Superb Mercedes-Benz MB-trac 900 restoration

Posted by Chris Graham on 11th June 2024

Peter Love meets Jeff Burgess for the inside story on the restoration of his spectacular 1982 Mercedes-Benz MB-trac 900

The quality of this restoration is testament to Jeff Burgess’ skill and determination. This East Sussex scene, with the pine trees, could almost pass for rural Bavaria, in Germany!

While the MB-trac has been gaining an increasingly enthusiastic following in recent years, few have yet to tackle the restoration of one of these mammoth machines in quite the way that Jeff Burgess has.

His 900, based in East Sussex, made its public debut at the 2024 National Vintage Tractor Road Run at the end of March but, as I discovered, the renovation of this Teutonic giant wasn’t a particularly straightforward affair.

Historical background

It was in 1951 that Daimler-Benz took on the Unimog Universal-Motorgerat range as part of its long-term plan to create a proper farm tractor. Its first road tractor appeared in 1912, and was followed by the OE 26hp 4.2-litre single-cylinder diesel in 1928. But, with the German economy on a downward trend at that time, it was out of production by 1932.

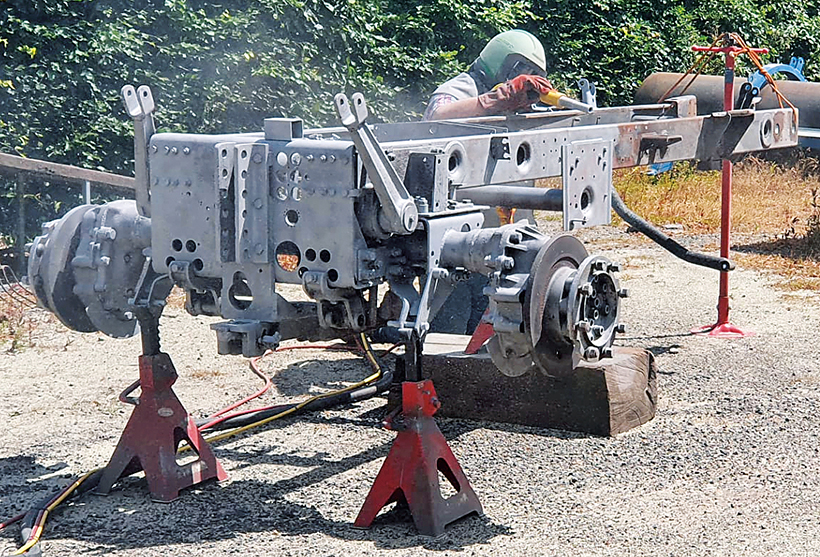

This is what Jeff started with. It was a project that became more involved as the weeks and months passed.

Fast-forward to March 25th, 1968, and Daimler-Benz – the Mercedes-Benz parent company – issued a directive to instigate the development of an agricultural tractor based on the Unimog 403. By 1973 it had become a reality in the shape of the 440.161, and the MB-trac range continued in production through until 1993, when the operation was sold to Werner Forsttechnik.

It’s always been rumoured that Mercedes-Benz never made any money out of the 41,365 production tractors it built and, in 1987, the company established a joint development agreement with Deutz, which was making the Intrac. But MB later pulled out of that arrangement, on grounds of cost. When it was announced that the MB-trac was being cancelled, some of the engineers involved transferred to JCB, with that manufacturer not believing its luck, given the impending demise of a major competitor.

The tractor’s original cab was too corroded to be saved, so a secondhand replacement was supplied by Paul James and required some welded repairs before priming.

Engineering overtones

Jeff Burgess has been a ‘farm boy’ all his life, albeit with practical engineering overtones – he established a successful garage MoT business that’s now run by his daughter, Emily. He’s restored some superb machinery over the years, including a Muir-Hill, the farm’s David Brown 900 and a 1908 Stanley steam car that was a total rebuild.

He evidently likes unusual challenges and the 1982 MB-trac Baumuster 440.164 that was badged as a ‘900 turbo’ (possibly because it was the end of the old line and was given the highest specification to help it sell) certainly fitted the bill. In fact, No. 44016400084882, registered ADV 338X, was one of 1,090 of the 440.164 type built, and could possibly be the very last one of them.

Jeff spotted the tractor for sale on Facebook, back in April 2022, and it was at dealer Andrew Johnson’s yard in South Cave, East Yorkshire.

