Buying a Fordson E27N

Posted by Chris Graham on 31st March 2020

In its 75th anniversary year, Chris Graham champions the Fordson E27N; a vintage tractor with bags of character and a bargain price tag

Despite its many virtues, the Fordson E27N isn’t a particularly popular tractor with buyers, nowadays. Originally christened the ‘Major’, the model is now widely identified using Ford’s factory code for it – ‘E’ stands for made in England, ’27’ is the power output and ‘N’ is Ford’s designation for an agricultural vehicle.

‘Stopgap’ is the term often used to describe the Fordson Major; a tractor that arrived immediately after the Second World War, and was intended as a stepping stone between the pre-war Standard N and the New Major E1A, launched in 1952. But, classifying the Major – or Fordson E27N as it’s now popularly known – in this way belittles the achievements of what turned out to be an amazingly successful, much-liked and extremely durable tractor.

Granted, the new model relied heavily on the Standard N it replaced for key componentry but, in many respects, Ford’s hands were tied in this regard. The vice-like grip of enforced wartime shortages that ruled both everyday life and industry in an exhausted UK leading up to the end of WW2, made such economies inevitable. Ford was forced to make do and mend so, arguably to devise and produce a tractor that turned out to be as good as the E27N against that backdrop, was akin to pulling a rabbit out of the hat.

Overlapping production

Being launched in March, 1945, the E27N’s arrival overlapped Standard N production by a few months; the latter continuing to roll from the Dagenham line until the summer of the same year. Inevitably, the new model was more evolution than revolution, and Ford was wise to bring forward many of the most successful aspects of the popular and influential Standard N, including the venerable but ageing four-cylinder, 4.4-litre petrol/paraffin, side-valve engine, the three-speed gearbox (with a modified motion shaft), braking system, fuel tank plus other ancillaries including the air cleaner and exhaust manifold.

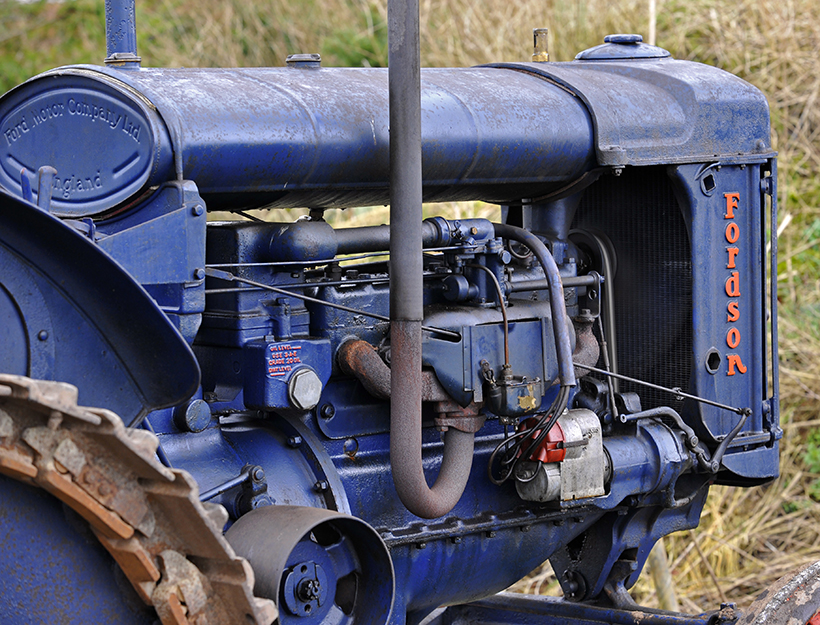

This is a ‘land utility’ model, with a fixed track front axle. A ‘row crop’ version, with adjustable front axle, arrived in 1946.

