1979 ERF B-Series lorry amazingly restored in the back garden!

Posted by Chris Graham on 4th March 2024

Peter Simpson tells the story of David Whitehead’s 1979 ERF B-Series lorry, and how it was restored in his back garden!

David Whitehead’s 1979 ERF B-Series lorry; a first-time restoration that was undertaken in his back garden.

Like so many people who have restored old lorries, 60 year old David Whitehead from Skipton in North Yorkshire is, it would be fair to say, a lorry-man through and through. His late father Jack drove lorries, and as a youngster, David frequently rode in the cab of his Dad’s lorries, with one that he remembers especially being an ERF B-Series.

Owner/restorer David, beside his name on his lorry.

In due course David followed his dad into the industry, first as an apprentice fitter/mechanic. Driving, however, was what he really wanted to do, so he trained for and passed his HGV test as soon as he was 21. Then, over the ensuing 39 years, he drove pretty-much the whole range of artics from heavy haulage to tankers and curtainsiders. This included 20 years with Longthornes of Hebden on tipper work.

The lorry when it was with its original owner, Ravenhead Glass.

Lifetime ambition

Pretty-much from the start David aspired to own his own preserved lorry, but as a family man he had other priorities and calls on his money, and it wasn’t until 2018 that he was able to fulfil that particular lifetime ambition. He is a keen an enthusiastic user of online commerce sites such as eBay and Facebook marketplace, both of which were extremely useful when it came to sourcing parts, so used these to put out an appeal. His requirements were pretty specific; an ERF B-Series tractor unit with a black and beige interior. The interior colour was important because that was what he remembered from those childhood trips with Dad.

In fairground service, as a generator lorry and motive power unit.

In due course a response came which led him to GED 634V. There was one slight issue; it was blue inside. However as the interior was going to need renewing anyway, that wasn’t actually a problem. The interior was also probably one of the least of David’s concerns as the ERF was in a scrapyard in Rugeley, Staffordshire, and in need of significant surgery. In fact it was going to have its Rolls-Royce 265 engine sand Eaton gearbox removed for resale and the rest scrapped. It was, though, the type of project David wanted, a deal was done and the ERF was transported up to Skipton, where David had secured a barn in which to do the work. “But you said it was done outside” I hear you say. Yes I did, and yes it was, but I’ll come back to that…

The ERF as it arrived in Skipton for restoration.

First, though, a bit of history. GED 634V was new to Ravenhead Glass based in St Helens on Merseyside, which is of course the centre of glass manufacture in the UK. After 10 years or so here it passed, with four others, to Peter Parker, a lorry breaker based in Hyde, Greater Manchester. David made contact with Peter shortly after buying the lorry, and Peter has “helped out greatly with parts and always been on the end of the phone for advice.” Peter recalls the lorry David now owns was the “roughest of the five ex-Ravenhead ERFs, but it pulled like a train.” It wasn’t however, broken for spares but was resold and subsequently spent many years on fairground work. David isn’t sure who owned it then, or how it subsequently reached the Rugeley breakers yard, but he has seen photos of it in grey at what appears to be Great Dorset and in the blue it was wearing when bought with a generator on the back and bearing the name Ryan and Rigby.

This is where the five-year restoration was carried out.

At first glance, the ERF as bought didn’t actually look too bad, but a glassfibre cab can be hiding all manner of defects especially when, as in this case, it’s covered in numerous coats of brushed-on paint.

Chassis and spring restoration underway; shot-blasted and ready to paint.

But before we talk about the restoration proper, we need to look again at where the work was to be done. As noted a moment ago, David initially intended using a rented barn and had actually spent some time preparing to receive the lorry. However, before that happened, the barn was broken into and a number of items stolen. This prompted a rapid rethink, and David decided quickly that he would feel happier doing the job at home, where there was room in his garden, and though this would mean working on it in the open, at least the lorry would be safe there.

Work at the back included reinstating the fifth wheel.

I should perhaps mention at this point that David has lived where he does for many years, has excellent relationships with his neighbours, and far from objecting or being hostile, they took an interest in the project. In terms of personal skills, though he had chosen to drive lorries as a profession rather than fix them, he had his mechanics training from 35 years earlier, and once learnt, skills such as welding stay with you for life.

Chassis in primer. After eight coats of primer the red top-coat went on.

The chassis

Anyway, work started with stripping the vehicle down to its bare chassis, after which everything – springs, front crossmember, chassis and so on – were shot-blasted. Some welding and fabrication was needed; specifically, the mudguard stays needed renewing along with the flitch plates, and as the fifth wheel had been removed for the fairground work a replacement was sourced, via Facebook marketplace, from a guy near Ipswich. The springs were stripped, cleaned, regreased and refitted with new shackle pins, and David then primed and painted the chassis using eight coats of primer followed by six of Post Office Red chassis paint. All the paints used in the project were supplied by Trade Paints of Birmingham.

Cab steps required remaking from scratch.

