The wartime history of General Motors

Posted by Chris Graham on 13th March 2023

Ed Burrows delves into the wartime history of General Motors, which manufactured around 1.2 million trucks during World War Two.

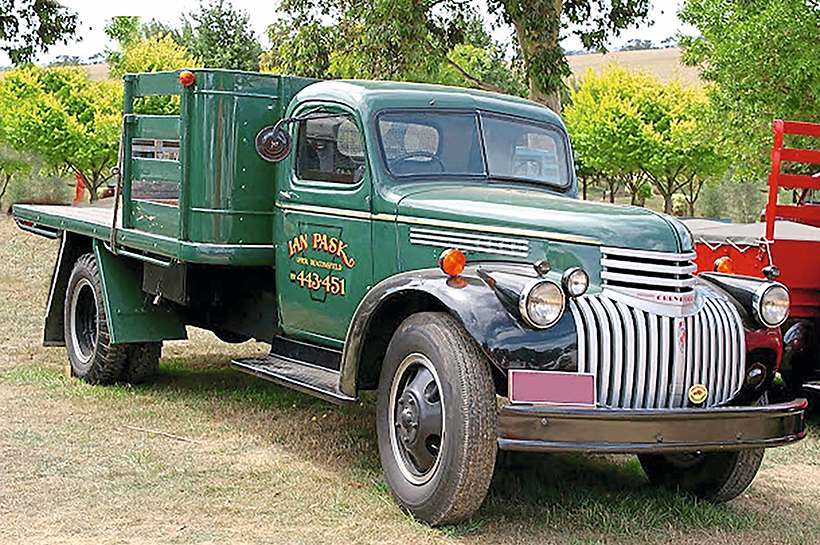

History of General Motors: A 1941 makeover with a wide lower grille give Chevrolet and GMC civilian trucks a distinctive new ‘face’. The cab itself , was a carryover – and used on CCKWs and Chevrolet 1.5-ton 4x4s.

Over half a million 6×6 Jimmys were delivered by General Motors (GM) during World War Two. (‘Jimmy’ was US Army slang for GM.) All-in-all, type CCKW 2.5-tonners (also known as ‘Duce-and-a-half’) accounted for around 40% of GM’s group-wide WW2 contracts for a combined total WW2 of some 1,200,000 million trucks for US, British/British Commonwealth and allied armed forces. The other 60-percent or so comprised 201,000 Canadian Military Pattern (CMP) Chevrolets, 280,000 US Chevrolets and 250,000 Bedfords.

In those days, General Motors was the world’s biggest industrial corporation. The claim: ‘What’s good for GM is good for America – and what’s good for America is good for GM’ has considerable justification. This certainly held true when the US became a direct participant in WW2 following the Japanese 7th December 1941 attack on Pearl Harbor, Honolulu, in the Hawaiian Islands.

GM’s – and America’s – prodigious engineering and volume manufacturing capacity swung into action. That said, before US might joined the fray, some sections of US industry – and overseas GM subsidiaries – had already got their act together fulfilling orders for war materiel against contracts placed by Britain’s War Office.

The 4×2 version of the 1941 Chevvy, supplied by GM Canada and seen here operated by the British Army Long Range Desert Group.

As the saying goes: ‘When the going gets tough, the tough get going’. This certainly applied GM’s US, Canadian and British truck divisions. Urgency dictated that the various types were either militarised upgrades of commercial designs, or their engineering was heavily reliant on standard commercial truck components.

The soundness of GM commercial truck engineering ensured they could hack it, especially the many hundreds of thousands built with two-axle or three-axle all-wheel-drive.

No GM volume-built wartime type had a rigid-chassis payload rating exceeding three tons. This is consistent with the pre-WW2 history of Chevrolet, its GMC nameplate sibling and the group’s Canadian and UK subsidiaries. (The only exceptions were GMC’s 1930s 10- and 12-ton artic derivatives).

