Road-rolling at Ragley Hall

Posted by Chris Graham on 25th November 2021

We report on some unique road-rolling at Ragley Hall, which saw a steam roller back working for its living after 50 years of ownership.

road-rolling at Ragley Hall: Miles Banks keeps the engine in a straight line. Everyone just loves the patina on this engine.

The occasion of the road-rolling at Ragley Hall also allowed Daisy the steam roller to meet Jack, the 11-year-old Shire horse, all in front of the magnificent 1683-built stately home on a balmy September day. The event had been organised to celebrate the estate’s new road system, which will certainly help as it expands the corporate events on this stunning 6,500-acre estate.

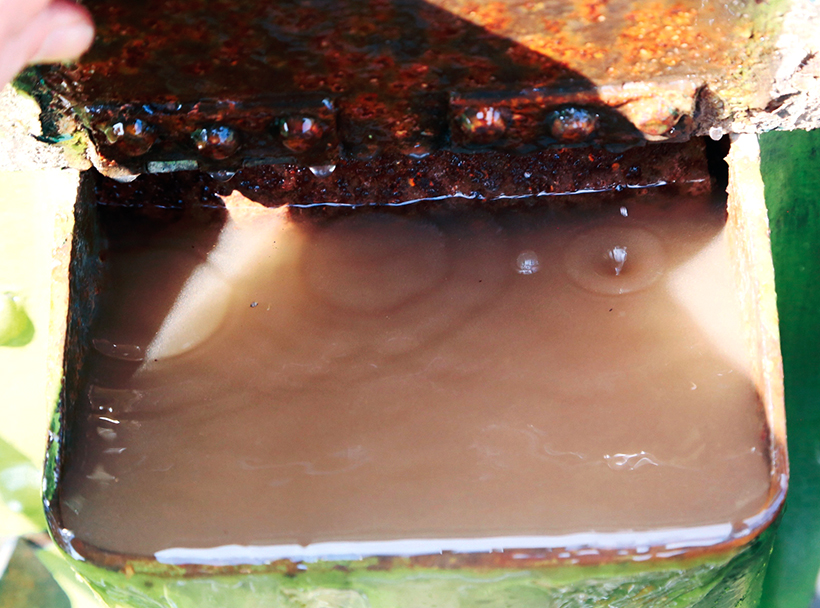

450mm of stone is rolled around the conservation area.

Here we were on the day, it was finally happening after months of planning for SE Davis & Son Ltd of Astwood Bank, Redditch, to celebrate working for the Marquess of Hertford for over 50 years. An added bonus was the fact that Bob Davis had purchased 1932 Aveling & Porter AB type 8-ton compound No. 14150 DW7867 some 50 years ago from Mr Stacey, of Bridgnorth, Shropshire.

Jack meets Daisy as they journey past Ragley Hall together.

Stacey had bought the engine from Cardigan County Council in 1968; it had worked in the Aberystwyth area for most of its time with the council. In fact, they’d kept the engine in excellent order and had only purchased it as late as 1959 from well-known contractor W Richards of Newport, in Monmouthshire, who had the engine new as No. 70 in his fleet. He also had a similar AB compound 8-ton example, No. 14136 of 1931 and fleet No. 67, which was later scrapped.

The splendid Ragley Hall makes an excellent setting for any event you might want to plan.

The Davis business goes back four generations, to Stanley Ernest Davis who was a poultry farmer in 1930. From there his son, Bob Davis, who is such a kind and hospitable person, got involved with straw and haulage, and that led to demolition, road-rolling and so much more.

His son, Andrew, is well-known for his exploits with Komatsu equipment at demonstrations and county shows during the late 1960s, when he was perhaps rather underage to be driving them! It started off when the importer wanted a place to store their new plant, bulldozers etc, and the relationship grew from there and particularly the way Andrew could handle the equipment in the yard and field. They became so impressed that the importer asked Andrew to demonstrate the equipment publicly, which was well received back in the ‘Swinging Sixties.’ It did UK Komatsu and Andrew Davis a lot of good when you look back.

The roller makes a great getaway ahead of Jack, who is following sedately behind.

It’s an interesting thing that Andrew’s son Paul, who is the leading light in the company these days, and other members of the Davis family including the ladies, all have a natural talent to learn and drive trucks and plant like no-one else, which is so impressive. It’s certainly in their genes so to speak. Besides this Paul and Andrew have developed their own stone washing plants that have been very successful throughout the UK since their introduction in 2006, with some people unsuccessfully trying to copy their designs.

