Exotic eight-leggers!

Posted by Chris Graham on 2nd August 2021

Bob Tuck looks at some of the most exotic eight-leggers you’re ever likely to see, spot-lighting some incredible loadbed vehicles.

Exotic eight-leggers!: The 8×4 Butler Mark 5: 800-1,000hp, automatic transmission, 300 tons on dirt roads with trailer.

What’s not to like?

In Britain, in parallel with the pioneering mid-1930s generation of four-axle commercials, the first 8x8s appeared. Guy’s bonneted military prototype was trialled in 1930. It was followed by astonishingly innovative drawbar truck/tractors designed respectively by Leyland and AEC for overseas multiple-trailer cross-country operation.

The one-off Leyland had a designed gross train weight of 15 tons. Its axles were equidistantly spaced – and were both driven and steered. With its 80hp petrol ‘six’ installed behind the cab, in terms of automotive layout, the Leyland was a genuine first. Even as experimental vehicles, cab-forward 8x8s didn’t see the light of day for another two decades.

With its stylish cab and optional big-singles, Scammell’s Rigid Eight was the most imposing of Britain’s 1930s-generation eight-wheelers.

Four 30-ton gross AEC 8x8s were built in 1933-34. Like the slightly earlier Leyland, the project was a government-backed initiative. They were engineered by AEC’s Hardy Motors subsidiary. Hardy had an association with the British arm of America’s FWD, which had supplied large numbers of 4x4s for British military service during the First World War. Of the four AECs built, one went to Africa and two went to Russia. The fourth went Down Under, where it clocked 1.3 million miles over outback tracks between 1934 and 1946. A crucial lifeline in Australia’s sparsely-populated Northern Territories in the Second World War, the AEC ‘Government Roadtrain’ is justifiably the star exhibit at the National Road Transport Hall of Fame, in Alice Springs.

The spec includes a 130hp, 8.5-litre, six-cylinder direct injection AEC diesel. A front cooling fan draws air through the engine bay to the radiator installed behind the cab. Tyres are 10.5×20 bar grips, the centre two axles are more closely spaced; the front and rearmost axles steer. Working with four trailers, it’s recorded as having grossed 45 tons – a 50% overload – on a run of more than 600 miles across outback terrain.

A German take on four-axle trucks: the 1938 Faun 15-tonner’s behind-the-cab diesel delivered 200hp; absolutely stonking for those days!

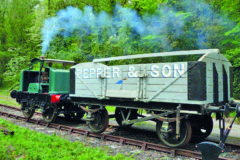

Also in 1934 – and four years after its first coal-fired eight-legger – Sentinel introduced the 13-ton payload four-axle S8. Very much steam’s last hurrah, fewer than 10 were built. Happily, one survives, owned by Richard Hazell of Pangbourne, Berkshire, (whose collection also includes the S8’s two counterpart S types, the two-axle S4 seven-tonner and 11-ton payload, three-axle S6).

For its S types, Sentinel introduced a four-cylinder, single acting horizontal inline engine design incorporating a longitudinal crankshaft, and shaft-drive replaced the chain drive of its predecessors (the S8 and S6 had drive to the rearmost axle only). Advances over earlier steam vehicles included an automatic stoker and extensive use of aluminium in an effort to reduce a steamer’s inherent weight penalty. But in its rear-guard fight against diesel, what Sentinel couldn’t overcome was the hour or more needed every morning to get the fire going and raise steam to working pressure.

Deliberately designed to look like a diesel, the Sentinel S8 was the ultimate in smooth, near-silent coal-fuelled commercials.

Scammell was late to the eight-wheeler party. Entering production in 1938, the 22-24-ton Rigid Eight was also Watford’s first forward-control chassis. The early vehicles weighed a third-of-a-ton less than the competition. This was made possible by innovations including – exotic by the standards of the time – front and rear rubber suspension. However, its edge was blunted by the subsequent adoption of coil, and finally, leaf set-ups. As well as a cab with distinctive, steeply-sloped windscreen and radiused front corners (evidencing consideration to airflow), the Rigid Eight stood out for having brakes on all wheels, and the option of ‘big single’ balloon tyres at the rear. A double-drive rear bogie was introduced after the Second World War. Limited production continued until 1960.