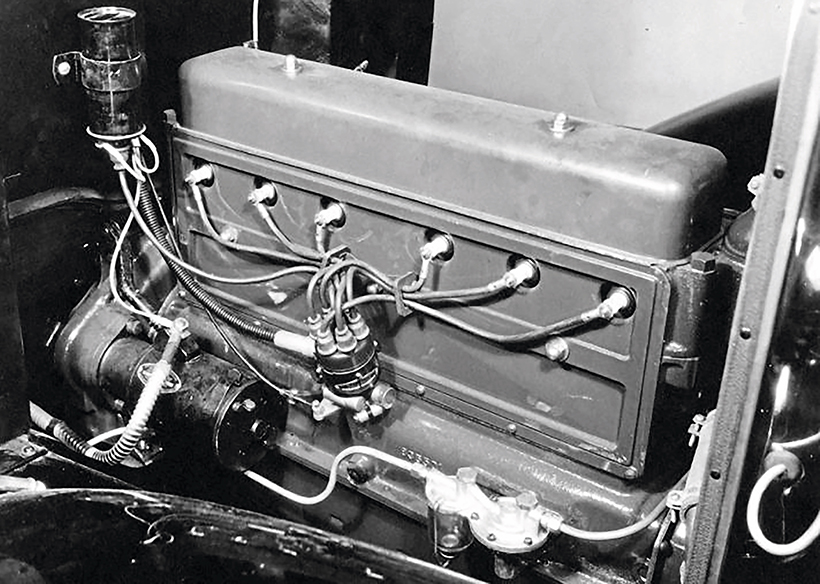

Also worthy of note, the ‘Stovebolt’ inline-six used by Chevrolet in the US and Canada – and by Bedford in the UK – was an automobile engine as much as a light-truck power unit.

Expediency was the order of the day, and perfectly demonstrated by the double-drive bogie of the CCKW ‘Jimmy’.

Churchill tanks were manufactured by Vauxhall Motors (and others). The Vauxhall-designed 350-bhp flat-12 was derived from the Stovebolt straight-six.

In the absence in GM’s parts bins of a suitably rated front bogie axle differential that also took drive to the rearmost axle, the 6×6’s transfer box drove two bogie prop shafts, one taking power to the lead-axle diff, the other to the rearmost diff.

The various GM divisions had a degree of competitive autonomy, tempered with judicious engineering collaboration and component supply commonality.

The exceptions were two separate ranges of gasoline (petrol) straight-sixes. One, the ‘270’, powered the CCKW. The other, popularly known as the Stovebolt, powered military-spec trucks built by Chevrolet’s US and Canadian divisions and by Bedford in Britain. The first-generation Stovebolt was introduced in 1929, initially for passenger cars. Its upgraded second-generation successors – designed with two– to three-ton trucks in mind – entered production in 1937.

The Stovebolt name derived from the fact that in the opinion of some it looked old fashioned. Did they think side-valves were the future? Or was their jealousy from the fact that when first introduced, Chevrolet was able to advertise it as a ‘six’ for the price of a ‘four’?

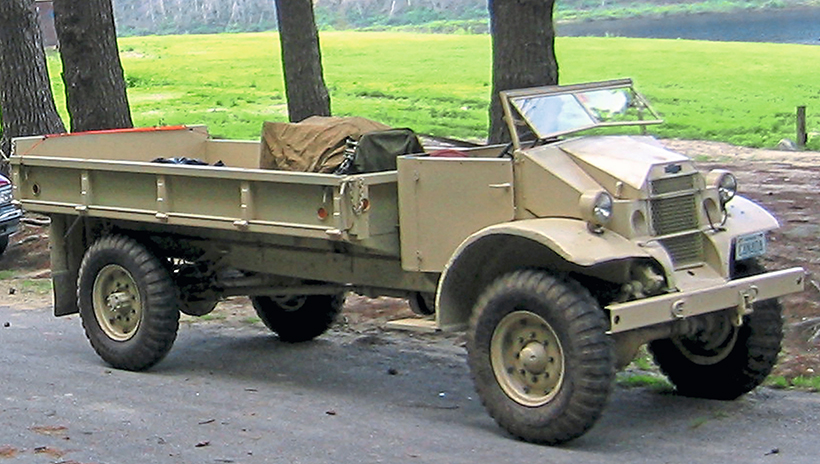

The Chevrolet USA type G7100/G506 1.5-ton 4×4, production of which totalled some 154,000 chassis.

Make no mistake. This was one of the all-time great engines. In various evolutions from 1929 onwards, it remained in production in the US until 1962, powering models including the first-generation Corvette sports car. After a production life of half a century, the Stovebolt series was finally withdrawn by GM’s Brazilian subsidiary in 1979.

But that’s not quite the end of the story. Austin used the Stovebolt as the basis for its 1930s inline-six truck engine (which, after WW2 worked its way into the Austin-Healey 3000, Austin’s Sheerline limousine, the Jensen 541 and – with two pistons lopped off, in Austin’s including the K8 van featured elsewhere in this issue of Heritage Commercials.

As the saying goes, paths cross many times…

The 270 series of engines – the designation indicating the six’s combined cylinder capacity in cubic inches – were developed from the 248- and 256-cu.in GM units that powered the CCKW’s precursors – a series 6x6s produced in low volume between 1937 and 1941.

