FE 35 tractor buying guide

Posted by Chris Graham on 9th January 2023

Chris Graham meets Ferguson enthusiast Dave Woolerton to discuss the pros and cons of his beautifully-restored, early FE 35.

The distinctive, grey and bronze-coloured Ferguson FE 35 was only in production for a short while during the late 1950s and, due to its relative rarity nowadays, always attracts plenty of attention at shows.

It’s all too easy to forget the considerable age of tractors like the Ferguson FE 35 when you see fully-operational and beautifully-restored examples like Dave Woolereton’s machine featured here. The uninitiated could be forgiven for failing to appreciate how long ago models like this one were built. This FE 35 dates from a time when Anthony Eden was at the helm in Downing Street, the AEC Routemaster double-decker bus had just been introduced, Premium Bonds were launched and Bill Haley and his Comets were storming the UK charts with Rock Around the Clock. The year was 1956 and, for Ferguson, it was an important one.

Glittering arrival

The FE 35 was launched to the press at a glittering, London reception, held at the Grosvenor House Hotel in October 1956. Later the same month, the public got to see the exciting new model at the British Ploughing Championships which, that year, were held at Shillingford, in Oxfordshire. Ferguson had positioned four of the new models prominently along the main roads leading to Shillingford, giving visitors a sneak preview of the new tractor as they journeyed towards the event.

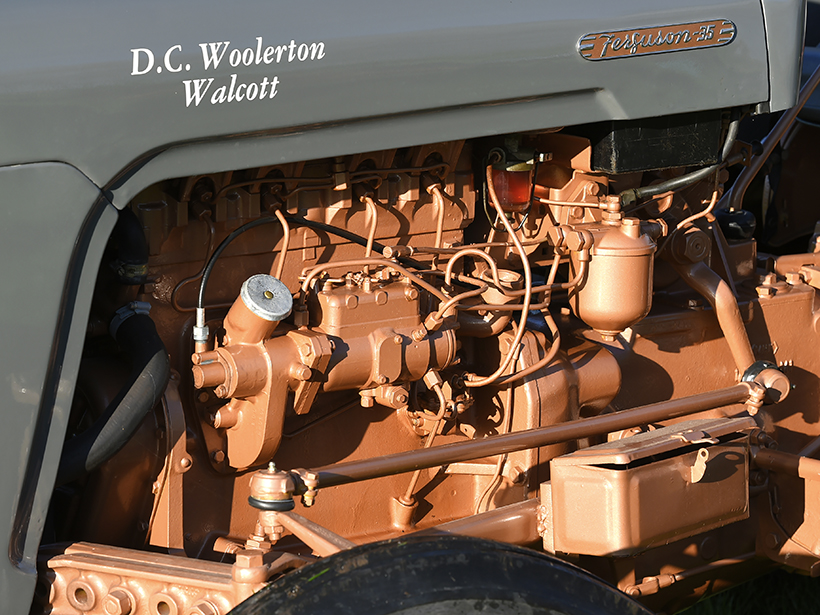

Based very much on the Massey-Harris-Ferguson TO30 and 35 models that were developed and produced for the American market from the TO20 model, the Banner Lane-produced FE 35 relied on engines built by the Standard Motor Company, at the Canley Road factory in Coventry. The first FE 35 (Serial No. SDM 1001) was actually put together at Banner Lane on August 22nd, 1956, and that machine is now preserved for posterity at Massey Ferguson’s museum in Beauvais, in France.

Five more were built on that same day, but production didn’t really get into full swing until November of that year. The earliest models featured a plain ‘Ferguson’ script badge on the front, but this was soon replaced with the more familiar version, which sees the ‘Ferguson’ script incorporated into a chrome-edge, rectangular-shaped solid badge.

You’ll see various shades of bronze and gold paint used on restored FE 35s, but Dave Woolerton reckons the version on his tractor is as accurate as you can get. There colour was matched to an unfaded section of an original, factory-finished top link he bought.

The FE 35 was available as either a Basic or a Deluxe model, with the former having a single-stage clutch, a pan-type driver’s seat and narrow section front wheels fitted with 4.00x19in tyres. The more expensive Deluxe variant featured a two-stage clutch (allowing the tractor to be stopped while the PTO continued running), a tractormeter on the dash, a tiltable and cushioned seat with low backrest and wider front wheels shod with 6.00x16in tyres. It was possible to specify agricultural, industrial or vineyard models, although no narrow version was offered, as had been the case with the preceding TE-20 range.

