1962 Fordson Dexta tractor

Posted by Chris Graham on 14th September 2021

Willie Carson tells the tale of a much-loved, 1962 Fordson Dexta tractor which is enjoying a relaxed life on the family farm in Northern Ireland.

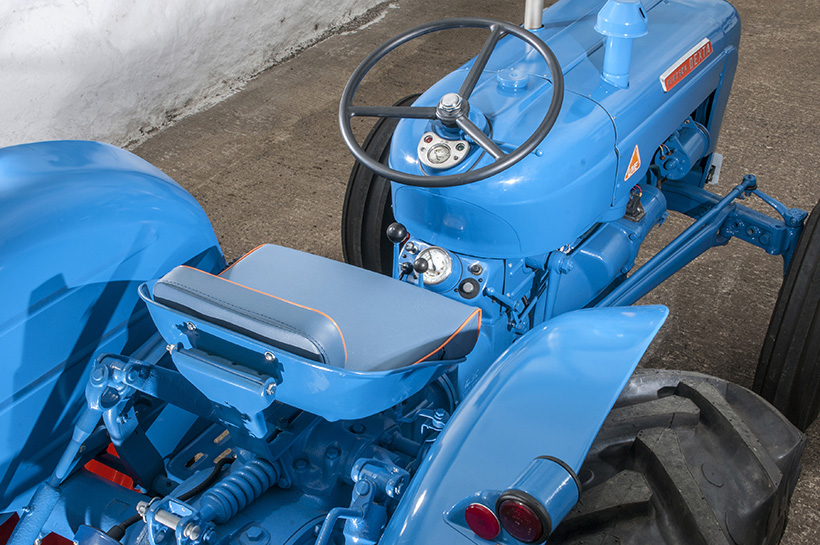

1962 Fordson Dexta tractor: Here’s the beautifully-restored Dexta in the yard – both very much as they were back in the 1960s.

Many important headlines dominated the news during 1962. The world heaved a sigh of relief as the Cuban missile crisis was defused. President Kennedy asked Congress for $531 million to pursue the idea that men could walk on the moon. The communication satellite, Telstar, went into orbit around the earth, and then beamed the first live TV signal across the Atlantic.

The British and French, under McMillan and De Gaulle, agreed to join forces and develop Concorde, as the world’s first supersonic passenger aircraft. The Beatles had their first hit with Love Me Do, Ford launched the Consul Cortina and the Beverly Hill Billies appeared on TV screens across the nation for the first time. Yet, despite all these momentous international events, the big news on Anderson’s farm just outside Coleraine, in Northern Ireland, centred on the arrival of a shiny new Fordson Dexta.

The standard of the respray is outstanding, especially considering that Alan’s skills are self-taught.

Single-tractor farm

Brothers Billy and John Anderson farmed the usual enterprises of dairy cows, beef stock, cereals and potatoes on their 53 acres. John outlines the history of tractor power on the farm, up until the 1960s. “Our first tractor was a Fordson Standard N. It was replaced by a Ferguson TEF-20 diesel and then, in 1962, we changed it for the Dexta .

“This new machine was bought, together with a Ransomes plough, from TD McFarland of Church Street, for £680.” Since the brothers still owned just one tractor, the compact and capable Fordson was put to work making hay, cultivating the arable ground and ploughing at local matches with Billy at the wheel.

“For the potato harvest it pulled a Massey Ferguson 711 ’round table’ digger,” John continued. “We used four springs to make a basic version of Ferguson’s pressure-control coupling. It added extra traction in difficult conditions.” Before long, there was a David Brown loader fitted for mucking out duties, and for filling the spreader. The Dexta soldiered on as the only tractor on the farm until 1968, when a Massey Ferguson 135 arrived to keep it company. Billy’s son, Alan, learned to drive in his teens on the Dexta, and remembers building up some muscles, pulling on the steering wheel while mucking out the cattle sheds.

For several years, the back axle was a half Fordson/half Ferguson set-up!

Inevitable shortcomings

As always, there was a demand for more horsepower as tractors needed to pull ever-bigger implements and, by the 1970s, the Dexta had started to be overshadowed by the abilities of a couple of 100 Series Massey Fergusons. Nevertheless, there remained a place for the faithful old Fordson in the Anderson’s tractor shed.

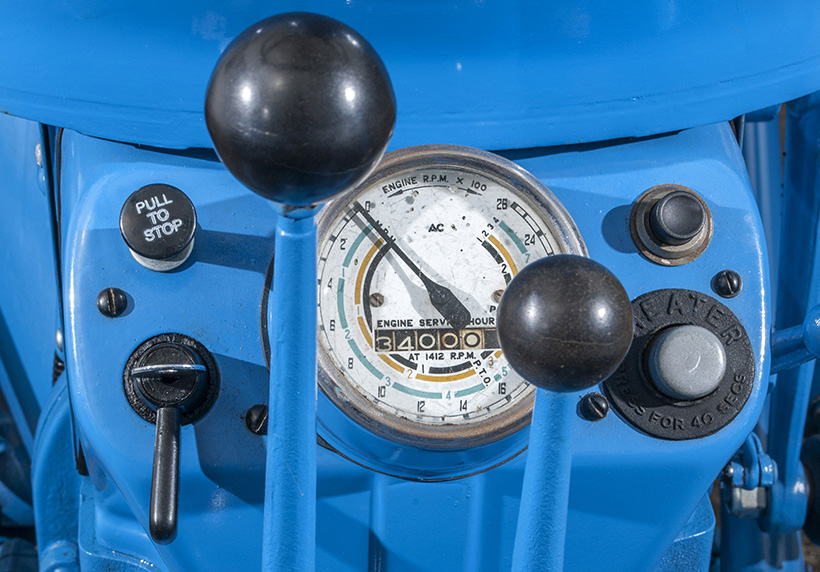

The brothers now farm 230 acres but, as Billy explains: “The Dexta used to do all the work and now we need six Masseys.” Hard work in its early days had taken its inevitable mechanical toll and, by 1978 – and with about 4,000 hours on the engine (the hour meter stopped recording at precisely 3,400 hours!) – some major surgery was required.

