Buying a Massey Ferguson 135

Posted by Chris Graham on 12th December 2021

Chris Graham profiles the Massey Ferguson 135; a universally popular model that may just represent the perfect first-timer’s tractor.

The Massey Ferguson 135: Early versions, like this 1965 example, featured rounded mudguards and red wheel centres, but the latter didn’t last long as the factory soon decided the two-tone effect was a cosmetic extravagance. Wheels became all-silver from late 1965 onwards (apart from the PAVT-type examples).

Massey Ferguson’s introduction of the 100 Series tractors – named The Red Giants by the marketing men – represented a very important development for the company. Building on the sales and performance successes of the MF35X and MF65 MkII models, the 100 Series was intended to create a whole new, modern image for the domestic tractor market around the world.

Here in the UK, those two models got transformed into the MF135 and MF165 respectively, and were launched – together with the brand new MF175 model – at the 1964 Smithfield Show, in London.

Entry-level model

Although there was a smaller, MF130 model created for the French market, the 135 was the entry-level machine in the UK, and was an instant success. Outwardly, it looked very different from the MF35X it replaced, with more contemporary and sharply-styled new bodywork, although traditional, shell-type mud guards were retained on the earliest models.

These were updated to a more angular, flat-topped design in 1965, that was more in keeping with the rest of the 135’s tinwork, and featured integral, cast aluminium hand grips and front side lights. Then, a couple of years later, the factory switched to an all pressed-steel mud guard design which, presumably, was a cost-saving measure.

The silver headlamp bezels were aluminium to begin with, until plastic housings became available as a more cost-effective solution. The exhaust silencer is, in this case, finished in white, as per factory spec. Many owner nowadays opt for silver or black.

Aluminium had also been used for the headlamp casings on the first 135s, but these were replaced by plastic alternatives in 1969. Another money-saver saw the originally two-tone wheels (red centres, silver rims) changed for simpler, all-silver finish after only six months of production.

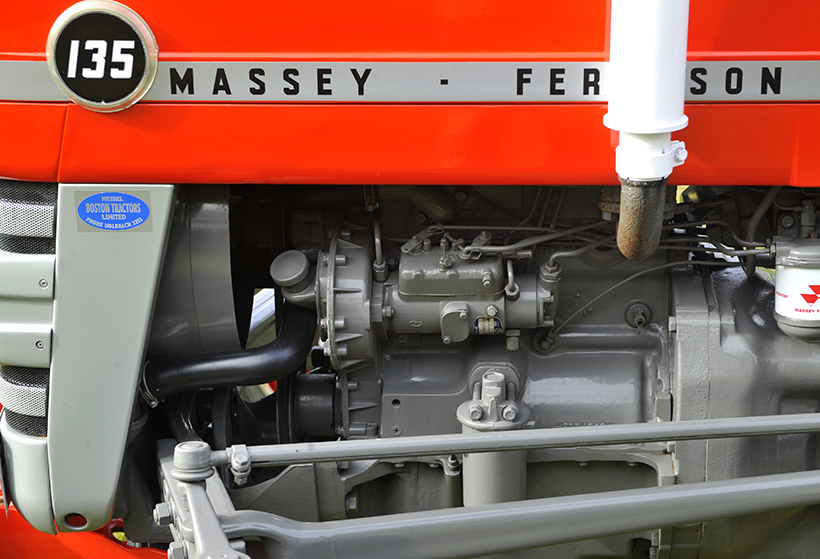

Under the skin, though, there were plenty of similarities with the previous model. Power still came from the 45.5hp, Perkins AD3-152, 2.5-litre, three-cylinder, direct injection diesel engine, but there was also a petrol-powered version. This utilised a four-cylinder unit supplied by the Standard Motor Company, but the variant wasn’t a popular seller here and was aimed primarily at export markets (it sold especially well in Denmark and New Zealand).