Standard power

As far as engine choice was concerned, you could have had whatever you liked, as long as it had a ‘Standard 23C’ badge on it! Diesel-, petrol-, TVO- and lamp oil-powered versions were available, with all the engines being put together by the Standard Motor Company at its Canley Road factory in Coventry. The lamp oil-, TVO- and petrol-fuelled units were all essentially improved versions of the 20C engine fitted to the TE-20, while the diesel-powered motor was rather more of a departure. Ferguson engaged Ricardo Comet to design the cylinder head for this motor.

Capacity was significantly increased for the diesel version of the 23C, compared to the similarly-fuelled 20C used in the TE-20, and power output rose usefully as a result. The 2,092cc 20C produced 25hp, while the newer, higher-compression 2,259cc 23C pushed out an impressive 35.9hp, with both outputs being generated at 2,000rpm. All models also featured a standardised, six-spline, 1 3/8in diameter PTO shaft, which made much more sense than the TE-20’s quirky, 1 1/8in fitting. The PTO was controlled by a leaver located on the nearside of the transmission casting, offering ‘Engine PTO’, ‘Neutral’ or ‘Ground PLT’ settings.

The gearbox represented another big improvement over the TE-20, offering six forward and two reverse ratios, thanks to the inclusion of an epicyclic reduction box with its own, three-position control lever offering ‘high’, ‘neutral’ and ‘low’ settings. The ‘neutral’ position also incorporated a safety switch to prevent the engine from being started while in gear (as on the TE-20).

The Standard 23C engine’s reputation as a poor starter colours the reputation of this model for many people. Dave Woolerton’s experience suggests that the potential for trouble is somewhat exaggerated.

Additional strength

Moving further back, the rear axle casting was strengthened for the new model, with the trumpet housings featuring more fixings. In addition, the number of bolts securing the half-shaft bearings to the outer ends of the trumpet housings was increased from six to 12 early on in the production run.

These strengthening measures were taken not only to cope with the additional power, but also with one eye on the increased lifting capacity of the hydraulic system and the larger, heavier implements that were already in the pipeline. However, probably the single most significant feature of the new FE 35 – from an engineering point of view – was the introduction of both Ferguson System draft control and position control, operated by a pair of quadrant-mounted levers positioned conveniently on the driver’s right.

Further strengthening was introduced at the front of the tractor, with the mounting for the front axle being beefed-up, and the axle itself being made from heavier components. The FE 35 also benefitted from the inclusion of a screw-and-recirculating-ball-nut steering box linked to unequal-length drop arms which helped reduce steering ‘kickback’ – something that had been an undesirable characteristic on the TE-20.

Outwardly, of course, the most noticeable aspect of the FE 35 was its striking new colour scheme. The combination of metallic bronze skid unit and Ferguson grey on the tinwork and wheels was a real attention-grabber, and remains so to this day. The paint was definitely classified as metallic bronze, though, not gold; a fact that’s not obvious nowadays given that this model is commonly referred to as the ‘grey/gold’ or even the ‘gold belly’.

The FE 35’s simple dash included a centrally-placed tractormeter on Deluxe models. It’s flanked by an oil pressure gauge (left) and an ammeter (fitted to diesel-powered models only). Petrol-, TVO- and lamp oil-fuelled versions also got a coolant temperature gauge as standard.

All change

However, the grey/bronze colour scheme didn’t last long as, late in 1957, Ferguson decided to switch to a more corporate look. The tractor’s tinwork was switched from grey to red, while the engine/transmission casting/rear axle plus the wheels were painted in metallic Flint Grey, and the MF 35 was born. However, the technical specification remained more or less the same until, in 1959, the three-cylinder Perkins A3.152 diesel engine arrived, but that’s another story! Altogether, just over 73,600 grey/bronze versions were built, out of a total of about 165,500 35s produced between 1956 and 1959.

Of course, these days it’s the Standard engine that dominates peoples’ impression of the FE 35. “Oh, you mean the one that’s difficult to start!” is typically how many regard this model and, while the 23C certainly can be tricky to start, the difficulty levels encountered do seem to vary from tractor to tractor. So it’s important not to let this prospect overshadow a purchase decision as, in most cases, it’s simply a question of getting to know a particular engine’s foibles. Then, once you’re familiar with an individual’s starting routine, you’ll be free to enjoy the rest of the FE 35’s benefits.

