Crawford’s 1958 Austin Gipsy

Posted by Chris Graham on 27th March 2021

Brian Culpan tells the fascinating story of Crawford’s 1958 Austin Gipsy, which truly is a ‘van for all seasons’.

In 2014, older Robert Crawford was driven down to the Crystal Palace start of the HCVS London to Brighton Run by son, young Robert, in the company’s 1958 Austin Gipsy.

This very smart, 1958 Austin Gipsy was supplied new to Robert H Crawford & Son, of Frithville, in Lincolnshire, and worked as a service vehicle in this agricultural engineering business until 1975.

Back in the 1950s, choosing a diesel engine for a small commercial was unusual, unless the rest of the fleet of larger vehicles ran on DERV (an acronym for ‘diesel engine road vehicle’, but often applied to the light oil fuel, itself), and the fuel was bought in bulk. Of course, it had the big advantage of vastly improved economy. On the downside, though, opting for a diesel bumped the price up by £125, to £755.

Still looking magnificent and ready for a day’s work even at 50 years old, the Crawford Series 1 Gipsy. The canvas tilt is the original, but it was stored for much of the vehicle’s working life, as an optional hardtop was used.

Early Series 1

The registration number SFU 145 is the vehicle’s original; it came from the old County Council of Lindsey – part of Lincolnshire. Being new in August 1958, this is a very early Series 1 – maybe only the 15th assembled. Crawfords always was (and still is) loyal to the Ford brand, but that manufacturer didn’t offer a small 4×4 off-road commercial for use as a service van.

The company’s base is in the centre of Lincolnshire’s fertile, flat land – excellent for both dairy and arable farming. When the business started up in 1921, the horse was the preferred choice for powering machinery, but tractors would soon takeover, and Crawfords was very much into them. Of great interest to vintage tractor owners of today is the fact that Crawfords was a dealer for the very distinctive, single-cylinder Field Marshall tractors and, when that company folded, it bought-up all the existing spares.

The company was awarded the coveted Royal Warrant in 1976, for supplying agricultural machinery to Her Majesty Queen Elizabeth II. A Royal Warrant of Appointment is the document that appoints the company in its trading capacity, and is granted to a named individual (known as the Grantee) permission, and responsibility for the display of the relevant Royal Arms in connection with the business. They are given to holders in recognition of the goods or services they provide to the three most senior royals: HM The Queen, HRH Duke of Edinburgh and HRH Prince of Wales. Anyone who supplies goods or services to one of those three for five out of seven years (including the immediate past 12 months) can apply for a warrant.

London to Brighton Run

In May 2014, the Austin Gipsy was brought to Crystal Palace, in south London, for the start of the HCVS London to Brighton Run, by Robert E Crawford – the ‘son’ who was then in his late 70s (known within the company as ‘older Robert’). It was driven down by son Robert Jonathan (younger Robert).

The cab interior is Spartan and the instrument panel is hinged for easy access to the electrical wiring.

Apart from a re-paint in 1990, the vehicle remains almost original but, at some time in its later life, it acquired the better cab doors from a Series 2; these feature sliding glass windows and external door handles. The earliest doors had flexible tops containing the Celluloid windows, and the lower edge of the driver’s door was made of fabric, to facilitate hand signals and access to the interior handles – no external ones!

The cab doors and bonnet were mounted on quick lift-off, patented, pin hinges, so the doors weren’t provided with locks; there was no point! Gipsy hubcaps were painted black as standard (stainless steel ones were an optional extra). Chromed ones would have rusted immediately in an agricultural setting.

No padded door cards for this working vehicle.

Very early examples of the model were only available in Cheviot Fawn (or primer), and as soft-tops. This one was delivered in primer, but immediately painted in the company’s orange livery. Surprisingly, the tilt cover is the original, and the reason that it remains in such good condition is that, when a fibreglass hardtop became available (shortly after the model’s introduction), the cover was removed and put away, and the pick-up worked as a hardtop for most of the time. However, the soft top has been replaced to re-create the vehicle’s original

The soft-top canvas was originally made from hemp (later cotton), and does have some natural resistance to moisture. However, it does require extra water-proofing treatment when being used as a tilt using a specialist liquid or, more latterly, a thin, plastic coating. Austin sales literature described this tilt material as ‘PVC coated leathercloth.’

Exciting, heady days!

In those exciting, heady days of tubeless tyres, carrying a spare was thought to be unnecessary – a small ‘plug and fix it’ kit was all you needed! Consequently, a spare was an optional extra; it could be carried on the bonnet. A popular tubeless tyre repair kit made by Dunlop was called ‘Reddiplug’. The procedure was something like: remove the offending nail; lubricate the hole with adhesive; thread a suitable size ‘worm’ (plug) of rubber on the crochet hook; push right through the tyre tread; withdraw the hook (the plug stays in place); trim off the excess and leave it to set.

Door handles are a lesson in simplicity.

However, this was only a temporary fix until the tyre could be removed and a mushroom-headed plug inserted from inside, and vulcanised in position. Tubed tyres deflated rapidly if punctured – like a ‘popped’ balloon – and often led to a loss of control (highly dangerous at high speed). A tubeless tyre lost air very, very slowly (over a period of days, if not weeks). As often happens, drivers abused the repair system by driving off at high speed before the adhesive had set; consequently, the wet plugs were flung out by centrifugal force. Some also tried to fill a large gash by using multiple plugs!

Gipsy model history

The name Land Rover is reminiscent of roaming anywhere in the land, and Austin chose the name ‘Gipsy’ for its association with Romany travellers wandering the land.