In the same year as the Rigid Eight, Faun introduced Germany’s first four-axle commercial truck design, the 15-tonne the L1500 D 587. In a radical departure from convention, like the Leyland 8×8 of 1930, the engine was installed to the rear of the low-set cab. Drive was taken rearwards from an eight-cylinder, 200hp Deutz diesel, the weight of which was borne chiefly by the lead steering axle.

The fact that its restoration was paid for by Australia’s Northern Territory Government indicates the respect accorded to the AEC Government Roadtrain’s Second World War heroics.

The cab-forward arrangement became the template of a series of post-Second World War Faun types, built for the German Army – and subsequently imitated by a variety of manufacturers of military trucks. With an unladen weight of 10.3 tonnes and a 15-tonne carrying capacity, the L1500 D 587 was designed specifically for long-distance goods transport. Two examples were built. One, in service with Paul Schütze, a long-haul operator, survived the Second World War.

In the movie The Third Man, the Swiss were disparaged as only having the cuckoo clock to show for 500 years of democracy and peace. But, credit where it’s due. In the Second World War, the armed forces of neutral Switzerland operated the world’s first-ever fleet of 8×8 trucks built in significant numbers. During 1943-44, Saurer delivered a fleet of 3.5-ton rated cab-over-engine M8s. Deployed chiefly for towing artillery, power was supplied by a 100hp, eight-litre six-cylinder diesel. The M8 had swing axles and – rather than time-honoured leaf springs – an ingenious coil spring suspension system with cross-chassis interconnection via bell cranks and rods.

Compliance with West Coast bridge-loading formulae dictated the configuration of this 1980s 75ft long Freightliner eight-legger truck-trailer rig.

When it comes to on-highway 8×4 commercials, Swiss manufacturer Mowag produced the ultimate exotic. Now an armoured vehicles subsidiary of US-owned international defence systems group General Dynamics, Mowag was established in 1953. Trucks with engines installed amidships under the chassis were an early speciality. In 1977, Mowag reached the summit for chassis designed for romping up the Alps. Its 28-/32-tonner was powered by an underfloor-mounted 10.8-litre, two-stroke V8 with a peak output of 500hp.

The 1934 AEC 8×8 Government Roadtrain amply demonstrated the virtues of vehicles purpose-engineered for specific export niches. While AEC showed the way, for the most part, rather than offering overseas customers with what they really needed, British makes preferred to sell modified home-market gaffers’ trucks. It wasn’t simply a matter of fobbing-off; return on investment was another factor – although so was commercial ambition (or lack thereof).

US Army big boys’ toys in the mid-1940s, Sterling T26 series 8x8s combined chain drive with high articulation suspension and turntable bogie steering.

We are, of course, talking here about premium spec trucks. Of the more accommodating exporters, Foden and Atkinson were standouts and, doubtless, Scammell would have done more if allowed to by Leyland.

Foden in South Africa enjoyed extra latitude due to regulations determining local content. But, whereas in South Africa, Foden distributed through a wholly-owned subsidiary, in Australia, it sold through import agents. This did make a difference (as Atkinson proved).

Foden’s top-spec 8×4 roadtrain outfits featured insulated steel hot-climate cabs, supersized tropical radiators, Gardner 150hp 8LW diesels and, later, 200hp+ Rolls-Royce and Cummins power units.

The Swiss Army’s independent-suspension Saurer M8 was the only 8×8 both developed and in service during the Second World War.

Even Scammell, under the aegis of Leyland Motors, went so far as to permit local assembly twin-steer 8×4 bonneted Contractors, shipped from the UK in kit form. Designed around front axle loading regulations that otherwise presented a problem for vehicles running at higher gross weights, Cummins-engined four-axle Contractors saw service in mine-train drawbar tractors form and – with extended wheelbases – as cattle transporters.

Recognising the limitations of modified, home-market products, in the mid-1960s, Atkinson eventually gave its Australian subsidiary a completely free hand. The resulting all-mod-cons GRP hot-climate cab was on a par with the best US cabovers. The ultimate specs were 8×4 roadtrain truck/tractors. As hunger for power increased, Detroit Diesel and Cummins engines supplanted glorious Gardner 150- to 240hp straight-eights and Rolls-Royce units. These were Anglo-Aussies to be proud of – though the ‘Anglo’ element was negligible at the end.

