Priestman Lion crane returns to roaring life!

Posted by Chris Graham on 8th November 2020

Jeremy Rowland reports on the incredible work involved in bringing a tired old Priestman Lion crane back to roaring life.

Priestman Lion crane returns: After delivery to Andrew’s farm; ready for the hard work to begin.

Andrew Beaulah bought his Priestman Lion crane (a Mk111 model) in November 2016 and, since then, I’ve been privileged to be able to help out where I can with its on-going restoration. This machine spent it’s working life operating in one of Hull’s last dry-docks; a gruelling environment in which to work, especially given the salty atmosphere. Consequently, the machine had suffered the ravages of time and sea air, and its outer panels certainly bore witness to that battle. However, Andrew was undeterred as he knew that, mechanically, the crane was in remarkably good condition, considering its age and history.

The work begins

There was some serious preparation required to get the crane moved to Andrew’s farm but, once it finally landed, the work to both restore and re-equip it could begin. The area of greatest concern – rather surprisingly – wasn’t the exterior bodywork, which had certainly suffered greatly over the years thanks to the sea air, but was the fact that the corrosion went so deep. Cutting off successive bits of rotten tinwork simply revealed more rust and decay. Some of the panels were repairable, but other parts were beyond, so new pieces had to be fabricated and welded into place.

Many of the crane’s nearside panels have already been removed in this photo; Tony Wilson inspects the crane’s upper superstructure on this side of the machine, looking for advanced corrosion damage.

From the Lion’s first appearance at the farm, to its debut at a working event in February 2019, I’ve been able to photograph much of the restoration work carried out during visits to work on my own machines. However, the plan for the Lion was much more than a simple restoration; Andrew’s hope was to obtain and install a back-actor boom and dipper and, fortunately, he knew of one that was for sale in Scandinavia.

Piled up outside the main workshop is just a small helping of the rotten body and superstructure panels that were removed from the crane. This gives an idea of the level of rust damage the machine had suffered over its lifetime at the dry dock in Hull.

The front-end equipment was purchased and brought back to the UK by Clive Gray who, at the same time, brought back his classic, Caterpillar 212 motor grader, which was also purchased over there. Now that it’s fitted, the front-end equipment makes this Lion probably the largest cable-operated back-actor in preservation in the UK at the moment.

Almost stripped bare; the Lion with most of her body panels removed. The nearside superstructure walkway and support has already been replaced with a newly-fabricated piece of steel plate.

Many new panels were fabricated for the Lion, including support panels that were part of the crane’s upper works. These weren’t just aesthetic body panels, but formed part of the Lion’s upper superstructure. Once the upper works had been repaired, the time came to lift the boom into place. New pins had been made to secure it, and manoeuvring it into place required the services of Andrew’s JCB tele-handler.

