Austin Minor Pick-up restoration

Posted by Chris Graham on 30th May 2021

Russ Harvey tells the story of his 15-year, Austin Minor Pick-up restoration, which was finally finished during lockdown.

Russ Harvey’s Austin Minor Pick-up, resplendent in the spring sunshine following its 15-year restoration.

My December 2006 Christmas gift to myself, courtesy of Eric Payne in Worcestershire, was the vehicle that formed the basis of my Austin pick-up restoration. It was an early start when Godfrey Crew and myself left in freezing fog, our plan/aim being to be back home while ‘er’ indoors’ was still out shopping.

The vehicle arrived as a dismantled chassis-cab assembly, with little else included.

The garage had been emptied, my blue van was now stored for winter with fellow LCV enthusiast, Lawrence Homer, and I had arranged for our local vicar, David Hathaway, to assist Godfrey and myself with the unloading so that it would be safely tucked away in the garage before Mandy arrived home. It duly was, and she found us drinking tea and eating mince pies.

Work on the cab underway in Russ’s home garage.

An internet find

BMF 148H was an eBay purchase, and was advertised as an Austin 8cwt LCV chassis/cab. Upon arrival, the chassis and cab were inspected and found to be sound, and a further deal was struck with the seller, as he also had a nice set of LP917 van wide rims kicking about.

Engine bay refinished in the ‘Titian Beige’ paint that eventually covered the whole vehicle.

‘BMF’, as it quickly became known, started life as a green van, but I wanted a pick-up to compliment my van so, from the start, intended to go down the modified route. It was registered on 15th July, 1970 – just two weeks off being a J reg – and MF is a London-area registration. This, unfortunately, makes tracing the early history difficult, as the Greater London Council was one of several authorities to destroy all its old records once everything had been transferred to DVLC, in the early 1980s.

Finally, a complete, rolling chassis.

First, I began collecting the required various modified parts needed; these included two pairs of genuine pick-up sides and two tailgates acquired as a job lot. Of these, one pair of sides and a tailgate were sold to fund the repairs that had been entrusted to metalwork guru, Iain McKenzie, of Fairmile Restorations.

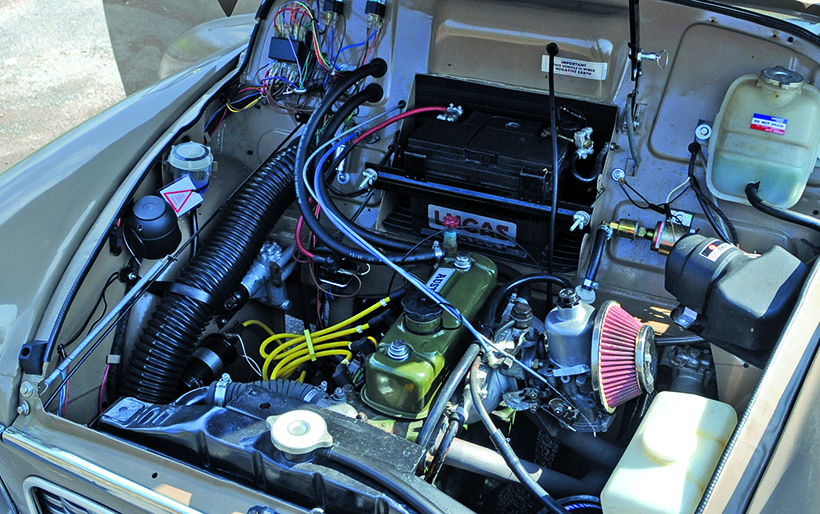

The modified, 1,275cc Midget engine in situ.

I knew the restoration was going to take a considerable time so in the meantime, as the photos show, I spent many months painting the various suspension parts front and back in gloss black and, while out in the garage, I always added an extra coat to the chassis. I lost count after seven or eight applications!

The rear end mounted to the chassis, before being painted.

I went for a 1,275cc Midget engine, which was acquired very cheaply from a good friend. This had been dismantled and bored, and I rebuilt it using new parts plus a 1275 Metro unleaded head and HIF44 carb; the latter came back to haunt me!

Patience pays off!

The engine was assembled and painted green, a Midget flywheel obtained and bolted on, it had been sitting in a garage under a plastic sheet for a considerable time. Hunting for parts and obtaining them at a realistic price often pays off, and both a 1,275cc Midget gearbox and a 3.9 differential were acquired a very reasonable prices; I was chuffed with my purchases!

With the pick-up back from the paint shop, the fitting-up could begin.