8x8s fielded by Soviet Cold War armed forces included the complex ZIL-135, which had twin engines – and twin drivelines.

There is actually still a market Down Under for forward-control 8×4 rigids, chiefly taken care of by Kenworth Australia’s timeless K200, directly evolved from the classic cab-overs that used to patrol the US Interstates.

By the nature of its products and markets, for Kenworth, an ‘eight’ is more likely to be a tridem bogie 8×6 or 8×4. Twin-steers have been thinner on the ground, but include specs as different from each other as any trucks could be. In 1955, Kenworth rolled out the 825hp XM194E tank transporter tractor. It was a total rework of a big boy’s toy 8×8 fifth-wheel tractor, originally engineered by the US Army Tank-automotive Command’s Detroit Arsenal facility.

With an operating gross weight of over 70 tonnes, Terberg’s 1980s pipe-sections transporter had both eight-wheel-drive and steering.

Around the same time, Kenworth delivered a fleet of custom-spec Model 844 twin-steer chassis for hi-cube dromedary truck/tractors for Pacific Intermountain Express. The Cummins six-cylinder diesel was installed laid on its side under the chassis rails. The engine location permitted a shorter front-to-back cab dimension which, in turn, allowed the 844 to have a longer, ‘dromedary’ cargo van body sitting between the cab and the fifth-wheel. With a close-coupled semi-trailer, the arrangement maximised capacity within a regulated overall vehicle length. P-I-E’s Kenworth 844 rigs were so long that State length laws stopped them operating East of Denver, Colorado.

For over half a century, C500 conventionals have been Kenworth’s stock-in-trade for extreme-duty on-/off-highway tractor and rigid chassis applications. Custom-specs have been – and continue to be – permutated from Cummins diesels in the 400- to 650hp range, twin-steer bogie capacities up to 20 tons, and maximum rear bogie capacities of 60- to 75-tons. Driveline options are 8×8, 8×4 and tridem 8×6, with the option of hub reduction. Tyres are whatever suit the job; options include high flotation bag-type rubber to suit oil/gas rig bed-trucks operating over soft terrain. K500 cab-over options have always been available – and these days can be supplied with DAF cabs.

Some ex-US Air Force FWD Teracruzer missile-launcher tractors and support vehicles had a second life working on Dutch land reclaim projects.

In the US, in the early 1930s, Versare offered the US Army a bonneted twin-steer 8×4 with a suspension system designed to equalise axle loadings. Then, from the 1950s, four-axle crane-carrier and concrete mixer chassis began to appear. But for forward-control, twin-steer eight-wheeler commercial chassis, the most notable exponent was Freightliner. Its cab-over range during the 1970s and 1980s included regular and low-step cab options.

In 1942, the United States Army began experimenting with 8x8s. The first – more of a test rig than a truck or tractor – emerged from the Los Angeles factory of Cook Brothers. This was followed by eight-ton rated truck and tractor evolutions, after which the baton was passed to Sterling which, over the 1944-46 period, built the T26 series of experimental 12-ton cargo trucks and tank transporter tractors. With eight-wheel chain-drive and horse-cart style turntable bogie steering, the final prototype tractor was powered by a 525hp American LaFrance V12 petrol engine. Rated gross train weight was 90 tons. Despite the complexities of chain-drive and high articulation suspension, it performed perfectly. In the end, it was decided it was an indulgence that far exceeded what the Army required.

Oshkosh M977 HEMTT expanded mobility trucks were ordered for US Army service in 1981 – and continue to be the backbone of its heavy tactical fleet.

The first US military 8×8 entered service in 1956 – but with the US Air Force, not the Army. The eight-ton rated, 250hp, eight-cylinder gasoline opposed piston-engined Teracruzer series of missile transporter tractors was built by FWD for the US Air Force. They ran on 40×42-inch Goodyear Terra-tyres, with an inflation range of 3- to 18psi, adjustable from the cab to suit varying ground conditions. Steering was facilitated by a front bogie turntable system (in the manner of the Sterling T26).