The short (145in) wheelbase CCKW-352, typically used for towing light field artillery.

In parallel with these various truck and engine programmes, General Motors was also developing another straight-six, this time a two-stroke diesel. The work channelled the knowhow of its rail, marine and industrial diesel divisions – Electro-Motive and Cleveland – into the development into what emerged as a new engine operation, GM Diesel (which eventually grew to become Detroit Diesel). The new division’s purpose was to exploit the potential of two-stroke diesels for commercial trucks. Its first engine, the Series 71, was introduced in 1938.

Four years on, when the US declared war on Japan, Germany and its Axis allies, GM Diesel’s commercial truck aspirations were side-lined. US military trucks were standardised almost exclusively on gasoline. Attention was in consequence directed applications other than highway vehicles and heavy-duty plant applications that would later secure the reputation of Detroit two-stroke automotive diesels (nicknamed ‘Driptroits’, due to their propensity to leak).

A representative GMC CCKW/’Jimmy’ line-up, variously with closed and open cabs, with and without front winch and, on the left, with a machine gun ring mount.

It is worth delving in a bit more detail into these various GM engine and truck programmes – and along the way giving a thought to the massive souring, production and organisational challenges met by GM engineers and managers, together with a dedicated workforce that put in long shifts to meet demanding targets. And here, key contributors to on-time completion of delivery contracts were the tens of thousands of women who pitched in on skilled assembly line jobs ordinarily considered the preserve of their fathers, husbands and brothers.

With combined total of 517,641 CCKWs rolling out of various GM assembly plants, more Jimmys served in WW2 than any other vehicle family. (And that includes the ubiquitous Jeep). On top of the CCKW production total were 21,147 DUKW amphibians. The DUKW incorporated the CCKW’s ‘207’ engine and automotive units.

Although carrying the GMC nameplate, the CCKW Jimmy began under the wing of Yellow Truck and Coach, in which GM had a majority shareholding. In 1943, two years after the 6x6s entered production, GM gained full control and Yellow Truck and Coach was merged into GMC.

As the war progressed, CCKW production switched to an open cab. This is the 164in long wheelbase cargo variant.

The CCKW’s 207 4.4-litre straight-six valve-in-head gasoline engine developed a reliable 91.5-bhp at 2,750-rpm (subsequently 104-bhp at 3,000-rpm) and 216-lb.ft at 1,400-rpm. Gross laden weight was circa five tons, depending on spec. Power was delivered through a five-speed manual transmission coupled to a two-speed transfer box. All three axles had a 6.6:1 ratio. Tyres were 7.50x20s all round, with duals on the twin rear axles. The original split-type axle housings were later supplemented by one-piece ‘banjo’ units (which held twice the amount of lubricant).

There were two basic variants: the 164in long-wheelbase CCKW-353 and 145in short-wheelbase -352. The latter was distinguishable by two spare wheels located above the transverse fuel tank between the cab and the load compartment. Although the -353 was fundamentally a general cargo truck, initially with stake-side steel bodywork and canvas, production subsequently switched to timber bodywork to save steel. Variants produced in large numbers included gasoline and aircraft refuelling tankers and field engineer shop and ambulance box bodies. The short-wheelbase variant was standardised on a stake-sided steel body with canvas.

With a 50-year production life, the ubiquitous GM Stovebolt straight-six was used for both cars and trucks.

The V-windscreen cab was from civilian models introduced in 1939 and mated to simplified engine hood sheet-metal. Later production standardised on an open, canvas roof cab with a drop-down flat two-pane windscreen. A proportion of deliveries on both wheelbases had winches, and a proportion of both closed and open cab types mounted machine gun rings.

Modest numbers of a cabover version, the AFKWX-353, were also produced. The cabover derivative was on either a 164in or short-wheelbase CCKW chassis.

To reduce ground pressure, the DUKW-353, in common with a series of special CCKWs for the US Navy, ran on 11.00-18 ‘combat’ tyres. (Singles on the bogie axles).

The DUKW-353 amphibian was based on CCKW automotives, but had lower ground-pressure single tyres (and a ducted propeller for waterborne operation).

The CCKW-353 Jimmy became the primary workhorse of the Red Ball Express convoy system. This was introduced following the D-Day Normandy landings to move men, fuel, munitions and other materiel to the support the Allied advance. Red Ball routes were barred to civilian and other military traffic and operated as a one-way loop, outbound to the battle front from docks and temporary port facilities and back to reload on separate one-way traffic return roads. Three-quarters of the crews were African-American soldiers. Red Ball supply volume peaked at 12,500-tons per day delivered by convoys operated by a total of 6,000 trucks.

