International B-250 tractor restored

Posted by Chris Graham on 10th May 2021

Persistence pays off in the restoration of this International B-250 tractor, which was washed-up at the scrapyard, as Jo Roberts explains.

International B-250 tractor restored: Agricultural shows and ploughing matches usually fill Hefin’s calendar and, like many other enthusiasts, he’s been denied these pleasures over the past year, due to the pandemic.

In the world of collectables, provenance counts for an awful lot, and tractor enthusiasts will often favour a machine that has a known background over one which has seemingly appeared from nowhere. For tractors, often the only way to find a collectable machine with a good back story is via word of mouth, and this is where your network of ‘tractor chums’ comes into play. Through chatting with others, we find out useful information about machines with an interesting past, or a local connection and which might be for sale.

Tractor enthusiast, ploughman and Welshman, Hefin Jones, found his International B-250 via word of mouth; the fact that it had a Denbighshire registration was also enough of a lure. Besides, the tatty little tractor had a known past, some of which explained why it was in such a hopeless-looking state.

Colourful life

In 1957, a farmer named Thomas Evans from Llannefydd, North Wales, popped into his local International Harvester dealership, Edward Thomas’ of Denbigh, and ordered a brand new, B-250 tractor. Then, before long, the gleaming new workhorse was delivered to the farm ‘Gwyndy’, where it was used successfully for several years.

Hefin Jones is forever drawn to tractors that come with some local history, and he was on the look-out for a B-250, in particular.

It was after current owner Hefin had owned the tractor for some time, and had completed its restoration, that he discovered that, by coincidence, his own cousin – who’d worked at Gwyndy Farm in the 1950s, was the first person to drive the tractor when it was new. Sometimes, it seems like tractors just find us, and discovering this link to his own family confirmed to Hefin that the purchase of the B-250 was meant to be.

It seems that, after using the B-250 for several years, its first owner, Thomas Evans, sold it on to North Wales Engineers in Trefnant. This happened in the 1980s and, from there, it was sold on again, to a dealer in Lloc. By this time, the tractor hadn’t travelled more than a handful of miles from where it had been bought new.

Sitting in the dealer’s yard, some young men who were running a cockle-collecting business on the edge of the Dee Estuary, spotted the tractor. They decided it would be perfect for hauling their harvested cockles up the beach. The cockle-hauling work, which was hard on both humans and machines, continued for some five years until, one day, disaster struck and the tractor broke down on the beach.

As soon as the tractor was in working order, Hefin put it to good use and found it to be a simple, capable and very pleasant to use.

Saved from the scrappy

The cockle pickers couldn’t get the machine restarted, and couldn’t find anyone to tow it off the beach before the next tide came in, so it was engulfed by the sea. The tide came in twice over the tractor before they managed to rescue it, after which its sorry remains were sold to a scrap merchant in Connah’s Quay. It was while the tractor was parked in the scrapyard, looking sorry for itself, that International Harvester enthusiast and mechanic, Mike Speed, heard about it and, knowing that Hefin was looking for a B-250, Mike suggested he check it out.

Viewing the tractor for the first time, Hefin decided against buying it; it was in a bad way, and it was more of a project than he fancied taking on. The previous few years spent on the mudflats at the side of the Dee Estuary had been hard on the B-250. The salt air had almost stripped the tractor of its paint, the tinwork was tatty, the lights had been smashed and, most worrying of all, the tractor couldn’t be persuaded to run.

“However, Mike saw things differently to me,” says Hefin, explaining how Mike had been unwilling to leave a classic International on the scrapheap. He agreed to buy it, transported it home to Whitchurch, tinkered with it a bit, and soon had it running.

After a few years of working the tractor, Hefin felt it had earned a restoration.

