Massey Ferguson 135 Quick-Detach cab

Posted by Chris Graham on 31st October 2023

The changing faces of the Massey Ferguson 135 were largely determined by the cab design, but none was quite as dramatic as the Quick-Detach.

Massey Ferguson 135: An early MF 135 in action. (Pic: AGCO)

Massey Ferguson’s 135 sold well from the outset and, like the other models in the range, could incorporate an optional cab from early on in its production life. A fibreglass cab, built by Duple Motor Bodies Ltd, offered a stylish alternative to those that did not want to be exposed to the elements, but it was rather flimsy and did not offer any rollover protection.

MF said that its cabs were ‘styled to combine pleasing appearance with maximum comfort and convenience. They allow the driver complete freedom of movement and excellent vision to front, rear and side.’ The advantage of such construction was that, other than the frame, the structure was rust-proof.

A Duple-built cab was an option on early 135s. (Pic: AGCO)

A ‘roller blind’ with inset window was an optional extra for the cab, permitting maximum protection from the elements in the colder and wetter months, but in better weather the doors could be removed, as well as the top portion of the cab – leaving just the windscreen in place.

In June 1968, such a cab added £67-0-0 to the price of a De Luxe MF 135 (£891-15-0), with the additional roller blind costing £5-10-0, and an electric windscreen wiper (in lieu of the manual version) £3-0-0.

During this period, cab manufacturers offered a host of alternatives to MF’s Duple-built cab, with Alexander Duncan (Aberdeen) Ltd, Innes Walker Engineering Co Ltd, Lambourn Engineering Ltd, Sirocco Tractor Equipment Ltd and The Winsam Tractor Cabin Co among those offering various structures to suit the MF 135.

Specialists, such as Alexander Duncan (Aberdeen) Ltd, offered cabs to suit the MF 135. (Pic: Bob Weir)

From 1st September, 1970, all new tractors had to be fitted with an approved safety cab that would protect the operator in the event of the vehicle rolling over. This forced Massey Ferguson to introduce a new cab that would meet these requirements, and the result was the ‘Flexible cladding safety cab’.

The idea behind the design was that inherent noise-absorbing properties of the vinyl cladding material would improve operator comfort, and the result was that the cab proved to be extremely popular. Naturally, it was good for keeping the wind and rain out, but it wasn’t particularly luxurious, and the clear vinyl did not offer the same degree of visibility as glass could, so for those that wanted more there was an alternative.

Buyers could specify the ‘Rigid cladding safety cab’, using the same basic structure as its vinyl-clad sibling, and this provided better doors, more glass, and a ‘solid’ feel. The downside was an increase in noise/vibration, with many arguing that there was little point in spending an additional £70 (December 1972) on the rigid cladding.

A 135 equipped with a Flexible cladding safety cab. (Pic: Howard Sherren)

MkII cabs

The company listened to its customers and launched improved versions of the two cabs in 1973, with kits available for retrospective fitment to existing Flexible and Rigid cladding safety cabs. It’s easy to differentiate between the MkI and MkII versions of the Flexible cladding safety cab, as the former has the windscreen wiper mounted below the windscreen, rather than above, and triangular-shaped hand indicator flaps, rather than rectangular.

Improvements included a two-inch-thick layer of foam sandwiched into the lower door panels and roof, and a four-inch-thick foam noise barrier between the side of the bonnet and the lower front windows. In addition, vinyl-covered foam was added to the safety frame’s cross members.

As well as reducing noise levels, attention was paid to the heating system – with hot air from the engine now directed at the operator’s feet.

