Still rolling after 60 years

Posted by Chris Graham on 3rd November 2020

David Reed enjoys a memorable day in the presence of a 1937 Fowler T3B steam roller that’s still rolling after 60 years of ownership.

Still rolling after 60 years: John Selby’s 1937 Fowler T3B 4nhp compound is numbered 21632, and carries the registration BWY 847.

John Selby has owned his 1937 Fowler T3B 4hp No. 21632 compound eight-ton steam roller since 1960, having bought it to use commercially. Today it’s still rolling after 60 years and is occasionally used to earn its keep, as it did on August 5th, when Old Glory’s editor-at-large, David Reed, visited John at his north Lincolnshire base.

John Selby’s family has been involved with steam for well over 100 years. “It all started when my grandfather, Arthur Selby, began his threshing business in 1910, using a 1902 Marshall No. 37173 single-cylinder traction engine.” It was based near Epworth on The Isle of Axholme in north Lincolnshire, and the business flourished for many years. Steam continued being used for threshing until around 1948, then tractors began to take over.

Nevertheless, steam remained an important part of the family’s life, with John’s father, Harry, buying a 1925 Marshall 7hp No. 79441 FU 4677 single-cylinder general purpose. This was rallied for many years but, by the late 1950s, John’s father decided that it was time for young John (then 14) to get an engine of his own.

Julia, John and James Selby at a rally with their engines. (Pic: John Selby)

“Rallies were becoming popular and there were a few rollers around,” John said, “so my dad suggested that I should think about getting one.” It wasn’t long before some prospective purchases came to light. “A roller that my father had repaired came up for sale; it was at an auction and I decided that I wanted to buy it,” John said. With £50 to spend, his hopes of acquiring the roller were high. “Unfortunately, it sold for £120,” John added, “I just couldn’t afford it.”

The search continues

“We looked for a suitable roller all over the place, but just couldn’t find one,” John continued. But then John and Harry went to see James Stafford at Hatfield, near Doncaster. “He had lost a leg in WWI, yet still became a rolling contractor,” John said. “He initially went into business after buying a Fowler single-cylinder roller, and eventually had a fleet of them.” After WWII, James still had four of them standing in a yard sheeted-up, so John cycled over to his yard to see if he could purchase one. “I kept asking him if I could buy one, but he just wouldn’t sell,” John added.

Realising that John was keen on buying a roller, Mr Stafford told him that his father should take him to Wakefield Council, which was part of West Riding County Council at Lofthouse Park. “Dad went to see a chap with Mr Stafford, who said that they had none for sale at that time,” John explained, “but they would be added to their mailing list and alerted when one came up.”

John Selby seen with the Fowler T3B roller that he bought back in 1960. “It still works occasionally,” he says. (Pic: John Selby)

And it wasn’t that long before the letter that John had been waiting for finally delivered “The council said it had four rollers for sale,” John said, “so my father went to have a look at them.” Harry was obviously impressed, and bought one. “We tendered £105 for one,” John said, “James Stafford advised us that people often tendered £100, so £105 would often be enough,” and that’s exactly how it turned out. “We got a letter from the council around Christmas 1960, explaining that we’d been successful, so we drove over in early 1961 to pay for it.”

The roller that was bought was a 1937 Fowler T3B 4nhp compound No 21632 BWY 847. “It was the last steam roller to be bought new by West Riding County Council, so it was with them for all of its working life,” John confirmed. “It spent a long time at Skipton, before ending up at the Ingleton depot. When bought, the roller had been transferred back to the central depot at Lofthouse Park in Wakefield.”

An eventful journey

The next challenge was getting the engine back to north Lincolnshire. “We couldn’t get a low-loader to transport it, so had to get it home ourselves,” John added. It wasn’t a journey without incident. “To start with the roller had been totally drained to protect it from frost,” John recalled, “there were no hosepipes available, so to fill it up with water we had to use a bucket.” By the time that John got to Ackworth, a few miles out of Wakefield, the roller was struggling. “There were a few problems with it,” John continued, “some tubes had rusted through and had been plugged to keep the engine going, and the fire bars kept falling out.”

This rear view of the Fowler T3B roller show the type of lamp that was used by road workers for many years, “It should be red in colour, really,” John points out.

At Ackworth it was decided that the roller couldn’t continue, as there was nobody to drive it, so it was left with a threshing contractor, who said that he’d drive it home for John. With John following behind, the journey continued, but there were still a number of problems to solve, as John explains. “It had to stop in a lay-by where there was a horse trough to fill up with water.” It seemed that the roller kept running out of steam, “It always happened when we were near a pub,” John remembered, with a smile.

More problems arose as the roller approached Doncaster. “I lost him,” John said, “we just couldn’t find him.” Luckily a wisp of smoke was spotted, and John found the machine near Doncaster market, where it had stopped for water. “It was near a pub again,” John laughed. After setting off again, the roller eventually got to James Stafford’s yard, near Hatfield, where it was left for a few days before eventually making it back to Epworth.

