Brilliant Bedford O lorry budget restoration

Posted by Chris Graham on 18th June 2024

Peter Simpson meets Parry Davis and the 1946 Bedford O that he’s restored so well, despite the tightest of budgets.

Parry Davis’s 1946 Bedford O; a lorry restored on the tightest of budgets.

Parry Davis is well-known in lorry restoration circles. I’d also venture to suggest that the name will be familiar to most CVC readers, as we have featured several of his restorations in the past. Many of these have had a direct connection to Davis Brothers, the well-known East End firm which expanded rapidly throughout the 1950s and 1960s and which, it would be fair to say, did have a certain reputation for sailing close to the wind in many respects.

Parry’s father was Harry Davis, one of the Davis ‘Bros,’ and though GYB 988, the 1946 Bedford O that is the subject of this feature carries neither Davis Brothers branding or livery, it replicates a type and operator that were a significant part of the Davis Brothers story.

Direction indicator switch will be recognised by many who may also recall the sometimes over-quick cancellation timer!

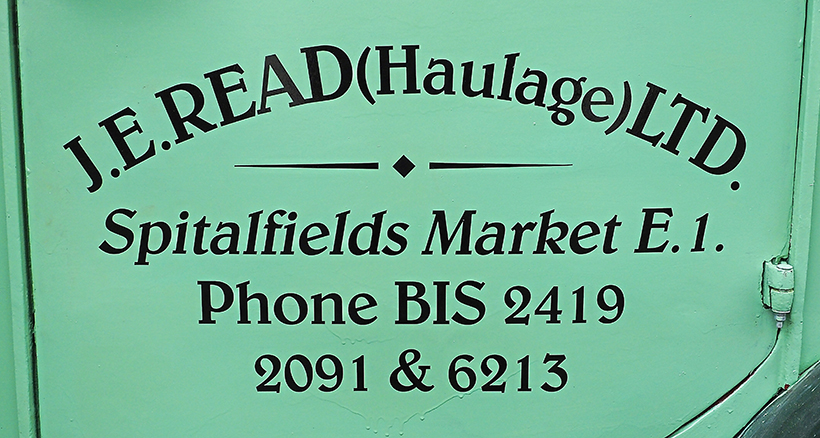

This chapter of that story starts towards the end of WW2, when the Davis family bought JE Read, a long-established East End firm based in Spitalfields, East London and whose main business was hauling fruit and veg into London. Harry Davis ran the business, and Parry recalls his Dad describing Read as “a profitable business with good traffic and a good team of blokes, but a motley fleet of worn-out motors.” This was not at all uncommon at this time. Anyway, somehow (“by fair means or foul” as Parry puts it) Harry managed to acquire a fleet of new Bedfords. Interestingly though, he never called them O Types, instead referring to them as 28-horse Bedfords. Which of course is what they were.

Instruments are the originals and exactly how they were when these lorries were no longer in the first flush of youth!

Sadly, although these lorries were just what the Read business needed, they couldn’t keep them long, as nationalisation was just around the corner, and when that happened, the business, and its lorries, were all absorbed into British Road Services. Though this was a far-from-happy episode in the story of Davis Brothers, it’s clearly one that’s especially poignant for Parry, and he was therefore keen to recreate one of the JE Read Bedfords as operated by the business under Davis ownership.

In 2020, he found a part-restored 1946 O Type which seemed to fit the bill pretty-much perfectly; right age, right spec, and with a certain amount of difficult work completed already, but in need of putting back together and generally finishing-off. As usual for him, Parry set out to recreate a period working vehicle rather than an immaculate show-winner.

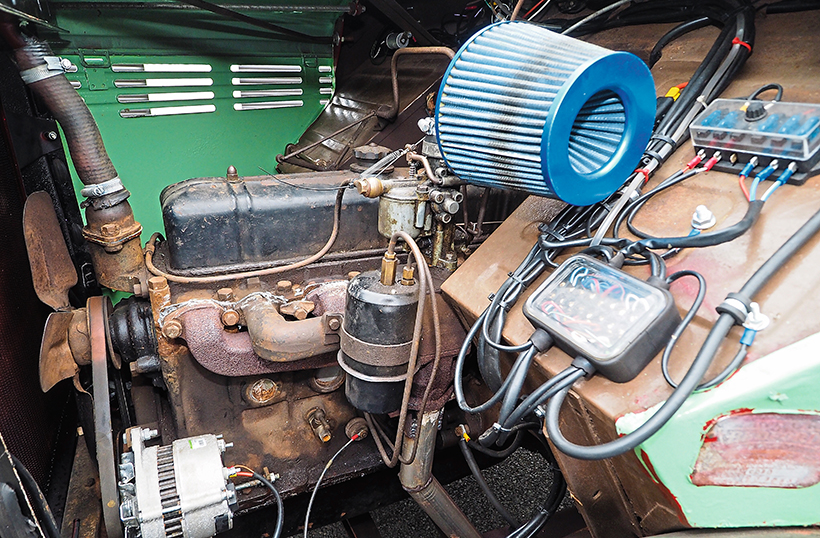

The ever-familiar 28 hp Bedford petrol engine. Note alternator, updated wiring and, because the original was missing, a modern air filter.