As usual in a restoration, all the airline pipes were renewed, and the brake chambers were also changed. Removing the brake drums however revealed that the shoes had been renewed recently in terms of mileage and needed only cleaning up. The slack adjusters also needed nothing more than a good clean and free-off, and the drums were also good to reuse. Clearly someone had been looking after the lorry’s mechanical needs and general maintenance.

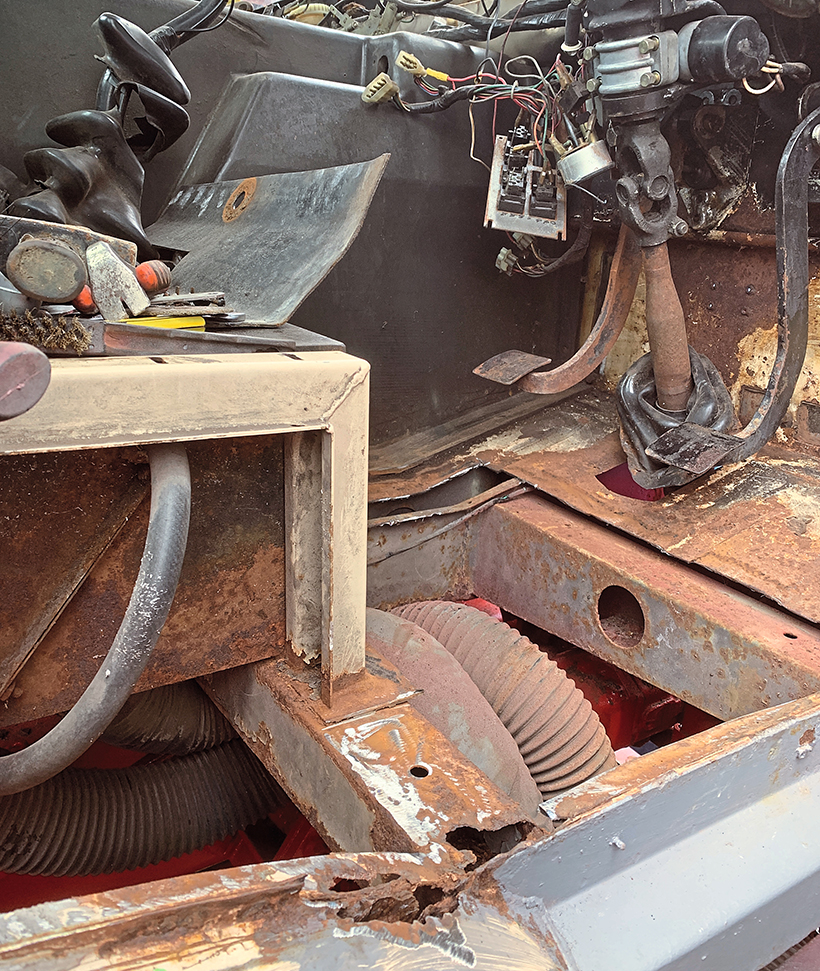

Rust cut out of cab floor. There was quite a lot to remove…

Steering-wise the box needed a thorough service and a couple of track-rod ends had to be changed, but that was about it. Continuing the cared-for theme, all six tyres were in good order and within date, so they were also retained, and the wheels were shot-blasted and painted.

Cab floor after restoration. Welding around glass-fibre requires extreme care, of course!

The cab

So far so good. The cab, however, proved to be rather more tricky – to put it mildly! David could see that there was significant corrosion in the cab frame and underpinnings, and as noted earlier, a complete change of interior was also needed. So the first stage was a complete strip down and strip out. In this, and several other aspects of the restoration, David was assisted by friend and fellow ERF owner Neil Evans. In terms of work, the cab floor needed extensive repair along with the frame at the back and the door pillars where the doors attach.

Front wheelarch rear sections were renewed.

Additionally, the front wheelarches needed repair sections and the cab steps had to be renewed. To make the more complex repair sections, David first made templates from old lino which was both easy to cut but also sufficiently rigid to stay in shape. The grille and headlight panel had to be renewed. When the ERF arrived, the ‘front bumper’ was actually a length of steel girder which was definitely more functional than attractive, but via his online searching David found a brand new, and not expensive, replacement.

Original cab interior was the wrong colour and in poor condition, so it all came out.

Then it was time to tackle the cab paint which was thick and comprised several brushed-on coats! The first job was to strip off all the existing stuff; you can’t use chemical strippers with glassfibre, so David and Neil’s technique was to carefully warm the surface and then scrape it off with equal care. After that, it was sanded, and a few repairs were needed on the gel coat before the fresh primer and top coat went on. Five coats of primer were used, with each being sanded before the next coat went on. The step-panels were painted separately. David also changed the headboard, as the original was, in his words, “pretty ugly and square.”

Replacement black interior part-way through being refitted; some controls had to be relocated which made the job more complex due to cable lengths etc, being wrong.

It was then time to tackle the interior. Well-known fellow owner/restorer Taylor Bland supplied a complete black and beige interior of the exact-type that David wanted, but it did of course need a certain amount of work. Specifically, all panels were repainted with trim paint, and the dash which was cracked in several places also needed repair. All the original instruments were damaged beyond repair, with replacements being sourced from various places. One very lucky find was a new, never-been-fitted analogue tachograph which cost just £90.