For an insider’s view on buying and living with an early FE 35 grey/bronze, I took a trip to rural Lincolnshire where, not far from Sleaford, I found arable farmer Dave Woolerton and his very smart and authentic 1956 model. He’s been buying and restoring for many years, and now has an interesting and varied collection of both classic tractors and implements, including a number of sympathetically-restored Ferguson and Massey Ferguson models.

Buying hints and tips

“First impressions are always very important when buying an old tractor,” Dave explained, “and I always take time to assess the overall condition when looking at a prospective purchase for the first time. I pay particular attention to the bodywork as, although most of the FE 35’s tinwork is replaceable nowadays thanks to specialist suppliers like Old 20 Parts, I’m a great believer in keeping things as original as possible. I’ll always opt to repair/refurbish panels if at all possible, rather than simply fit pattern part replacements; I like to retain a tractor’s history.

Dave Woolerton is a great fan of the FE 35’s control layout. He says that the model is one of the most comfortable tractors of its era to use.

“Check the wheels and tyres carefully. The rear rims can rot and, as with tyres, are expensive to replace. Wheels can look OK outwardly, but can be badly corroded on the inside. The edges often seem to suffer quite badly, which always looks unsightly and can’t really be repaired. While you’re inspecting the inside edges, keep an eye out for signs of dripping oil from the half-shaft oil seals. This can pool in the rims if the tractor has been standing for a long period.

“The Standard 23C engine has a reputation for being a poor starter but, in my experience, this isn’t across the board. Some are much better than others, and there seems no rhyme or reason to it. I know that some were difficult to start from the day they left the factory; that’s just the way the engine is. For this reason, I’d always want to see a prospective purchase started from cold. If you get there and the engine has been pre-warmed – or is already running – then be suspicious.

“It’s important to see how well it starts from cold to properly assess its condition,” Dave continued. “The engine was fitted with a Thermostart system; essentially a single glow plug fitted in the air intake. Controlled by the ignition switch on the dash, this starting aid triggers the burning of a small amount of fuel to warm the engine’s induction air during starting. But it’s not a very efficient system in my view, so can’t be relied upon. Often it packs up, but you can carry out a basic test by touching the outside of the plug where it enters the air intake. If you can’t detect any warmth after the ignition key has been held in the ‘heat’ position, then the mechanism probably isn’t working.

Internal problems?

“Once the engine is running, watch for any smoking from the exhaust and – perhaps more importantly – ‘steaming’ from the engine breather, which is a tell-tale sign of internal engine problems,” Dave added. It’s unlikely that you’re going to find any engine in pristine running order nowadays so, in practice, you should budget for some degree of mechanical repair/rebuild work.

While this tractor isn’t worked any more, Dave always attaches an implement for added interest when at shows.

Elsewhere on the tractor, Dave explained that “fuel tanks can corrode from the inside out, if water has been allowed to build up; it pools at the bottom and promotes rusting that can get bad enough to result in fuel leaks.

“Check the condition of the front axle mounting bush, especially if there are signs that the tractor has been used with a front loader. This will greatly increase wear rates in this area, resulting in undesirable front axle play. Talking of the tractor’s working life, the condition of the pedal surfaces is always a good indicator of how arduous that’s been. If most of the grip nobbles on the brake pedal surfaces have been worn smooth, then you know that the machine will have endured excessive use. Obviously, given the age of these models, you can set any store by the hours total displayed on the tractormeter, unless you’re looking at a tractor with cast-iron provenance.

“The simple, rod-activated, drum-based brakes on the FE 35 are OK when functioning properly. There’s no separate hand brake, but the pedals can be locked with a catch for parking. Seizures within the system are to be expected on anything other than well maintained examples, but the straightforward technology means that a brake overhaul isn’t a difficult or particularly expensive process.

“When checking the clutch,” Dave continued, “I usually run the tractor in second gear at decent engine revs, then stamp on the brakes momentarily. If all is well, this action will cause a dramatic loss of revs but, if doing so makes little difference to the engine’s speed, then the clutch will be slipping. Of course, this test requires a decently functioning braking system!”

The FE 35 offers six forward and two reverse ratios, thanks to the inclusion of an epicyclic reduction box with its own, three-position control lever offering ‘high’, ‘neutral’ and ‘low’ settings. The ‘neutral’ position incorporates a safety switch to prevent the engine from being started while in gear.

Other checks to make

“The hydraulic system on this model is known for its durability and reliability. As with the brakes, it’s a very simply set-up, so serious problems are rare. I’ve never encountered any issues at all. Nevertheless, while on a pre-purchase inspection it’s always worth testing the system, and the key thing to look for is smoothness of operation. Ideally, the linkage should be tested under load (with an implement attached), and any jumpiness in the travel will indicate a problem. Although this might be as simple as a filter issue, it might also point towards a hydraulic pump problem, which will be more involved and expensive to put right.