A good deal

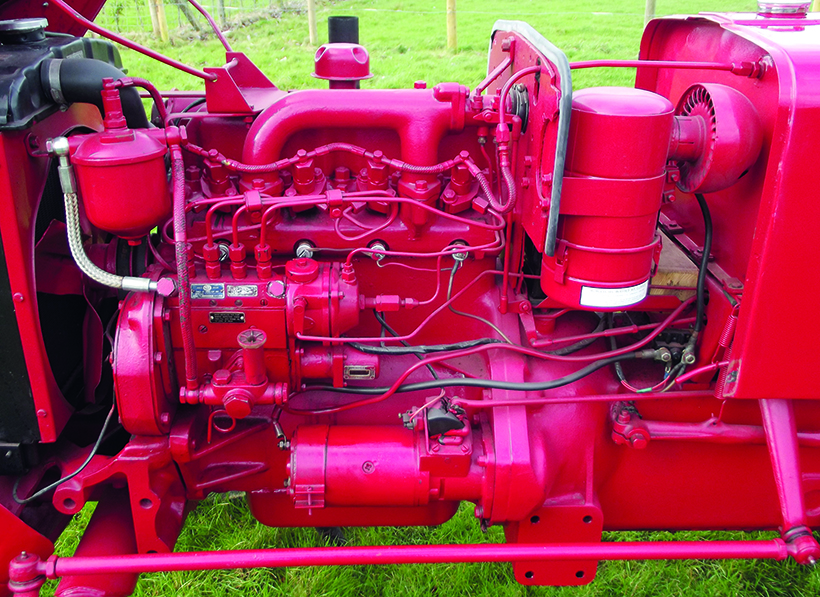

He called Hefin to let him know that the engine was now running, but warned that it was sounding a little rough! Hefin went to view the tractor a second time and, while things were looking a lot more hopeful, he still wasn’t sure about the engine. So, he and Mike came to an arrangement whereby Mike would rebuild the engine, and Hefin would then buy the tractor. This deal suited both; Hefin was getting a tractor that was going to be well worth restoring and keeping, while Mike would enjoy the satisfaction of knowing that another classic IH tractor had been saved from the scrapheap.

A few weeks later, Mike delivered the tractor. It was sounding good and Hefin put it straight to work. He used it for mowing – with an S1-42 IH mower – for muck-spreading with a Land Drive spreader, and for some general work like chain-harrowing, rolling, and shifting big bales around. The work gave Hefin a measure of the tractor, and allowed him to see what further repairs were required.

International Harvester tractors had been imported into the UK from America and Canada for some time before the decision was made to start assembling them here. Initially, tractors were put together at Orrell Park, near Liverpool docks then, in 1938, International Harvester bought a site at Wheatley Hall, Doncaster, intending to manufacture its machinery there. However, the factory was requisitioned during the Second World War, for munitions production, and wasn’t re-opened by International Harvester until after the war had ended. Once things had settled down, machinery and implements were manufactured there to begin with but then, in 1949, the first British-made International Harvester tractor – the Farmall M – started rolling off the production line.

The restored tractor powering a baler for a demonstration at the Flint & Denbigh Show.

B-250 launched

International Harvester went on to purchase an additional factory, this time in Bradford, which it bought from Jowett after the company had ceased to produce cars in 1954. The B-250 was the first of the ‘Bradford tractors’ to be built there, and it made its debut at the Royal Smithfield Show at Earl’s Court, London, in 1955.

The model was given the nickname ‘Little Giant’ because, while it was small and compact, it was also an extremely capable and well-equipped tractor. In 1956 – the first year of production – 3,435 tractors were built but, in the second year, this total increased dramatically to 12,000. The chief competitors of the B-250 were Fordson, Ferguson and (before long) Massey Ferguson. These were big names to compete against, but it was hoped that the high specifications of the B-250 would tempt buyers.

The B-250 had a 30hp, four-cylinder, indirect diesel engine with glow plugs, five forward gears and one reverse. It was extremely modern for the period in that it featured live hydraulics, automatic pick-up hitch, disc brakes and a differential lock. Many of those who bought a B-250 recall that it was extremely sophisticated compared to other tractors that were around.

The B-250 is well-matched with the IH baler at the Flint & Denbigh Show.

Restoration process

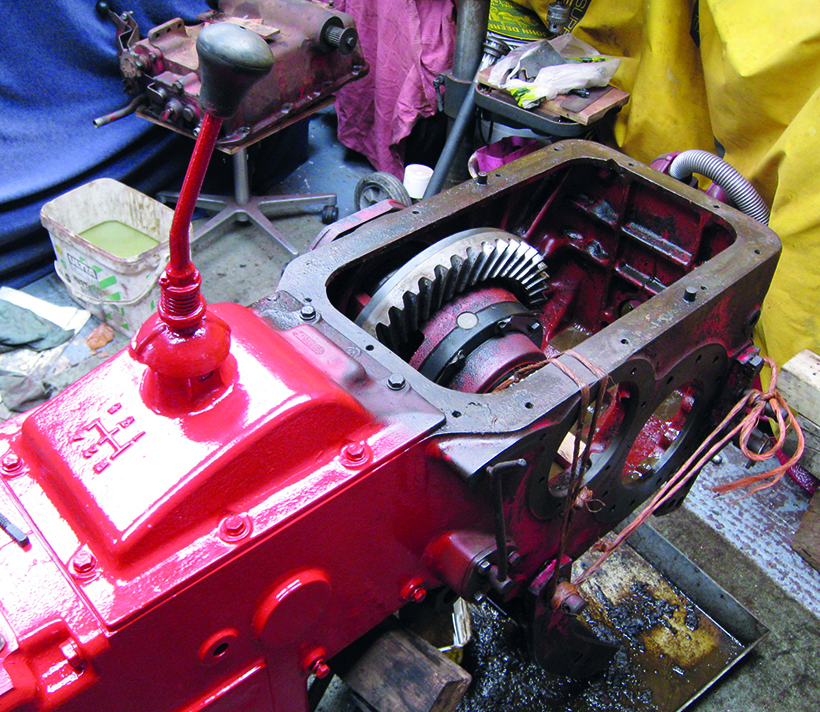

Six years later, Hefin decided the tractor had finally earned a restoration. He started by replacing all the oil seals and worn bearings, then set about straightening the bent front axle and rebuilding the steering box. The tractor had evidently endured a hard working life, and had probably received little in the way of maintenance since leaving its first owner.

