Gas turbine-powered commercials

Posted by Chris Graham on 14th April 2022

Ed Burrows takes a fascinating look at how truck manufacturers dabbled with gas turbine-powered commercials, starting back in the 1950s.

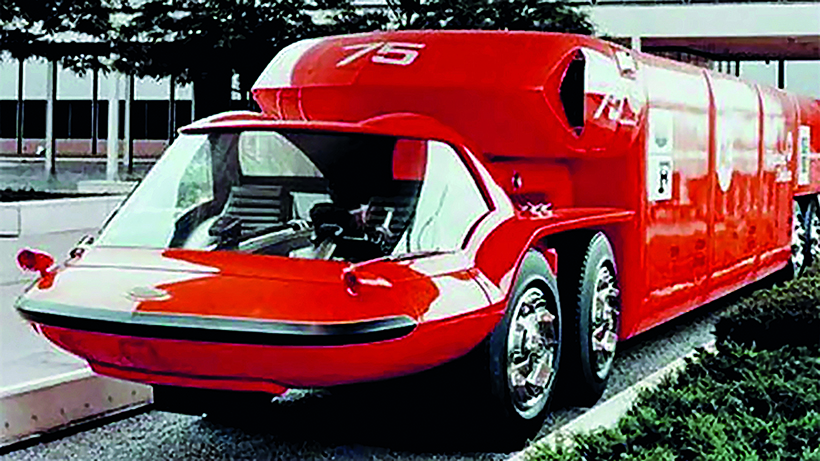

ISO containers were four years away when GM unveiled the Bison concept in 1964. The front of the 8×8-ft container plugged into front unit and at the rear to a two-axle dolly. Crazy? But it did gain extra stability from the arrangement’s lower C of G.

The originator of automotive gas turbines was Rover. In the 1960s, the Solihull firm collaborated with the BRM Formula One team and fielded gas turbine cars in the Le Mans 24 Hours Race. Rover’s work became the basis for Leyland’s gas turbine truck project a decade later.

Gas turbine engines with coupled mechanical shaft drive, power the Royal Navy’s Queen Elizabeth-class aircraft carriers. They also power other RN warships, electricity generators – and the US military’s Abrams Main Battle Tanks. But what they don’t power are road vehicles – despite the high hopes of experimental projects mounted from the 1940s until the 1970s by some of the automotive industry’s biggest names.

Pure jet turbines for aircraft propulsion were invented by Sir Frank Whittle when he was a young Royal Air Force Officer. On the eve of the Second World War, the Air Ministry – the arm of Government responsible for the RAF – recognised the need to accelerate development. It teamed under-resourced Whittle with Rover. At the time, the Solihull-based company was an independent manufacturer of motor cars.

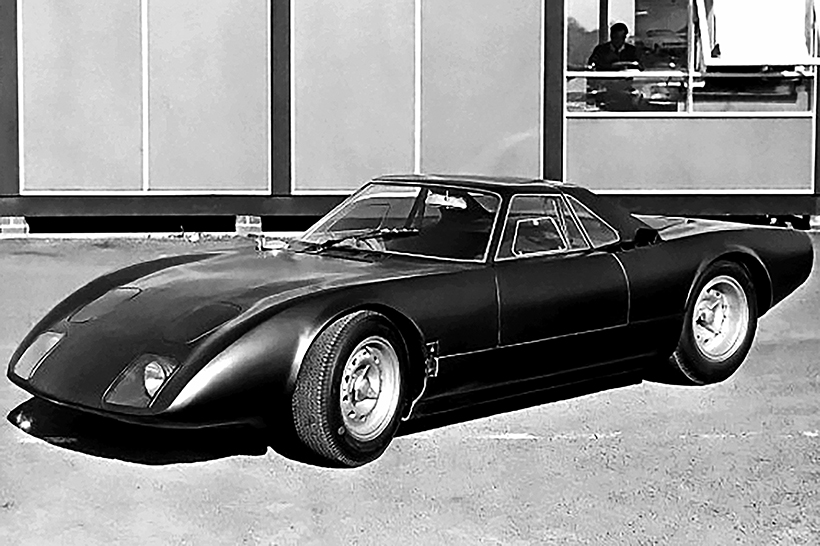

Designer William Towns’ seductive lines of the 1964-65 Rover-BRM Le Mans racing coupe helped turn the automotive world on to the possibility of gas turbines, which early in the Second World War, Rover had worked on with jet engine inventor Sir Frank Whittle.