“Remove the radiator cap to check the condition of the coolant. Ideally an additive will be mixed with the coolant (a good indicator of a cared-for tractor) but, if the coolant level is out of sight, that’s not such an encouraging sign. The presence of mayonnaise-like sludge on the underside of the cap indicates that oil’s mixing with the coolant, due to internal problems.

“With the engine running and the radiator cap removed (obviously, without the engine being too hot), if you spot bubbling in the coolant, then that’s a practical sign of head gasket problems. Finally, with the dipstick removed, rev the engine and check that there’s no oil being ejected. If there is, then it’s likely that piston wear is causing crankcase pressurisation.

“The electrical system is very simple so, once again, serious problems are rare. There are no lights to worry about and the most important thing is to ensure that the dash-mounted ammeter shows a decent charge being delivered to the battery when the engine’s running. Oil pressure should be good, too. If it’s low then you should suspect engine wear, and budget for rebuild work. Overall, though, the Standard 23C diesel engine is a tough and durable unit, assuming a decent level of maintenance.”

Dave Woolerton and his immaculate FE 35.

Owner’s view: Dave Woolerton

“I bought my 1956 grey/gold FE 35 in 2015, from an advert in Tractor & Machinery magazine. It came from Thetford, where it had been used in a caravan park. It was complete and running, and the transmission, brakes and hydraulics all worked. The only issue was that it was throwing out a bit of oil vapour from the engine’s crankcase breather pipe so, clearly, mechanical work was required.

“I gave it to a mechanic friend of mine who, after stripping the engine completely, told me that it wasn’t too bad at all. All he did was fit a set of new piston rings and clean the valves before putting it all back together again. Since then it’s run perfectly and hasn’t used a drop of oil.

“For me, the FE 35 is a wonderful looking tractor; I still remember the impression the model made on me the very first time I saw one. I think it’s a very attractive yet functional design. I also really like the driving position, which is just about perfect as far as I’m concerned. I’ve got a number of other, similarly-aged tractors from the likes of International, David Brown and Fordson, but the FE 35 is the most comfortable of the lot to drive and use. The pedals are perfectly placed and I never get my foot caught behind the clutch, as can often happen on other models.

The front axle was beefed-up compared to the set-up used on the TE-20. Also, the use of unequal-length drop arms helped reduce the steering ‘kickback’ present o the previous model.

“All the controls fall naturally to your hands and the designers evidently put a great deal of effort into the ergonomics. The weights of the controls are excellent, too. There’s never any straining required when changing gears; I’ve got somer other machines that take two hands to get them into gear, but there’s nothing like that with this Ferguson. I also like the easy access to the fuel and coolant filler points under the central flap on the top of the bonnet.

“I think it’s one of the nicest tractors that Ferguson made. The FE 35 is a great all-round package that’s easy to live with and still capable of a decent day’s work. It represented a worthwhile improvement over the TE-20 in many important, practical ways. I don’t work mine nowadays, but do show it regularly, and always with something on the back. I have a number of period, Ferguson implements that I’ve restored, including cultivators, ploughs, sub-soilers and drills, and feel that attaching one of these always adds a lot of interest at shows.

“The early FE 35 is growing in popularity in my view, and the ‘grey/gold’ colour scheme never fails to attract attention. If I park mine next to a red and grey version at a show, it’s mine that will draw the visitors. I’ve heard that the desirability of the grey and bronze paint combination has led to some newer models being painted in this way by less scrupulous owners, although the serial number should always clarify the authenticity. I’ve also been told that, when the red and grey colour scheme was introduced, there were some dealers that painted existing, unsold ‘grey/gold’ stock in the new colours, in an effort to boost sales!”

Rear wheels can be prone to rusting. Replacements are expensive so check a proposed purchase carefully.

WHAT TO PAY

The good news is that, overall, The Ferguson FE 35 remains a relatively affordable classic tractor. At the bottom end of the market you should expect to pay about £2,000 for an unrestored ’grey/gold’ diesel model, rising to around £3,000 for a runner in need of further work. Examples at the smarter end of the condition scale will set you back between £4,000 and £5,000, while FE 35s that have been restored to concours condition can go as high as £7,000.

This feature comes from the latest issue of Classic Massey & Ferguson Enthusiast, and you can get a money-saving subscription to this magazine simply by clicking HERE