A real passion for Ford and Fordson tractors

Posted by Chris Graham on 10th April 2024

Bob Weir meets Tanya and Dave Steele to discover more about the passion they share for their Ford and Fordson tractors.

Tanya and Dave Steele are certainly big Ford and Fordson enthusiasts.

After spending some time with Tanya and Dave Steele, who live in Market Drayton, Shropshire, there’s no denying the fact that they’re dedicated Ford and Fordson fans. “It all started with my father,” Tanya explained. “He’s been collecting Ford and Fordson tractors for many years.”

Shropshire is a county that’s well known for both its agriculture and its tractors. I bumped into dad and daughter at Tern Valley Vintage Machinery Trust Ltd’s rally last August, at which the family was exhibiting a couple of blue machines from the collection and, due to time constraints, we decided to do the article there and then.

They’re in the blood!

“We’ve lived in Shropshire for many years,” said Tanya, who works as a telemarketing manager. “I learned to drive the New Performance Super Major before I learned to drive a car, so Ford and Fordson is in my blood.”

The Fordson New Performance Super Major and Ford 5000 spotted at the Tern Valley Show.

Tanya can still recall sitting with her father, Dave, on the tractor when she was very young. Her family comes from a farming background, and her grandad’s first tractor was a Ford 4000. “We’ve had the Super Major for as long as I can remember,” she added, “and it’s become part of the family. We’ve added several other Fords over the years and, during the summer months, most of our weekends are spent away at tractor rallies or on road runs. We’ve always been keen on Ford machinery and friends know our motto: ‘Blue is the Colour!’ We even have our own Facebook page, called ‘Stay true to the Blue’.”

The family’s tractor collection currently includes a New Performance Super Major, a Power Major, a 5000, a 4000 and a 3000. There’s also a Super Dexta and a green, 1940s Fordson Standard N. That, I’m sure you’ll agree, is a stable to whet the appetite of any Ford and Fordson enthusiast, and the family has acquired the tractors over many years. What’s more, they are always on the look-out for interesting new machinery to add to the collection.

“The New Performance is my favourite,” says Tanya, “and we’re really lucky to have it. The model was introduced in July 1963 and was only available for a few months, so you don’t see many examples around these days that haven’t been fully restored. It was originally supplied by George Oakley, the local dealer, and has remained in the Shropshire area ever since. We’ve owned the tractor for about 15 years.”

The New Performance Super Major’s transmission was tweaked to provide a larger spread of gears, particularly at lower speeds, which improved low-speed control and usability. The blue and white colour scheme was introduced to help prepare UK customers for the upcoming demise of the Fordson brand, in 1964.

Lasting quality

It’s a testament to the quality of the original Fordson design that the final incarnation of the Major was very similar to the first E1A, except for branding, power output and a few extra features. It certainly proved its worth in practical terms, being both reliable and durable, which is why it was such a mainstay of UK farming during the 1950s.

Typically for Ford, the E1A’s design evolved over time and there were changes under the bonnet. Earlier versions of the Major had been criticised for not generating the PTO performance needed to run the latest generation of larger implements. But, with the increase in engine revolutions, more power was available at the PTO shaft.

“Our Major was actually saved from a local scrapyard, which was a large slice of luck,” Tanya told me. “My father was told that the previous owner had died, and that his wife simply wanted to see the back of the tractor. This is probably why it was in such good condition. When my father got the Fordson home, he decided to take stock. It turned out that all it really needed was some TLC plus a bit of a makeover. He decided to brush-paint the bodywork to improve its appearance.”