Replacement dashboard undergoing restoration.

Oh, almost forgot. The original wiring loom was damaged beyond repair having been attacked by mice, but rather than buying-in a replacement that a specialist had made, David made his own, using the old one as a pattern. Make no mistake about it, this lorry is all the work of David and his friends! This also extended to the lettering – this is actually vinyl and was made and applied by Davd’s son Liam.

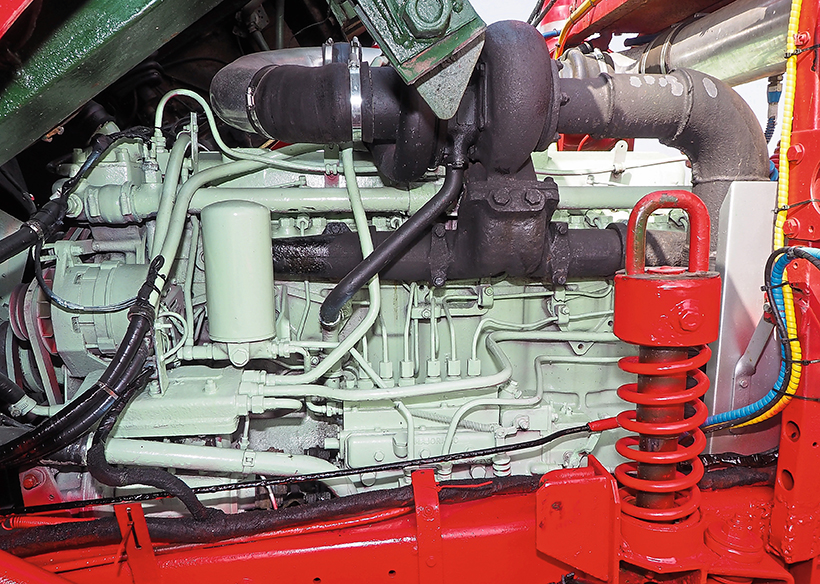

The Rolls-Royce Eagle engine needed minimal mechanical attention, but it was cleaned and painted.

Mechanically good

And finally, the mechanical side. Here the good maintenance theme continued, with the gearbox and rear axle both being in good order; David did remove the differential to check it, but it was good, and the clean gearbox oil confirmed that there were no issues here. When it came to the engine, a tiny coolant weep was apparent from one of the head gaskets, so that was changed. The air cleaner boxes also needed renewing and the rack within the injection pump needed freeing off as it was sticking, leading to the engine sticking at high revs…

Cab after painting; getting to this stage required six weeks of stripping and prepping.

Finally, in mid-2023, and after five years work, the lorry was ready to go back on the road. While for many of us the enforced Covid lockdown was a nuisance (to put it mildly), for David it was actually a blessing because with the lorry at his home, he could just carry on working on it. What’s more, being off work on furlough allowed him extra time to do just that! His first trip out was to the Cumbria Steam Gathering in Flookburgh; at this point the lorry hadn’t done any shakedown mileage post-restoration, so David trailered it the 100-odd miles there. When it came to coming back though, he decided to drive it, and just one tiny issue arose; a tiny oil leak from the rear axle’s pinion oil seal. When he stripped it out, he found that the leak was being caused by a teeny spec of dirt in the wrong place that was stopping the seal from sealing properly. After cleaning it all went back together without problems and didn’t even need a new seal.

Cab floor was also repainted in body colour. A complete new wiring loom was needed, so David made one himself.

During the rest of 2023 David attended events in Otley and Barnard Castle, and his season ended with an invite to take part in the annual Huddersfield to Wakefield Halloween Run. All were of course completed without missing a beat.

Final fit-up underway; rear wheelarch stays are new, as well as the arches themselves.

So there we are. This is a remarkable restoration on many levels, but probably mostly due to the conditions under which it was done and the fact that David has done the entire job himself or with unpaid help from friends. It is also, I think, worth noting that this lorry has been restored by a working man (David is still a full-time driver) who has funded the whole job himself; no big business backing here! David has dedicated the completed ERF to his late father, and also wishes to acknowledge the help and support received from wife Patricia and sons Liam and Alex and daughter Jenna and her husband Jason.

Five years on, and almost there; the Suzie frame supporting the pipework etc is all-new.

As to whether there will be any more lorry projects, I can only quote directly what David said when I asked that very question: “If I have my way I will, but if Patricia has hers I probably won’t.”

The Rolls-Royce Eagle engine was, in most driver’s opinion, the best B-Series engine option.

On the move. Nine-speed gearbox was – and still is – in good condition.

Dash, including the new-old-stock analogue tachograph that David managed to track down.

Fully refurbished cab interior. Almost everything you see here was renewed during the restoration.

A very, very thorough restoration indeed!

This feature comes from the latest issue of Classic & Vintage Commercials, and you can get a money-saving subscription to this magazine simply by clicking HERE

Previous Post

A pair of my favourite Ferguson and Massey Ferguson tractors!

Next Post

Great Rempstone Steam & Country Show