Youngster’s 1956 Fordson Major Industrial restoration

Posted by Chris Graham on 26th February 2023

Bernard Holloway enjoys a meeting with Liam Banks and the young man’s recently-restored 1956 Fordson Major Industrial.

1956 Fordson Major Industrial: Wayne and Liam Banks are justifiably proud of bringing this Holman conversion back to life. It would have left the factory in standard Fordson blue paint before being shipped to Holman Brothers Limited. It has subsequently been re-painted by one of the four previous owners or Holman in yellow livery, which Liam has retained.

While the livery of this Fordson Major is difficult to forget, it was the many facets of Liam Banks’ character that left the deepest impression on me. Mechanically capable beyond his 19 years, he’s a man on a mission to ensure that any tractor he restores with his father, Wayne, is as true to the original as possible.

That ambition, in itself, isn’t so unusual in the tractor preservation world, but it’s his drive to learn, absorb and put into practice everything he can about the restoration of agricultural equipment, as well as his determination to bring more younger people into the hobby, that really shine through.

A great teacher!

“Having been brought up on a small-holding,” he explained to me, “tractors have always been part of my life, and I subconsciously picked up skills while watching my father using his ingenuity to repair them. As my interest grew, we attended country shows and one in particular sticks out in my memory. I was 14 years old and approached a group of older tractor owners for advice as I was unsure how to undertake a specific repair to my first tractor – a Grey and Gold Massey Ferguson 35.

“While I may not have been as fluent then as I am now with my questions, I felt as though I was being dismissed as a time-waster, and it was clear that they weren’t taking me seriously as I was a youngster. I found the experience very upsetting. There’s a wealth of practical knowledge and historical information held by older members in our hobby, and it’ll be lost if it’s not handed down. So, for that reason I’m determined to raise the numbers and profile of my peer group, to encourage them to get involved and ensure the hobby prospers and that vital knowledge isn’t lost.

“I hope to do this through my own network of friends and social media. But I should also add that I recently met with members of the Ford & Fordson Association, and found them to be extremely welcoming and helpful with my technical queries. If only I’d met them when I was younger!”