But one area where Ford did invest some development cash was at the rear end, where a new reduction final drive was specified to replace the worm gear-based version used on the N. This improved the tractor’s ground clearance, was more efficient (better fuel economy) and, importantly for Ford, was said to be cheaper to manufacture. Overall, the E27N was taller than the Standard N, and its wheelbase was longer. It was a little heavier, too, but Ford countered this by tweaking the engine so that it revved a little higher, boosting power to 27hp (hence the E27N factory designation). But there was no getting away from the fact that the engine was ‘old school’; its pump-less, splash-feed lubrication system was dated even when the model launched, and was to prove problematic down the years in the field, when penny-pinching farmers ignored the engine’s oil change requirements.

Lubrication issues

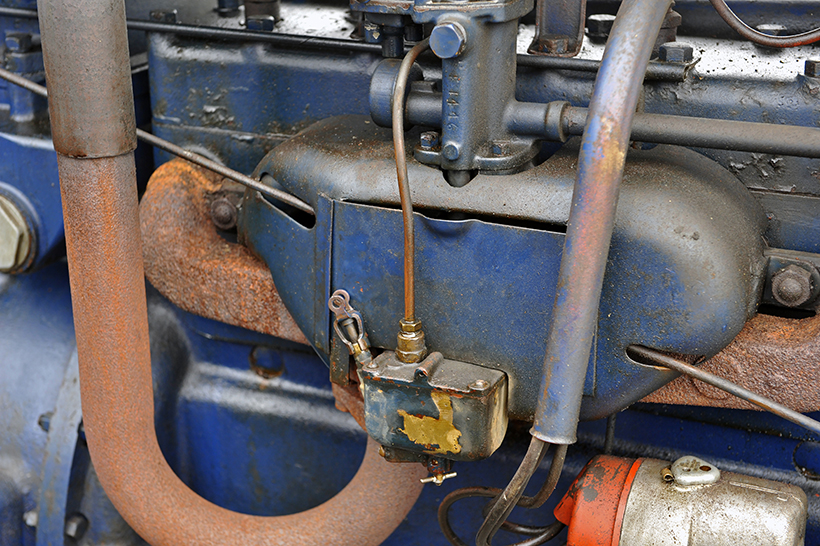

Nowadays, of course, the much-improved quality of modern engine oils means that rebuilt side-valve engines will run happily for years and years, assuming decent, basic maintenance. But, the inferior lubricants of yesteryear – combined with an often slapdash approach to routine maintenance – frequently led to trouble. There’s an oil delivery tube that runs from the top of the flywheel, diagonally down to supply the middle and front main bearings with essential lubrication. But if the engine oil is worked too hard, this pipe becomes blocked with sludge and the bearings are starved of essential oil. The centre bearing is the one that typically suffers most.

Consequently, it’s not uncommon to come across E27Ns with knocking engines today, and centre main bearing wear is frequently the culprit. In bad cases, the crankshaft may even start ‘whipping’, adding all sorts of additional stresses and strains, so engine knocking should never be ignored. The bearings were white-metaled, so are relatively expensive to deal with, which is why many owners opted for the head-in-the-sand approach. Shims are available for adjustment purposes, but removing the slack in this way can actually worsen the situation. The only real solution is to deal properly with the bearings.

Ford utilised the tried and trusted side-valve engine, from the pre-war Standard N model, when the Fordson Major (E27N) was launched in 1945. The cooling system contains 10 gallons of water.

The E27N was a blue tractor, and remained so all its life. This was complemented with orange wheels, but the shade of this varied. For the first year, Ford used the pale, Harvest Gold shade seen on the pre-war Fordson N. Then, in about 1946, this was switched to a much brighter orange, probably in an attempt to liven things up a bit to help with the marketing. Ford was well aware of the increased and colourful competition it was facing from the likes of Nuffield and McCormick International.

