Classic tractor becomes farming reality for enthusiast owner

Posted by Chris Graham on 19th August 2024

Chris Graham meets Paul Merrick, who has turned a childhood fascination into an absorbing and productive farming reality.

Farming reality: Paul Merrick has owned his John Deere 3050 for 18 years. It’s a model he remembers from his childhood and it now works very effectively on his small-scale arable farm.

I should start this feature with a warning! Never underestimate the life-changing potential that classic tractors possess. Thankfully, the effects are generally positive, as in Paul Merrick’s case, but be in no doubt that these innocuous-looking machines have the ability to trigger chain-reactions that can send the lives of their owners off in the most unexpected directions!

Paul’s story starts very conventionally, built on a childhood fascination with farm machinery. It’s a familiar tale; growing up in a rural environment and being drawn by the size, sounds and smells of the machines working in fields nearby. “I grew up in the 1980s,” Paul explained, “on the edge of a village and quickly developed a keen interest in the farm machinery being used around me.

“I particularly loved harvest time, and remember being enthralled by big tractors like the Muir-Hill 121 working with the combines of the day, such as the John Deere 1075, the Claas Dominator and the International 1460 Axial-Flow.”

Engineering beckons

Paul had no family connection to farming and thinks that, at that stage, it was the machines he was interested in, rather than what they were actually doing. “There were diggers, too, and I particularly recall a white-cabbed JCB 3CX digging trenches for drainage pipes one year. Then, once into my early teens, I became interested in machine tools, primarily, I think, because my father was a dealer in lathes and milling machines. That blossomed into a passion for engineering generally and, by the time I hit my mid-teens, I’d decided that my future lay in that profession.”

Soon after purchase in 2006, the 3050 underwent a front axle rebuild, done by Paul.

Paul duly became a design engineer, first with a company producing CNC woodwork machine tools, followed by one specialising in ‘growing’ the silicon used in solar panels. Then, happily married and with a house, his thoughts started drifting back to agriculture and, in particular, the memorable tractors from his childhood. “I finally made the decision to buy my own tractor in 2006. At that stage, I had nowhere to keep one, so started asking local farmers about spare barn space that I could rent.

“As it turned out, a farmer I knew locally said he could help once I’d explained that I was after a medium-sized tractor from the 1980s. He collected Caterpillar machinery, so appreciated my thinking. But what to get? I knew that I wanted one of the machines I’d watched working back in the day, and that narrowed the options down to a John Deere 50 Series, a Ford 8210 Series II or perhaps a Case MX130, although that was a bit more modern.”

Internet search

Paul set himself a decent budget of £10,000 and began his search on the internet. “I wasn’t keen on buying from an auction,” he explained, “because I wanted to be able to try the machine properly first, so I restricted myself to private ads. Of course, I’d never driven a tractor at that point, so would be relying on my own practical, engineering-based knowledge plus the information I’d picked up from various magazine buying guides.

This JD 3050 came with an unusual but informative, Dymo tape service record!

“I’d also set a limit of 7,000 hours for any potential purchase and, while I did come across a few Ford 8210s, it was the John Deeres that seemed most readily available at that time. However, I was disappointed to find how scruffy and down-at-heel many of them were. I drove quite long distances on three separate occasions to look at 50 Series machines, but each turned out to be a poor example.”

Then Paul stumbled upon an advert for a JD 3050 being sold by a dealer in Sussex, near Gatwick Airport. Although it had 12,000 hours on the clock, the seller assured him that it was a good, straight example and well worth him seeing. “I live near Thame, in Oxfordshire, so it was a fair distance to travel and I was initially reluctant given the wild goose chases I’d already been on. But the dealer convinced me to go and have a look.

“I left work early one day, drove straight to Sussex and found a very tidy, one-owner, 1987 3050 waiting for me. Clearly the tractor had been well looked after during its working life and there were no obvious defects. It was complete, had a smart, fully-functional cab interior and, apart from some rust on the wings, everything was where it should be. Even the cooling system was topped-up with the all-important, green John Deere Cool-Gard. What’s more – and perhaps most encouragingly of all – I found a series of Dymo tape strips stuck to the top of the dash charting the tractor’s service history.”

