Fabulous Fordson E1A buying guide

Posted by Chris Graham on 31st October 2021

Chris Graham spotlights the fabulous Fordson E1A range, and explains how to buy a decent example in this, the model’s 70th anniversary year.

The fabulous Fordson E1A remains an affordable and very appealing tractor, whether you want to restore, compete in match ploughing, go on road runs or simply own a large, attractive tractor.

The dawning of the 1950s brought with it new hope for a nation still labouring under the considerable after-effects of the bruising and protracted Second World War. Fordson tractors, which had done so much to help the country’s farmers revolutionise food production during those hard years, remained a dominant force in the market and, despite being something of a stop-gap model, the company’s E27N Major had been a rip-roaring sales success.

But Ford was understandably anxious to ensure that its next model represented a significant improvement over what had gone before. It wanted to produce a machine that was more powerful, more versatile and more productive, and its offering was the Fordson E1A range, popularly known as the New Major.

Heart transplant

Launched in November 1951, the New Major featured much more attractive, modern-looking, Empire blue-painted tinwork that cloaked a brand new engine. Gone was the antiquated, side-valve motor that had powered so many Fordson tractors in the past, and in its place sat a Ford-built D4, 3.3-litre, four-cylinder, overhead valve engine that could be powered by petrol/paraffin (E1A DKN), petrol (E1A DN) or diesel (E1A DDN). The petrol, and TVO versions cost about the same to buy, but those opting for a diesel-powered New Major needed to spend an extra £55, which was a considerable amount of money in the early 1950s, especially for cash-strapped farmers.

The Super Major benefitted from the introduction of Qualitrol draft control, a differential lock to enhance traction and disc brakes.

Consequently, everyone expected the TVO model to be the big seller, as the petrol/paraffin combination was the option with which farmers were traditionally most familiar. However, the easy-starting diesel proved to be an almost instant success, especially compared to the less economical and more temperamental TVO-powered alternative. The petrol version never really caught on the UK (apart from for industrial applications), but proved to be a decent seller on the export market.

But, engine and tinwork aside, the New Major still relied heavily on underpinnings from the previous E27N model, although a clever gearbox re-design resulted in six forward and two reverse gears; a significant, practical improvement over the original Major. Somewhat disappointingly, though, the overall power figures weren’t that exciting, with maximum outputs ranging between 34 and 37hp, depending on the model. Awkwardly for Ford, the Perkins P6-powered version of the outdated E27N could deliver 41hp so, evidently, more development work was required.

Ford’s engineers worked hard over the coming years to address the power shortfall and, in 1957, a Mark II version of the engine arrived (from serial number 1425097). This came together with the option of ‘Live Drive’ for the PTO, although there was very little fanfare from the factory about these developments. At the same time – and with similar levels of reserve – the TVO-powered version disappeared from the range. It seems that Ford was keeping its marketing powder dry, and resisting the temptation to promote the power increase until the arrival of the Power Major, which happened during the summer of 1958.

This is an early, petrol/paraffin New Major built to a very basic spec; the original customer didn’t bother lights, a pulley, hydraulics or even a handbrake! An underslung exhaust was a feature of early models like this, and the air pre-cleaner was tucked away under the bonnet on all pre-’53 models.

Significant upgrade

Boasting a much more respectable 51.8hp (thanks mainly to camshaft and fuel pump tweaks), the Power Major also saw the relocation of the instrument cluster (and throttle lever) to a much more convenient binnacle beneath the steering wheel. However, the Power Major’s production life was to be a short one as, just two years later, the Super Major at the Smithfield Show, in London.

This was another significant step forward for the E1A as, although things under the bonnet remained much about the same, the Super Major benefitted from the introduction of Qualitrol draft control, a differential lock to enhance traction and disc brakes. In addition, the headlights were moved from their traditional, external location on either side of the nosecone, to a far less vulnerable position within the twin radiator grille panels. This was a popular seller, and provided the reliable, working backbone on many farms across the UK, and around the world.

The E1A’s final iteration appeared in 1963, as part of Ford’s final flourish for the Fordson brand. The blue and grey-liveried range included the New Performance Super Major, complete with a Minimec fuel pump-equipped diesel engine that pushed power output to 54hp. But the designers also addressed both gearing and PTO speed issues on this model, too. Previous E1As had been criticised for not having the PTO power needed to run the ever-larger implements being introduced, so an increase in engine speed dealt with that. Gear ratios were adjusted, as well, improving low-speed control and usability.

This is a 1954 Diesel Major with its original, Ford-built D4 engine. Other original and desirable features include the single rear light, period headlights (lenses domed on pre-’58 models, flat thereafter) and the dome-topped air cleaner inlet. The latter changed to a flat-topped design in 1954, which was more effective at removing dust.

