1971 Massey Ferguson 178 painstakingly restored

Posted by Chris Graham on 2nd May 2024

Chris Graham meets Simon Wright and enjoys a close encounter with his beautifully restored 1971 Massey Ferguson 178.

Simon Wright’s MF 178 Multi-Power took two years to restore and, despite appearances, it was completed six years ago.

People are attracted to classic tractors for all sorts of reasons. For some it’s all about re-kindling childhood memories or maintaining links with a grandfather or favourite uncle who worked the same model back in the day. For others its more about a straightforward appreciation of the engineering involved. Tractors from the 1950s, ‘60s and ‘70s were designed with genuine longevity in mind. They were built to last, over-engineered in many respects and, in comparison to the models that came later, deliver a much more DIY-friendly ownership proposition.

Simon Wright falls into the latter category and, for him, it’s all about the engineering. He’s a great admirer of the agricultural equipment that was around in the 1970s and, in particular, has a real soft spot for Massey Ferguson 100 Series tractors. So far he’s restored two of these popular machines, and he’s the first to admit that he gets enormous pleasure and satisfaction from the practical mechanics of a restoration project.

An enjoyable process

“I finished restoring my first tractor – an MF 165 – in 2013 and, because I’d enjoyed the process so much, was very keen to repeat the exercise with a different model,” he explained. “I’m a big fan of 1970s tractors and the quality of engineering that went into them, and the 100 Series machines are a particular favourite of mine. So it seemed obvious to opt for another red and grey tractor from that era.

“I had, of course, considered an MF 135, and was actually offered one by a neighbour, but he was asking too much money for it. Also, while the 135 is undoubtedly a great machine in all respects, you see so many of them around that I fancied something a little bit different. Then, in late 2016 and purely by chance, a 1971 MF 178 popped up in the classified section of the Friends of Ferguson Heritage (FoFH) club’s website, and I was instantly drawn to it.”

The 178 in ‘as bought’ condition, back in late 2016. Simon was happy to buy the tractor ‘unseen’ once he’d established that it was complete and largely original.

Simon, who is the Surrey and Sussex co-ordinator for the FoFH club, wasted little time in contacting the seller and discovered that the tractor was still available. “The ad didn’t include any photographs, so the first thing was to request a few so that I could get an idea about the overall condition. Judging by what I saw, the 178 looked to be a complete and essentially straight example, which was exactly what I wanted, so I agreed to buy it there and then.

“The seller was located somewhere in the Midlands, although I don’t know exactly where as I didn’t go to inspect the tractor before purchase. As had been the case with the MF 165, my plan was to strip the 178 completely, refurbishing and replacing components as necessary, then put it all back together again. This meant that, essentially, the fine details of the tractor’s condition didn’t really matter, and I was perfectly happy to buy it unseen.”

Trust issues

“Admittedly, I put some trust in the seller’s assertions that the engine ran well and that the tractor was was in good, usable condition,” Simon explained. “But I was reasonably confident that I’d be able to cope with most eventualities, having cut my restoration teeth on the 165. That tractor was much more of a ‘basket case’ than this one appeared to be, so I was quite happy to press on. The main thing, from my point of view, was that the 178 was complete and, as far as possible, original and standard. All I required was a solid base to work from.”

As it turned out, the seller was a part-time dealer, and had bought the 178 from a collector, which meant there was no further information about the tractor’s working life, or whether it had been restored in more recent times. However, Simon was pleased to note that it was a Multi-Power model, and was fitted with PAVT wheels. “I was convinced that I’d be able to transform it into a smart-looking tractor once again. I was also delighted that it represented a slightly more complex project than the MF 165, in mechanical terms.

One session with the steam cleaner was sufficient to lift the grey paint and reveal this odd shade of pink primer.

“I agreed to pay £5,000 for it, which included delivery from the Midlands to me in Surrey, so I was happy with that. I think, at that time, it was a fair price and, given the tractor’s level of originality, it seemed like a good deal to me. More by luck than judgement, I was fortunate with the timing because very soon after that the values of classics of this sort started to shoot up.”