You wouldn’t think the engine is in steam, but it’s at full working pressure!

Another thing is the fact that they just love history and the machines that men toiled with in decades past, and have built up a wonderful collection today – if you want someone to start your engine whether it be a cantankerous Allis Chalmers HD10 or a Caterpillar RD8 crawler just call in Paul, he has a great knack of getting them started as I have witnessed over many years. One has to say it has all been driven on by granddad Bob’s enthusiasm and his great passion. He even experienced, in working times, a runaway Huber three-point Caterpillar diesel roller which jumped out of gear with the living van and more behind and survived to tell the tale!

With water treatment applied, the tender is replenished for the day’s work ahead.

After signing the deal to put in 5,096 linear metres of roads at Ragley Hall, made up of 17,400 tonnes of materials with a width of 4-6 metres, it was decided it would be a wonderful way of celebrating various anniversaries and publicising the new road structure at the Hall.

All coaled up with that Allison Supplies shovel in place.

Just by chance Allison Engineering were able to squeeze in Daisy, the first engine that Bob Davis bought, for its ten-year test – it hasn’t been about for many decades so no-one was quite sure what was going to be found inside its boiler, even though No. 14150 had been cleaned out well when last put to bed.

After removing the front end the Allison team knocked the tubes out before the inspector cast his beady eye over everything, which he deemed acceptable. In went the new tubes and hydraulic and steam tests were carried out and passed. After a two-mile road test the engine was ready to do a good day’s work and was shipped back to Astwood Bank in late July ready for the big occasion in September.

With the 450mm stone base down, on go the road planings to be rolled in by Daisy.

Daisy is not a piston-valve roller, but a post-1930 (from No. 14000) slide-valve engine, which Avelings of course had to go back to as potential owners did not like the former design whatsoever – it had gained a poor reputation in priming and particularly wear. In fact there are 5 8-ton AB type compound rollers in preservation today from my understanding.

The 1999 Vogele paver with its hopper fully loaded.

It carries a differential which gives it a great advantage and is very much a one-man engine I concluded at the end of the day. It still has all the roller water spray equipment in place and a Charles Price of Broadheath scarifier, and everything still works if needed. An added bonus to all of this, the engine was just the right size for this type of work.

The Bell B30D is used to keep the paver’s hopper topped up.

The new road structure has been taking great shape helped by the good weather – nothing is flat here, the terrain is very much up and down. The land had been opened out with the 1989 Caterpillar 627E grader with its twin 3306 engines. Driving a grader can make a monkey out of many drivers in the way you place the blade that wants to go in all angles. Today however it’s a lot easier with hydraulics, cab screen and engine power making the job easier compared to cable and weight operations of the 1930-50s. Even so, you need lots of practice to get it right and having watched Andy and Paul on this kind of work before I came away with great respect for both of them.

The man in charge; Paul Davis with his Vogele AB375T paver.

The materials were picked up and moved around the site by the operator-friendly 22 tonne 2017 Komatsu PC21 10 LCi-17 excavator with 149.06 kN tear-force using swivel buckets and IPS and more.

Carrying the heavy materials around was the 18.7 tonne Bell B30D ADT with a net load capacity of 27.3 tonnes of the 20x100mm road planings that had been crushed and sieved by S E Davis themselves. The planings were then tipped into their wonderful well-modified 1999 Vogele AB375T paver from Mannheim, Germany. It was certainly doing the job well and very operator friendly at that, with Paul Davis at the controls.

Daisy gets down to some serious work as the adjoining road between the two top entrances is completed.

The various field entrances needed half loads which were moved about and tipped with the 2014 Hydrema 912D 12-tonne dump truck that carries a Perkins/Caterpillar 4.4 litre four-cylinder engine made at Peterborough.

Used to tidy things up was the very adaptable compact 2015 Bobcat T770 multi-terrain loader. The back-up road roller was the three-point German-made Hamm 3412 HT Hammtronic 14.200kg hydraulic vibratory roller with Deutz air-cooled power which Neal, a print buyer by trade, operated with cool precision.

There’s over 60 years between these two rollers.