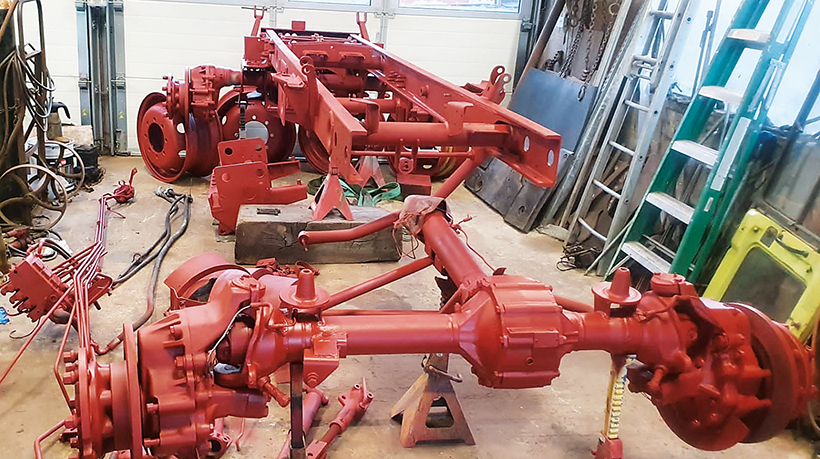

The chassis (and many other parts) were painstakingly shot-blasted back to bare metal before being primed and painted.

“The only way to see things properly is ‘live’,” Jeff told me, “not just relying on photographs, which can give a false impression.” So Jeff and Sue Burgess travelled north and, after being made welcome by their host, seeing the tractor in action and noting that new wings and rear lights had been fitted, a deal was struck. Jeff also established that the tractor had originally worked in Ireland.

Once the tractor had been delivered to Sussex, Jeff’s first move was to make a thorough assessment of its overall condition. The conclusion from that was that, rather than needing just a superficial tidy-up as had originally been thought, the tractor was going require a full, nuts-and-bolts restoration.

Work begins

Jeff started by disconnecting the cab’s hydraulic pipes, winding down the rear window to expose a coupling hook and, with a winch cable connected to the rear hydraulic linkage, tipping the cab backwards. What a novel way of doing it, but it’s all in the workshop manual, apparently. Removal of the cab provided the access needed to get at the engine and transmission. The cab was in a bad state and there was plenty of rust evident elsewhere on the carrier bodywork, which had also been removed. Clearly, major surgery would be needed to rectify all the corrosion damage.

Looking from the rear of the chassis, with many components in primer

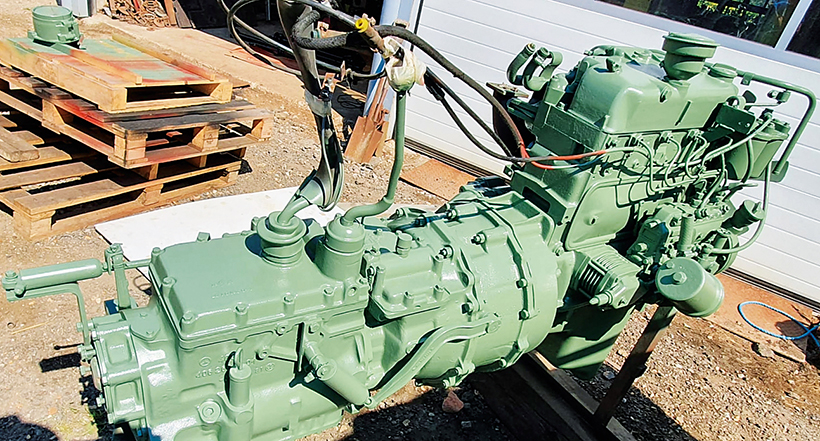

The four-cylinder OM314A 85hp engine and the air-splitter-operated transmission came out together. This combination delivers 16-speeds and a top speed of 40kph, if you really want to push the tractor.

Back in the workshop, the steering set-up was found to be perfect, as were all the universal joints, bearings and so on. However, the air brakes required a complete strip-down, with new, four-pot callipers, pads, brake pipes and hoses being fitted all round. On went a new brake servo and the non-original master cylinder pots were replaced with original types. Jeff’s objective all along was to rebuild the tractor to its original specification. A new engine-driven compressor was also fitted, the hydraulic pumps were overhauled and three new belts were installed.

The engine and transmission together and in the correct paint colour, as mixed by Andy Johnson.

By this stage, the chassis and wheels had been sand-blasted, together with so many other smaller components. Jeff recommends Bonda Rust Primer for use on bare metal. It’s an extremely effective, cellulose-based, spray-on product that’s widely available.

As the project progressed, Jeff engaged the help of Berkshire-based specialist, Paul James (MB Trac Man). “Paul was a great help with his technical knowledge and the spares he was able to provide. He even makes various panels for these models and works very hard to help keep these amazing machines going,” Jeff added.

Cab choice

Further investigation revealed that, in fact, the cab was corroded beyond the point of no return, so a replacement would be needed. Fortunately, Paul was able to offer a choice of alternatives and, once the ‘new’ one had arrived, Jeff spent time re-fitting it with parts from the original, including the doors. Some welding was required around the rear window rail area, after which the whole structure was taken down to bare metal with a grinderette. On went the Bonda Rust primer, followed by heavy-duty, high-build primer then, after much rubbing down, the official Kramp MB-trac yellow-green paint (643508 KR) was applied.

Re-wiring the dashboard was a tricky and time-consuming job, thanks to a very complicated wiring diagram.