The paintwork has definitely been left to give this roller a ‘just finished working’ appearance.

It was obviously unusual for a teenager to buy a steam roller, so much so that John was interviewed by non-other that the BBC’s Fyfe Robertson, with the interview being titled 14-year-old boy buys steam roller – news indeed.

Shortly afterwards, an old driver wrote to John about his new roller, and told him that he had a full set of lamps at his home, in a box. “He said that, if I came and collected them, I could have them for nothing,” John said. “He lived in Ingleton, but sadly I couldn’t get over there to collect them, something that I’ve regretted ever since.”

The first thing that John did was to look at the tubes. “We decided that we needed some new boiler tubes for the roller,” he said, “so we went to Drapers scrapyard at Hull for some.” This was a good place to go as they were cutting up steam railway locomotives at the time. “We could get just what we wanted from them,” John added. The roller also needed some new fire bars, which were cast at a local foundry, in Conisbrough, “The boiler inspector gave me a certificate for the boiler,” John confirmed, “something that I was really pleased about.”

A popular machine

The roller became a popular machine in the north Lincolnshire area. “As soon as we got it home and back in working order,” John continued, “people were ringing us up wanting to use it for a variety of jobs.” John didn’t like to refuse, so the roller was hired out, with his father or Uncle Jack as the driver. One of the biggest jobs that was tackled was at the new ports being built alongside the River Trent. “The ports were expanding,” John said, “they were building new storage areas and sheds, and we went for weeks on end, rolling the bases for them.” By now John was 16 years old. “Nobody questioned that somebody so young was doing all of this work,” he added.

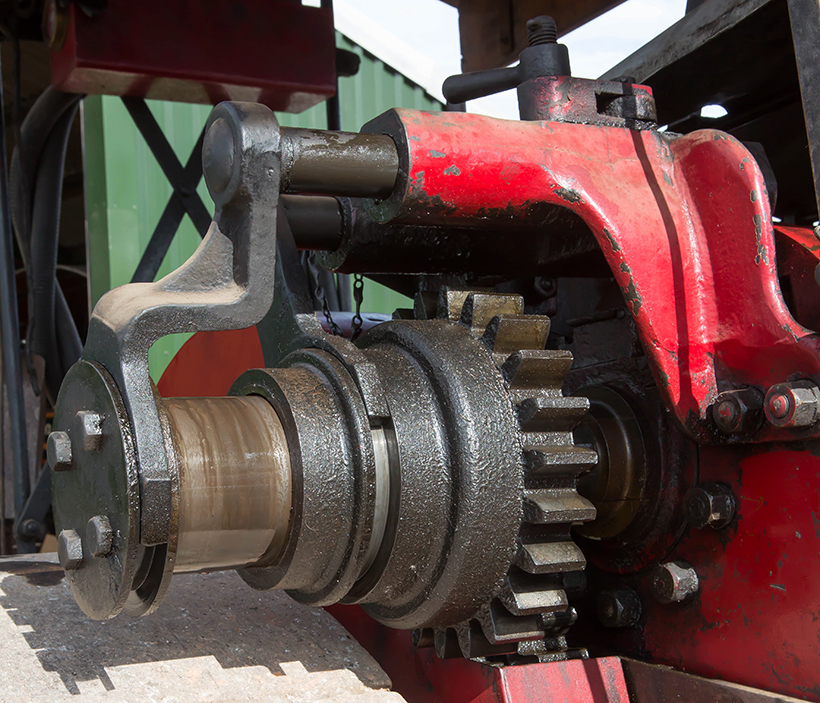

The gearing cogs on the roller are in good condition.

“My father, Uncle Jack and I had been at a farm sale and, when we arrived back, we realised that the roller was not in the yard,” explained John. It wasn’t too hard to trace though. “We just followed the wheel marks down the road to the council yard, where we found my grandfather, who was by then well into his eighties, rolling tarmac,” John told me. “He said that we’d been asked to do it, so he’d decided to get on with it himself.”

The jobs kept coming. “We worked for the local council during the 1960s, and also rolled lots of bases for farm sheds,” John continued. “We did that for a long time, and employed Frank Popple as a driver; he was experienced, and worked on showground engines, as well as owning a Burrell roller.”

The roller was then put to work in the local villages. “They were putting in new sewage pipes,” John added. “They worked all week, then we came along on the Friday and filled in the trench behind them, until it was solid, then added a layer of tarmac and rolled that.” It was a job that kept the roller pretty busy, “We did that for a year or two,” John confirmed.

The Fowler had been used for crushing bricks and stones in the yard on the day that these photographs were taken.

The nature of steam means caution is required at all times, as Harry found out one day. “He was raising steam in the roller, and when he pulled the regulator forward, there was a great whoosh of escaping steam,” John said. “He immediately jumped off the footplate, thinking that it was going to blow back.” Luckily, it didn’t. “As it turned out, water had corroded the straps on the safety valves, which resulted in mayhem,” John explained. “It took us over an hour to find all of the bits so that we could put it all back together and steam the engine again.”