The main team was seven people on the day I was there and I was welcomed on my arrival by well-known steam man Miles Banks. He is a top-class bespoke joiner by trade who in his spare time restores living vans and has five on the go at the moment. He also owns a very interesting late 1925 Clayton & Shuttleworth 10hp single-cylinder portable No. 48980 Lucy that will go well with his fine Ruston & Hornsby saw bench.

Miles Banks concentrates on keeping the 8-ton compound roller moving forwards in a straight line.

He was to be the ‘master’ of Daisy and had driven it over from S E Davis’ premises 3½ miles away with Paul Davis the previous Saturday. He had steamed the engine up at 6.30am and had oiled all around when I arrived at 10am and already the roller was out on the job finely rolling the edges of the 450mm thick recycled 6F5 stone that had to be used on the road near Ragley Hall, owing to the conservation requirements of that area of the estate.

I could see Miles was making a good job as he went forward and back keeping things straight and smooth and not exaggerating his movement at the steering wheel which could affect the front rolls’ line and leave a mark on the road surface.

The two rollers work as a team to consolidate the surfaces together.

After completing this section of the job we were joined by the Marquess of Hertford and his team for a photo session in front of the hall with Jack, an 11-year-old Shire horse who was not bothered by the steam roller, which was certainly a docile performer. Everyone loved Daisy for its patina’d condition and it looked so authentic for the surroundings we were in.

Miles reversed it to the water tank and I placed the hose in the tank as Miles turned the wheel valve on the rear spectacle plate manifold. As Miles went for his tea break I took over and built the fire up while the water tank filled up, and I tested out the short-handled Allison Supplies steam shovel.

I must say the fire door is not the easiest to get to, nor is seeing the water gauge glasses, they are very well hidden under the third shaft. I tested one of the gauge glass cocks to see where the water was as I turned the excellent injector on. This stopped the safety valves from blowing off and in no time at all we were right on the red line ready to head to another part of the site for more rolling work, after I’d put the water hose back on the tender’s rear bracket.

Daisy is passed by the 2014 Hydrema 912D 12-tonne dump truck which has an excellent all-round view.

Off I went across the grass and on to the original road section laid some years ago now. The engine was compounding well as I opened the regulator up, but it needs a little work in this area as you could not take your hand off the regulator lever as it just closed the regulator valve otherwise. Once I got used to this it was fine and I climbed the hill where I opened the ashpan to let air into the firebars, which drew the pressure back up in no time.

At the top of the hill on went the injector and I closed the ashpan for a few seconds as I fumbled around for the firedoor chain so I could put a few knobs on the fire. Miles joined me now and steered as I tackled the steep decent to the bottom of the valley – the two connecting rods got some speed up, but I was in control! Around the corner we went with the differential doing its job well. The gears on the engine are very good indeed, so she must have had an easy life that’s for sure.

We were now up with the gang with Paul Davis operating the paver as dad Andy worked the Bobcat 770 and others moved the planings to various entrances as required.

We were instructed to climb to the top of the hill and roll the two entrance roads in this location. Miles was now on his own as I clicked away. Daisy is very much a one-man engine, but being a compound makes it such a joy to drive.

It was time to stop for the wonderful lunch provided, as the roller was parked by the paver and the flywheel brake was applied, as was a block in front of the o/s rear wheel. From the footplate we looked across to the field where the estate’s broken down 2012 New Holland T9.560 artic tractor stood. It was made at Fargo, North Dakota, USA, not far from the Bobcat works where the 770 Andy was using had been made

In fact a new diesel injector pipe had been fitted on the morning of the rolling job, but the 560hp tractor was still in trouble as the computer came up with 10 error faults. The dinosaur was not going anywhere that day whereas the 89-year-old Daisy was!

Miles continued to roll various other areas with the engine even though he needed some more water. Daisy had certainly earned her keep that day and didn’t need a computer to tell us what was going on! Interestingly the coal burned was excellent and didn’t smoke whatsoever, only when the pricker was used to create some smoke for a couple of quick pictures for the estate photographer.

What a wonderful way it had been to celebrate the various anniversaries and for me it will be a day I’ll certainly never forget.

Old Glory thanks the SE Davis team for the invitation to their wonderful occasion, for Miles Banks for putting up with me and to the staff at Ragley Hall who were also very accommodating. The Hall is well worth visiting when you get a chance.

For a money-saving subscription to Old Glory magazine, simply click here