Once that had dried, it was flatted back with 600-grade wet and dry paper and another coat was sprayed on. This was then flatted with 800-grade paper before applying the final coat of colour. This same painting method was applied to the rest of the tractor. The black areas were, of course, finished in ‘official’ Kramp MB-trac Jet Black paint (UN1263-RL0005).

With regard to the tractor’s glass, the cab has three different types of rubber section, which took time to source and fit. Mick, who runs Two Plus One Windscreens Ltd, in Uckfield, East Sussex, was a great help at this important stage.

MB Trac man supplied some new panels for the rear body section but, luckily, the original and somewhat complicated side panels were in good enough condition to re-use. All was then MIG-welded together, dressed and painted accordingly, by which time the chassis had also been painted and finished. With the new wings that Andrew had fitted before the tractor headed south, things were looking good. The bonnet required lots of welding but, thanks to Jeff’s skill, the result is perfection.

At first glance it looked in better condition than it really was, when Jeff bought it. Note the rotted floor/sill showing here.

Interior fittings

Inside the cab, all the parts were re-fitted, including the seat with its genuine covering material – all part of the Andrew Johnson set-up. However, when it came to the cab heater, that’s when Jeff ran into a problem. The replacement heater radiator housing had to be modified to enable it to fit correctly, and it required a lot of thought to get this right, but it came good in the end.

Jeff told me: “When the tractor is running it sounds amazingly quiet from inside the cab, and I think this is mainly due to the floor insulation that I built up using Tiger Seal. The dash panel and gauges were in quite a state, so all were removed so that I could prepare and then Hammerite the dash. That paint was specially mixed to match the original colour. I had to do a lot of re-wiring to get all the gauges working again; a process that wasn’t helped by the over-complicated German wiring diagram. It’s divided up into sections and is difficult to understand if you’re not German!”

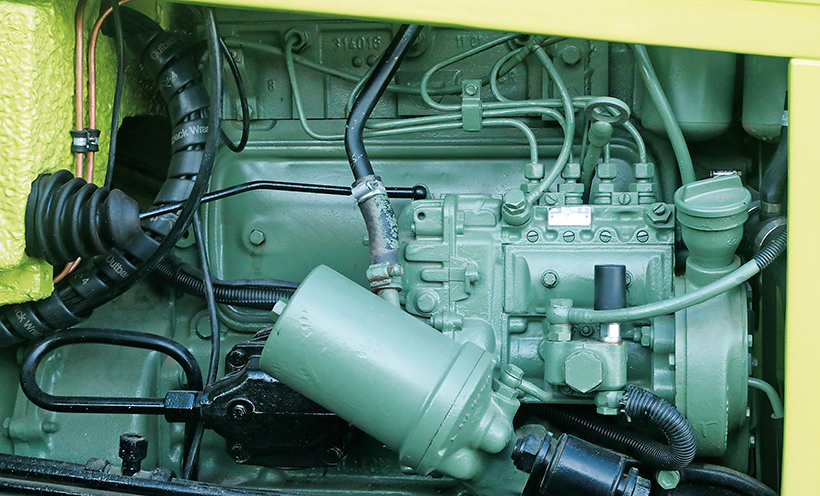

The engine was fully serviced and the new nylon and rubber parts look great.

With the tractor running, sorting out where the 10, small-section airlines went was a real job, and fitting the pipe ends was a nightmare until Paul James suggested that Jeff buy himself the special grip clamp that made the job much easier. One air leak that took time to track down turned out to be in the foot trailer brake poppet valve assembly, but a new part made by Jeff cured that problem.

With the wheel rims sand-blasted, primed and painted in body colour, on went four new 15.5/80-24in tyres that were sourced from the agricultural division of Setyres Heathfield, in East Sussex. By now the tractor was getting close to the end of its restoration, although one or two niggles remained. Nevertheless, the machine was much admired by many taking part in the Boxing Day Six Bells Tractor Road Run, which Jeff and his friends stage.

The 900 was the third most popular type of MB-trac.

Among the items still to be sorted out were a new battery cover, which Jeff fabricated himself, plus the front lower cover that sits below the grille. Jeff only realised that a panel was required here after studying some period sale brochure photographs. He made a pattern from which to create the pressing for the replacement and, not only does the result fit perfectly, it finished the restoration off a treat.

Jeff said there have been hardly any running-in problems. “The alternator charges correctly and the engine runs sweetly. However, although the hand brake works perfectly, I discovered the actuation light was fitted the wrong way, but that was an easy one to sort out.”

The MB-trac on its way to the half-way lunch stop on this year’s NVTRR, with Jeff and Emily in the cab.

The restoration has been a great success, and Jeff should be congratulated for the quality of his work and for taking it on in the first place. The size and relative complexity of this tractor meant is wasn’t a job for the faint-hearted!

This feature comes from the latest issue of Tractor & Machinery, and you can get a money-saving subscription to this magazine simply by clicking HERE

Previous Post

Full report from the brilliant Beamish Steam Gala

Next Post

1903 Burrell 8hp traction engine returns to the road