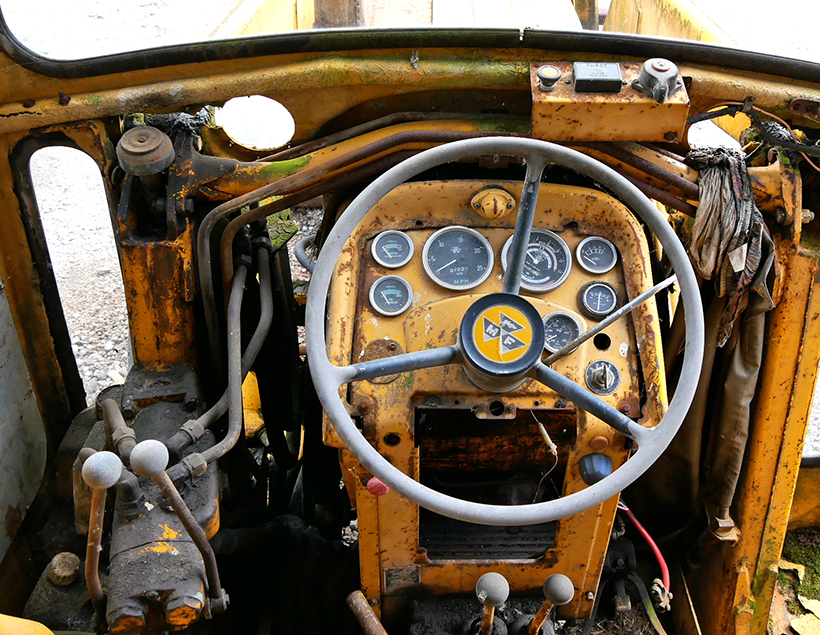

Massey Ferguson 3305 backhoe loader

Posted by Chris Graham on 3rd September 2021

Jane Brooks explains the appeal of a much-loved, 1960s Massey Ferguson 3305 backhoe loader that remains in regular use today.

Massey Ferguson 3305 backhoe loader: In addition to the two different 3303 and 3305 models, two specifications of digger were originally available; a standard unit that had an 11’6″ IEMC-rated digging depth, and a deep-dig version capable of digging down to 15’5″. Steve’s model is a standard unit.

“I was really lucky to get the 3305” Steve explained. “It was on a local farm and I’d seen it working on and off over the years, before it was taken out of service and stored in a barn. I’d always hoped I’d get the chance to buy it and, luckily enough, it was offered to me a few years ago.”

After striking a deal with the previous owner, the digger was brought back to Steve’s South Warwickshire base where he was very pleasantly surprised to find that, after a change of oil, new filters, a good clean and a new battery, the old girl sprung into life.

Pleasantly surprised!

“I had actually anticipated that there might be a little work needed because the machine had been standing in a barn for quite a few years, so I was pleasantly surprised by how little I needed to do,” he added.

In the UK, the heritage of the Massey Ferguson backhoe loader dates back to the 1950s, when the Tractor Digger Shovel – or ‘Three in One’ as it was commonly known – was introduced. It was based on a Massey Ferguson tractor skid unit and was produced between 1959 and 1961, at Massey Ferguson’s Manchester plant.

The Massey Ferguson 3303/3305 models were introduced in 1966, and both were equipped with the 250 loader and 252 backhoe.

In 1961, the 203/205 and 65S/65R models were launched; ‘S’ models were equipped with a six-speed, manual transmission, while the ‘R’s featured four-speed Instant Reverse. The models were updated in 1965, with the introduction of the 203/205 Mk2 and 3165S/3165R models. That same year, the 220 Backhoe – with five-position POWR-SLIDE – was also introduced.

POWR-SLIDE enables the operator to offset the digger to any position on the main frame. Hydraulic clamps allow the operator to side-shift the boom from inside the cab. The four-bar bucket linkage gives the bucket an arc of rotation of 190°, from full dump to full crowd.

It was in 1966 that the 3303/3305 models were launched, equipped with the 250 loader and 252 backhoe. These models offered digging depths down to 13’6″, and both models were powered by a 60hp A4.212 Perkins engine.

Keep a wary eye out for any welded repairs to the backhoe arm or boom. Once these break, there’s a strong chance they’ll go again. Also check that the bucket teeth are all there, are in good condition and that no bolts are missing.

Original condition

Steve’s Massey Ferguson 3305 is in very original condition. Unlike the 3303 model, which had a conventional transmission giving six forward and two reverse gears, the 3305 was fitted with Instant Reverse Transmission plus a torque converter, as standard. Massey Ferguson claimed that this set-up gave a valuable boost to output when the loader was in use over long periods. The reason for this was that ‘instant reverse’ provides direction changes at the touch of a toe, without declutching. The torque driver takes up the drive smoothly, and adjusts forward speed to the load requirements.

