Restoring a superb, 1941 Bucyrus-Erie 10-B excavator

Posted by Chris Graham on 7th March 2024

Keith Haddock tells the story of acquiring, restoring and operating his amazing, 1941 Bucyrus-Erie 10-B excavator.

1941 Bucyrus-Erie 10-B excavator: This is the machine when purchased by Keith Haddock, back in 1981. The gentleman in the picture is Henry Gyte, the excavator’s operator from 1949 to 1962.

I’ve been involved with earth-moving all my life, from digging in the garden with my toy diggers and visiting opencast coal sites from age 10, to becoming a civil engineer planning and supervising large excavation projects. I used to say, “If I fail my exams, I will become a digger driver” but I passed my exams and became a Charted Civil Engineer in the United Kingdom and a professional engineer in Alberta when I moved to Canada.

After restoring the machine to mechanically sound condition, Keith performed his first job, working on a drainage ditch in Edson, Alberta.

Although I have driven many types of earth-moving machines, I have never actually been paid as an operator. My brief periods ‘in the seat’ were sporadic and usually the result of asking “Can I have a go?” With practice I did become proficient enough to be asked to put in the occasional Saturday morning shift as a favour to a friendly driver. After I took on senior management positions, operating machines became inappropriate, so as a hobby project, I eventually purchased my own machine, a Bucyrus-Erie 10-B excavator.

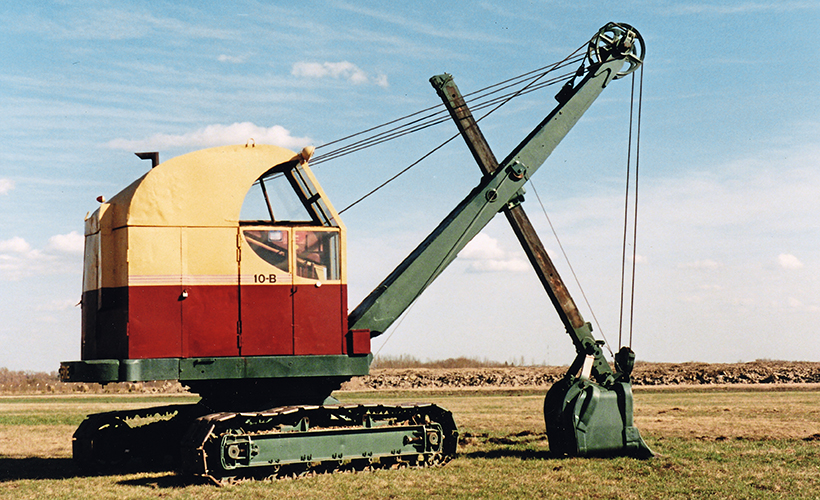

Fully restored 10-B in sharp, Bucyrus-Erie colours.

I decided on the 10-B because of its simple design, lack of hydraulics or air control, and compactness which allows all parts to be maintained without heavy lifting equipment. Weighing only about 10 tons allows it to be moved without a permit, yet it boasts all the working parts and movements of its larger brothers. Some claim its fast, 20-second cycle makes it one of the most difficult excavators to operate.

