1972 Massey Ferguson 1150 beautifully restored

Posted by Chris Graham on 24th March 2023

Chris Graham meets Simon Wright and his beautifully-restored and impressively large, 1972 Massey Ferguson 1150.

Simon Wright believes that the MF 1150 was a pretty advanced machine in its day, with features such as a hydraulically-adjustable seat setting it apart from the competition during the early 1970s.

Having successfully restored a Massey Ferguson 165 and then a 178, Surrey-based Massey Ferguson enthusiast Simon Wright decided to set his sights on a bigger challenge, quite literally. It was while at the 2018 Somerset Show that he got his first glimpse of the mighty MF 1150, and it made quite an impression. Just the sight and sound of that American-made, Perkins V8-powered monster were all it took to convince him that he needed to have one of his own!

“One of my first thoughts,” Simon told me, “was how well an 1150 would sit with my other two tractors, with such similar looks albeit on a bigger scale. I was also attracted by the V8 engine which not only looks superb and very different, but makes a fantastic noise, too! What’s not to like?”

The search begins

Having hot-footed it back from Somerset, Simon wasted little time in beginning his search for an MF 1150 to buy. Of course, with the model never having been officially imported into the UK, he quickly found that possible purchases were thin on the ground. Fortunately, with luck on his side, he stumbled upon an advert in a tractor magazine from an enthusiast with a recently-imported example that he wanted to sell.

The tractor in ‘as bought’ condition. It was a runner but, more importantly, it was essentially complete.

“I wasted no time in getting to Oxford for a closer look,” Simon recalls, “and was impressed by what I found. It was a tractor that had obviously worked for its living (with about 7,000 hours on the clock), but it didn’t look as though it had been abused. More importantly, it seemed to be pretty much complete. The engine started and ran, but I could tell it had issues as it was ‘breathing’ hard. However, as with my previous restoration projects, my intention was to strip everything, so the prospect of some engine fault rectification work didn’t worry me. Nothing had been done to the tractor during the six months it had been in the UK, and I liked the fact that it remained so original.” Simon agreed a price, bought the tractor and immediately started planning the nut-and-bolt restoration that lay ahead.

“I was under no illusion about the amount of work I had ahead of me, but was relishing that prospect. The MF 165 was my first tractor, and that was an eBay purchase. Everyone laughed at me when I bought it because of the state it was in; there was oil leaking from every possible place! At that stage I had no previous tractor-related experience – and had never tackled the restoration of anything before – so most people thought I was mad! But I had confidence in my own ability to work methodically through the project and, in the end, I think that turned out to have been justified.”

Simon’s well-organised approach to the restoration saw him take special care with the cleaning, preparation and painting of literally every component. The gearbox and rear axle were in pretty decent shape. The tractor doesn’t appear to have been abused during its working life in Iowa, USA.

Fully optimistic

“Having carried out full restorations on both the 165 and the 178, I wasn’t at all daunted by the prospect of the 1150; it’s size and relative complexity didn’t bother me. The only thing that did surprise me was the number of parts involved, although this didn’t really hit me until I was well into the strip-down process.v

“I have a very ordered way of working and, as I take things apart, every component is photographed, cleaned, bagged (complete with fixings) and labelled. This work started over the Christmas period in 2019, and the fact that the tractor was so complete meant that I didn’t have to waste time searching for lots of obscure, missing parts. In fact, I was lucky and managed to find the few items I did need at reclamation yards in America, arranged for them to be sent to friends over there, then had them shipped back that way.”

Simon says that most of the initial dismantling work was done at a friend’s workshop. “He’s a steel fabricator so, as well as having more space than I have in my garage at home, he also has a couple of fork-lifts which came in very handy when I got to the tractor-splitting stage. My aim was to get the tractor dismantled into ‘bite-sized’ pieces that could then be transported back to my garage where the more detailed work could begin.