But the New Performance Super Major’s life was an all-to-short one as, in 1964, Ford ended tractor production at Dagenham, and launched a whole new range of Ford-branded models that were manufactured at the new production plant in Basildon.

Buying pointers

For some practical insight into the dos and don’ts of buying an E1A, I took a trip to Cheshire to consult Fordson enthusiast Phil Moston, who runs engineering firm PA Moston (tel: 01606 737464) in Middlewich. After many years spent repairing, restoring and owning Ford and Fordson tractors of all sorts, Phil is well placed to offer experienced-based advice.

The first point he made to me was that it’s important always to take your time assessing the overall condition of any prospective purchase. “The ideal is to find a tractor that’s essentially original but, of course, machines like that are becoming increasingly few and far between nowadays,” Phil told me. “But, with the youngest E1A now being nearly 60 years old now, the chances are that most will have been messed around with to some degree.”

Phil Moston is a big fan of the Fordson E1A, and his collection includes both standard and modified examples.

Of course, much depends on what your intentions are for the tractor; overall condition might not be an important issue if you’re planning a full restoration, but originality and mechanical integrity may be more important if you want a machine to use and enjoy straight away. Inexperienced buyers are always well advised to take an expert with them, who can assess a tractor’s originality, and offer informed guidance on what might already have been done to it. Perhaps it’ll only have been fitted with a new headlamp, or a pair of new mudguards or, at the other extreme, its engine may have been swapped. Phil added: “Everything depends on the quality of the work that’s been done.

In many respects, it’s better to opt for a down-at-heel but original example than one that’s been messed around with. Putting right other people’s sub-standard restoration work can be a frustrating and needlessly expensive process.”

He continued: “In my experience, the most significant problem to affect the Fordson E1A, from a renovation point of view, concerns the tin work. All mechanical issues and there are typically few – can be dealt with and rectified with new parts which are, by and large, affordable and fit for purpose. But rusty or damaged panels are a different matter. If you don’t have the skills needed to make welded repairs, beat out dents using a hammer and dollies, then refinish the surface effectively with minimal filler, primer and topcoat, then the only alternative is modern, pattern part panels.

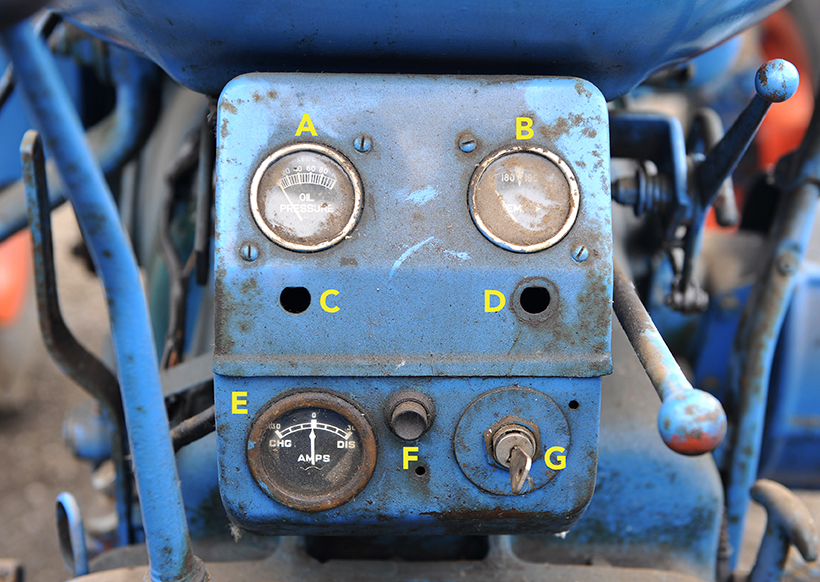

The original dash panel was mounted low down and consisted of the following: A – Oil pressure, B – Temperature, C – Starter control (not fitted), D – Starting device (not fitted), E – Ammeter, F – Horn, G – Ignition key (also incorporated lights switch, when fitted). The gauges were relocated to a binnacle beneath the steering with the introduction of the Power Major, in 1958.

Panel issues

“The disappointing reality is that the quality and fit of some of the reproduction panels – many of which are sourced from the Far East – leaves much to be desired. It’s common to find bolt drillings inaccurately made and curvatures that are simply wrong, so the wise customer should always be prepared for a struggle when it comes to fitting.”

The keys areas for metal corrosion on the E1A, according to Phil, are at the base of the radiator grilles, and at the sides of the nosecone where the panels have been welded together. There are mud traps behind the joints which allow dirt and moisture to accumulate so, inevitably, the metal rots from the inside out. The situation was better on the very earliest models, which were made in the days when panel joints were still being leaded and have stood the test of time better. But, once economics drove a money- and time-saving switch to spot-welding and no leading, long-term corrosion resistance fell away dramatically.

