reason not to ignore routine oil and filter changes.

Moving to the front of the tractor, Nick’s advice is to “pay special attention to the condition of the prop shaft and look, in particular, for signs of wear in the universal joints. You’ll need to get underneath to assess these properly. Also, put the steering on full lock so that you are able to check for play in the steering joints and front hubs. On a machine that’s in good condition, there should be no appreciable play at the steering wheel; the front wheels should react without delay.”

Braking issues

“The power braking system is perfectly adequate when operating correctly, however, it is prone to getting air in the system, creating a spongy feel at the pedal. Bleeding may well be required on tractors that haven’t been maintained properly. But brake-related problems can also be caused by hydraulic fluid leaks from the pipework beneath the cab. This is quite common, and it typically caused by stress-related cracking in the metal pipes – Jim’s tractor was suffering like this when he bought it. A common mistake that some owners make is that they see a dribble of leaking fluid from a joint and their first thought is to tighten the bolt further which, typically, over-tightens it and makes the problem worse.”

The digital dash appears to have stood the test of time well, with switch and control problems reportedly few and far between.

It’s also worth noting that the exhaust silencer is big and heavy on this tractor, which places a lot of strain on the exhaust manifold beneath. This can promote the risk of manifold cracking, especially if the silencer gets accidentally knocked while in use. Replacement manifolds are available, but will cost over £1,000, plus £200 for the set of high-tensile steel bolts needed to fit it.

The engines themselves are strong and reliable, assuming regular oil and filter changes (every 200 hours), the use of a coolant additive at the recommended concentration and the correct adjustment of the tappets. As a general rule, anyone buying a new tractor is well advised to change all the fluids and filters – using the correct specification fluids and O/E parts – and flush the systems as soon as they take ownership. This is good workshop practice and is certainly something that we’d recommend for a 30 Series machine that’s new to you.

How is the cab?

As far as corrosion is concerned, your greatest attention should be focused on the condition of the cab. “Dirt and moisture tend to settle under the rubbers along the bottoms of the front and rear screens, especially on tractors that were kept outside and were rarely cleaned,” Nick explained. “This inevitably led to trapped water and eventual rusting. So watch for bubbling paintwork in these areas, and under the side and door windows, too.

“While cab condition will vary significantly from tractor to tractor, you should be aware that metalwork repairs needed to put bad cases right is both involved and expensive, whether it’s the outer panels or the frame that’s affected. Typically the corrosion works from the inside out so that, by the time problems start to show themselves under the paint, things have got pretty serious within. The presence of rusted holes in the cab would be a deal-breaker for many potential purchasers.

You can easily check for linkage wear during a pre-purchase inspection by pulling and pushing on the arms and looking for play in the splines of the bottom pivots.

“The doors themselves are vulnerable to damage. Some drivers would leave them open while driving, then accidentally catch them on a passing branch and distort the frame. There’s a hydraulic gas strut at the top to prevent the doors opening too wide, but these can fail, allowing the door to swing, unchecked, onto the wing-mounted stop, possibly causing further damage that way. Finally, the large mirrors can also take a pounding which, in turn, can damage the door frame onto which they are mounted.

While a tractor from the Ford 30 Series range won’t be to everyone’s taste or budget, it is an option that is gaining in both popularity and desirability. It’s the type of machine that can still be used for serious work, so for enthusiasts who are still actively farming it could make a practical and interesting, second-string machine. Of course, it’s not the sort of machine that you can go out and buy for the price of a secondhand Ford Fiesta, and purchasing one requires a significant investment.

However, it could be argued that these machines are now as cheap as they’ll ever be and that, from now on, their values are only heading in one direction, and that’s up. So, now could be the smart time to bag yourself one of these good-looking, powerful and refined workhorses built in the era before tractors became completely festooned with electronic gadgetry.

Cab corrosion – most typically along the bottom edges of the windows – can be a very experience problem to rectify, so be always be vigilant when buying.

WHAT TO PAY

Although the 30 Series remains a relatively new tractor by the standards of the machine typically featured in this magazine, the earliest examples are now 33 years old so, by that measure, they already fall into the ‘classic’ category.

Prices are still a bit variable at the moment, but they do appear to be on the increase. At the entry-level end of the market, you should expect to pay anything from £19,000 for an 8630 in need of work, up to able £25,000 for one that’s in good condition.

If you dance one of the range-topping 8830s, then the cheapest you’re likely to find will be about £20,000 while, for something at the top end of the condition scale, you should expect to part with £34,000 our so.

FORD 8630 4WD SPECS

| Production period | 1989-1994 |

| Produced at | Antwerp, Belgium |

| Engine: | Ford six-cylinder, turbocharged, diesel, 6.6-litre |

| Bore/stroke | 112mm x 112mm |

| Compression ratio | 15.6:1 |

| Max. power | 132hp |

| Transmission | Power Shift – 18fwd, 9rev |

| Dimensions | Length: 4,360mm (172in)

Width: 2,080mm (82in) Wheelbase: 2,660mm (105in) |

| Weight | 6,332kg (13,960lb) |

Jim Aikman (right) and Ford-trained tractor technician Nick Wright have nothing but good things to say about the 30 Series models.

OWNER’S VIEW

“The Ford 30 Series have started to appreciate; there’s no doubt about that, as far as I’m concerned. Only the other day I saw a couple of 8630s being sold, for £25,000 and £30,000. I bought mine – the one featured in the photos here – in the autumn of 2019, and it cost me about half the lower of those two prices.

“Built in 1992, the 8630 is by far the newest tractor in my Ford collection, and I was attracted to it partly because of its overall good looks, and partly because of the Power Shift transmission. It wasn’t in perfect condition when I bought it, but we’ve put it right now and I’m delighted with it, in every respect. It’s a great looking machine and I really enjoy driving and working it. What’s more, the six-cylinder engine makes a great sound!

“My tractor has just over 8,300 hours on the clock and, interestingly, we put it on a dyno recently and the results that came back surprised me. It recorded 137hp, which is higher than the book says it should have been producing when it left the factory 30 years ago! Overall, I think it’s a great advert for the underlying quality of this design, and I’m certainly delighted that I bought it.

Jim Aikman

This feature is from the latest issue of Ford & Fordson Tractors magazine, and you can take advantage of a money-saving subscription simply by clicking HERE

Previous Post

Coventry Transport Museum visit

Next Post

1945 Guppy-type American submarine to be scrapped