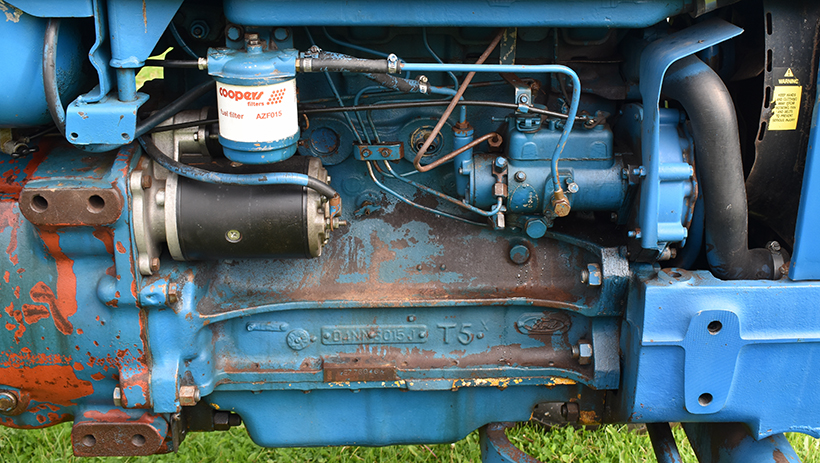

The Ford 5000 was built at Highland Park, Michigan, and Basildon, in Essex. The Steele family’s example is the American version.

Of course, the Steele family’s Major won’t be the only tractor that’s avoided being scrapped by the skin of its teeth, and their example looks in remarkably good condition. The bodywork has aged well, and Tanya told me that the engine can still do the business.

“Apart from servicing and general maintenance, the tractor has had next to no money spent on it, and yet it still performs well,” she said. “It’s a testament to the original design, as the Major was one of the dominant tractors during the immediate post-war years.”

Out and about

According to Tanya, the family has taken the Major here, there and everywhere over the years, particularly during the summer months. “Apart from the fact that it’s simply a nice tractor, the Fordson has a lot of sentimental value,” she said. “It was part of my and my brother Michael’s childhood. We grew up with the machine. If it hadn’t been for this tractor, we wouldn’t have gone to any of the shows, or created so many happy memories. The Major is an important part of our past.”

The Steele family’s 5000 is missing its cab, although the introduction of the Agricultural Cabs Regulations in 1970 meant that safety cabs had to be fitted as standard.

Although the New Performance Super Major is a home-grown Ford, the 5000 the family owns was imported from the USA. “We were told that the tractor was first registered in 1975, and that it originally came from South Carolina,” Tanya explained. “However, its early history is a bit of a grey area. The Ford was brought into the UK by tractor enthusiast Chris Ridgeway, who ran an advert on Facebook.”

The Ford 5000 was first introduced in 1965, as part of the New Generation series. The move was part of Ford’s strategy to deliver a global range of tractors, and the model sold exceptionally well in the UK. The North American version was slightly different from the model sold here, and was marketed as the Ford Major. The 5000 was pitched as a mid-range tractor, which appealed to the majority of British farmers.

The model was upgraded in 1968 when it became part of the Ford Force series. The engine’s horsepower was upgraded, and changes were made to the tinwork to give the tractor a more modern appearance. A further review took place in 1971, including the addition of factory-fitted safety cabs. The model was also modified by specialist conversion companies like E Doe. Over the years, the Ford 5000 has acquired a reputation as one of the most popular ever made, and is still widely in service despite its age.

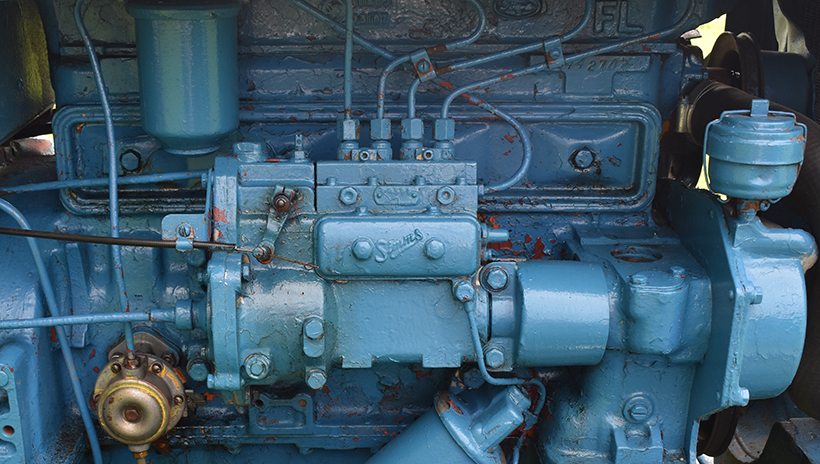

The NP Super Major’s engine benefitted from a Simms Minimec fuel pump, which increased power output to a very useful 55hp.