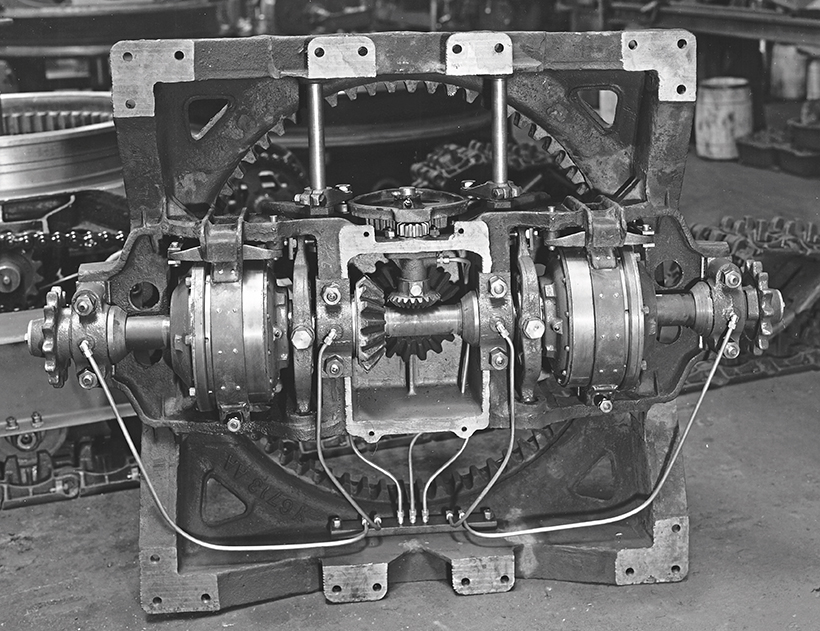

Looking underneath the 10-B undercarriage. The two shafts at the top of the photograph are slightly rotated by the cam wheel seen between them. The cam wheel operates the clutches and brakes on the travel shaft.

I purchased my 10-B from Prodor Construction of Edmonton, Alberta, who at that time had a yard full of old plant including Lorain 57, Marion 101-M, Northwest 4, Dominion 425 and several Quickway model E excavators. Prodors had purchased the machine a few years earlier with a view to restoring it themselves, but never found time to do it. It was equipped with 33ft boom and 3/8-yard dragline bucket, crane hook block, grab bucket with tagline, shovel and backacter front ends, and many spare parts including a spare set of tracks.

A big job for a little machine! After its move to Forestburg, the 10-B excavated this farmer’s dugout to provide watering for cattle.

Looking into its history, the 10-B was built in Bucyrus-Erie Company’s factory at Erie, Pennsylvania, and was assigned serial number 21096. It was purchased new in 1941 by Alberta Highways Department (later known as Alberta Transportation), and worked all over the province, mostly on road projects or in gravel pits before wheel loaders and backhoe-loaders made these small cable excavators obsolete. In rusty condition and missing some glass, the machine had been idle for about 10 years before I rescued it from further deterioration. It was generally in good mechanical condition and obviously well maintained during its ownership with Alberta Highways, but it needed a few parts rebuilding and modifications made to bring it to the working standard I wanted. With a new battery and full lubrication job, the engine fired up on the third pull!

Keith casts another bucketful onto the spoil pile.

My 10-B was powered by a Buda petrol engine type HP260. I was very impressed when I phoned Allis-Chalmers at Harvey, Illinois, who took over the Buda Company. The parts man, on being given the engine serial number, was able to confirm the installation of the Buda engine in my machine in 1941! He sent me a new parts book and copy of an operator’s manual for the engine. I also obtained a Bucyrus-Erie operator’s and parts books from our local Bucyrus-Erie dealer in Edmonton.

Machine restoration

During my ownership, the machine was moved several times. Starting in Edson, Alberta (where I lived at the time as Engineering Manager at the Coal Valley Mine), I restored the machine to good mechanical condition. Mechanical work included rebuilding the boom hoist jaw clutch which is mounted on the same shaft as the drag drum. This necessitated removing the entire shaft and drum assembly so the jaw clutch could be pulled clear. The clutch teeth were worn, risking the possibility of the clutch jumping out while lowering the boom. I had the teeth built up and then re-ground in a local machine shop. I also carried out two design modifications which I recommend to all owners of 10-Bs of this vintage: I had a small lever welded onto the bolt head which controls the safety pawl to lock the boom when hoisted. This lever provides a better grasp on the pawl bolt than simply trying to twist the bolt head to engage or disengage the pawl.

Moving Keith Haddock’s 10-B on a ‘high-boy’ trailer from Edson to Forestburg, Alberta.

The other modification was on the small dog clutch which engages the hand-wound propel steering chain to the winding handle. I found this clutch had a tendency to jump out of engagement with the possibility of a runaway if the brakes happened to be off at the time. On machines of this vintage this clutch is automatically engaged when the swing lock lever was pushed in to lock the upper works to the lower when traveling. Movement of the swing lock lever engages the swing lock dog as well as the steering hand crank jaw clutch through a linkage. I disconnected the linkage from the swing lock lever, making the two actions independent. On to the clutch shifter assembly at the lower end of the hand chain, I had a foot lever welded, so that the hand cranked clutch could be engaged with the toe of my boot, maintaining pressure during cranking. This more positive clutch engagement has been most successful.

