This is certainly no ordinary 1953 TE-D 20!

Posted by Chris Graham on 4th December 2023

Ferguson conversions come in many shapes and sizes, but John Jones’ 1953 TE-D 20 is certainly a real head-turner, as Bob Weir discovers.

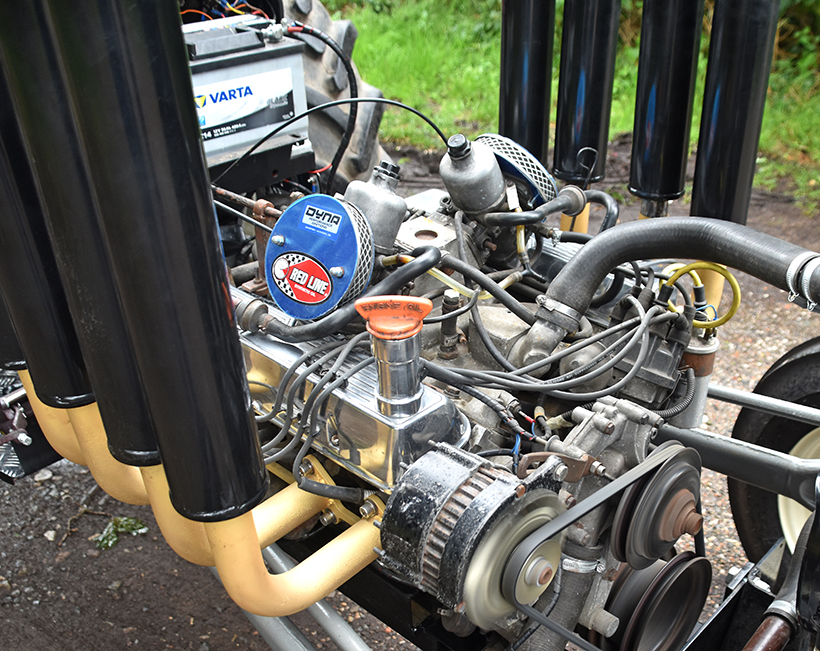

1953 TE-D 20 mean machine! The ‘220 V8’ badging signifies this is no ordinary grey Fergie. The V8 engine certainly transforms the tractor’s looks.

John Jones is a shot-blaster by trade and has lived in the Wrexham area of North Wales for the past 30 years. He’s a big fan of the grey Fergie and, apart from the V8 model featured here, owns a trio of other TE-20s

“I come from a farming background, and my family used to own a smallholding near Oswestry,” he explained. “I learned to drive tractors as soon as I was old enough to sit on the seat. The first machine I drove was a grey Fergie, and I’ve liked them ever since.”

John had been looking to acquire a TE-20 for some time and finally decided to do something about it. “I had a chat with my son about five years ago,” he recalled, “and the result was a 1948 TE-A 20. That tractor had a rebuilt engine and was in a bit of a mess, but we managed to sort it out. I’ve also got a pair of TE-D 20s.”

A cracking find!

When John bought the tractor that was to become his V8 conversion, it was also in a sorry state. “Its bonnet had been painted orange, which is an unusual colour for a grey Fergie!” he laughed. “But, the Fergie still had its original engine, although the block was cracked. Initially I planned to stitch the unit, but then decided to replace it altogether with a V8 engine.”

John is still in the process of verifying the tractor’s top speed but, with a V8 engine under the bonnet, the sky’s the limit!

John had owned the V8 for some time, and the engine was already being used on his specially built trike. “I’d put the V8 into a trike because I was into motorbikes at the time, and used to go to rallies. But time passes, and I thought the engine would be better used in a tractor. It’s a 3.9-litre unit that we took out of an old Range Rover.”

Range Rovers and V8 engines go hand-in-hand, and were available from the early days of the marque. The original Range Rover was fitted with a de-tuned, 127hp 3.5-litres version of the Buick-based Rover V8, and this was boosted with fuel-injection in 1984. The engine was subsequently bored-out to 3.9-litres in 1990.

Fitting a V8 engine into a grey Fergie is no easy task, and John realised he would need some assistance. “My mate, Paul, helped with the work,” he told me. “I’ve known him for years, and we also built several trikes together. He’s very reliable and knows his stuff.”