The 5000 arrives

“We went to check the machine out and managed to come to an arrangement.” said Tanya. “The tractor was in reasonable condition and ideal for rallying. At some point it had been fitted with a Select-O-Speed transmission. “We rallied the 5000 for about a year without making any changes, then my father decided that he wanted to convert the tractor back to its original gearbox. We all mucked in, but we remain particularly grateful to enthusiast John Williams up in Cheshire. He did most of the work, and we’d certainly have struggled without his help.”

Tanya explained that the tractor has also been fitted with a non-standard differential. “We substituted the original differential because it wasn’t working properly, but the replacement also had issues and was too slow. John then suggested we try another unit, which we did. Now the tractor can run at up to 30mph, which is a significant improvement over the model’s standard specification.”

With so many members of the family keen to drive the tractor, the 5000 has its work cut out. Tanya explained that Michael usually drives it on tractor runs, while she takes turns with dad handling the Major. “If we want to make it a true family outing, then we also take some of the other tractors along,” she smiled. “That way we can all have a turn!” Tanya is particularly keen to support the smaller tractor shows, which she sees as an important way of encouraging younger enthusiasts. “It’s hard work organising events, and they cost a lot in both time and money,” she explained. “The smaller shows have a significant role to play in the local community. I think they’re vital for encouraging the next generation of tractor fans to get actively involved.”

Although they looked similar, the Ford Force tractors introduced in 1968 were considerably better than the models they replaced. The 5000 was the most popular model, particularly in the UK.

Finally, with regard to the family’s current collection, Tanya assured me that the tractors aren’t going anywhere, anytime soon. “Both my brother and I are keen Ford and Fordson fans, and we will look after the tractors when my parents decide to call it a day. These old tractors are part of our heritage, and it’s our responsibility to preserve them for the future.”

RECOMMENDED SUPPLIERS

Agriline Products Ltd

Harris Business Park

Hanbury Road, Stoke Prior

Bromsgrove

Worcs. B60 4DJ

agrilineproducts.com

Patrick Edwards Ltd

Langley Farm

Langley Lane

Clanfield, Bampton

Oxon. OX18 2RZ

tel: 01367 810259

patrickedwardsmachinery.co.uk

Sparex Agricultural Parts

Exeter Airport

Devon EX5 2LJ

gb.sparex.com

TRACTOR PRODUCTION AT DEARBORN

Henry Ford built the Fordson Tractor Plant in the village of Dearborn, near Detroit, Michigan, in 1913. The site had previously belonged to the Wagner Brick Company.

By 1921 production had been transferred to the nearby Rouge complex. Construction on the site had started in 1917 and by the time it was completed in 1928, it was the largest integrated factory in the world.

The Rouge facility measured 1.5 miles (2.4km) wide by one mile (2.6km) long, and included 93 buildings offering nearly 16 million square feet of factory floor space. It had its own docks in the dredged Rouge River, together with 100 miles (160km) of interior railroad track. Other facilities included a dedicated electricity plant and an integrated steel mill. The key to the success of the plant was vertical-integration production.

The Ford 5000 is powered by a four-cylinder engine and most types were fitted with a two-speed PTO. Porous engine blocks were one of the few issues with Force tractors.

Although the Rouge facility would eventually become famous for producing cars, the first vehicles assembled there were farm tractors. The Fordson F had already achieved the distinction of being the world’s first mass-produced tractor and, of course, became an icon in tractor development.

By the 1970s, Ford had begun to decentralise its manufacturing process, and production was moved away from its heartland in Detroit as factories were built in other cities. The Rouge site was downsized, with items like the docks and furnaces being sold to independent companies. The last vehicle rolled off the assembly line in 2004 and the site was demolished in 2008.

This feature comes from the latest issue of Ford & Fordson Tractors, and you can get a money-saving subscription to this magazine simply by clicking HERE

Previous Post

Visiting the wonderful Darjeeling Himalayan Railway

Next Post

Those who preserve our cherished vehicles deserve praise