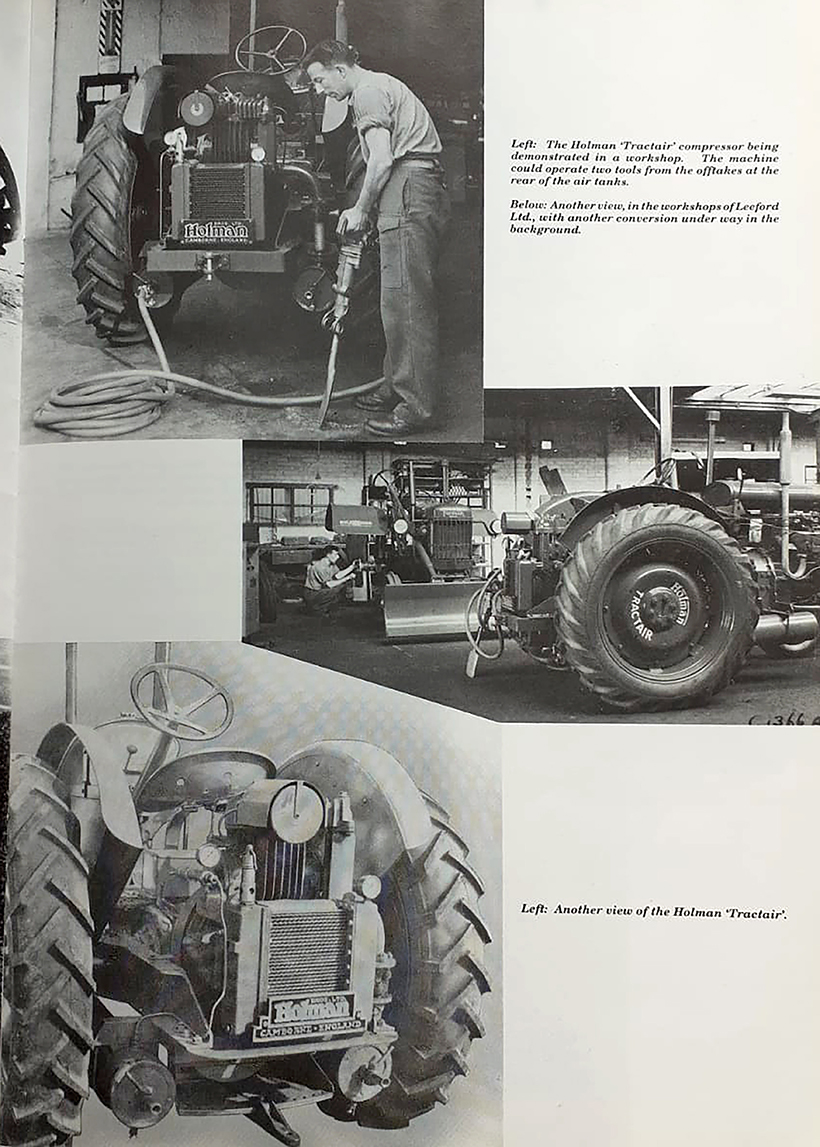

This rear three-quarters view shows the balancing pipework between the reservoirs. Two pieces of pneumatic equipment could be run at the same time. Ordering a ‘Holpack’ allowed the compressor built into a tubular frame to be demountable from the tractor’s chassis.

Originality is key

For Liam originality is all important. He’s currently planning a visit to the factory of Holman Brothers Ltd, in Cambourne (now merged with Broom and Wade), to hopefully learn more about his Fordson that the company converted, fitting a rear PTO-driven ‘Tractaire’ compressor and a pulley-driven dynamo on the front. The latter was probably manufactured by English Electric, but the build plate is missing so this can’t be confirmed for now. If any readers can provide any further information, please send your comments care of the Editor.

Wayne keeps very much to the background, taking pride in Liam’s achievements. But I know that, like many a father, he’s enormously proud of his son’s efforts, and that he’s given more than just a helping hand with complimentary skills. The pair make a particularly good team. “I’ve watched him struggle with a problem on his tractors,” Wayne told me, “but he never gives up until he solves it.”

One of Liam’s many practical aims is to let his restoration work speak for itself, and showcase his skills. Eventually he hopes that his standard of work will, by word of mouth, encourage other tractor owners to have the confidence to bring their tractors to him for repair or restoration. Judging by some of the other restoration projects that I’ve seen in the collection (including the Grey/Gold, a B275 and a Super Dexta), that shouldn’t be too much of a problem!

Liam is keen to add tractors that are a little bit different and rare to the collection, which explains his attraction to this Fordson Industrial and its Holman ‘Tractaire’ Compressor conversion and generator. The machine was advertised for sale in the Midlands and, to avoid missing such an interesting tractor, he decided to take the plunge and buy it unseen by agreeing the deal over the ‘phone.

Liam has attended other shows since pulling out all the stops to debut the tractor at last year’s Biddenden Tractorfest. He’s determined to encourage a younger element to join tractor clubs and attend events to ensure a healthy future for the hobby.

So, the first-time that he and his father saw it was when the haulage contractor delivered it to their small-holding in southern England, whereupon it was rolled into a barn where, apart from some minor tinkering, it then sat for the following 18 months.

Spurred into action!

Fast-forward to the summer of 2022, and it was that year’s Biddenden Tractorfest – which takes place in late August – that provided the impetus needed to kick-start the restoration project into action. He thought that event would provide the perfect venue to show thew finished Fordson, but to get it finished for the August 20th/21st show weekend would require many long days and late nights. But Liam and Wayne were determined to make the deadline, so set to work in earnest.

“The restoration took a month and a half to complete,” Liam says. “We actually had the tractor in pieces on the Monday before the show to paint it – in Ford construction yellow – then we had to reassemble it, fit the loom and be ready to leave home on Friday the 19th.”

At the show the tractor’s rarity, plus the sight and smell of the freshly-applied livery, drew the crowds, and provided a just reward for all of the challenging work. Liam is extremely hard on himself in respect of many aspects of the build; unjustly so, in my view. As an example, he’s overly critical of the paint finish due to one or two minor blemishes caused by dust from the barn floor. “If I’d had more time before the show, I would have constructed a spray booth and spent longer on the preparation, but I will revisit those areas once the show season has finished,” he added.

The ‘Tractaire’ compressor is belt-driven from the PTO. It runs well but oil and pressure gauges, an exhaust plus an overhaul of the pipework and valves are still required. Holman Brothers Ltd also manufactured a demountable version of the compressor, although this model (Serial number 3392) is fixed to the modified chassis frame.