The logical partner for jet engine development was Rolls-Royce, which took over the project once its engineering capacity was on top of demand for Merlin V12 military aircraft engines.

In the opposite direction, Rover was contracted to produce Merlin-derived V8s for British Army tanks – and first-generation Thornycroft Antar tank transporters.

After the Second World War, Rover developed gas turbines with a coupled shaft-drive system for aircraft and auxiliary power industrial applications. This work led to an automotive derivative, publicly demonstrated in 1950. The engine powered a much modified, open-top prototype based on the P4 Rover 75 saloon. By 1952, with engine output raised from 100- to 230shp (horsepower at the output shaft), the car, dubbed JET1, achieved 152mph on a stretch of highway in Belgium.

The GM Bison concept was designed with two gas turbines with a combined 1,000-bhp in the aero-pod above the fifth wheel position. The driver’s eyeline was about level with a modern SUV. The front-end one-piece wraparound glazing lifted automatically for entry and exit.

Further prototypes led to the construction of racing cars using BRM Formula One components in the Le Mans 24 Hours in 1963 and 1965. In the latter race, the 150shp Rover-BRM ran in the 2-litre class. It sported an eye-wateringly beautiful coupe bodywork made by Motor Panels, (the former Coventry-based truck cab manufacturer). Driven by Graham Hill and BRM team-mate Jackie Stewart, it placed tenth out of the race’s 51 starters and 14 finishers. This was despite suffering foreign body damage to vanes of one of the turbines. It averaged 98.8mph and 13.5mpg,

Although Rover then gave up on automotive gas turbines, the publicity generated from JET1 onwards, caused others to get excited about the theoretical potential.

Why? And how do gas turbines work – and why was development for automotive use universally abandoned? Good questions. A gas turbine is an internal combustion engine.

However, unlike the thump-thump-thump of a piston engine, combustion is continuous. Air is sucked by a rotating fan turbine to a compressor turbine. The compressed airflow is ducted to a combustion chamber. The fuel/air mix combusts, creating high pressure, high temperature gas. The high-pressure, high-velocity gas is streamed to a centrifugal impeller. Via a power turbine, this drives an output shaft and gear train.

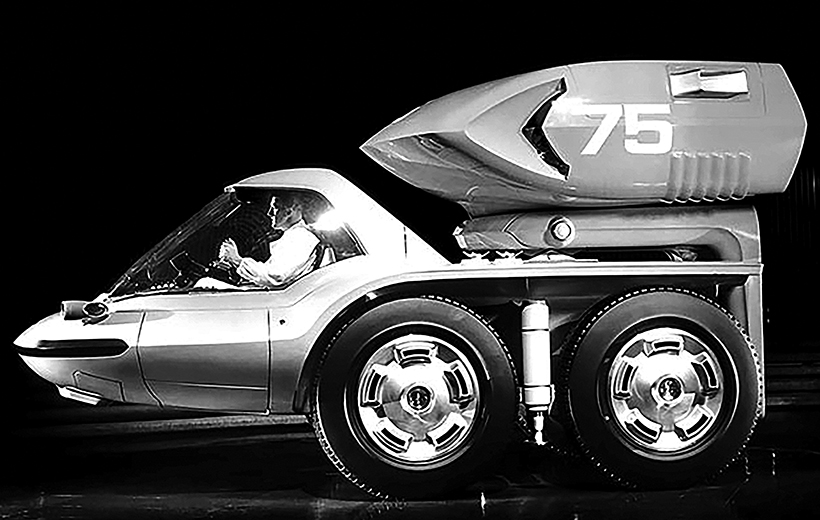

GM’s Chevrolet Turbo Titan III of 1966 was powered by a 280 shaft horsepower gas turbine. Great looking, but road testing demonstrated the limitations of this type of power unit.

As thousands of turboprop civil and military aircraft demonstrate every day, the principle is simple. But in road vehicles, quite the opposite in practice.