Bucket too big! 10-B on display at the open house of Forestburg Collieries Ltd in June 1992. The 68-yard bucket of Marion 8200 placed in front drew lots of attention!

The 10-B has a unique cam system for operating the steering clutches and brakes when in propel mode. Basically it steers like a crawler tractor using friction clutches. The cam, located in the lower works, is rotated by the above-mentioned hand crank through a chain and bevel gears, then through the centre drive shaft to the lower works. With the cam in its central position, both steering clutches are engaged and both brakes released. This permits travel in a straight direction when the main clutch is engaged. Continuing rotation of the cam wheel by the crank handle causes the clutch to disengage on one side and the brake applied on the same side, depending on which direction the cam is rotated. Turning the cam wheel to its fullest extent in either direction applies the brakes on both sides. This position is selected during digging to secure the machine from movement.

Ready for work, freshly painted and converted to a shovel.

While at Edson I did my first actual digging job, a drainage ditch for a farmer. After that I moved the machine back to Edmonton where I completed its outside restoration which included replacement windows, some steel panels, sand blasting and repainting using genuine B-E maroon, cream and green paint. I have repainted the machine twice since then, keeping paint in good condition by treating any peeled areas and thus eliminating the need to sandblast the entire machine.

On show

In 1984, the company for which I worked transferred me to the Paintearth opencast coal mine near Forestburg, Alberta, as Engineering Manager there. My10-B soon followed and went straight to work on digging a large pond to provide water for a farmer’s cattle. The 45-year-old machine worked at maximum digging depth, maximum dump height and maximum radius for many evenings and weekends during the summer. It was fun doing this in my spare time as a hobby, although I did charge an hourly rate to cover my running and repair costs. The next job I did was another dugout, this time near a highway. I received many enquiries from people passing by who wanted similar dragline work done on their own properties, but I wasn’t actively seeking work with a full-time day job to attend to.

Here shown loading a Mack Bulldog, the 10-B moved large quantities of material.

Looking like new again after one of its repaints, the 10-B was put on show at the Open House we held at our Paintearth mine in 1992. Here, bus tours of two mines and the adjacent Battle River power plant were organised as well as many other activities and technical displays shown to the public. Some 2,000 people attended and the little 3/8-yard 10-B dragline attracted much attention, especially as we had placed it beside the 68-yard bucket from our Marion 8200 dragline!

On demonstration again at Leduc West Heritage Park, in Alberta.

From the owner of another scrapped 10-B shovel, I purchased the parts I needed to run my machine as a shovel. I already had the shovel attachment but needed the crowd chain sprocket and adjustment assembly, crowd chain, bucket trip drum and clutch assembly. With some help from a boom truck, I converted my excavator from dragline to shovel. Since then, I moved the machine to a new home at the Leduc West Antique Society Heritage Park at Leduc, Alberta, where it took part in working demonstrations over several years.

Two heavy-duty boom trucks hoist the 10-B by remote control onto a trailer, ready for its journey to Utah.

At 64 years old in 2005, and still with its original engine, my 10-B worked hard at the annual HCEA event, held that year at the world-famous Reynolds Alberta Museum, Wetaskiwin, Alberta. In the hands of three experienced operators, who spelled each other on shifts, the 10-B shovel loaded many tons of topsoil into the old Mack truck in the picture. At another museum event that same summer, the 10-B loaded about 200 tons of gravel into an antique crusher also in operation. With good maintenance and some TLC, my 10-B performance proves these old cable excavators will last a very long time.

On the road again. In 2019, the 10-B is ready for its long journey to the new owner in Utah.

In 2019, I sold my 10-B and all its attachments to a collector in Farmington, Utah. The new owner arranged the permits and customs declarations necessary to cross the border into America. The machine was hoisted clear off the ground by a pair of boom trucks onto a suitable trailer. A few days later it was reported to have arrived safely at its new home. Now at 82 years old, the Bucyrus-Erie classic excavator is enjoying yet another chapter of its varied life under the caring hands of its new owner, and in the company of two other 10-B excavators in various stages of restoration.

This feature comes from the latest issue of Old Glory, and you can get a money-saving subscription to this magazine simply by clicking HERE

Previous Post

A fine pair of modern Ford classic tractors!

Next Post

Beautifully preserved 1949 Dennis Lancet III coach