The deal is done

The only potential fly in the ointment was the higher-than-wanted hours total, but Paul knew that that needn’t be a problem given a correct level of maintenance which, apparently, this tractor had enjoyed. “With the asking price within my budget and without taking a test drive, I agreed to buy it,” he said. “It was the right model from the right era, I was a big John Deere fan and I had a John Deere dealership – Farol Ltd (Milton Common) – just down the road.” Everything had fallen neatly into place, and Paul had bought himself a tractor.

The 3050 benefits from the excellent SG2 cab. The wrap-around screen is great, visibility is excellent, the air con works and Paul has updated the radio to a modern unit offering Bluetooth functionality.

The 3050 was delivered to nearby High Wycombe and then, after a little bit of practice, Paul drove it to the farm where his rented storage space awaited. “It was all very exciting as I was fulfilling a boyhood dream,” he recalled, “although the first few miles of the journey, through High Wycombe town centre, were a little nerve-wracking. Fortunately, this model is simple and straightforward to drive, which was just as well because, as far as controlling it was concerned, all I had to go on was what I’d read about it!”

At this stage, Paul had no clue about what he was going to do with the 3050. “I’d bought it simply because I wanted a tractor,” he explained. “I had no ambitions regarding using it, attending shows or taking it on road runs. I just wanted to own a machine that I could service, maintain and generally mess about with at the weekends; it was as simple as that.

“The first thing I did was give it a good clean, even though a knowledgeable neighbour had advised that as soon as I did that the oil leaks would start, which is exactly what happened! This was most apparent from the front axle, which gave me my starting point. I changed all the seals myself, stripped the knuckle joints and replaced the steering tie rods and bearings. The parts situation for the John Deere 50 Series remains excellent; everything is available. I used my local JD dealership, Farols, as well as independent specialist, Nick Young Tractor Parts, in Market Rasen.”

Winging it

“Next I removed the wings,” Paul continued, “cleaned them, filled the rust holes and sent them to an automotive sprayer for painting – I wasn’t able to do that myself, at that stage. I’d also read some worrying things about the wet disc brakes and how, when wear becomes excessive and they start disintegrating, all the metallic fragments are carried into the gearbox in the shared oil, with disastrous and expensive consequences.

Paul is fortunate in that his land is relatively ‘kind’ to his equipment as there aren’t too many flints. However, it is a heavy, clay-based soil, so standing water can be an issue.

“Worse still, there’s no way of telling how worn the brakes are so, for my own peace of mind, I opted to send the tractor to Farols for a full brake overhaul. I didn’t have the equipment needed to remove the axle trumpets myself, so entrusted the work to the professionals. As it turned out, everything in there was fine, but I had all the internals replaced anyway at a cost of about £700.”

Then, after changing all the tractor’s oil and fluids, Paul had the machine in a condition he was happy with. “My objective was never to create a concours-winning tractor,” he told me, “I simply wanted a smart, essentially original and usable machine.”

In 2007 Paul had a chance encounter with Gary Anderson, the organiser of the Chiltern Charity Tractor Road Run, who invited him to take part in the event with the 3050, which he did. Then, soon after that, his parents bought a small paddock and asked if he’d cut the grass. “I jumped at the chance to put the tractor to proper use, and bought a Teagle 510 topper. This really fired my enthusiasm for working the 3050, so I joined a local tractor club that organised working days.

Harvesting with the 3050 and Paul’s International 1420 combine. A pair of 1980s classics still working hard.

“I wanted to have a go at ploughing, and bought a four-furrow Dowdeswell. I’d read everything I could but, in the end, you just have to get out and try these things, and the club had plenty of knowledgeable and experienced members who were more than happy to help and advise me. Like all traditional skills – especially those where there are so many variables – there’s no substitute for experience when ploughing.”