The first item on the agenda was to establish a plan of action for the conversion. “We knew that this was going to be a difficult project, and everything would have to be spot-on for it to work,” he said. “Shoehorning a bulky V8 engine into the space formerly occupied by a simple four-cylinder unit was never going to be straightforward, and it tested our mechanical skills to the limit.”

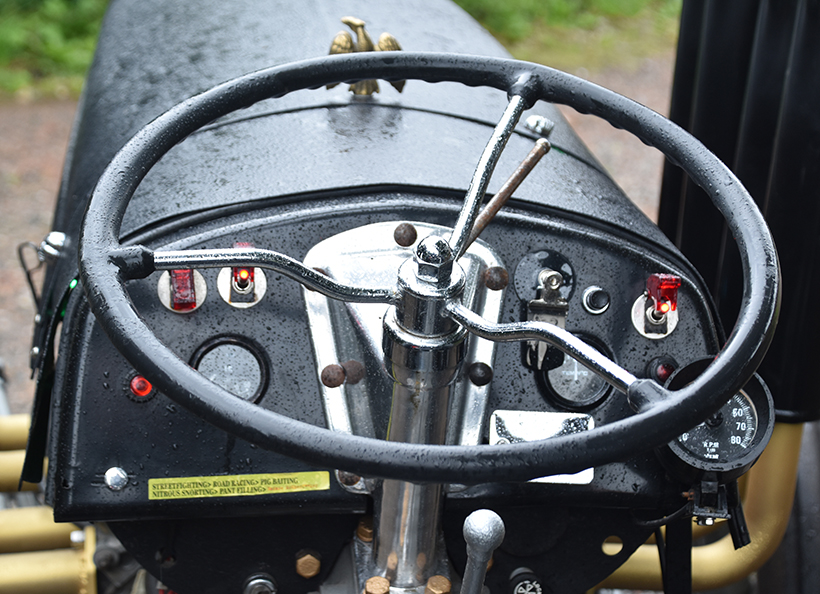

The steering wheel and instruments will be familiar to most tractor drivers.

Engine allowances

John recalls that he got a lot of useful information from the internet. “There are several modified Ferguson sites, and I started making enquiries,” he said. “I realised the chassis would have to be altered to take the V8, and we increased the length by eight inches. We also had to remount the front axle and there was a lot of drilling and welding involved.”

There was no manual available for this type of conversion, and John remembers a lot of headaches. “It was often a case of ‘one step forward, and six back’,” he recalls. “The exhausts, in particular, were a real nightmare. I decided to use a local motorsport specialist to do the work, and specifically told him that the pre-formed bends in the pipes had to be the same length.”

Unfortunately, when John came to fit the pipes to the manifold, he discovered a problem. “We fitted the left side first and these were OK. We then welded the second set then, once we were ready to put the stacks on, we realised they were set at different heights. The pipes hadn’t been bent properly at the workshop.”

Having finally sorted out the exhaust pipes, it was time to move on to the next job. “I got another specialist, Andy Fisher at A&M Motorcycle Engineers in Chester, to undertake the machining on the flywheel,” said John. “He also did some lathe work on the rest of the tractor, and there was a lot of ‘to-ing’ and ‘fro-ing’ from Chester to Wrexham, taking measurements. All-in-all, this part of the job took about four months.”

The comfortable, leather-sprung seat is a nice touch; particularly as careless drivers could end up hanging on for dear life!

Time is often the biggest enemy on a long-term project like this, but John was determined to press on. The conversion would eventually take the best part of two years to complete, and most of the work took place during the Covid lockdown. “Although there were a lot of issues to resolve, I was determined to finish the job,” he recalls. “A lot of the work was trial and error, and that took up a lot of time.”

Good time management

Carrying out a restoration project when you’re working full-time can require a difficult balancing act. Fortunately, John and Paul have the use of a small workshop, which means the tractor was stored under cover. This was an important factor during the winter months. “It’s a question of putting in the hours, and being patient in your approach,” he said. “I’ve found it’s when you rush things, that you often run into problems.”

John also recalls having a big issue with the spigot on the tractor’s clutch. “This is an important component of a clutch, as it sits in the centre of the gearbox flywheel or crankshaft flange,” he explained.