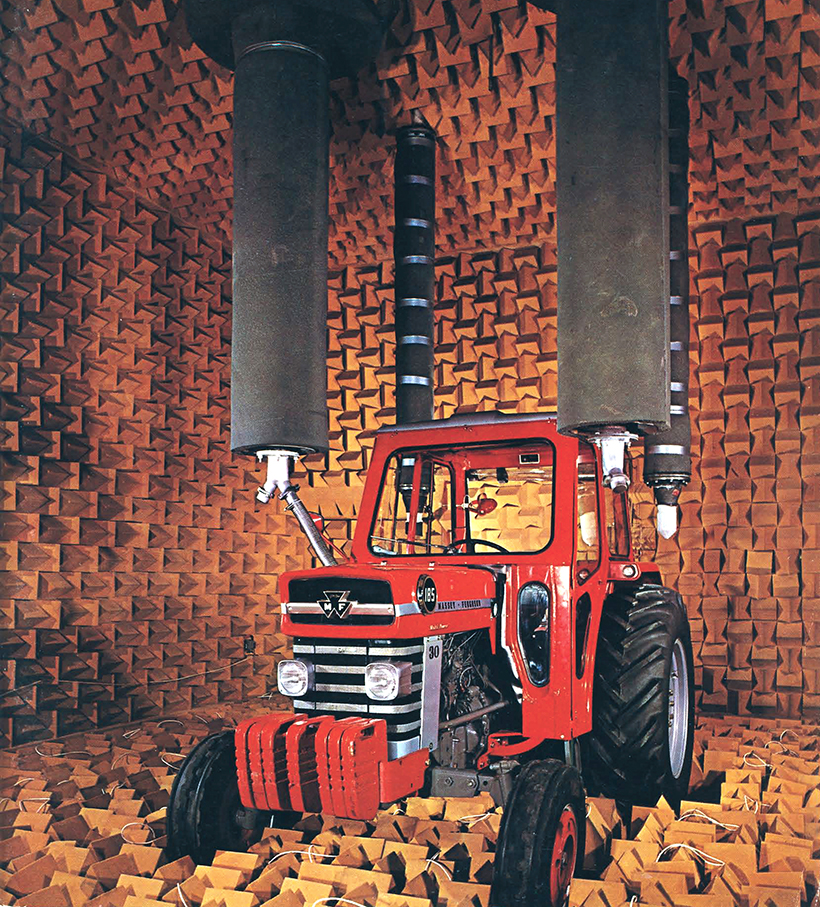

Acoustic testing led to improvements that resulted in the MkII versions of the Flexible and Rigid cladding safety cabs. (Pic: AGCO)

Improvements to the Rigid cladding safety cab included noise barriers fitted between the engine and the cab, and noise-absorbing foam in the roof, over the safety frame, and over the bonnet.

So-called ‘8 line’ tractors, like the 148 and 168, benefitted from the spacer fitted in the transmission, as this led to the need for a bigger cab and, thus, better access.

Further changes to tractor cab legislation meant that even the MkII version of the Flexible and Rigid cladding safety cabs would not cut it, and so Massey Ferguson had to look for a solution. The dilemma was that from 1st June, 1976, all new tractors had to be fitted with a safety cab that satisfied the noise requirements – which meant no more than 90dB(A) at the driver’s ear. This, ultimately, led to MF introducing the 500 Series – built in the UK and France – but as the 135 was such a volume seller it was important that it remained a part of the company’s offering.

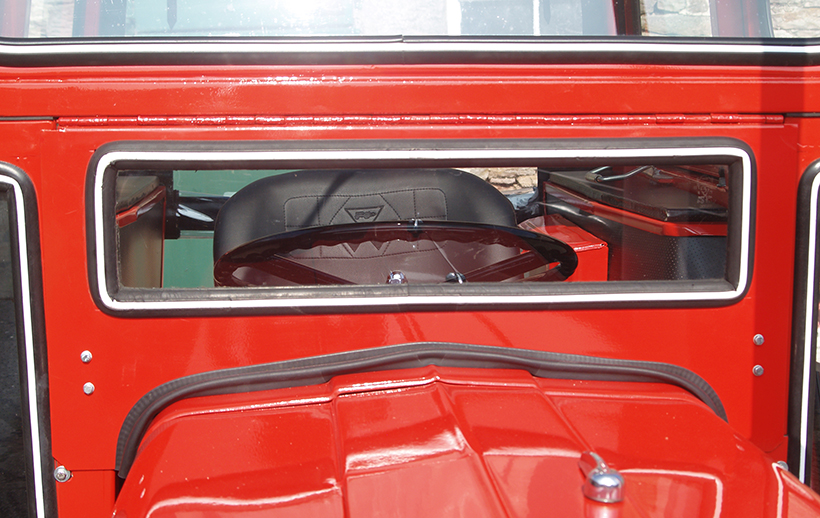

This hinged panel enabled access to the battery, but restricted visibility for the operator. (Pic: Dave Bowers)

Arguably, the 550 was of a similar power output and could have eliminated the need to produce the 135, but an additional £700 on the list price meant that there was still a need for a ‘budget’ tractor like the 135.