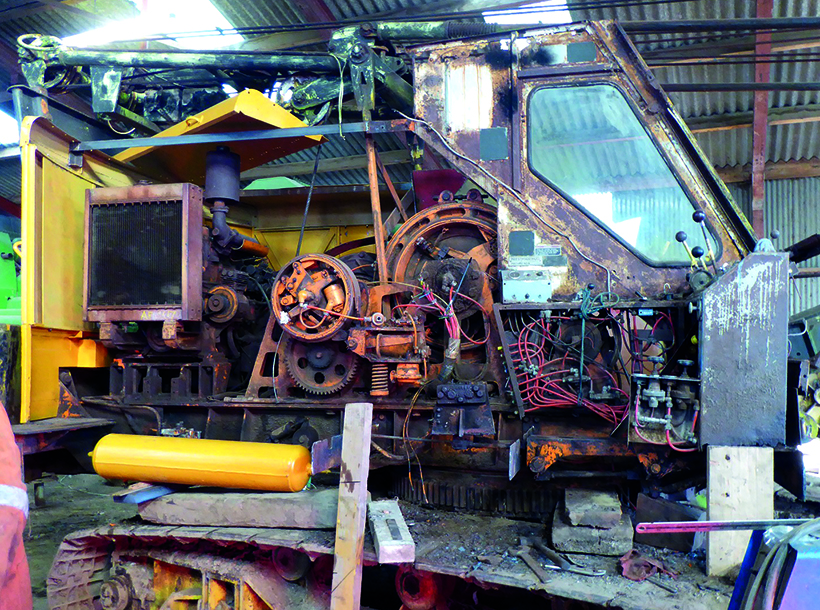

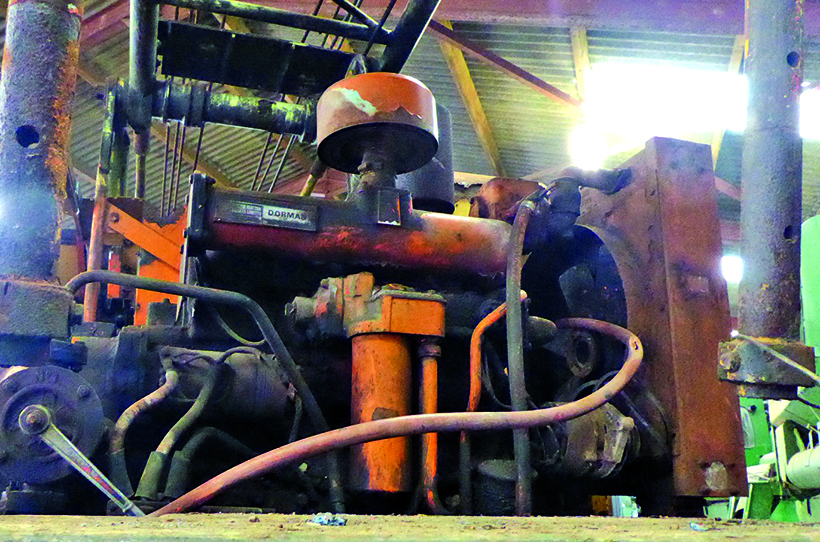

With the offside of the crane fully stripped, you can see the belt-driven air compressor on the side of the Dorman engine used to provide compressed air for the crane’s operating controls. Resting on the track is the refurbished air reservoir.

Hydraulic assistance

This back-actor set-up was one of the early attempts by cable machine manufacturers to cross-cable machines with hydraulics, by powering the crowd action using a hydraulic ram. Cable-operated back-actor machines rely on gravity to hold the spoil in the bucket, and this is emptied by extending the dipper arm. Adding hydraulics to the crowd was supposed to increase breakout force, and speed up the digging cycle.

With the panels removed, the Dorman engine can be seen. The engine’s cooling fan has been taken off in this shot for some repairs.

At the present time, the Lion is limited to being solely a cable-operated machine, but the hydraulic crowd action may be restored at a later date. This will entail stripping and rebuilding the hydraulic ram, fitting a hydraulic reservoir, an engine-driven pump and, of course, a control valve in the cab plus a system relief valve.

This photo shows that work on the cab is progressing well.

The Priestman Lion did indeed roar into action at the February 2019 Working Event but, since then, clutch and engine issues have seen the machine temporarily put out of action. But this Lion will be set to roar again in the near future and I, like many others, am looking forward to seeing it in action once again. Many other people have helped Andrew with the hard work involved to make this restoration happen, including Tony Wilson, Tim Brown, John Herbert, Graham Curwood and not forgetting David and Christine Jewitt. Hopefully the photographs included here will help give everyone some idea of just a small part of the work that’s gone into this single restoration project.

For a money-saving subscription to Old Glory magazine, simply click here

Assisted by Tim Brown (right), the offside walkway panel is marked out by Tony Wilson. This panel also holds the air reservoir for which new mounting brackets were manufactured.

With the crane’s offside walkway and superstructure panel having been welded into place, Tony Wilson carries out further welding repair to the front of the cab.

Much of the panelling repairs have now been carried out. With only half of the operator’s cab left, the Lion is starting to look more like a crane once again.

With repair work progressing, Andrew is actually in the cab and about to move the Lion outside.

Andrew taking the removed, bottom section of the jib out of the workshop using his JCB telehandler.

The back-actor boom and dipper arm was imported from Scandinavia, and sits here, awaiting fitment.

Work on the ‘A’ frame is carried out prior to the installation of the boom.

With much work still to be done the Priestman Lion emblem starts to give the crane its character back.

Andrew, Tony and Tim all work at installing the boom.

The tele-handler supports the boom while the newly-made holding pins are driven into place.

Tony Wilson hammers the second of the boom support pins into position.

Not long before the February 2019 working event, the Lion is stretched out with more work being carried out.

Andrew at the Lion’s controls taking a cut. Work was being done on the machine right up to the morning of the event.

Phil Peacock at the controls of the Lion during the working event.