Austin designers had their ambitions set on toppling the rival Land Rover from its throne as the most desirable off-road 4×4, stealing its crown, and securing the lucrative and prestigious contracts with the armed forces (and, of course, also replacing the civilian Champ). They were keen to pacify the very disappointed military men by creating a more reliable vehicle than the Champ.

To achieve all this, they had to create a vehicle that was as good (or better), and which boasted some distinctive features. They gambled on the provision of novel and innovative all-round independent suspension – using rubber to give a more comfortable ride. Also, the world shortage of steel during the aftermath of WW2 had been overcome, so the use by Land Rover of aluminium for body panels wasn’t now essential. Austin opted for cheaper steel pressings that could be spot-welded; a faster fabrication method more suitable for mass-production. Advertising emphasised a one-piece, all-steel body of great strength and rigidity.

The Gipsy’s big brother, the Austin Champ, wasn’t liked by the armed forces; perhaps it represented a step too far into untried, advanced designs.

From the outset, the Gipsy had been designed as a rugged, cross-country vehicle, based on the experiences gained from the Champ model, which was built from 1952, for both the military and civilian markets. The Champ used independent suspension all round, with torsion bar springing, but the designers started with a clean sheet when devising the Gipsy.

New suspension system

One of the first decisions taken was to adopt a new type of suspension, called ‘Flexitor’, that was made by Moulton (the company that would also supply the Mini’s rubber springs and, in the future, Hydrolastic suspension units). A pre-compressed rubber sleeve was inserted between two tubes, and bonded in place. The outer tube was secured to the chassis, the inner one to the trailing arms carrying the wheel hubs. The units didn’t need lubrication, and coped well with repeated impact over bumps.

A further advantage with this system was that the units gave a natural damping to the suspension and, with the addition of hydraulic shock absorbers, made for a controlled ride. A long torsion bar was inserted across the vehicle, connecting the front units, to control body roll. Eliminating heavy, solid axles considerably reduced the un-sprung weight of the Gipsy, but a disadvantage was the large number of universal joints needed in the driveline.

The main and transfer gearboxes are in found in a neat, one-piece housing. Similar, hypoid diffs are used back and front. Another small, new detail, was the use of nylon and steel steering joints – something we now take for granted.

The chassis used well-rounded channel-section members welded together to form a box-section, and had a wheel base of 90 inches, which was two inches longer than the SWB Land Rover. Attached to the chassis at six points was the all-steel body (unlike the aluminium Land Rover body) built from sheet steel with box section reinforcement. As a consequence, the Gipsy chassis rarely rots, but the Land Rover’s does.

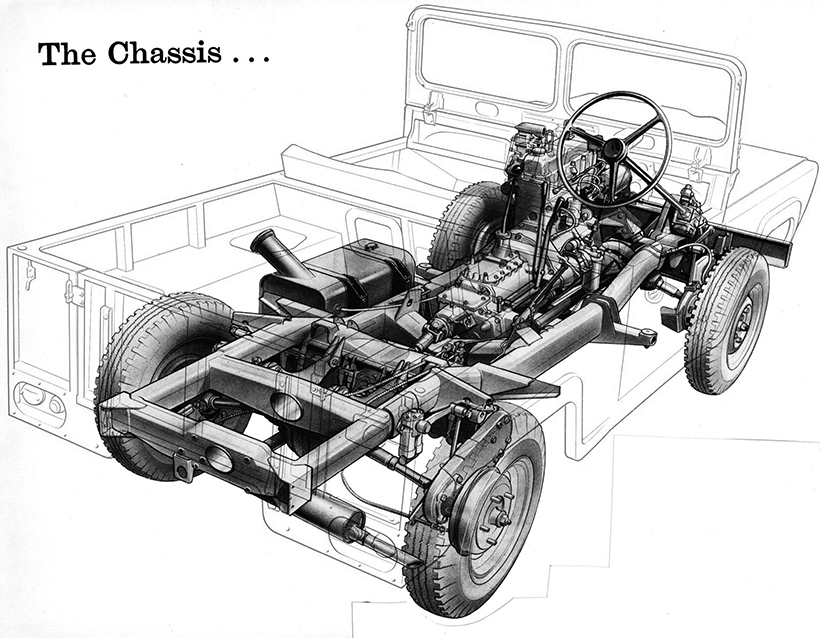

A ‘ghosted’ view of the Austin Gipsy’s chassis and driveline. (Pic: Brian Culpan)

Corrosion with time

Unfortunately, as time went by, although Gipsy bodies had been put through the ‘Rotodip’ at the factoy, for protection against rust, in service, severe corrosion did become a problem. Development work carried out to improve the Gipsy, resulted in it becoming increasingly more like the Land Rover, and this is probably what led to its downfall. When two, large organisations merge, there’s inevitably rationalisation. Following the merger of British Motor Holdings (formerly BMC), and the Leyland Group, ruthless axing of models was carried out to avoid model duplication and internal competition. The Austin Gipsy was one of the casualties; it had lost out to its rival, the Land Rover. So, just as it was beginning to sell well, the decision was taken – in 1968 – to kill it off. A total of 21,208 Gipsies were built and, of these, about 10,000 were the later Series IV models. The Austin Gipsy Register currently has about 130 members, and actively promotes the preservation of this model. It’s believed that about 100 examples have been preserved, plus another 97 released by the Home Office, in the late 1990s.

These early models (later known as Series 1) were built between February 28th, 1958, and July 12th, 1960, at which the Series 2 arrived. Incidentally, the oldest known Gipsy is a Cheviot Fawn soft-top currently in a private collection in Bedfordshire.

For a money-saving subscription to Old Glory magazine, simply click here

Previous Post

David Brown 25D: A powerful performer!

Next Post

Fowler 6nhp traction engine finds new home