With this one, however, he took that one stage further, and rather than buy parts for the project, use instead stuff that he already had. I should probably mention at this stage that having been involved with lorry restoration for pretty-much his whole life, Parry has no shortage of stuff that’s been saved because it might come in handy. He has, though, done nothing that cannot be reversed should a future owner decide to return GYB 988 to original.

Dancing dizzy!

Overall, the restoration was “fairly simple in broad terms but did have its moments.” One such concerned the engine. When the Bedford arrived on site, Parry got it running, and as it seemed to run well enough, he thought no more about it. However, when he returned to it later, he noticed that the distributor was dancing around. Initial thoughts were that the distributor was loose, but it wasn’t. Then Parry noticed that the distributor’s incorrect movements were regular rather than random.

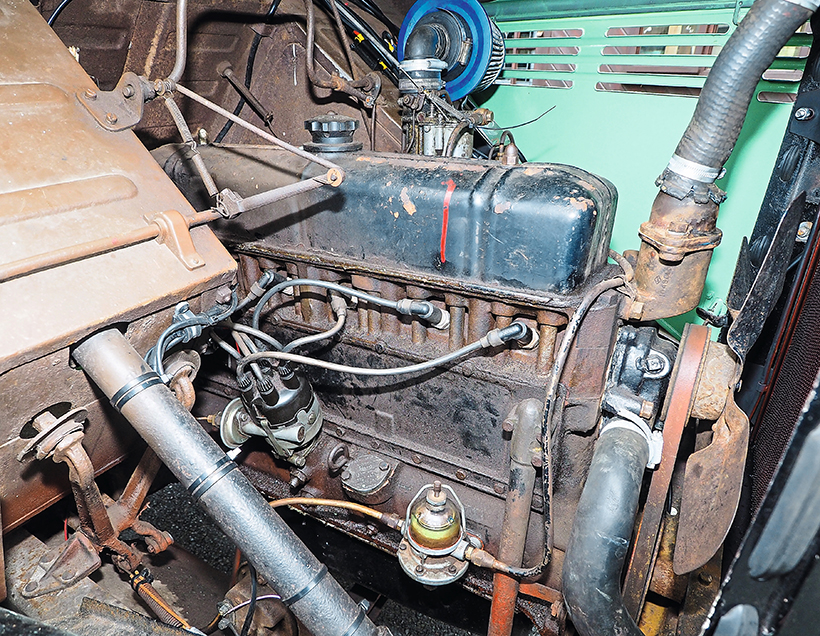

Engine from the offside; clean and clearly cared-for but there’s been no attempt at a prize-winning finish.

So the distributor came out and Parry noticed that the shaft end was damaged. Further investigation, confirmed using a dial gauge, revealed that the problem was the distributor drive gear. This had been renewed by a previous owner, but the replacement hadn’t been machined correctly. Fortunately, Norman Aish at Bygone Bedford Bits had a replacement in stock, and this cured the issue, though fitting it involved significant engine dismantling as the same gear also drives the oil pump.

Body was built by Parry at home, and took less tan a fortnight to make from scratch.

On the positive side, however, the chassis was in sound condition having been renovated by the previous owner. The lorry came, however as a chassis-cab unit, and while the cab itself was reasonably solid, the seats needed retrimming. New seat covers and so on were made by Parry’s wife Sheila, using materials obtained from Abakhan Fabrics (www.abakhan.co.uk) based in Mostyn, North Wales. They supply textured Faux Leather at £9 a metre, compared to £30plus for the real stuff. Faux leather is also easier to work, and rather more comfortable in hot summer.

Parry built the body himself but chose to use tanalised softwood rather than hardwood; lighter, perfectly good for load-carrying and being thoroughly protected already, it needs no further treatment once the body has been made. It’s also, of course, significantly cheaper. Reeves Timber of Wem supplied it, but the maximum length available is 13ft 9in, and the body should really be 14ft. So, following his cost-conscious restoration theme, Parry just made the body 3in shorter…

The main reason for this project was Parry’s desire to recreate a J E Read lorry, as his late father ran the company until it was nationalised.

Upgraded electrics

The electrics needed pretty-much remaking from scratch, and in doing so Parry has improved on the original setup. Rather than pay upwards of £100 for replacement sidelights, Parry made his own using copper plumbing fittings. We can’t help but wonder whether, if these homemade units were to be put on sale in some trendy city recycling-type shop, they’d sell for more than enough to pay the £100plus now needed to buy correct original items.