A CMP three-ton 4×4 with the Number 12 cab, the second type of front-end sheet-metal fitted to both Ford and Chevrolet versions.

The second-generation Stovebolt overhead valve straight-six used by wartime North American Chevrolets and by Bedford was introduced in 1937. It had a four main bearing crankshaft rather than the three of the original. The US-built Chevrolet G-7100 series of trucks used the 235-cu.in/3.5-litre version of the Stovebolt. This developed 93-bhp at 3,100-rpm/174-lb.ft at 1,200-/2,000-rpm.

Chevrolet Canada CMP trucks and the Bedford QL 4×4 and O series 4x2s used the 216-cu.in/3.5-litre variant, though with differing outputs. The CMP spec produced 85-bhp at 3,200-rpm/170-cu.in at 1,200-rpm. The Bedford spec made 72-bhp at 3,000-rpm and 156-lb.ft at 900-/2,000-rpm.

CMPs were produced in 0.8-ton, 1.5-ton and three-ton versions. The many body types included timber, like the C30 three-tonner depicted here.

Chevrolet USA’s G7100 (aka the G506) was the US Army’s standard WW2 1.5-ton rated 4×4. In all, combined output from various GM factories rolled out just over 154,000 examples of the type. Of these, some 48,000 were provided to the Soviet communists under Lease-Lend.

The chassis incorporated a ladder frame, with front and rear beam axles on semi-elliptic leaf springs. Transmission was by a non-synchro four-speed with two-speed transfer box. Aside from an extra short-wheelbase aircraft bomb support truck with a CCKW type open cab, most were standardised on the same front-end sheet-metal as the CCKW (but with fewer cooling louvres on the side panels). The regular general cargo spec, variously with or without a winch, had stake-sided steel bodywork with canvas. Gross weight was 7.5-tons.

A restored Chevrolet USA type G7100/G506 1.5-ton 4×4 equipped with pioneer tools, a characteristic of many batches of GM truck types.

Appearance wise, despite its civilian panel van bodywork, no WW2 soft-skin vehicle looked more up-for-it than G7100/G506’s the K-51 US Army Signal Corps 1.5-ton radio van derivative. Its aggressive wide-track stance resulted from twin rears located outside the comparatively narrow bodywork.

Then as now, the corridors of institutional incompetence in Whitehall were stuffed with Oxford-educated Government mandarins versed in ancient Greek and Latin. Legitimately, the term ‘educated’ can be considered a stretch when it comes to comprehending the practicalities of the real world. Hence when war was declared on Germany, for the most part, British Army trucks of the period can be regarded as a bit quaint and spindly – and tanks and other armour were woeful under-performers relative to the panzers of the Nazi hoards. Germany was waging mobile, motorised warfare, and was equipped accordingly.

The US Chevrolet G7100/G506’s type K-51 US Army Signal Corps 1.5-ton radio van derivative.

In some respects, the Fall of France in 1940 and the consequent evacuation of 330,000 British and Allied troops from the beaches of Dunkirk was a blessing in disguise. The British Expeditionary Force (BEF) was compelled to abandon all its trucks, tanks, armour and munitions. Result: Britain had to re-equip with extreme urgency.

The dimwit nature endemic in so much of British military procurement is perfectly exemplified by the experience of Vauxhall Motors. The BEF’s retreat left behind thousands of 4×2 Bedford 0.75-ton MWs, 1.5-ton OXs and OY three-tonners. The three weight ratings were standard British Army classes – and exposed Whitehall aversion to all-wheel-drive.

A Chevrolet C60X 6×6 CMP with the Number 13 cab, which was less cramped than its Number 12 predecessor.

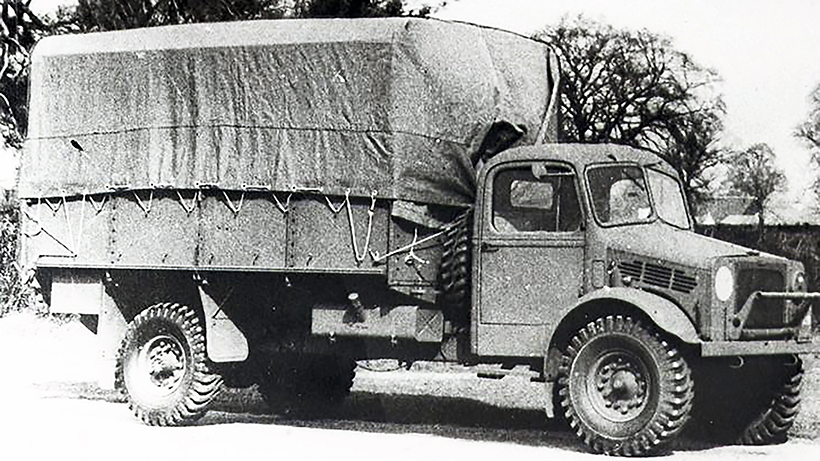

In 1938, Vauxhall proposed a three-ton 4×4 to the War Office. In the September 1939, the month Britain declared war, the War Office indicated a specification of this type was not required. With the kick of reality up its backside, a few weeks later Whitehall about turned and gave the project priority. The result was the QL, which entered service in early 1941.