Smooth running

“The engine ran very well when it arrived here,” Simon recalled, “and, strictly speaking, it probably didn’t need the nut-and-bolt rebuild I had planned for it. Nevertheless, I was keen to go through it all carefully, and wanted to create an engine that I’d have full confidence in afterwards.

“Once I started delving a little deeper, I did start to unearth a few signs that the tractor had been restored by a previous owner. The most obvious of these became apparent when I gave the machine its first going over with a steam cleaner. This made short work of peeling off most the grey paint from the engine and frame to reveal a thick layer of pink primer. I don’t think that these tractors were prepared this way at Banner Lane, so I can only assume it was evidence of more recent activity.”

Everything on the tractor was given four coats of paint, and Simon applied it all with a brush, apart from the top coats on the bonnet and mudguard panels.

The tractor was certainly grubby when it arrived with Simon but, overall, it looked to be in pretty decent condition. He was keen to crack-on with the project and, as with the 165, he undertook virtually all the work single-handed, in his double garage. “I began by removing all the tinwork, then I lifted out the engine and put that to one side. The wheels were taken off and stored behind the garage, then I stripped the gearbox and back axle.

“I always work very methodically, and approach each project in exactly the same way. Everything is carefully photographed, stripped, cleaned, bagged and labelled. I’m certainly not one of those people who likes working surrounded by piles of oily bits. I prefer an ordered, clean workshop environment and, with everything sorted and bagged with its nuts, bolts and washers, nothing ever gets lost.”

Amazingly, Simon didn’t discover a single major mechanical issue during the strip-down process. “I came across all the usual niggles that you would expect with a 53-year-old-machine, such as leaking seals,” he told me, “But as all of those sort of perts were scheduled to replaced anyway, none of that was a problem. Even the tinwork was in pretty good nick. There was a bit of rusting on the mudguards, and I had to make a few MIG-welded repairs to deal with small holes, but that was it. Most of the corrosion I found was surface stuff, which could be ground away and refinished. Virtually everything was restorable.”

Attention to detail

Simon spent many hours removing rust and primer from all the external components. “It was a painstaking job,” he admits, “but all part of the process. As I mentioned earlier, I work to a prescriptive method. It’s the approach I adopted with my MF 165 and, while it may be slow, it gets the job done. I don’t have any unusual or very expensive workshop kit, just all the normal hand tools and, in those days, an elderly, one-ton engine hoist. This is one of the reasons why I’m such a fan of agricultural engineering from the 1970s; it’s all perfectly manageable for the DIY enthusiast equipped with a decent workshop manual, a basic set of tools and plenty of determination. As far as parts preparation is concerned, it’s amazing what can be achieved with nothing more than caustic soda, a wire brush, elbow grease and patience.”

Everything at the back end is original and the fact that everything’s still pleasingly straight points to the likelihood that this tractor enjoyed a relatively easy working life.

The whole process of restoring the 178, from start to finish, took Simon almost exactly two years, and that was the same as he spent on the 165. “That seems to be my cycle! Nearly all the work is restricted to weekends. I work in construction as my day job, so I’m usually too tired to do much on weekday evenings. The only time I really work in the evenings is once I get to the painting stage. Most of the parts are finished by hand, then my approach involves the application of four coats to each component, over four consecutive nights.

“The only bits I didn’t brush-paint were the large panels – bonnet and mud guards – which, once prepped, were entrusted to a friend who is an accomplished spray-painter. All the smaller parts were prepped, primed and then top-coated, with careful rubbing-down after each successive coat.”

Enjoyable challenge

“In many respects, I enjoy the challenge of the restoration process more than actually using and showing the finished tractor afterwards. The engineering side of the restoration really appeals to me and helps maintain my interest for the duration of the project. I love that side of the hobby more than anything else.