Interesting history

Since the purchase, Paul has managed to find out more about his 3050’s back story. “I got in touch with the previous owner and discovered that it spent its working life on a farm in the Cotswolds. I managed to get chapter and verse on its service and repair history, including details of a transmission problem. It developed a jumping-out-of-gear fault due to synchro wear, and the cab was removed to sort that out.

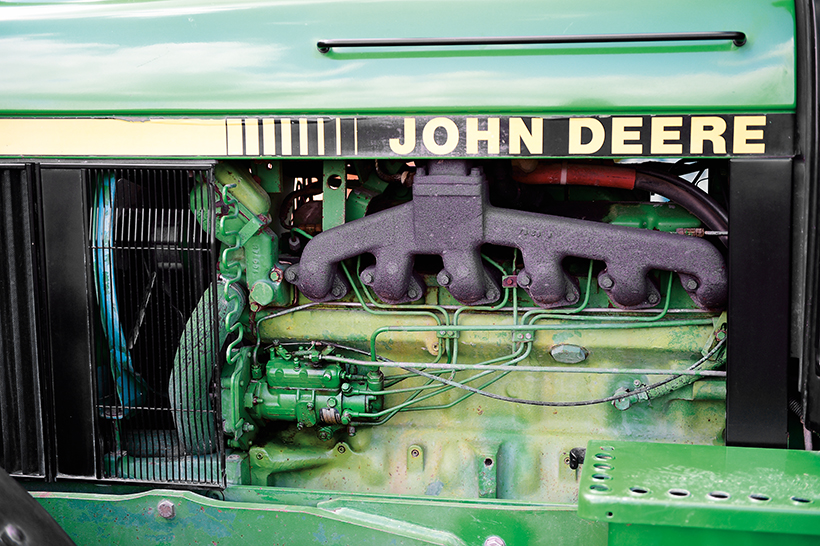

“I was also able to visit the farm and found out all about how the tractor had been used. It was the farm’s primary machine so did a bit of everything, including working with a four-furrow plough and on the silage pit with a front-mounted buck rake (hence the heavy-duty front linkage that’s still fitted). Interestingly, it also turns out that the farm upgraded the 3050’s engine with an aftermarket TB Turbo, boosting output from the standard 90hp to 126hp. The only downside of that modification that I’ve noticed is that the engine can’t be worked too hard when ploughing, without getting hot. It’ll sit quite happily at 1,600rpm, but if you push that to 1,900rpm, cooling becomes an issue and you have to back off.”

The 3050’s engine was upgraded by the original owner with an aftermarket turbocharger that boosts output from 90 to 126hp.

Time moved on and, after about seven years of happy ownership, Paul started hankering for an additional machine. “When I mentioned to my wife that what I’d really like was a classic combine harvester, her reaction was to suggest that if I did that, then I’d need some land to go with it. That set me thinking and I liked the idea of 50 acres to cultivate! But, this was back in 2013 and, even then, it soon became clear that plots that size were too expensive – however, 30-acre parcels of land seemed to be within my financial reach.”

Productive search

A long and frustrating search ensued and, in the end, it took Paul two years to find the arable land he now owns. But that had given him time to formulate a plan that was to take his involvement in agriculture to a whole new level; he’d decided to become a farmer. “I’d been spending time on a neighbour’s farm, getting actively involved in all aspects of cultivation and crop harvesting, which was both fascinating and great fun. I’d also learned a great deal and became convinced that growing crops on my own land was what I wanted to do.

“The land I finally managed to buy was a 28.5-acre plot of trees and scrubland that, essentially, nobody else wanted. But I was sure that I could make it work,” he told me. “My first job was to apply for the permissions and registrations I needed from the authorities that would allow me to switch its classification from ‘woodland’ to ‘agricultural use’, so that I could start cultivating crops.

This JD 3050 came with an unusual but informative, Dymo tape service record!