“The castings in the rear axle trumpets caused a bit of bother,” recalls Hefin. “Because the tractor had been in salt water, the castings had absorbed salt, and I spent hours with a wire wheel and brush cleaning and preparing them, only to find that the casting would be covered in rust again the next day.” But Hefin just kept cleaning until, finally, the castings stopped rusting over.

The rear wheels were badly pitted, too, and Hefin thought of trying to fill in the pits. But there’s a fine line between restoring a tractor and obliterating any trace of its past, so he opted to leave the pits where they were. A local firm that made rabbit hutches, supplied the mesh for the front grille, and a replacement hydraulic pump was fitted too.

The B-250 was a strong, reliable little tractor and, for its era, it had some very modern features.

“Unfortunately, it’s a replacement part for a later model,” says Hefin. “At the time, I just couldn’t find an original.” He went on to de-rust the five lamps by using electrolysis, as sand-blasting would have been too aggressive. “I soured some correct, Butler lenses from some other lamps I already had, replaced the innards with new fittings and got the bezels re-chromed.”

Hefin also bought a new, authentic control box, a replacement amp meter and made up a complete wiring loom. Now the lamps – including the plough lamp – all work perfectly, and the whole system charges as it should. The hydraulic arms were refurbished with new ends, while the lift arms were fitted with new bushes. Hefin also found an original top link to finish it off.

The B-250 was the first of the ‘Bradford tractors’, and it made its debut at the Royal Smithfield Show at Earl’s Court, London.

Tinwork terrors

By far, the lengthiest aspect of the restoration concerned the tinwork. Years of use, plus that rather unfortunate stint in the sea, meant that the panels were in poor shape. But, given that Hefin wanted to retain as much of the old tractor as possible, he bravely restored rather than replaced the tatty tinwork.

Today, you can’t see the joins where old tinwork meets new; where the old, salvageable part of the mudguards has been welded on to the new steel sections. Hefin reckons you can just about feel a ridge if you know where to find it, but I wasn’t convinced! There’s certainly no visible seam, and it’s certainly a repair job to be proud of.

Hefin’s talented wife, Eleri, managed to re-upholster this extremely comfortable seat.

The original bonnet was beyond repair, and Mike found a replacement for Hefin, but it still needed a lot of work to get it looking right. “The replacement hood had come off a tractor which had a front-end loader fitted and, as was the practice in those days, the headlamps had been moved from the side to the top of the hood. It looked like the holes for the lamps had been made with a cold chisel,” recalls Hefin.

Deluxe resto

It seemed to take forever to get the bonnet and the mudguards right but, finally, when Hefin was satisfied, all four wheels, the mudguards, dashboard and front axle were sand-blasted, and the tractor was ready for its first coat of paint. New tubes and tyres were fitted all around, by which time the tractor was ready for its final coat of paint. Hefin’s wife, Eleri, re-upholstered the ‘deluxe’ seat, and got it looking pretty close to the original.

The 30hp, four-cylinder diesel engine was rebuilt by Mike Speed.

“I’ve attempted to make the restoration as near to a factory finish of the time as possible,” says Hefin. “The lamps were painted black during this period; later they were painted red, the same as the rest of the tractor. I very much feel restored tractors and machinery should be returned to original, using the original or authentic parts as much as possible.”

Since the restoration, Hefin has taken the tractor to several events, including the Flint & Denbigh Show, where it worked with an IH baler, giving a baling demonstration. Now it’s ready to take to ploughing matches, but Covid-19 has meant that it’s been a long time since anyone has competed, and ploughmen are restless and keen to get back on the match fields as soon as possible.

Rather than fit new mudguards, Hefin carefully patched the old ones, adding new steel where required.

“There’s now a growing interest in having classes in vintage ploughing matches, with only ‘as built’ equipment being used,” explains Hefin, “so to compete in the IH class, I’ve bought and restored a B12 plough.”

Let’s hope that Hefin, together with the rest of our competitive ploughmen, won’t have to wait too much longer before competition restarts.

With thanks to the International Harvester Club of Great Britain and the Museum of English Rural Life, Reading for background information on the International B-250.

For a money-saving subscription to Tractor & Farming Heritage magazine, simply click here