Jobs for the roller continued to come. “Farmers got grants to improve their roads, so we did a lot of that,” John said, “then James Stafford put a contract our way. Based on a council housing estate in Hatfield, we rolled all of the ground works and were busy doing that for ages,” said John. After working during the week in Hatfield, John and his father couldn’t resist attending a local rally at the weekend, but things didn’t quite go to plan. “We got to the edge of Hatfield and the back axle broke when we were in the middle of the road,” John explained. “Luckily the roller had a scarifier fitted, which stopped the wheel falling off completely.”

The problem was to find a way to get the roller back home. “Robey TE owner Richard Booty had built a long trailer, but didn’t have anything to pull it with,” John explained. “So we came to an agreement that we’d supply a tractor to pull it, if we could use the trailer occasionally. But, by the time that we needed it to recover the Fowler, he was using one of the Oliver 90s that he’d bought from Harry.”

The trailer that was built by Richard Booty, that rescued John’s 1937 Fowler T3B roller after it broke its rear axle. (Pic: John Selby)

A lot of effort, including winching and packing, was required to get the roller on to the trailer, with the Oliver 90 providing the power. When it got back to Epworth, there was the problem of getting the roller off the trailer. This time it was a Nuffield Universal tractor that was used to ease the roller back on to the ground. “We double-headed the tractors with a Nuffield and the Oliver to get to Gainsborough quickly to pick up Frank Strange’s 1913 Marshall No. 61880 7hp TE, that had been left on the roadside, while we recovered the Fowler,” John explained

The Fowler’s future

The decision now had to be made regarding the Fowler’s future. “We’d thought about scrapping it altogether and getting another roller,” John said, “but we decided to persevere and get it fixed.” The result was that a new axle was built at a Thorne shipyard. “It cost more than the roller did in the first place,” John said.

The roller continued to work but, eventually, the jobs fizzled out. John did attend rallies with the roller in Yorkshire and Lincolnshire. “I used to go to the Carrington event, and it was there that I met my late wife Julia Riggall, who came from a family of engine owners,” John continued. “We were married in 1972, and she did a lot of steering on the roller for me.”

This side view of the Fowler shows the classic shape of the roller, which still works occasionally.

As well as the roller being exhibited at shows, the 1925 Marshall 7hp No. 79441 FU 4677 Maverick GP traction engine would also be in attendance. And it was around this time that the next generation of the Selby family became involved with steam. “As my son, James, got older, he did a few jobs with the roller before it got too neglected,” John said.

By 2015, John and James had a discussion regarding the roller’s future. “James wanted to keep it, so we decided to get it back into running order. As with any piece of machinery, until you get into it, you don’t really know what needs doing. That was certainly true for the roller, which needed a lot of work to get it back on the road.

The first thing that John did was to get boiler smith Jack Meeker to come and have a look at the roller. It turned out that work on the boiler was required. Jack initially said that a new backhead needed to be fitted but, after further examination, decided that the boiler was getting a bit ‘shady’. The result was that it, along with the cylinder block, was sent away to Howards of Derby, which fitted a new boiler barrel and new tube plate.

“It also needed a new firebox and the backhead,” John said. With a practically new boiler being fitted and other repairs being completed, the roller was returned to John and James, for further use like new!

But there has been one type of engine that John has wanted to own for many years. That’s a Fowler R3 8hp general purpose TE engine. “Out of the blue, I had a chance to buy a similar engine to the R3 I knew as a boy. It’s either a C Special or a TE2 Russian-type road locomotive,” John said. “There wasn’t a lot of difference between them; they were built on the basis of an R3, but modified for military purposes,” he explained.

The engine in question was No 14910 Rising Star, which was built in 1917, and was an engine that John simply couldn’t resist. With the Fowler roller and the 1925 Marshall general purpose engine already in his collection, it became clear that something had to go to help finance the purchase of the Fowler R3. “This led to a discussion about whether we should sell the roller,” John said, “but we decided to sell the Marshall No. 79441 instead. It passed to Sean Anthony, of Berrybrook Classics & Steam, in Devon, where it’s used on driver-training courses.”

This led to further discussions about whether they should sell the roller. “But we never got round to it, and I have a suspicion that it’ll stay here now,” John added. Although it still does attend some rallies, it does some commercial work as well. On the day I visited, the Fowler was hard at work crushing stones in the yard. “It’s kept in working condition with a little bit of employment coming its was, occasionally,” John concluded. “Carl Davis was working on it recently, adding that he must be the only person in the world that’s still being paid to work on a semi-commercial steam roller,” John told me. There really can’t be many steam rollers from the 1930s that still work for a living occasionally, can there?

For a money-saving subscription to Old Glory magazine, simply click here