The headlights, mounted inside the original housings, are Volvo car units sourced at an autojumble, and in the interests of safety, the lorry now has direction indicators; this was of course something that many operators did back in the day.

Sidelights have been made from some copper plumbing fittings that Parry found in his workshop.

Also for safety, and as you can see from the engine photographs, modern fuseboxes have been used, and overall, the Bedford’s wiring now is a massive improvement in what it would have had when new.

No work was needed to the running gear, and the brakes and steering were stripped and checked, but again nothing was needed beyond normal greasing and adjustment. The carburettor presently fitted has been made up from three identical units Parry had ‘in stock’ – the same unit was used on Scammell Scarabs.

More modern Volvo headlights inside the original housings perform much better than the original 6V items.

The ‘distinctive’ light green colour scheme results from a mistake. Christine Thomas at the Bedford Enthusiasts Club supplied some original paint codes, but the colour Parry chose from these was actually for a cab interior, and had he realised this, he’d probably have chosen something else. But having now used it, he likes it, and no-one can doubt that it’s eye-catching.

Anyway, it’s Parry’s lorry to paint how he chooses, he likes it, and as I look at the photos from our shoot, it’s definitely grown on me!

Radiator filler cap top has been turned on a lathe from a lump of hardwood.

So it was time for a first road test. That was, however, fairly short-lived, as within the first half-mile the fuel system blocked up due to the inlet union from the tank to the fuel pump becoming blocked with crud that had accumulated in the bottom of the fuel tank. Due to what Parry describes as “Bedford’s penny-pinching” there’s no hand primer here. Cleaning the tank however proved difficult due to the presence of baffles in the bottom of the tank. Parry has done the best he can, and to hopefully catch any that he can’t remove, he’s fitted an inline filter.

Petrol tank was clogged up, and difficult to clean out due to the presence of internal baffles.

The second road test lasted a bit longer, but it too was cut short due to overheating resulting from a partially-blocked radiator. A tin of radiator flush soon shifted the blockage, but as so often happens, it also transformed the previously watertight radiator into a colander by uncovering three holes and two splits. This issue couldn’t, unfortunately, be fixed on the cheap, and there was no realistic option but to have the radiator rebuilt with a new core at a cost of “several hundred pounds.” It does, though, have one bit of Parry penny-pinching; the top of the screw-on filler cap has been lathe-turned from a hardwood offcut from the Scammell R8 restoration that we featured back in December 2022.

The misformed distributor drive gear which caused problems early in the project.

And with that done, the lorry was basically back on the road. Parry clearly enjoys driving his latest restoration which he reports is capable of cruising comfortably at 45mph and has “decent brakes” though he is still getting used to the gearbox and driving a petrol-engined lorry does, he says, require a slightly different technique to a diesel. The intention is for the Bedford to be out and about this year; Parry always drives his lorries to and from events and isn’t afraid to take them some distance; he’ll often do more miles getting to and from a road run than on the run itself.

And as you’d expect, there are more projects in the pipeline. The next lorry is likely to be another Bedford O, this time a 1950 OSS with a Perkins P6 engine and Eaton two-speed axle. The issue with this one is that it is remarkably original, but much of that originality is sort-of on the border between being patina that should be preserved and deterioration which should perhaps be rectified. Parry has, however, a plan which should meet both these needs, and hopefully we’ll be back to see the results in a few years time.

Parry Davis driving his Bedford, something he enjoys doing a lot.

Conclusions

Clearly, the approach that Parry has chosen for this lorry is not one that will appeal to everyone. I’ll admit too that I was a tad sceptical when I first heard about it. But having now seen the lorry in the flesh and talked to Parry about what he’s done and why, I do kind-of get it, and understand why it was right for him. In this context, don’t forget that Parry has six lorries on the road and another four awaiting or under restoration, and it’s therefore perhaps understandable that he wanted to do something slightly different with this one.

He has also shown that it is possible for someone working with a tight budget to undertake a successful restoration, and some of what he’s done – for example the reworking of the electrics – has made the lorry more useable. As for the rest? Well as stated at the start, he’s done nothing that can’t be undone should a future owner choose to do so. As it stands, the lorry is on the road, being driven and enjoyed as an example of what can be achieved using time rather than money and it certainly brings a bit of variety to the rally field.

And for those reasons, while some of this restoration hasn’t, perhaps, been done how I’d have chosen to, I can certainly see merit in this slightly different approach to lorry restoration.

This feature comes from the latest issue of Classic & Vintage Commercials, and you can get a money-saving subscription to this magazine simply by clicking HERE

Previous Post

Exciting debuts spotted at Yeovil’s Abbey Hill Rally

Next Post

Ferguson and Massey Ferguson tractor classics on display