As well as copying the Teracruzer, the USSR produced a long series of 8x8s (and ultimately, all-wheel-drive rigid-chassis missile transporter derivatives with a mesmerising number of axles). One standout that saw extensive service was the ZIL-135 series of 8x8s. Introduced in 1959, these had close-paired centre axles and twin, 180hp V8s behind the forward-set cab – and separate left- and right-side drivelines. The Soviets were certainly undaunted in putting complexity into production.

Introduced in 1977, the spec of 8×8 Magnum 4 pipe carriers built by Foremost Industries, Canada, included walking beam suspension and frame steering.

In 1980, Oshkosh won a US Marine Corps order for the unique LVS, a centrally-articulated 8×8. The rear, load-carrying module could be decoupled, allowing it to switch between cargo, container flatbed and other configurations. Payload module bogie capacities ranged from 19 to 29 tons. The cab unit and 445hp Detroit V8 were shared with the HEMTT (Heavy Expanded Mobility Tactical Truck) family of rigid 8x8s, initial US Army orders for which were placed with Oshkosh in 1981.

Current generation HEMTT tactical trucks are powered by a 500hp Caterpillar C15, and serve a variety of roles – and slotting above them are tridem-bogie derivatives.

Son-of-Scammell Unipower’s BR90 bridging system trucks were so ‘right’ straight out of the box, that even the prototypes became part of the British Army’s in-service inventory.

Of similar cab-forward layout was Britain’s first (and only) 8×8 truck to be produced in reasonable numbers, the Unipower family of 40-ton GVW BR90 military bridging system vehicles. Engineered to go wherever a tank can go by Unipower after its acquisition of the Scammell business in the late 1980s, around 140 entered service with the British Army. A few related 8x8s were built for the French armed forces for beach landing ISO containers.

Three super-sized, four-axle trucks meriting a mention were each purpose-engineered to carry exceptionally long loads. Two, the Magnum 4 by Foremost in Canada, and the TS60 by Terberg in The Netherlands, were 70-ton capacity 8x8s designed to carry pipeline sections. Introduced in 1977, the frame-steer Magnum 4 featured a low-mounted, offset cab, allowing it to carry pipes of a length that extended beyond the front of the vehicle. Both front and rear bogies incorporated Hendrickson walking beams. Tyres were high flotation 66×43.00×25 Goodyear Terra Grips. Engines were 450hp+ Detroit or Cummins units, mounted ahead of the front bogie.

Terberg’s equivalent, built in the 1980s, had all-wheel steering and a forward-set cab. With a 350hp 12-litre Volvo ‘six’ and torque converter transmission, it weighed 28 tonnes unladen. Length options were 18.6 or 13.7 metres (correspondingly on 12.0 and 7.1 metre wheelbases). Width was 3.45 metres, tyres were 1.8-metre diameter 21×25 Michelins. A ground to top-of-cab height of only 2.4 metres resulted in an unobstructed load area capable of carrying steel pipeline sections of 24-plus metres length.

Kenworth C500 series custom-spec options include 8×8 rigids like this soft-terrain 550hp oil/gas industry roller-tail bedtruck.

Top prize for going against the grain must surely go to former logging contractor Butler Bros of Vancouver Island, British Columbia. Staring in 1960-61 with a complex pivot-steer 8x8s, Butler Bros produced a series of in-house engineered Detroit Diesel-powered one-off logging specials. Purpose-built for hauling old-growth timber up and down mountain graded dirt roads, all day, every day, other evolutions followed, culminating in the mid-1970s Butler Mark 5.

The Mark 5 was an 8×4 leviathan designed for a gross train weight of 300 tons with trailer. It was powered by a V16 turbocharged, intercooled Detroit developing 750/800hp (and had provision for 1,000hp). Like the Foremost Magnum 4, the engine was ahead of the front bogie and the cab was offset. The arrangement allowed logs to extend over the front of the vehicle, but close to its rear. This enabled the trailer to be hitched close. The Mark 5 is the biggest 8×4 rigid there’s ever been – or likely to be.

For a money-saving subscription to Heritage Commercials magazine, simply click here