David Brown 996 saved and beautifully restored

Posted by Chris Graham on 24th April 2024

Russell McNeill chats to Scott Lambert about the latest David Brown – a 996 – to join the family fleet, and the tractor’s fine restoration.

All photographs: Russell McNeill

The McNeill family’s David Brown 996 has serial number 11104088. The last example produced was 11104577.

During the 1970s, tractors of 50-70hp were still the norm on many farms, and to capitalise on this fact David Brown produced a choice of models in this category to tempt prospective purchasers. The 58hp (DIN) 990 and 64hp (DIN) 995 and 996 were available in both two- and four-wheel drive configuration, with a basic specification to suit most requirements.

Standard across the board was a 12 forward, four reverse transmission (with synchromesh on second and third gears in each forward range), 540/1,000rpm power take-off, Selectamatic hydraulic system, dual-category three-point linkage, heavy-duty drawbar, parking brake, foot throttle, differential lock, and lighting kit.

The AD4/49 and AD4/55 engines used were well proven, with reliability and performance at their heart. Liked for their lugging power and low fuel consumption, the two units had an enviable reputation that did much to provide peace of mind for new and existing users.

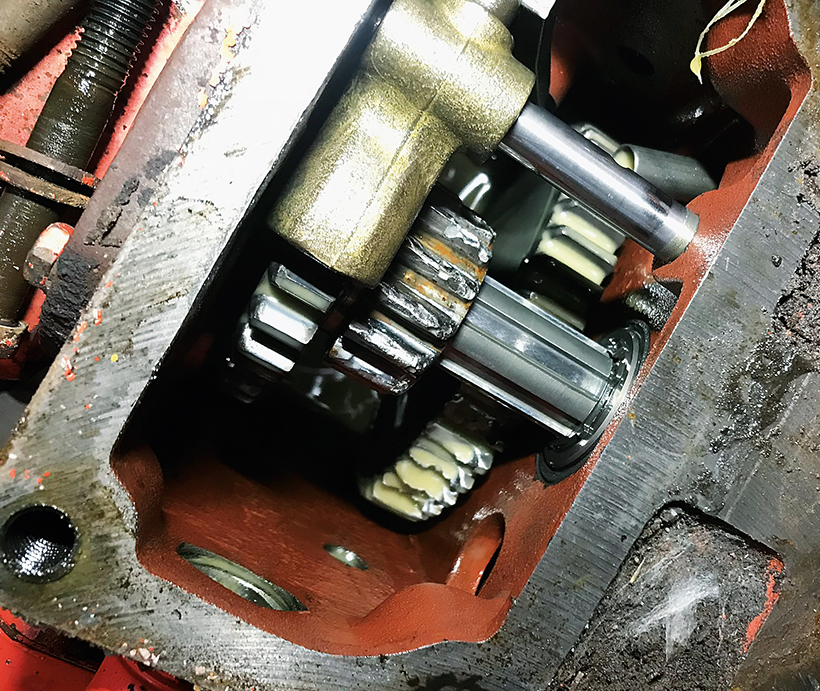

Removal of the engine block shows David Brown’s mainframe design and unit construction principle.

Unusual in the respect that the tractors were built on the unit construction principle, these models had inbuilt strength and stability, as well as the option to be overhauled without ‘splitting’ in the traditional manner – as the engine and transmission were fitted into the cast ‘mainframe’.

At the outer end of each axle was the final drive reduction unit, and this design had two advantages. Firstly, it reduced torque loadings on the transmission, and it could also be rotated to provide additional clearance in tall crops. When used in conjunction with front axle extension beams, the height of the tractor could be increased by 190mm (7½in) – effectively offering two tractors for little more than the price of one. This was only available for two-wheel drive 990 and 995 models.

All three models had the versatility afforded by David Brown’s multi-speed PTO, but there was also the luxury of an independent PTO, with hand-operated clutch, either as an option or standard fitment (dependent on model). As well as 540/1,000rpm speeds, the system offered 24/12 ground speeds and the ability to run the engine at a speed suited to the task being undertaken with the power take-off.

The PTO unit was in a poor state.

For example, high-power implements (such as forage harvesters) could utilise the high range and 1,000rpm PTO speed with the engine running at 2,000rpm, while medium-power implements (such as balers) could use the low range and 540rpm PTO speed with the engine at 1,800rpm. For implements like fertiliser spreaders, not requiring much power, high range could be used in conjunction with 540rpm and the engine at just 1,100rpm in what would be classed today as ‘Eco/Economy’ mode.

Simple operation

The Selectamatic hydraulic system had also proved itself by this point and was used across the 990/995/996 range. It was simple in operation, with one quadrant lever and a dial at the operator’s disposal to get the best from the tractor in relation to the job in hand (see pages 57-60).