The E27N began its production life as the Standard Agricultural on steel wheels, but tyres were introduced as a more comfortable alternative later in 1945. The basic ‘land utility’ model, with fixed track front axle, was joined by a ‘row crop’ version in 1946, which featured an adjustable front axle and independent wheel brakes. Also, that year, Ford introduced the provision for a hydraulic, three-point linkage as well as the option of electric starting. A few years later, in 1949, a modified exhaust manifold was introduced that included an improved and more efficient vapouriser, making the engine easier to start and more efficient.

The manifold design was changed by Ford in 1949, to a version that featured an improved vapouriser.

More power

As a solution to the limited power and rather antiquated technology of its side-valve engine, Ford decided to make a much more powerful, six-cylinder, 4.7-litre diesel engine available as a factory-fitted option. In 1948 it began sourcing a motor from Peterborough-based Perkins Engines Co Ltd and, although an expensive choice, the availability of this more accomplished powerplant did much to enhance the image of the E27N. Boasting a hefty power output of 46hp and, with more usable torque than the four-cylinder Ford engine, the Perkins P6 was an instant success.

The reputation the new engine prompted plenty of P6 conversions during the 1950s, with farmers ditching their often clapped-out side-valves for the more reliable and durable diesel motor. Likewise, the switch has also proved popular among enthusiast owners in more recent times, who’ve been tempted by a more practical and economical engine option.

Another engine swap that proved increasingly popular utilised the four-cylinder Perkins L4, which became available in 1953. The unit was built as a dedicated, agricultural engine (which the P6 wasn’t), and was particularly strong with regard to low-down torque. It represented a slightly cheaper option as a retro-fit than the P6, which made it attractive to farmers. Today, L4-engined E27Ns are highly sought-after, despite the engine’s reputation for being difficult to start.

What to check

For some practical insights into the dos and don’ts of buying an E27N, I took a trip to Cheshire to consult see Phil Moston; a man whose been involved with old tractors virtually all his life and, for his day job, runs agricultural engineering firm, PA Moston (tel: 01606 737464). Phil’s first piece of advice was that any prospective purchaser looking at a tractor should always start with the basics.

“As always, start by assessing the level of general wear and tear,” he explained, “and make a judgement about how this compares with your expectations for the tractor. If you’re looking to buy a machine for restoration, then something that’s obviously scruffy, with odd wheels and rusty tinwork, isn’t going to put you off. In fact, the more down at heel a tractor looks, the better your chances of striking a good deal with the seller!

There are no instruments on the E27N, so driving one is very much a back to basics, seat of the pants-type of operation, but none the worse for that!

“However, if you’re after something that’s going to be a reliable runner, and which you hope to take to a few shows straight away, then obvious defects are much more of a problem. It always makes sense to take somebody with you who is experienced with the tractor; doubly so if you’re new to the hobby.

“The first thing that most people check is the amount of play in the steering. Rotate the steering wheel from side to side and, if there’s more than about an inch-and-a-half of free movement. If you spot any movement at all at the track rods ends, as the steering is operated, then you know that one of the first jobs will be a complete steering overhaul. The steering joints always wore quite quickly on the E27N because the original seals weren’t great. Water and dirt got into the joints, and wear was the inevitable result.

“The E27N was available with two options of gearbox from new; ‘high top’ or ‘low top’ units, governing the maximum speed of the tractor. Buyers could also specify a ‘special ratio’ (SR) version in either case, which offered closely-spaced first and second gear ratios, to assist with ploughing and cultivation operations. The type of gearbox fitted can be an important consideration with regard to your eventual plans for the tractor. For example, if you’re hoping to take part in road runs, then a ‘high top’ is the obvious choice. But, if your aim is ploughing, then a ‘low top’ ‘box will do the job perfectly well.”

The ‘high top’ gearbox will allow an E27N to run at nearly twice the speed of one fitted with the ‘low top’ option. But, having said that, we’re only talking about 8mph versus 4mph, so don’t get too excited! Phil explained: “The gearbox type fitted is identifiable from a number and letter sequence that’s stamped into the bell housing flange (on the right-hand side of the vehicle). If this includes ‘4.3’, then you’re looking at a ‘low top’ ‘box, while ‘7.75’ indicates the ‘high top’ transmission which, for many buyers, is the more desirable spec.”