Front disc brakes were on the agenda and, of course, the Midget choice for me made perfect sense and, had the Minor remained in production, I believe that this would have been the route the factory would have taken. The Midget ‘steel wheel’ hub bolts on to the front swivel pins, and new callipers from the same vehicle were mounted using a clever mounting bracket.

One of my biggest problems during the rebuild was that this restoration was carried out in a single garage. Accordingly, to clear space, once most parts were painted, I started boxing them up, and lots went into the attic.

There are 5.5J rims fitted at the rear – note the Leyland flaps.

With all the painted bits covered or boxed and away, my attention turned to the cab. I needed to purchase new floors, cab join pieces, and the two pieces that fit across the back, under the tailgate. Then, with space in the garage at last, the cab was up on its end, and I applied stone-chip to the floor, inside and out.

I then painted it using synthetic enamel inside the cab, as well as the engine bay. The colour – chosen by my wife – was Titian Beige (BG18), a colour used on Mini commercials. I also sprayed the two, new-old-stock doors, pick-up cab back and my GRP spoiler, as this would make life easier at the paint shop, and allowed me to start assembly and get chassis/cab on to four wheels, and eventually able to move under its own power, though that day was still some way off.

The cab interior.

Chassis build

Meanwhile, the refurbished chassis was placed on axle stands, front torsion bars were fitted and the suspension front and back completed with poly bushes. By August 2007, it was a rolling chassis that actually rolled!

Next came the wiring, for which I called upon the services of my very good friend, Godfrey Crew. Sadly, Godfrey died before we finished, and so never saw this project completed. I am, though, grateful for all his input, especially during the early, electrical stages which, in turn, gave me the confidence to wire the rest of the pick-up. I’d purchased a very early loom (brand new) one Christmas Eve on eBay for a mere £25, after speaking to Godfrey who advised me to buy it; “We’ll get it to fit!” and, of course, he duly did. As with all projects, though, time drifts as does life, and progress slowed for several years, although more parts kept arriving.

There’s now a 1,275cc Midget engine, complete HIF44 carburettor, nestling under this pick-up’s bonnet.

The next major milestone came in March 2012, when the engine and gearbox were installed, together with the propshaft, and a modified steering column, using a late Mini double stalk wiper/indicator switch set.

The main problem was wiring the loom to get power to turn the engine. Eventually the starter turned, but it wouldn’t start! After much head-scratching, the distributor-dog was found to be 180° out. We turned it around and the little A-Series burst into life and, for the first time in our ownership, the Minor moved under its own power.

Additional mods

A number of additional modifications over and above the MG Midget engine, were also incorporated at this stage. These included a servo-assisted braking system, a three-branch manifold and large-bore exhaust, front and rear fog lights, reversing lights and a set of four, genuine NOS British Leyland mudflaps.

The rear end was assembled by Iain then reunited together with a modified, Ford 10-gallon fuel tank. By the summer of 2015, there was a complete-looking vehicle in my garage, but lots still to do, including most of the painting. However, due again to family circumstances, the project had to take a back seat, and work didn’t restart until 2018.

In November, a start-date of January 2019 was agreed with painter Keith Gore, who returned the vehicle, fully-painted, in March. Reassembly then started but, during May, I was diagnosed as needing a new hip so, with surgery booked for November, I was unable to carry out any more work from the summer of that year

My new hip was ‘installed’ on Halloween on 2019, but time for recouperation was needed, so it was February 2020, before work resumed. By then we were, of course, entering the Covid era, which at least meant plenty of time for working on the vehicle with fewer distractions than normal during a summer. Work continued apace, with new, red carpets being fitted together with a new canvas tilt. The Austin was finally MoT’d in September, 2020.

At last, it was on the road! The inaugural, 300-mile run to Shropshire was completed, but the Minor wasn’t running as I wanted! Suspecting the HIF44 carburettor, I bought and rebuilt a Maestro 1275 unit, and fitted a new BES needle, recommended as best for my set-up. The improvement was amazing; it was like driving a new and completely different vehicle!

So, there we are! It’s been a roller-coaster of a journey but, with a lot of help from my friends, I got there in the end. I’d like to thank everyone who provided so much helpful advice along the way, but the list would be too long! However, special and posthumous thanks must go to Godfrey Crew and Im also so very grateful to Eric Payne, Iain McKenzie, Glen Reid (for mixing and supplying the paint) and Keith Gore for applying it. They were all brilliant!

Russ is justifiably proud of his restoration achievement, but is quick to pay tribute to those others who offered so much help and advice during the 15-year renovation project.

And finally, I treated myself to a number plate, so ‘BMF’ has now been renamed, ‘RH’.

For a money-saving subscription to Classic & Vintage Commercials magazine, simply click here