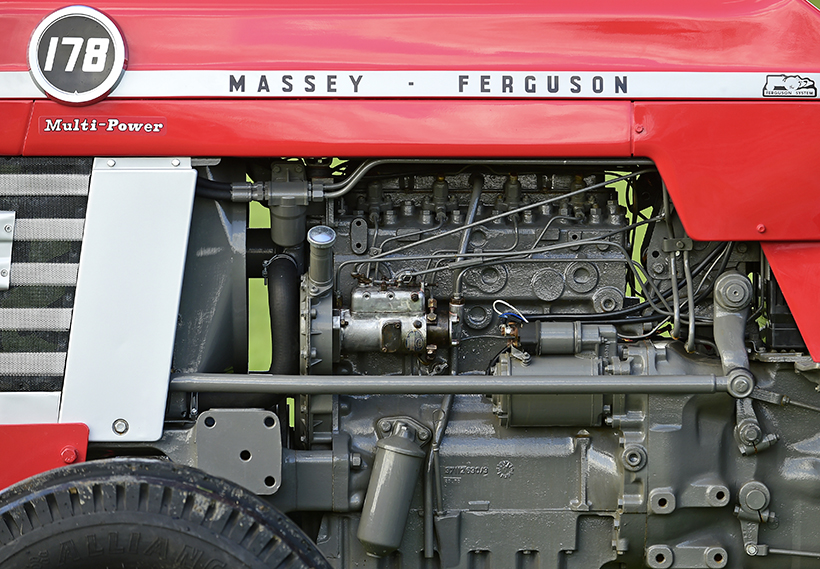

“As far as I can tell, the tractor is still fitted with its original, Perkins A4.248 four-cylinder diesel engine and my impression, having taken it apart completely, is that it had been very well maintained during its working life. I found no evidence of any significant internal wear.”

The Perkins engine benefitted from a nut-and-bolt restoration. The crankshaft was re-ground and new cylinder liners were fitted.

However, despite the good overall condition, Simon opted to have the crankshaft re-ground and fitted a new set of cylinder liners. “This was done for my own peace of mind, really. Strictly speaking, I don’t think that either measure was mechanically necessary; I’m sure the engine would have run on perfectly well for many more years in ‘as bought’ condition. But I always feel happier adopting a belt and braces approach, plus I enjoy the work!”

As far as other aspects were concerned, Simon went through the whole braking system carefully. “There was wear showing in this area,” he said, “so I took my time replacing components as necessary. All the oil seals on the driveshafts, PTO and axles were replaced, too, as were the steering bushes. I also fitted new wheel bearings all round and really enjoyed the parts-sourcing side of the process. That’s another challenge that I relish and, in the end, I don’t think that there was a single part that I wasn’t able to find a replacement for.

“One of my best sources of parts turned out to be a breakers yard run by Ron Greets, near Totnes, in Devon. I drove down there several times and the effort was certainly worth it. I always prefer to do that sort of thing face-to-face, just to make sure that everyone’s talking about the same part and no time-wasting mistakes are made.”

Good availability

“Surprisingly,” Simon added, “the majority of new parts I needed were still available from Massey Ferguson main dealer, Chandlers (massey-parts.co.uk) and a Perkins engine specialist called Gosnays Engineering (gosnays.co.uk). This is pretty impressive for a 50+-year-old vehicle, I think. I always specified genuine parts and never skimped on quality. I don’t see the point of that, but I know that it goes on. With engine bearings, for example, it’s possible to buy the proper ones or much cheaper alternatives which I believe are certainly inferior. To me, the choice is obvious when it comes to such fundamentally important components.

Simon has a background in construction and only started restoring tractors just over 10 years ago. The methodical and organised approach he adopts pays dividends.

“I have pride in what I do, and would like to think that the time, effort and investment I put into my tractor restorations will ensure that these machines will happily sail through the next 50 years. It’s important to me that I know I’ve done my best on projects like this, not only for my own satisfaction, but for the ongoing preservation of the tractor.”