As per all restorations, this one presented its challenges. The PTO-driven compressor was seized, but now runs perfectly. It resisted all gentle attempts to free it, but eventually its resistance crumbled following a week-long soak in Coca-Cola! But, for it to be fully functional, authentic air pressure and oil gauges are required for the dashboard, plus either overhauled or new air lines and valves to enable it to be connected to the underslung reservoirs, one of which was severely corroded and required specialist repair. While undertaking this work, a ‘1957’ date stamp was discovered, and this most likely relates to the date of conversion by Holman Brothers Limited. Now Liam is on the lookout for a Holman Brothers Limited rock drill, which was a popular piece of equipment back in the day.

The generator requires a complete overhaul and is powered by a multitude of belts from the pulley, which are easily tensioned by moving the generator within slots cut into its mounting frame. A specialist was commissioned – for a considerable sum – to overhaul it but after an inspection, he decided that it wasn’t feasible. So that remains a major item on the ‘to do’ list, and I have a feeling that Liam won’t take no for an answer regarding that.

Another essential job – when time and funds allow – is the fabrication of a new belt guard. This will need to be done by a specialist, and is an essential safety requirement. Other than an engine top end, steering and brake overhaul, the Fordson was in fait-to-good running order. The tinwork (with the exception of the wings) is original and more good news is that the tractor arrived with nearly-new tyres.

Elsewhere around the tractor there’s still a list of sundry items requiring attention, including a number of those always-hard-to-source parts which are missing and need to be located. Such items inevitably take time to find, but often pop-up in the most unexpected locations. For example, one lucky find recently was a handbrake lever, which Liam managed to discover in his late uncle’s garage. That can now be mated with the exiting pawl.

Cantilevered off an angle-iron frame that’s bolted to the standard tractor, the generator drive belts can be tensioned by moving the generator relative to the slotted bolt holes that secure it. The fabrication and fitting of a bespoke belt guard is on the ‘to do’ list, as is a front vent grill.

Liam summed up the restoration as follows. “We’ll get there in the end by learning from experience and from those with the experience who can help us.” The tractor’s logbook indicates four previous owners, and the serial number confirms a build date of December 1956, although it wasn’t registered until mid-March in 1957. This tends to indicate that it was being worked on at Holman Brothers Limited during those months, which links well with the date stamp discovered on the reservoir.

Unfortunately, nothing more about the tractor’s working history so, once again, if any readers have more information, please let the Editor know.

Holman Brothers Limited and ‘Tractaire’ Conversions

Nicholas Holman established the company in 1839 and Holman Brothers became a limited company. Based in Cambourne, Somerset, it specialised in mining equipment and was well known for its pioneering, water-spray-based dust-supression equipment used in the Cornish mining industry.

This equipment was generically refereed to, after collaboration with James McCulloch, as the ‘Cornish Rock Drill’ and was in use in local and Welsh mines from 1882. The company went on to specialise in mining-based equipment, including winding and pumping engines, rock drills, ore-dressing machinery and air compressors.

This period advert shows a pneumatic hammer being powered by the Holman ‘Tractaire’ compressor. It was taken at Leeford Limited and is kindly supplied here by Rodney Gibson, from the Ford & Fordson Association.

By the early 1960s it had grown to employ 2,500 people and, in 1968, it merged with Broom & Wade to form the International Compressed Air Corporation, before being renamed Compare Construction and Mining.

The ‘Tractaire’ compressor is permanently mounted on the tractor. The company developed a range of reciprocating air-cooled compressors for permanent fitting to the rear of tractors, typically delivering 71.5-110cu ft of air per minute, at 100-125psi. The air is compressed in two stages by a piston and intercooler. Power is taken from the rear PTO and engine speeds are air-governed when the compressor isn’t working at full load.

A ‘Holpack’ could be ordered to allow for the equipment to be demountable and free standing from the tractor. It consisted of a compressor built into a separate tubular frame that could be easily removed from the rear once disconnected and the safety catch unlocked, using either a hydraulic lift or powered linkage. It is belt-driven via a UJ and layshaft from the PTO.

The company advertised the ‘Tractaire’ as ideal for a variety of pneumatic equipment to facilitate construction work including, trenching, road-breaking and pipe-laying using ripper, hammers and, of course, drills.

This features comes from the latest issue of Ford & Fordson Tractors, and you can get a money-saving subscription to this magazine simply by clicking HERE

Previous Post

Collectable Austin A55 and A60 models

Next Post

Amazing disused and derelict lorries in scrapyards