Tried and trusted

Of course, the Perkins engine was a tried and trusted performer, and the early models featured an oil bath air cleaner. This was changed – early in the 1970s – to a dry element-based system, with a replaceable filter linked to a service indicator below the dash panel. The engine was supported by a 12-volt electrical system and fuel supply was managed by a CAV injector pump. A comprehensive instrument cluster provided gauges for fuel level, coolant temperature and oil pressure as well as a tractormeter and an ammeter.

Single or double Auburn clutches were available, linking the engine to the familiar six forward and two reverse gear transmission also taken from the 35X. A Multi-Power option was available for those who wanted it, although was only fitted on dual clutch-equipped models. It offered drivers on-the-move changes, even under load. However, this was only up or down from the selected gear, and the system couldn’t handle complete ratio changes. Another limitation was the fact that engine braking was only available with Multi-Power engaged.

Note the position of the small, ‘Ferguson System’ sticker here, that sits on the tinwork above the air cleaner oil bath housing. This is the correct positioning for early models like this, but lots or restorers incorporate it into the ‘Massey Ferguson’ decal strip above. In fact, this relocation only happened when the wheels switched to an all-silver finish.

An ‘updated’ MF135 was officially introduced in 1971, and featured a number of significant enhancements. As already mentioned, the air filtration system was changed but, perhaps more significantly, the fuel tank capacity was increased from 8.5 to 10 gallons, which also involved raising the height of the radiator grille by 1.5in. Also, as a knock-on consequence of the higher bonnet, the steering column was lengthened. Perhaps more significantly, the old-style, swept-back front axle was also changed at this point for a straight, box-section design that was both stronger and cheaper to produce.

Alternative models

Narrow and vineyard versions of the MF135 were also available, with conversions to standard models being undertaken in Kent by Lenfield Engineering, using parts shipped from the Massey Ferguson factory at Beauvais, in France. The narrow version was simply, narrower, than the standard model (shorter trumpet housings and half shafts), but the vineyard version was both narrower and lower, representing a more complicated engineering job.

A cab was offered right from the start for the 135, but the earliest ones – made by Duple Coachworks, in Blackpool – used glass fibre panels on a lightweight steel frame and plenty of glass to ensure good visibility. However, when driver safety started to become an issue in 1970. Rollover protection became a requirement, and the mountings for this necessitated a re-design of the gearbox casting. Then, in 1976, more legislation set a standard for the maximum noise level (90db) permitted inside a tractor cab, so sound-deadening material was added to every surface possible to achieve the necessary result.

To say that the MF135 was a sales success is something of an understatement. Between 1965 and 1971, Massey Ferguson produced 322,428 examples of the model than, between 1971 and 1979, churned out an additional 90,725 of the updated version. Over the 14-year production run, 413,153 rolled from the factory gates in Coventry. Now, just over 40 years since the last example was made, the MF135’s place in the affections of enthusiasts around the world is set in stone. It’s become an incredibly popular tractor for experienced showmen and novice owners alike.

The MF135 benefitted from a comprehensive instrument array. Not the centrally-placed tractormeter. This was offset to the right on later models. Also, the tractor’s all-important serial number can be found on the riveted-on plate below the instrument cluster, the top of which can just be seen here.

Buying advice

For some down-to-earth advice on buying an MF135, I took a trip Holbeach, in Lincolnshire, to consult Ferguson and Massey Ferguson enthusiast and experienced restorer, John Sharpe. Having completely renovated his 1965 model way back in 2001, the present condition of John’s 135 is testament to the quality and thoroughness of the work he undertook all those years ago. Unsurprisingly, he’s a many who understands his tractors and, as such, is well qualified to offer experienced-based hints and tips for newcomers considering one of these versatile and still incredibly popular tractors.

The first point John made, as we stood in the garage with his gleaming, 1965 MF135, was that buyers always need to be clear about what they want their tractor for. “The use to which would-be owners intend to put their new machine should be a big factor at the buying stage,” he explained. Perhaps the owner wants to take part in road runs, attend shows or actually work the tractor on a smallholding or in ploughing competitions.