The rear wheels on early E27Ns featured six studs fastening them on to the hub, and a ring of 10 studs attaching the wheel centre to the rim. This latter stud number was reduced to eight in 1946, presumably as a cost-saving exercise.

Bright ideas

Continuing with your general inspection, take time to check the condition and operation of the lights, if any are fitted. These were an optional extra on the E27N, and used headlamp units taken from a Ford Prefect E93A van. Nowadays these are expensive to replace, so check them carefully. They contain the sidelight, dipped and high beam bulbs all in the single unit, and can easily cost you £500 for a replacement pair. There was only a single, rear light fitted by Ford.

“Next you’ll need to start the engine to see how it runs,” Phil added. “There are a lot of noisy-engined examples out there and, ideally, these are best avoided. The starting procedure for a side-valve-engined E27N involves first draining the carburettor of any residual paraffin – the engine must start on petrol only – then turning off the paraffin control tap. Open the throttle by four clicks, pull the choke lever almost fully open, then you’re ready to crank the handle.

Draining residual paraffin from the carburettor is an essential part of the starting procedure. The engine must be fired-up on petrol alone, then switched to paraffin once it’s warm.

“The side-valve engine doesn’t have a great reputation as an easy starter but, more often than not, the problems are caused by a failing or broken magneto. It’s possible to get magnetos reconditioned, which really is advisable of you’re after long-term reliability. It’s not a cheap process though, typically costing about £400, but the modern sealant materials used should guarantee faultless performance thereafter.

“Ideally, assuming all’s well with the electrical and fuel systems, and the correct procedure has been followed, it shouldn’t take more than three or four turns of the handle to get the engine running. However, remember that even a small amount of paraffin in the system will make starting difficult, so don’t dismiss a ‘bad’ starter out of hand.”

There’s a knack to starting the E27N. Most problems experienced relate to the correct procedure not being followed, or issues with the magneto.

How’s it running?

“Once the engine fires,” Phil continued, “the choke will need to be adjusted to keep it running, during which time you want to be listening carefully for any, expensive-sounding mechanical knocking. Of course, the old side-valve isn’t the quietest engine in the world at the best of times, which is why it’s always sensible to have a knowledgeable pair of ears with you to recognise the tell-tale signs of trouble. Engine smoking shouldn’t be much of an issue, so be suspicious if the exhaust is belching. Problems with the vapouriser can be at the root of this.

“As a rule of thumb, the engine can be switched over the paraffin running after it’s been idling for about five minutes, although this does vary from unit to unit. It really comes down to experience. Switch it too early and the engine will simply smoke and then stall so, getting used to a new engine always involves a certain amount of trial and error.

“With the engine suitably warmed, you’ll then need to drive the tractor to check the performance of clutch, gearbox and brakes. But make sure you understand the pedal layout first. Assess the gear selector for play; it should be positive and too much movement can be an indicator or wear, and will make it more difficult to find the gears (arranged in a conventional, ‘H’ pattern) than it should be.

“Although the three-speed gearbox fitted to the E27N was a sturdy unit, the potential for wear is something you should be aware of. The maintenance schedule called for a transmission oil every 1,000 hours but, regrettably, this was frequently ignored. So, it’s always a good practice to change all fluids (engine, gearbox and final drive oil, plus coolant solution) at the earliest opportunity after buying.

“On this tractor, the gearbox sits higher than the final drive, and defective seals in the ‘box can allow lubricant to drain down into the final drive, leaving the gearbox short and vulnerable to increased wear. The seals were made from leather and, if allowed to dry out due to long periods of inactivity, they start allowing oil to escape.

“Fortunately, it’s simple to investigate this situation. Check the oil level on the final drive’s dipstick and, if it’s found to be higher than it should be, then oil is probably escaping from the gearbox. Internal wear will be indicated by gears that are hard to engage, and noisy operation.