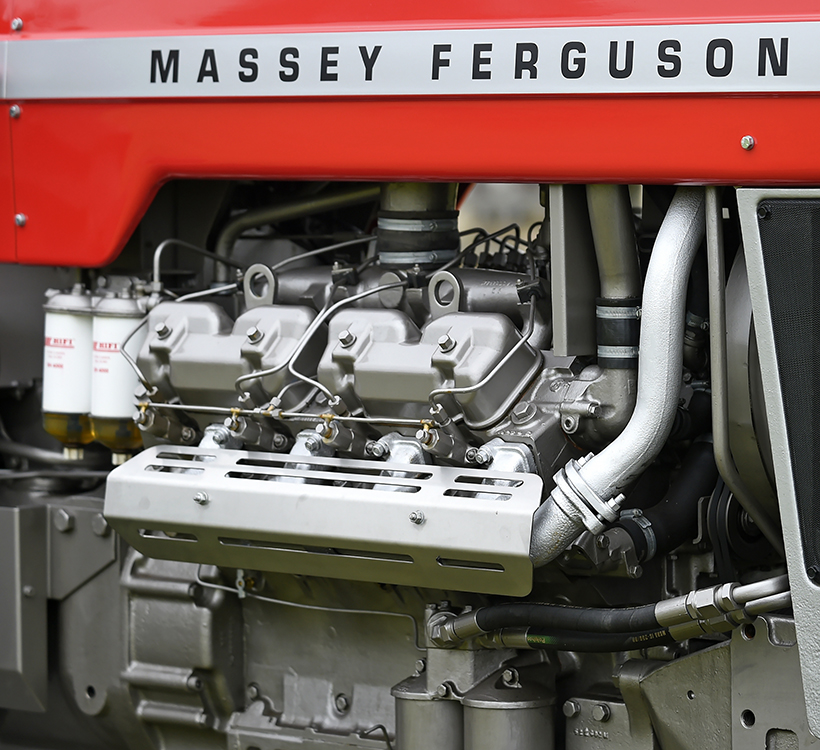

The Perkins V8 engine really is the beating heart of the MF 1150. It’s a superb unit although can be a little reluctant to start when hot. Simon rebuilt this engine entirely on his own, apart from inserting new cylinder liners, which he had done professionally.

“The 1150’s V8 engine is a Perkins AV8.510 unit, and I sourced all the parts I needed for that from a well-respected engine specialist in Essex – Gosnays Engineering Co Ltd, in Romford (gosnsays.co.uk). That company is fantastically experienced with engines like this one, and I called on their expertise to fit the new cylinder liners for me. But I did everything else on the engine myself, including replacing the damaged piston I’d found. One of the biggest practical problems I encountered, though, was man-handling the around. I only have a one-ton hoist and the V8’s weight is just about on that limit, so my hoist required regular pumping to keep the engine aloft!”

Cleaning and painting

“Every component that I’d removed as part of the strip-down process was carefully cleaned (using a bristle disc and plenty of elbow grease), then I could start the painting. This was done by hand and took a long while as I applied four coats to each item. The only parts that I didn’t tackle in this way were the bonnet and the wings, which were sent to a friend with professional spraying equipment. I opted for a modern, two-pack finish, having tried twice to spray the 165 myself with traditional enamel, without much success.

The partially rebuilt tractor. The bonnet and wings were sprayed in two-pack paint with professional equipment. Everything else was brush-painted by Simon and the quality of his work is superb.

“The gearbox and back axle were both pretty sound, and neither was leaking any fluid when I got the tractor. Nevertheless, I removed the cover plates, drained the sludgy old fluid and cleaned everything as thoroughly as could. The hydraulic braking system was stripped, cleaned and rebuilt and now works well, as long as the engine is running!

“The 1150’s electrical system is very straightforward, so I was able to fabricate and fit a new wiring loom without too much difficulty. The original wiring was pretty ropey, but it was easy to route the new stuff as there’s plenty of space to play with. Sadly, I had to replace all the instruments. I did send the central rev counter away to a specialist to see if it could be repaired, but it was too far gone to save.

“The hydraulic system is the only area of the tractor that I’m not yet happy with. It wasn’t working properly when I got the tractor, and still isn’t now. I’ve bought a new control valve which, hopefully, will do the trick, but it’s just a case of finding the time to fit it. That’s a job that needs to be done outside so, once the weather improves, that’ll be high on my ‘to do’ list.”

All the instrument gauges are new. Simon did try to save the original, central rev counter, but poor condition prevented that from happening.