“They may also be looking specifically for a restoration project or, alternatively, want a tractor that’s already complete and usable from day one. I also believe that it’s important for buyers to decide how important originality is to them, and whether they’re keen to own a machine that’s correct in every detail. All these factors have a bearing on the sort of tractors you’ll be looking at, and how much you’re prepared to spend.”

Registered or not?

John continued: “Be aware that if you want to a tractor on the road, it’ll need to be registered for that purpose so, if it isn’t when you buy it, you have that process to negotiate, too. Doing this requires, at the very least, the tractor’s serial number, but I don’t believe that it’s as easy as it used to be to get an unregistered tractor added to the DVLA database. Authentication – typically by a knowledgeable club official – will be required to reassure the authorities that the machine is what you claim it is, and only then will they issue an age-appropriate registration number.

This is the extremely reliable, 45.5hp, Perkins AD3-152, 2.5-litre, three-cylinder, diesel engine which powered most MF135s. A petrol-powered model was available with an engine from the Standard Motor Company, but most went for export.

“The whole process will be more complicated if the serial plate is missing from the panel beneath the steering wheel (the panel can be missing altogether, or the number may have become illegible due to years of wear from the driver’s left knee). Ideally, the tractor you buy will have a logbook and a numberplate (or a painted-on number), confirming the original number and making it possible for it to be re-registered for road use with that.

“The worst option is to end up with a Q-plate! I’ve heard that once one of these has been assigned, the vehicle can’t be switched back to an age-appropriate registration, so be warned if you’re considering a tractor that’s already carrying a Q-plate.”

Restoration advice

If you’re looking at a restoration project, then John says that it all boils down to the condition of the tinwork. “All the mechanical parts needed to rebuild one of these tractors are available nowadays from specialist suppliers, and are of reasonable quality,” he told me. “Unfortunately, the same can’t be said for many of the remanufactured panels being produced these days. Those items that originate in places like Turkey or the Far East, tend not to be as good as the originals.

“So, the golden rules with major parts such mud guards, bonnets, foot rests, front grille assemblies and seats, is to ensure all the originals are present, and to repair any that are damaged, if possible.” The bonnet is a key component on the MF135, and John says that it’s worth entrusting even quite beaten-up but original examples to a professional body repair specialist. There will be a cost involved, but it’ll be worth it to ensure a decent job and retain the good-fitting original.

The seat was un-sprung on early 135s, but featured comfortable cushions. The design was updated later in the production run.

“Remanufactured, pattern panels often fall down on the small but important details,” John added. Often, with replacement mud guards, for example, you’ll find drillings all over the place, which were never on the original. This – presumably – is done to allow the parts to be fitted to the widest possible range of tractors. Others may show metal joints or swage lines in the wrong places, which is a problem for those who want to create an authentic-looking restoration.”

Judgement call

If you have no information about the provenance of a tractor, then you’re left having to make a judgement based on nothing more than the machine’s overall condition. As always, the key factors are how hard the machine was worked and how well it was looked after during that period, and in subsequent years. There will be rare occasions, as in John’s case with his 135, that a tractor will come with a creditable back story. But, in most cases, there will be little clue about how it’s been used in the past, so your decision to purchase or not will come down to your own gut feeling about the machine.

Hour meters can be checked, of course, but there’s no telling whether the figure displayed is accurate. However, if there’s an obvious miss-match between the claimed hours and the general state of the tractor, then that’s a warning sign. Obvious tell-tale signs of wear and tear, such as heavily worn pedals, excessive play in the steering and gear lever, dented tinwork and non-existent brakes all speak of a hard working life and a general lack of care and attention.