By the end of the war, 52,248 examples of the first forward-control Bedford had rolled off the assembly lines. The purpose engineered QL was built in greater numbers than any other British wartime all-wheel-drive truck. Grossing 6.85-tons, the 3.5-litre six drove through a four-speed transmission. Tyres were 1.0.50-20s. The rugged, dependable QL was to all intents soldier-proof – in all but one respect. There was a tendency to overturn if cornered too fast.

Sparce but functional, the CMP Number 13 cab’s driving position.

So – GM to the rescue.

During the course of the war, Bedford production of all types amounted to 215,258 trucks. Vauxhall Motors contributions to the war effort included designing and building the Stovebolt-derived 350-bhp flat-twelve ‘Twin-Six’ petrol engine that powered the Churchill tank.

The QL – along with the Morris-Commercial C8 4×4 – conformed to the pattern for Canada’s massive contribution to the war effort in the shape of the CMP series of trucks. These were built by the Canadian arms of Chevrolet and Ford. Collaborative development of the CMP project began in 1936, encouraged by the British War Office.

Vauxhall/Bedford produced 52,248 QL 4x4s, making the type the backbone of the British Army’s WW2 all-wheel-drive truck inventory.

The base models of the CMP chassis family were rated as 0.4-ton, 0.75-ton, 1.5-ton and three-ton. Chevrolet designations were respectively C8, C15, C30 and C60X. They were produced with a multitude of standard types of bodywork. Drive line configurations were 4×2, 4×4, 6×4 and 6×6. Tyres, singles all-round, were 10.50-16 for lighter types, 10.50-20 for the three-tonners. Of the three-axle variants, only 2,700 CMP 6x6s were produced. Powered by the GMC 270 six rather than the Stovebolt, the C60X bore the GM nameplate rather than the Chevrolet bowtie emblem.

Of the 410,000 CMP Chevrolets and Fords built during WW2, Chevrolet Canada contributed 201,000 units.

Bred in WW2, Detroit two-strokes were not a popular Beford TM option, but Scammell quite like the sound. This one-off Samson 60-ton 8×4 prime mover with a ‘71’ Series V8 two-stroke served Pickfords for over 10 years.

The idea behind the CMPs’ distinctive short-nosed, semi-forward control cab layout was to achieve the most compact possible overall length. This helped maximise the number of trucks that could be transported to the UK from Canada by cargo ship. Over the CMPs’ production life three generations of cab/engine hood sheet metal were used. The most numerous was the final – more-roomy – Number 13 design. This featured a reverse-slope anti-glare two-pane windscreen.

With few exceptions, in WW2 the US Army ran off gasoline rather than diesel. Although GM Diesel (precursor to Detroit Diesel) launched in 1938 in time for wartime production, ambitions for two-stroke powered trucks went on hold until after the cessation of hostilities. The first engine type, the ‘71’ Series, took its designation from the cubic inch swept volume of a single cylinder, bore diameter being 4.25in (107.95-mm) and stroke 5.0in (127mm).

In addition to the QL, during WW2 Bedford produced 160,000 other types, including MW 0.75-tonners, OX 1.5-tonners, OY three-tonners (seen here) and OXC six-ton semi-trailer tractors.

The modular nature of the base design resulted wartime units ranging from a 10hp single-cylinder to a 238-bhp ‘six’. For tank and marine applications including landing craft, sixes were assembled as parallel block 12-cylinder, 476-bhp ‘Twins’ and 24-cylinder 925-bhp ‘Quads’.

Like much of the former GM empire, Detroit two-strokes are no more. (The brand, part of Mercedes-Benz group’s North American operation). While Driptroit powered Bedfords were a minority taste in the UK, Scammell quite liked the sound of them and listed them for export Crusaders and other types.

This feature comes from the latest issue of Heritage Commercials, and you can get a money-saving subscription to this magazine simply by clicking HERE

Previous Post

A tragic day in 1953

Next Post

Vintage Horticultural & Garden Machinery Club’s Working Day