Finishing touches

Regarding the tractor as it is now, Simon said: “The whole project took me just over two years of evenings and weekends to reach this stage. It was an immensely satisfying process and I’m very pleased with the results. The tractor’s first outing was to the Malvern show last year, and I was amazed by the amount of interest it generated; there seemed to be people around it for the whole weekend. I suppose it remains a rare sight here in the UK, given that there are only eight that I’m aware of and, although all are runners, I believe that mine’s the only one that’s been fully restored. The most I’ve seen gathered at any one event is two, which happened at last year’s Biddenden Tractorfest, when mine was joined by Mick Blunt’s example.

“As far as possible new additions to my fleet are concerned, I can’t really go much bigger, so I’ve been wondering about a 188, or maybe a little 35X. The trouble is, another machine would create a storage problem – my existing three are already spread around the place – and transportation would become even more of an issue.

The size of the MF 1150 really becomes apparent out on the road, where slightly wandery steering and a bouncy ride mean that drivers must keep their whits about them at all times. The hydraulics are not fully functional yet, but Simon has a new control valve that’s ready to be fitted.

“Talking of which, I did my HGV licence recently so that I’d be able to move the machines around myself. I did a week-long intensive course, and have to say that I found the test itself to be one of the most stressful things I’ve done for many years. During the course there was no build-up, in terms of vehicle size. The first time I went out with an instructor, I was driving a full-sized truck on the public roads, which was quite daunting!

I now have a Daf 26-ton flatbed truck (complete with Hiab crane), which allows me to transport two out of the three at a time. However, it’s quite a nerve-wracking process loading the 1150, as the tractor is the same width as the flatbed, so there’s no room for error. The height you are off the ground makes it more difficult and, driving on forwards means that the angle of the incline leaves you with just a view of the bonnet and sky! More recently I’ve fitted a winch and pulling the tractor on – rather than driving it – makes loading a little less stressful.”

It’s no wonder this tractor attracted so much attention at its first outing in Malvern last year. Then quality of finish is quite superb and testament to Simon’s attention-to-detail approach to the restoration.

On the road

Simon finds the 1150 quite a handful on the road. “It’s not only the size of the tractor, but the steering’s a bit wandery and the ride is pretty bouncy, which means you really have to concentrate all the time. I think it’s purely down to the tractor’s design, as well as the size of the tyres fitted. The steering as been completely rebuilt with new bushes, so I know that play in the system isn’t a problem. Essentially, the open road isn’t the 1150’s natural habitat, which is one of the reasons why I haven’t taken it on many tractor road runs so far.

“On the plus side, the brakes are good and the machine will cruise happily at a steady 20mph. Overall, though, I have to say that my 178 is a much nicer tractor to drive on tarmac. I’ve recently taken on the role of co-ordinator for Surrey and Sussex with the Friends of Ferguson Heritage Club, so will no doubt be getting out and about more this coming season.

The 140hp V8 engine certainly catches the eye, and is unlike anything else you’re likely to see on a classic tractor from the 1970s.

“I haven’t done any work with the tractor and, to be honest, I’m not terribly interested in that side of the hobby. I’m sure it would be an impressive performer with a plough on the back, but I wouldn’t know where to start with that. The engine has a bit of a reputation for being tricky to restart when hot, and I have experienced that issue. It always goes in the end, but tends to need a bit of turning. A battery in good condition is essential at shows, and I tend to leave the engine running when in the ring, to avoid the risk of embarrassment!

“Overall, though, this tractor really has lived up to my expectations in every respect. I just think that it’s a fantastic piece of engineering, given that it’s now 50 years old. There are so many quality details which I really appreciate. The engine’s air inlet manifold, for example, is a single, cast iron component that’s beautifully designed and made. I also like the fact that, because it’s a traditional-looking tractor, all the mechanical workings remain fully exposed, unlike on the 1200 Series, where everything got hidden from view.

Simon Wright deserves enormous credit for the overall quality he’s achieved with this project. His MF 1150 is one of only eight that he knows of in the UK.

“The exhaust makes a superb sound and while some people have suggested that a silencer should be fitted, I haven’t done that. My feeling is that if you have a wonderful V8 engine under the bonnet, then you really should be able to hear it in all its glory.”

This feature comes from the latest issue of Classic Massey & Ferguson Enthusiast, and you can get a money-saving subscription to this magazine simply by clicking HERE

Previous Post

The sad demise of 1953 Mediterranean Sky

Next Post

Shuttleworth Collection’s Engineering Weekend