While none of these issues are deal-breakers if the tractor is for sale at the right price and/or you have the budget, time and skills needed to put things right, having to replace exterior componentry isn’t always ideal, as John explained. “While most parts are available for the MF135, the quality of some of them isn’t great. For example, you can buy remanufactured pedals, but they’re not exact replicas. Import details like shaft shape and thickness are incorrect, so they look instantly wrong to anyone who knows how they should be.”

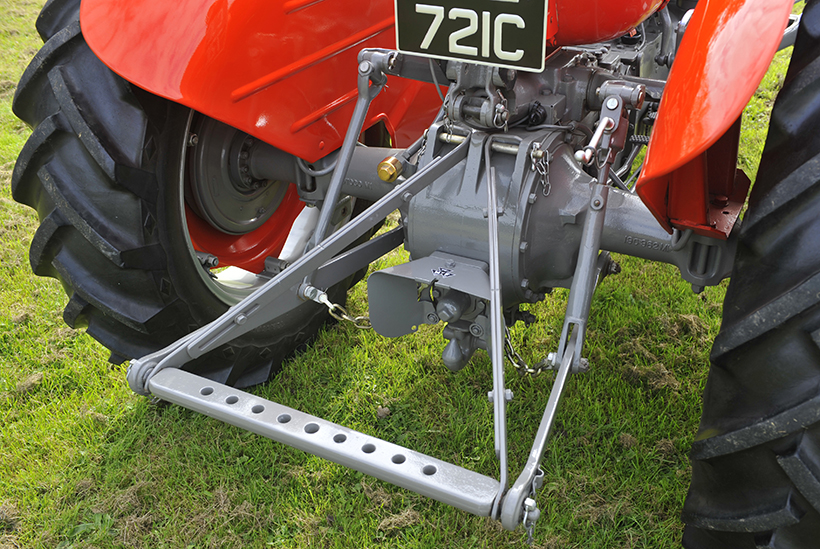

The 135’s hydraulics are both reliable and functional. The tractor will happily pull a two-furrow plough.

Reliable power

The good news, with regard to the engine, is that the Perkins three-cylinder diesel engine that powers most MF135s is all-but bulletproof. It’s an engine that was used in many different applications and was thoroughly established before appearing in this model. So, even if you do come across a badly worn example that suffered with years of neglect and mechanical abuse, most problems will be straightforward to rectify.

You can by replacement cylinder heads, short engines, plus all the internals parts needed, so all bases are covered. Essentially, everything is doable so, as with any other renovation issues, it simply comes down to whether or not you have the inclination and experience to tackle the work yourself, or the funds available to pay somebody reputable to do the job for you.

John says that the transmission is tough and durable, and that serious problems in this department are very rare. However, if you notice that the rubber gaiter at the base the base of the gear lever has perished, then it’s likely that water will have got inside. Consequently, check the condition of the oil in the gearbox; there is a dipstick, so use it to see if the contents look like milk or oil. Apart from this, just about the only gearbox-related issue commonly found is worn selectors.

A simple check for this involves attempting to twist the gear lever, as you might rotate a screwdriver when tightening a screw. If you detect excessive rotational movement while doing this, then the chances are that the selectors beneath are badly worn. The danger then is that, during certain changes, the base of the lever can pop out of the selector, leaving the gearbox stuck in gear and the lever floating ineffectually above it. This can be temporarily rectified by removing the oil filler plug???? and using a screwdriver to realign the selectors with the base of the gear lever.

The battery is found beneath a hinged panel towards the rear of the bonnet. The hinges were often broken and it’s quite common for the compartment cover to be missing altogether. This second, hinged bonnet cover reveals fuel and coolant filling points.

Fluid dynamics

The hydraulic system and rear axle are both fundamentally reliable, although age-related axle oil seal failure can result in oil leaking out and finding its way onto the brakes. Putting this right necessitates the removal of the half-shafts which isn’t an easy job, but it’s doable, according to John.