Four functions could be selected via the Selectamatic dial – Height, Depth, TCU/External – with the former for accurate positioning of the linkage, irrespective of implement weight. Depth control offered precise control of working depth for ploughs and the like, while TCU (Traction Control Unit) was for use with implements fitted with depth wheels to maintain a constant depth and reduce wheel slip.

While waiting for engine parts, the front axle was overhauled and painted.

With the dial in the TCU/External position, and in conjunction with an optional three-way valve, the operation of external cylinders (loaders, tipping trailers and the like) was possible.

As enthusiasts of the David Brown marque, brothers Russell and David McNeill are well versed in the features and operation of these models, and were only too pleased to add a 996 to their collection earlier this year.

“My brother and I are mechanical and civil engineers by trade, respectively, and along with my two young boys, Robbie (15) and Jude (8), we look after our late father’s small farm in Aghadowey, near Coleraine in Northern Ireland. It’s a good break from the stresses of business!” Russell told T&M.

The cab was in a poor state…

“Since I stated my own engineering business, in 2014, we have been fortunate enough, time wise, to be able to renovate the farm buildings and buy lots of period machinery, which at the time my father was farming, in tighter times, would have been impossible. We only hobby farm, with two or so acres of old variety potatoes and some hay.”

The McNeills’ fascination with David Brown tractors started in their early years, when the farm ran a 995 – which was worn out, by Russell’s own admission. It would have been nice to find it and restore it, he says, but he suspects it was scrapped. As a result, he purchased a David Brown 885 with a ‘Q’ cab a few years ago.

“It has phenomenal power and is a great gripping machine for its size,” he explained. “Last year I bought the second of our David Browns – a 1212 that needed a complete restoration and rebuild – and then in December 2022, thanks to eBay, a little chocolate 885, again needing a massive rebuild and restoration!

… and many new parts had to be fabricated.

“I had thought we were finished until I was offered this 996 for scrap, which I took my youngest boy to see. He said we had to save it!”

With the tractor delivered to the farm, Russell took the pressure washer to it and tinkered with it to get it going. It ran, poorly, but was easier to move around than it had been before.

Worth saving

An investigation revealed that it was low on compression on cylinders two and four, water ingress was considerable, the clutch was heavy, the PTO unit was noisy, the cab was rotten, and there were serious fuel and coolant leaks. It would be a considerable restoration, but one that Russell felt was worth it, particularly as so many tractors in this condition are either broken for parts or scrapped in their entirety.

Russell’s son, Jude, stands beside the 996 after it was moved to the confines of the shed.

He said: “The teardown revealed a previous, poor quality rebuild, and bored out block to plus 40 thou – a complete botch! We set about pulling apart the block and sent it away to get liners fitted, as it was at the limit. The injection pump went for reconditioning and the crank for polishing, while the cylinder head received new valves and an overhaul.

“A reconditioned clutch went in, and the fuel tank was removed to enable new pipes to be fitted to the hard-to-access steering orbital.

“We rebuilt the front axle and thrust washers while waiting on engine bits, but when the time came for engine assembly my partner Carolyn and the kids did it one Friday! It’s very simple to do, illustrated by the fact that once it was bled it started on the first turn of the key, with that characteristic DB bark!

Everything looks better after it’s been painted!

“Then it was on to the body and cab. We made new doors, the rear window mechanisms, and most of the roof and mudguards.

“The noisy power take-off unit turned out to be stripped gears, due to the PTO cable being seized and it being forced into gear cab. It was decided to swap the entire unit, rather than rebuild it, and this only cost £60.

“The valve chest out was checked with a special tool that we made to enable the use of a Porta Power and, surprisingly, this one was fine. The cab prevents a lot of water ingress to the transmission on these models, which was obviously the case here.

Starting to take shape.

“When we had the hydraulics down, I fitted a Power Beyond manifold and a new, three-bank spool for a machine that I’m designing. This spool has priority over the Selectamatic system, just like the David Brown spools. Points to note are the difficulty in finding DB spools and, as you will guess, the cost of any old ones that are available, as well as the stacking difficulty of any more than two.”

With the mechanical work and fabrication complete, parts were shot blasted and coated in epoxy primer before the application of two-pack paint. Alliance 16.9-30 radial tyres were fitted at the rear, which, Russell says, were very reasonable and provide excellent grip – having fitted a pair to his DB 885.

The remaining tasks were to get the cab glazed, which Russell entrusted to the professionals, a full rewire, and to get it re-registered with its original registration – something that purportedly took as long as the restoration itself!

The result made the hard work worthwhile.

The 996 was finished in time to cut and ted hay, tasks that Russell says it performed admirably, thanks to its size and agility. It joins the other David Browns in the McNeill fleet and won’t, T&M feels, be the last to be saved by the family!

This feature comes from a recent issue of Tractor & Machinery, and you can get a money-saving subscription to this magazine simply by clicking HERE

Previous Post

This 1936 Fordson breakdown truck is simply superb!

Next Post

The Trans Pennine Road Run is back on this summer!