The centrally-hinged bonnet panels can rust, too, but this is no worse than on any other tractor of a similar age. Also, check along the bottom edges of the mudguards; another favourite area for corrosion. Much depends – as always – on how a tractor’s been used, as well as how well it’s been looked after. By and large, those that worked on arable farms tend to be in better condition than those that ended their working lives as yard-scrapers on a dairy unit.

Wear in the steering system is inevitable on tractors of this age, unless they’ve already been restored. Fortunately, the spare parts situation is good, so problems are easily rectified.

The diesel-engined E1A was by far the most popular seller back in the 1950s and ’60s, and that’s reflected in its current domination of the E1A preservation scene. Fortunately, Phil says that serious mechanical problems with the diesel engine are very rare. What’s more, even if you do come across a badly worn example with smoking exhaust and rattling bearings, all the parts are available to put it right.

Nevertheless, it’s sensible to make all the usual checks, assessing the condition of both coolant and oil. Ideally, the coolant should contain some additive and look clean. Signs of emulsification caused by its mixing with oil, is bad news. Likewise, evidence of a mayonnaise-like gloop under the oil filler, or on the dipstick, speaks of significant trouble within. So, factor anything like that into the price you’re prepared to pay. Finding fluid levels as they should be is always a good sign, and points towards a tractor that’s been properly maintained.

Other routine checks

Take some time to check steering joints and kingpins at the front for signs of play and recent greasing. Also, note the amount of free play at the steering wheel; another useful indicator of age-related wear in the system. Of course, unless you’re looking at a properly restored example, you must expect to find wear in and around the front axle and steering set-up.

The grey and blue-painted New Performance Super Major represented the E1A’s final flourish, and was among the last tractors to wear the ‘Fordson’ badge.

If you can, have a look underneath the tractor to check for any signs of leaking fluids. Careless jacking can cause cracks in the castings as, of course, can winter freezing due to a lack of anti-freeze. Don’t expect everything to be pristine under there, though (unless you’re looking at a Concourse machine), as even perfectly healthy engines will always blow a bit of oil to create some misting.

The hydraulic system is generally very durable, and Phil says that serious problems are rare. The Qualitrol system on the newest, New Performance Super Majors, might warrant some more careful investigation and testing, but that all depends on what you have in mind for the tractor once you’ve bought it.

The New Major is blessed with a durable transmission system although, the later models fitted with Live Drive can throw up clutch problems. The two-stage clutch is much more expensive to replace than the single variant, and seems prone to premature failure, even on tractors that aren’t being worked terribly hard. This problem was exacerbated back in the day when operators – in search of more power – would fit their Live Drive-equipped E1A with a six-cylinder engine, placing an even greater loading on the clutch.

Fordson E1A New Major values are slowly climbing, with tractors in ‘as found’, original condition, like this one, becoming increasingly desirable.

Check the gearbox and/or rear axle oil level. Oil can pass freely from one to the other once the internal seals become perished. These were made of leather on the gearbox output shaft and PTO unit and, once breached, will allow oil to flow from the gearbox down into the back axle. So, if you find the axle over-full, and the gearbox low, that’s what’s happened. Allowing the gearbox oil level to become low can not only promote internal wear, but will also cause the parking brake discs to dry out and fail.

The rear axle has a dipstick, but the gearbox simply uses a level created by the positioning of the filler plug. So, remove the large cap and check the level. If it’s at the lip of the cap’s thread, then the level is fine. But if it’s out of sight, then there’s likely to be a seal problem to deal with. Alternatively, check the axle dipstick and if the level is obviously high, then you know what’s probably happened.

All-in-all, then, buying a Fordson E1A is a relatively straightforward business. There are still plenty on the market although those looking for a TVO- or petrol-powered example will have more of a struggle. But, whichever model you choose, the E1A is a big, solid, capable and well-made tractor that remains a useful performer to this day. It’s certainly a better, more accomplished machine than the E27N, which was limited by its three-speed gearbox. The New Major is a good deal more user-friendly than its predecessor; easier to get on and off and, with its electric start, more of a pleasure to live with, year-round.

Moving the fuel tank away from the top of the engine and fitting a centrally-hinged bonnet, ensured excellent access for servicing and maintenance work, especially when compared to the E27N’s set-up.

The prospects for restoration are excellent thanks to a healthy spares scene and, providing you have the necessary storage space and suitable transportation, living with and showing one of these still-affordable machines remains a very tempting proposition.

For a money-saving subscription to Ford & Fordson Tractors magazine, simply click here