With regard to the hydraulics, John says: “A useful, practical test can be to put your foot under the lift arm and raise it slightly, to note how much free play there is in the system. Then, if you’re feeling a bit cheeky, you can also test the system with the engine running, by standing on the lift arms and seeing if the system is capable of lifting you up. Obviously, this isn’t a realistic, real-world test, but it will at least demonstrate that there is some power in the system, and that it’s operating.

“However, the only true test for any tractor will come when you put it to work. Once it’s under heavy load, that’s when you’ll be able to see how the engine copes; whether it overheats, dumps its coolant or starts leaking oil. If you’re looking at a Multi-Power-equipped model, you can test that system by driving the tractor up a slope in ‘high’ setting, stopping and then depressing the clutch pedal to the first stage point. At this point the tractor should remain stationary if all’s well; if not, it’ll start rolling backwards. Depressing the clutch pedal fully will, of course, free it to roll.”

Choose carefully

As we’ve already mentioned, the beauty of the MF135 is that it’s a tractor that you can virtually rebuild from new parts sourced from well-known specialist suppliers. So, in some respects, having that kind of ‘safety net’ means that the penalties for buying a ‘lemon’ aren’t disastrous. But, as we’ve also noted, the use of remanufactured new parts isn’t always the ideal solution, especially when they’re on the ‘outside’.

Owners like John Sharpe consider that the MF135 offers just about the perfect tractor for the first-time owner new to the hobby.

The inaccuracy of some of the components and panels available nowadays can detract from the overall appearance of a restored tractor, which is why the retention of original parts is so important. The popularity of the MF135 means that good quality, secondhand parts are becoming increasingly hard to source, which is why bagging yourself a complete, unmolested example is such an advantage.

Original-condition 135s do still come up in sales and auctions, so there’s always hope for the patient buyer. John told me that he saw a perfect example being sold recently; it was an essentially complete, original tractor (just missing its headlights) that sold for £5,600 (plus VAT and auction commission).

However, whichever example you eventually buy, you can be assured that the MF135 will tick all the right boxes. It’s a model that’s perfectly sized for the first-time owner; it’s not too heavy or too big, so is easy to handle, to store and to transport. Its straightforward design, and use of tried and trusted components, means that servicing, repair and ever full restoration are all within the grasp of the keen enthusiast. Couple this with the comprehensive spare parts availability situation, and it’s clear that the MF135 represents an immensely appealing proposition, whichever way you look at it.

OWNER’S VIEW: John Sharpe

“My MF135 was owned from new by a farmer who lived just a few miles away from me here in Lincolnshire. It’s a 1965 model, has just 6,000 hours on the clock and was known to both my grandfather and dad.

John Sharpe’s 1965 MF135 has just 6,000 hours on the clock.

“It hadn’t been taxed for several years when I bought it, but it came with its original registration number and matching serial number, so the application process was just about as simple as it could be.

“In my opinion, the 135 is the perfect all-rounder. It makes a great road run tractor; mine will easily do 16mph, although I usually set it at about 10mph, especially when I’m leading a run. It’s also ideal for those wanting to attend shows as, with it weighing just 1,500kg, it’s easy to transport without the need for a top-end 4×4 and, once on the rally field, it’s a model that always seems to attract plenty of attention.

“I also think that it makes a perfect first-time tractor for those new to the hobby. It’s so easy to live with and handle. Anyone can drive a 135, and a properly set-up example will have good steering and brakes. Don’t listen to people who tell you that the brakes are rubbish, because that’s simply not true. There’s plenty of stopping power for a tractor of this size, and systems that aren’t working effectively have either been poorly maintained, or are badly adjusted.

“The MF135 is also a genuinely useful machine for those who want to work it. While 45hp isn’t powerful by modern standards, the 135 remains perfectly capable of pulling a two-furrow plough very effectively. Also, in practical terms, it’s easy to get on and off as it’s not too high off the ground and, once in the driver’s seat, it’s not too cramped so is comfortable to drive.”

For a money-saving subscription to Classic Massey & Ferguson Enthusiast magazine, simply click here