By this time, TD McFarlands was no longer a tractor dealer; the business was concentrating solely on Ford motor sales instead. So, neighbour and ‘old hand’ Fordson mechanic, James McCaughan, was engaged by the brothers to carry out all the necessary engine work. With new internals and a new clutch fitted, the old stager was rejuvenated and remained on hand to offer nimble assistance with jobs around the yard. This continued to be the case until the Dexta was finally retired to the back of the workshop, where it lived quietly beneath a pile of potato bags for the following 30-something years.

Alan sits back in the seat where he learned to drive during his youth.

However, after some gentle encouragement from a neighbour, and inspired by some of the tractors he saw on show at Mount Druid each summer, Alan decided that the time had come to re-awaken the Dexta. The engine was still turning freely, but the water pump was solid so, with that replaced, the starter was engaged and the tractor was soon coaxed back into life. But it took some deft use of the brake pedals to free up the seized clutch.

Component swap

In the middle of a harvest at some point in the dim and distant past, the dynamo on the NH 1520 combine packed up, and the eagle-eyed Andersons noticed that the one from the Dexta would make a suitable, temporary replacement. Since it still showed a healthy output, this unit was refitted, together with the original starter motor, which still brings the engine to life with confidence. However, Alan was slightly concerned about the fuel system, so he sent the pump and injectors off to Gary Wishart for testing and a rebuild. The final task in the engine recommission was to have the radiator re-cored and fitted.

The quality seat cover adds style to this first-class home restoration.

In its heyday, the Dexta was used to plant potatoes with a Ferguson ‘bell’ dropper and fertiliser attachment. It’s interesting to note that the Fordson levelling box fouled this combination, so a complete drop-arm from an MF 35 was fitted for this operation. It was while setting off down the lane one spring morning, on the way to the potato field, that disaster struck. The nearside axle housing broke in two. Thankfully, a breaker was able to supply an MF 35 axle which, after modification, allowed the tractor to return to work.

There had also been, at some time in the past, a crack in the PTO shaft circlip groove which led to a broken casting and a missing circlip, presumably hiding somewhere in the diff housing. So Alan bought a secondhand transaxle unit locally for £70, and replaced the axle and PTO retainer and, at the same time, fished out the broken circlip – plus a piece of casting – using a magnet. That was another major part of the rebuild sorted.

Left-to-right: John, Billy and son, Alan, with the tractor that played such an important part on the family farm at Knockinkerragh, in Northern Ireland.

Electrical work

Next, attention turned to the electrics, and work in this are involved fitting a new loom and light/ignition switch (purchased from Bertie Dunlop), cleaning up the original horn and heater switches, and fitting the original Butler light lenses into new lamp units, both front and rear. Even though the tractormeter had stopped working, Alan decided not to replace it, preferring to keep that part of the Dexta’s history intact.

The original brake backplates were cleaned and rebuilt, and the linkages were freed off and adjusted to restore the brakes to full efficiency. The tinwork was assessed next. As with most loader tractors, the nose cone had taken a few hooks and jabs in its time, so it was replaced, along with the mudguards and the seat pan. The rest of the panels had survived because, as John says: “The tractor was always stored under a roof and, even though it was the only tractor on the farm when it was new, it was reasonably well looked after.”

A former engine rebuild meant that the Dexta was still a working tractor in the 1980s.

The rims, wheel centres, front axle and the drawbar went to be shot-blasted locally, but the rest of the tractor was prepared for paint by hand. Alan explains: “We used wire brush attachments in the angle grinder and the drill, and then wire-brushed by hand until it was ready for a coat of Bonda Primer. We bought the Empire Blue and the red for the wheels, again from Bertie Dunlop, and I painted it myself. I’d never sprayed a tractor before, but I just worked at it until I was happy with the finish. I gave it two coats of primer then rubbed it down and sprayed on two coats of colour.”

Attention to detail

When it came to the details, Alan came up with a novel technique for finishing the nose cone emblem. “We needed a new one which came in bare metal. I sprayed it without masking anything off, and then buffed back the paint on the high places with T-Cut to reveal the gear and wheat sheaf motif.” The final touches to this project – Alan’s first tractor restoration – came with the application of the all-important ‘Live Drive’ decals and a classy seat cushion.

The tractormeter stopped recording at 3,400 hours. Alan decided that this part of the Dexta’s history should remain untouched.

This is a restoration that will stand out from the crowd at any show. The engine runs like a clock and produces no visible smoke; a testament to the engine refurbishment that was undertaken back in the late 1970s. This tractor provides a good example of the advantages to be had from putting a tractor back to work after a rebuild, bedding-in the rings and preventing the bores from glazing.

Most of the engine’s original power is still available, and the ‘as new’ appearance is unmistakable. But the Andersons’ Dexta has been retired from agricultural duty now, and will enjoy a few outings to local shows where it’s sure to grab the headlines.

For a money-saving subscription to Ford & Fordson Tractors magazine, simply click here