The 178’s electrical system is relatively straightforward, so that didn’t create any problems for Simon. “It’s very similar to what I found on the MF 165, and I appreciated the simplicity as virtually nothing on the 178 was working when I bought it. Consequently, I had to fit a new loom and replace components like the rear lights. Unfortunately, I wasn’t able to find anything other than pattern part replacements for those, but ‘new’ originals will be fitted when I finally locate a pair. However, a real bonus was that all the tractor’s instrumentation and switchgear was in good order and original so, once I’d fitted the new loom, everything worked!”

Lasting results

With the restoration having taken place six years ago, Simon remains delighted with the way the overall condition of the tractor is holding up. “There are, of course, a few battle scars here and there, where bumps and nudges have chipped the paint during transportation, but I can live with those,” he says. “Getting it on and off my lorry, and securing it on the flatbed, can result in niggling chips and scratches but that’s life, I guess.

“I’m certainly not too precious about it and it’s not the sort of tractor that’s fitted with ‘Keep off’ signs when on display at shows. In fact, I’m always happy to allow children – and often adults – up onto the driver’s seat. Youngsters get a real kick out of climbing aboard and I’m always pleased to see them getting such pleasure from the experience.

All the instrumentation is original and, once Simon had fitted a new wiring loom, everything was found to be operational.

“At the end of the show season, there are always bits and bobs that need sorting as a result of all the clambering and button-pressing. Kids love to press things which aren’t always designed to be pressed, so I often find that rubber grommets disappear and need to be replaced. But that’s all fine.”

Interestingly, Simon has never felt inclined to work the 178, and has restricted its activities to shows and road runs. “I don’t have easy access to anywhere where I can work the tractor, so I’ve never really bothered about that side of things. I was given a reversible plough a while ago which would certainly fit well on the back but, to be honest, I don’t really know where to start. Maybe I should make the effort and take it to one of the increasing number of club-organised working days, especially as I’m not engaged in a restoration project at the moment. I think it would be interesting to learn how to use it ‘in the field’ as that, of course, is its natural environment.”

In terms of ongoing maintenance, Simon is quite a stickler for regular servicing. “I routinely change the oil and coolant but, because the tractor probably doesn’t run for more than 100 hours each year at the moment, I don’t feel it necessary to do that every year. I never skimp on oil quality, especially given the time and effort I put into the engine rebuild; using cheap lubricant really is a false economy.

The 178’s most recent outing was on the National Vintage Tractor Road Run on which – apart from a binding rear brake – it performed very well.

“The tractor doesn’t get much use during the winter months, but is securely stored in a dry shed. “I do usually take it out on a local road run at Christmas, but that’s it as far as outings go during the wet and cold months. The tractor was fitted with new tyres during the restoration, but I’m not particularly happy with the way they’ve worn. Nowadays tyres just don’t seem to last as they used to back in the day, and I’ve already noticed the first signs of deterioration. This is disappointing given the cost involved in replacing them, and the fact that the tractor has had so little use.

“To sum up, I’d say that the MF 178 is the best tractor I own, and I continue to be delighted with the way it turned out. But my appreciation of it isn’t simply based on the standard of finish achieved; the whole design of the machine is just spot-on. It’s such a nice tractor to drive and feels ‘right’ in every respect. It’s fast enough for road work, and handles beautifully when at cruising speed. It holds a great line on the road and never feels too big or unwieldy. As a result it’s easy to drive and manoeuvre, and a real pleasure to use, both on and off road. It’s comfortable, too, and I never find it a struggle to drive; it’s not a tractor that you ever have to fight with and its relaxing to operate, however long you spend behind the wheel.”

This feature comes from the latest issue of Classic Massey & Ferguson Enthusiast, and you can get a money-saving subscription to this magazine simply by clicking HERE

Previous Post

Super steam at the Black Country Living Museum

Next Post

Rare 1959 Austin 152 Bluebird Highwayman camper van