The machine is also equipped with a manually-controlled diff-lock that can be switched in to give the effect of a ‘solid axle’ on slippery surfaces, intended to reduce wheel spin.

In addition to the two different 3303 and 3305 models, two specifications of digger were originally available. There was a standard unit that had an 11’6″, IEMC-rated digging depth, and a deep-dig version with a longer dipper stick giving a 13’6″ digger depth resulting in a maximum digging depth of 15′ 5″. Steve’s model is a standard unit.

If it’s at all possible, test all the hydraulics on any prospective purchase, and make sure the system is capable of holding the arm extended without fluid leakage.

When it came to buying the 3305, Steve gave it a brief look over, but was prepared to put in some work because it was the model he wanted. If he’d been planning to use it ‘in anger’, then he may well have been more cautious, although he was already familiar with the actual machine.

Buying tips

However, even when buying from friends, things don’t always work out well, so here are a few tips which readers might find useful, especially those looking for machines to put to work.

It always pays to go to assess a prospective purchase with a checklist in hand. Then, once faced with the vehicle, be methodical with your inspection approach. Start with a good look at the tinwork, checking the entire machine for dents, cracks and bends. The boom and stick, which are the most heavily-used components, can become warped or bent, leading to the need for expensive replacements. Dents on the stick – or other parts of the machine – may be a sign that the digger was carelessly used either by inexperienced operators in the past, or that it might have been a hire machine at some time in its life.

Also carefully check the condition of the hydraulic hoses. Be on the lookout for signs of excessive wear or pinching, and also be prepared to replace any hoses that have become dry or brittle. Inspect the condition of the kingpin, as well as all other visible pins and bushes. The presence of rust around the kingpin is a good indicator that the machine hasn’t been used for quite some time. It’s also sensible to make sure that there’s oil in the axles, and that everything that should be greased, has been.

It always pays to go with a checklist. Start with a good look at the tinwork, checking the entire machine for dents, cracks and bends. The boom and stick, which are the most heavily-used parts, can warp or bend, leading to the need for expensive replacements.

Another important pointer to watch for is the presence of welded repairs that have been made to the backhoe arm or boom; once they break, there’s a strong chance that they will go again. Also check that all the bucket teeth are present and in good condition, and that no bolts are missing.

With regard to the loading bucket, make sure that the cutting edge isn’t too worn as excessive wear will detrimentally affect performance. Also check that none of the hydraulic cylinders is damaged, as any loss of oil will also lead to poor performance.

Sensible ideas

It’s a sensible idea to have a look inside the radiator, to check on the condition of the coolant solution. If there’s no sign of and antifreeze in the mix then this is a pointer towards sub-standard servicing and maintenance. As with all engines, running without antifreeze at the correct concentration is just asking for trouble.

If it’s at all possible, test the operation of all the hydraulics on the digger. In particular, make a point of checking that the system is capable of holding the arm. With it extended and the bucket raised, any gradual lowering will indicate a problem with the system.

Based on a Massey Ferguson 3305 tractor skid unit, the machine is equipped with a 60hp Perkins A4.212 engine.

High hours aren’t a problem, as many of these machines will have had a hard-working life. But, to last into old age with any degree of reliability, they will need to have been properly looked after and regularly serviced. Be on the lookout for a suspiciously low hours total, especially if it’s combined with excessive pedal wear; either the hour clock is broken, or the machine has operated for more hours than stated.

Massey Ferguson Excavators do hold their value, although it’s generally the 1970s 50B model which is the most sought after, However, in good condition, a Massey Ferguson 3305 is a pretty reliable old workhorse that can be picked up for between £2,000 and £3,000.

When buying, be on the lookout for a suspiciously low hours total, especially if it’s combined with excessive pedal wear; either the hour clock is broken, or the machine has operated for more hours than stated.

The 50.B model arrived in 1972, complete with a new safety cab and improved loader and backhoe performance. This machine also included an automatic, end-of-stroke cushioning feature in the backhoe boom cylinder. Four-wheel-drive was introduced in 1980 followed, in 1982, by the 50.B Mk 2, with its extended stabiliser legs. In 1984, the MF Industrial division introduced a power shuttle transmission, with synchromesh gear shifting and soft-shift direction.

After a management buyout of MF Industrial in 1992, the range was renamed Fermec, and the Series 90 range was introduced in 1993, featuring the Fermec 750, 860, 865 and 965 models. Fermec was to continue operating until 1996, when it was brought out by Case, only to be sold again to Terex, in 2000.

For a money-saving subscription to Classic Massey & Ferguson Enthusiast magazine, simply click here