With the Supercab reserved for the 500 Series, Massey Ferguson needed a cab that would comply with legislation without having a specification that would push the cost of the 135 to a point that it would not remain an attractive proposition at the lower end of the market.

The answer lay with Cab-Craft Ltd, of Wolverhampton, which would produce the Quick-Detach (QD) for the 135 and help it remain in production for the UK market. It was designed to comply with the new 90dB(A) noise level regulation, but was removable at fender level, with only eight bolts and one electrical connection. It weighed 109kg (240lb) and incorporated special lifting eyes to assist removal and was said to be removable in less than 10 minutes.

A ‘topless’ 135 QD can fit into a residential garage with relative ease. (Pic: Chris Rhodes)

Poor visibility

The Quick-Detach cab was a nice place to be, with enough rubber and vinyl padding to deaden the noise, but it had a drawback. As those familiar with the MF 135 will appreciate, the battery was located where the windscreen needed to go, and so, to facilitate maintenance and removal of the battery, the designers at Cab-Craft overcame the issue by incorporating a small, removable window below the main windscreen.

This solved that problem, but created another, as due to the size of this hinged pane of glass, the frame was directly in the operator’s line of sight. This put off all but the most loyal MF customers and meant that the 135 QD would not sell as well as perhaps envisaged.

The interior of the Quick-Detach cab incorporated thick, rubber cladding. (Pic: Dave Bowers)

Back now to the crux of such a cab – its removable nature. Those that wished to ‘go topless’, in and around low sheds (or at least as far as the exhaust silencer permitted, although a horizontal exhaust could be specified), could, and this was important for Massey Ferguson – as it was not a trait the 550 et al had.

In truth, it was an operation that rarely happened, or at least rarely happened frequently, as removing the top half was not as straightforward as company literature would have you believe.

In an ideal world you would have a tractor fitted with a loader, or an overhead crane of some description, as it was not the type of operation you would choose to do with three muscular friends to aid you, unless necessary. There is also the distinct possibility that you would damage the mudguards and/or bonnet in the process, so caution had to be exercised at all times!

A simple, roll-down ‘curtain’ was fitted at the rear. (Pic: Dave Bowers)

Once the cab was off the tractor, a separate part, called a stay bar, had to be installed before moving the tractor any distance. Each fender, which was mounted on a rubber bush on the axle, was attached to the footplate that, in turn, attached to the lower front section of the cab.

With the upper portion of the cab on the tractor, everything was held rigid, as it was the connecting medium between these left and right lower sections, but when it was removed the elements of the cab that remained on the tractor became floppy, and so the stay bar had to be fitted between the lower front windscreen sections (in front of the steering wheel and across the top of the battery access panel) to restore the necessary rigidity.

With the doors off, electrical connection unplugged, and bolts removed, the top section of the QD cab can be removed. Note the blankets used to protect the paintwork! (Pic: Chris Rhodes)

As you will now appreciate, the Quick-Detach cab wasn’t up to scratch in every respect, but it served a purpose and provided a compromise between operator safety and comfort, and access to low buildings, as well as keeping the tractor’s price competitive.

Today, even with its faults, the QD-cabbed Massey Ferguson 135 is a popular choice with enthusiasts of the marque, but it will never have the appeal that an example produced before 1976 will have – especially to those that are not loyal to the triple triangle brand.

This feature comes from the latest issue of Tractor & Machinery, and you can get a money-saving subscription to this magazine simply by clicking HERE

Previous Post

Rare Bedford PC van is collector’s star exhibit

Next Post

Remembering Bucyrus-Erie Company’s pull-type scrapers