“The bearing type can be a ball, roller or needle, packed in grease.” The gearbox input shaft and the engine’s crankshaft rotate at different speeds when the clutch pedal is engaged. The input shaft needs support to cope with this difference, and this is where the spigot comes in. A worn or faulty spigot bearing can cause whining or grinding noises, and will eventually damage the gearbox.

Lifting up the bonnet confirms this is no ordinary tractor. The eight exhausts are impressive, but the preparation and engine fitting required a lot of thought and work.

“The problem was gaining access as much as anything else,” said John. “Once the engine and gearbox were in place, the only path to the spigot was either through the starter motor holes with the flywheel in the way, or we had to go in through the top of the Fergie ‘box. You were literally working blind, trying to get the measurements right. It was very fiddly, I can tell you!”

Despite the increased power of the V8 engine, John still opted to stick with the TE-20’s original clutch. “We knew there would be some changes over the basic Fergie, but we wanted to use as many of the original parts as possible,” he explained. “With all that power on tap, you have to be gentle with the clutch but, so far, it’s still in one piece. If you’re careless there’s always the risk the tractor will flip up onto its back, and nobody wants that.”

Tasteful additions

Accessories are always important on a project of this nature, and John’s Fergie is superbly equipped in that regard. “The steering wheel and leather-sprung seat both came from a local supplier,” he said. “I’ve tried to make them as tasteful as possible. That said, I’m a big fan of the old Mad Max movies, so there’s a little bit of attitude in there, as well.”

The converted tractor’s first outing at the 2023 Oswestry Show

Driving the tractor is an experience in itself, and the conversion demands a lot of respect. As John manoeuvered the machine around his yard, it looked and sounded like a wild animal, chomping at the bit. “I’ve taken it above 20mph, but that’s only on the narrow access lane outside my workshop,” John explained. “There’s still plenty of power in reserve, but the tractor can bite if you’re not careful.”

There’s also a tinge of sadness hanging over the project, as John’s wife died recently. “She was keen on the project from the very beginning, and I have to admit I lost interest for a while following her death,” he said. “Fortunately, the rest of the family rallied around, and we agreed it would be a good idea to finish the tractor in time for the 2023 show season.”

As luck would have it, I spotted the Fergie at its first outing at this year’s Oswestry Show, and the tractor was warmly received by most enthusiasts. Whatever your opinion about conversions, John’s Fergie certainly stands out from the crowd!

John Jones and his V8-powered Fergie. What started as a bit of fun turned into a serious project.

ROVER V8 ENGINE HISTORY

The Rover V8 was the brainchild of General Motors (GM), and later re-designed and manufactured by Rover in the UK. The engine was first used in the Buick 215, and was an all-aluminium unit introduced in the USA for the 1961 model year. A feature of the new engine was that it was very light at 318lb (144kg), and could deliver high power outputs.

The engine was used by a number of American car makers, including Pontiac, Buick and Oldsmobile. Oldsmobile used a turbocharged version producing 215hp, as against the standard 200hp. Buick alone made over 350,000 cars in just three years, using this engine.

The engine soon acquired the nickname ‘BOP’ (Buick, Oldsmobile, Pontiac). Unfortunately, compared to other engines, the aluminium construction meant it was expensive to produce. There were also issues with the oil and coolant, and the radiator often clogged when using anti-freeze. This resulted in GM halting production in 1963.

In 1964, Rover gave its American office permission to investigate the possibilities of using the V8 in British cars. GM eventually agreed and provided technical help with production. The engine made its UK debut in 1967, and British-made engines were designed to run on two carburettors, provided by manufacturers Lucas and Stromberg.

The engine was eventually used in a number of cars produced by Morgan, Triumph, TVR, MG and Land Rover. Range Rovers would become synonymous with V8 engines, and used the engine in a variety of formats for many years.

The last Rover to use a genuine Rover V8 was the SD1 Vitesse saloon, which was introduced in the 1980s. The engine remains popular with kit car enthusiasts today.

This feature comes from the latest issue of Classic Massey & Ferguson Enthusiast, and you can get a money-saving subscription to this magazine simply by clicking HERE

Previous Post

Beautifully restored and detailed 1936 Commer 8cwt van

Next Post

Rail and Ale Festival on the popular Statfold Barn Railway