“By 2016 everything was in place and I could start clearing the land using a 1986 JCB 3CX that I’d bought for the job. It was a budget-priced machine that had been destined for export to Eastern Europe, but making it mine ticked another ‘boyhood dream’ box!”

By this stage Paul was committed to becoming a small-scale arable farmer producing and selling his own wheat, but there were still qualifications and accreditations to be gained first. “I passed the exams necessary for me to start spraying the land, and began the process of joining the Red Tractor Farm Assurance Scheme. Then, having bought a boom sprayer, I used the 3050 to apply Roundup to eradicate the grass and weeds on the areas that were to become my new fields.”

The clearances

The whole land-clearance process took Paul about a year to complete and, from his preliminary calculations, he estimated the area he’d be able to plant would yield about 75 tonnes of wheat. But, to sell that for human consumption required membership of the aforementioned Red Tractor scheme and, one of the conditions of that was to have a barn providing approved grain storage facilities. This, of course, required planning permission, and he opted for the biggest his land area permitted – a structure measuring 24 X 18m.

Paul says that he spends more time servicing and repairing his collection of machinery than he does working on the land. Note the impressive scale of his superb new barn in the background.

Paul continued: “Once the Roundup had done its job, I ploughed the three fields with the 3050 and planted a mustard crop, which was allowed to grow before being ploughed in to get more green matter into the soil. The first drilling happened in 2017, when I planted both wheat and oats and, as they were growing, the barn was going up.

“I’d bought a combine the year before. I’d been looking for a John Deere 1065 but ended up with a 1985 International 1420 Axial-Flow that came from Devon. While it was in running order, I’d never actually driven a combine but had spent many hours in cabs over the years beside experienced operators, so thought I knew the basics. It was delivered to a nearby farm where I was kindly allowed to test it, at which point I very quickly realised I had no idea what I was doing!”

But, with practice and lots of helpful advice, Paul eventually got to grips with all the variables and became proficient with his classic combine. “I’ve completed six harvests now,” he explained, “but can honestly say that each one has been different, so the experience gained from one is of little use for the next! Growing crops inevitably involves a fair degree of guesswork.

“As an engineer I’m used to being in complete control of every element of any project I’m working on. But, farming’s the complete opposite. Unpredictable yet vital variables such as the weather, fertiliser costs, yield size and cereal prices are completely out of a farmer’s control. Everything becomes a bit of a gamble, which makes it interesting but, at the same time, frustrating. I appreciate I can’t make enough profit to live on, especially if I factor-in the cost of my time. The real value to me is that I love every aspect of it, and you can’t put a price on that.

Paul believes that one of the beauties of older farm machinery is that it offers the potential for DIY repair, which simply isn’t possible with modern tractors.

“I get to pamper and protect my classic machinery, I’ve learned an huge amount over the years and I’ve met countless interesting people. I love being out on the combine at harvest time, especially when we work late into the lovely warm, September evenings. My wife and daughter will come and haul the grain trailer while I work, and we often stop for a meal in the fields, which is just fantastic.”

Paul devotes many hours a week to farming, but he clearly gets tremendous pleasure and satisfaction from the effort he puts in and the contrast with his day job. “I’m here most weekends and several evenings during the week,” he explained. “It can be frantic at certain times of the year and, in some respects, I’ve created a bit of a monster. But I’m certainly not complaining.

“I love the work and appreciate how lucky I am to be able to do it. You could say that I enjoy the best of both worlds, combining my exacting, engineering-based day job with the simple pleasure that comes from working the land. The 3050 is the machine that started it all off and it’s coped supremely well. I couldn’t have asked for more from it over the past 18 years and it’s been hugely capable and unfailingly reliable. But, being a John Deere, I always knew it would be!”

This feature comes from the latest issue of Tractor & Machinery, and you can get a money-saving subscription to this magazine simply by clicking HERE

Previous Post

Very collectable Leyland Comet models from Dinky

Next Post

Father’s Day commercial vehicle gathering at Bressingham Hall