“Don’t forget to check the operation of the handbrake. This was never the most effective system and, as a result, used to get left inadvertently on, causing the steel discs to wear prematurely. The main brakes on the E27N are just about OK if they’re in good order, but a big problem on this tractor is that they suffer with oil contamination. The shafts on which the brake drums are mounted are only short, which accelerates seal wear and allows oil out from the final drive to contaminate them. The shaft was lengthened on the subsequent E1A model, which solved the problem by reducing movement at the seal.”

Cosmetic issues

As far as the bodywork’s concerned, Phil’s advice is that: “most attention should be paid to the condition of the footplates and the wings, as these seem to be the most prone to rusting. But, given the age of these tractors, you have to expect that rust can strike anywhere. Replacement panels are available, so corrosion isn’t the end of the world, but it will obviously add to the cost of the project.

“However, a significant advantage with the E27N is that a good proportion of the parts typically needed are now available from small-scale producers in the UK. Part of the reason for this is that there isn’t much of a worldwide demand for E27N spares, so it’s simply not worth the big pattern part makers putting time and money into them. This has encouraged the specialist suppliers here and, while the prices they charge aren’t the cheapest, the items they produce are accurate and well made; they’re enthusiasts as well as parts producers, so have a vested interested in making sure that things are right.

Phil Moston has been involved with old tractors for most of his life, and is a great admirer of the Ford and Fordson machinery.

“Remember, though, that these parts are often produced on a one-off basis, so ordering can require a little patience, but the wait is usually worth it. Three highly-regarded companies that specialise in the E27N, and that I can recommend, are Engleman Farms Ltd (tel: 01799 522213), Cox & Turner Engineering (tel: 01935 826816, coxandturner.co.uk) and Cotswold Vintage Tractors (tel: 01386 841983, cotswoldvintagetractors.com).”

There’s no doubt that the Fordson E27N represents a fascinating and still practical option for the enthusiast owner. Better still, as you’ll see from the ‘What to pay’ panel, you won’t have to spend a fortune to buy one. But what’s not so encouraging is the model’s recent popularity slump.

One reason for this sad trend could be the ever-diminishing number of enthusiasts with first-hand memories of the E27N actually working. With so much of the old tractor market being driven by nostalgia, most buyers choose models that they can connect with and, generally, that’s often the machines they remember from their formative, teenage years.

But I think that those who ignore the E27N really are missing a trick. Given that you can still buy one of these characterful machines at such an affordable price, and become the owner of a machine with genuine character, the E27N represents an increasingly rare commodity these days – something that’s interesting, something that’s different and something that’ll deliver the sort of ownership experience that very few other tractors can match today.

• PEDAL CONFUSION

One, very important practical aspect to understand with the E27N – and something which sets it apart from any other similarly-aged machine – is that, for whatever reason, Ford decided to locate the clutch pedal on the right-hand side of the vehicle, and the brake pedal on the left.

For UK drivers, this is completely counter-intuitive, and at odds with everything we’re used to, which can make the E27N a difficult tractor to adjust to. While most people will get the hang of it for off-road driving situations, it’s on the road where problems can arise.

In an emergency-type situation, when a rapid reaction is required, the natural tendency is to hit the brake pedal with your right foot, as you would in your car. When on an E27N, though, all that’ll do is disengage the clutch. So, be warned!

• WHAT TO PAY

The cheapest, non-running E27Ns are currently available for £1,000-£1,500 while, for a tractor that’s in running order but requires maintenance/renovation work, you should expect between £2,000 and £3,000.

At the top of the price range, it’s the P6-engined models that attract the highest prices, with the best examples changing hands for £16,000-£18,000. However, smart but not Concours, side-valve-engined examples are out there for about £5,000.

To subscribe to Ford & Fordson Tractors magazine, simply click here