In most automotive projects, to boost efficiency, hot exhaust gas was fed via a heat exchanger to raise the temperature of fresh intake air.

On the upside, a gas turbine is compact, smooth, quiet and vibration-free, is much lighter than a piston engine of comparable output – and requires less maintenance. On the downside, a jet engine delivers optimal performance running at a constant speed. Unlike the responsiveness of a piston engine, accelerating Rover’s 150-shp Le Mans type unit’s compressor turbine to its 64,000-rpm optimal speed – and the power turbine to its 47,000-rpm maximum – was not instantaneous.

Although a gas turbine can run on a wide variety of liquid hydrocarbon fuels – and natural gas – fuel consumption proved higher than a truck diesel of equivalent output.

After Rover became part of the Leyland Group, Rover-derived gas turbines were installed in six Leyland prototypes, three of which were trialled by Esso, Castrol and Shell-BP.

If gas turbines ever had a future for civilian land vehicles, it would be in a hybrid setup, with the engine running at constant speed, driving a generator and battery system with electric motor drive. Gas turbines can run on hydrogen of course, which is increasingly seen as the future for zero-carbon emissions aviation – not forgetting increasingly recognised potential of H2 for heavy goods vehicles.

Besides Leyland in the 1970s, Europeans dabbling with turbine power included Magirus-Deutz, MAN, Fiat and Berliet of France. One of Berliet’s gargantuan T100 oilfield specials was fitted with a French Turbomeca helicopter-type gas turbine. Output was equivalent to the 600bhp Cummins V12 it was intended to replace. Its thirst was excessive; Berliet reverted to the V12.

It was the USA where automotive engineers got seriously carried away with the idea of gas turbine engined trucks. A key stimulus was the higher running speed potential offered by the US Interstate superhighways network (which, in the 1950s and 1960s was the world’s biggest infrastructure construction programme).

A novelty of the Chevrolet Turbo Titan III was twin-wheel steering. The driver having to master its unfamiliarity, as well as getting used to the gas turbine, cannot have helped the test programme.

With three standout exceptions, virtually all gas turbine truck projects were based on re-powering existing models. In 1964, the General Motors Bison concept and the Ford ‘Big Red’ project were both exhibited at the New York World’s Fair.

The most far out was GM’s Bison container transporter. To say it looked like no truck before or since is beyond understatement. The publicity blurb described the aerodynamic pod above the fifth wheel position as housing two gas turbines with a combined output close to 1,000shp.

One engine – for normal cruising – was a 280shp unit evolved from the gas turbines that powered GM’s mid-1950s Firebird series of jet-fighters-for-the-road style test cars. The Bison’s second engine, with 700shp, supplied reserve power for acceleration, climbing gradients and pulling additional trailers.

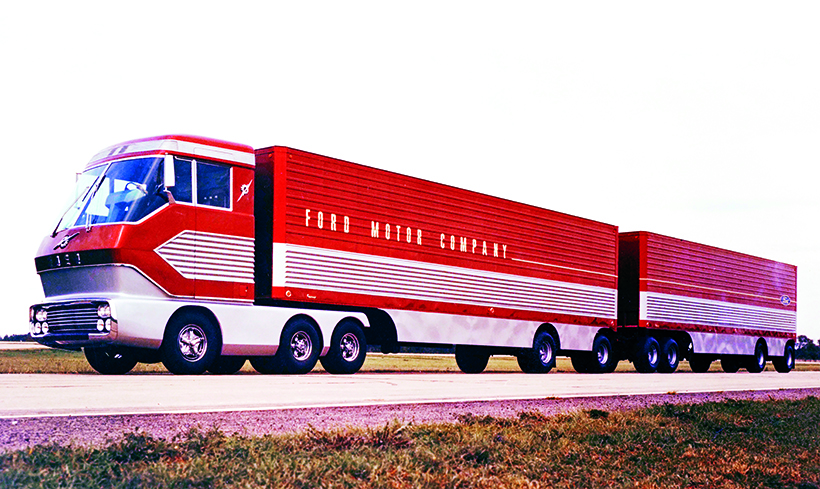

Big Red had a 560shp gas turbine. Height was 13ft. The tractor unit was eventually rescued from scrap and restored, although its owner has never shown it in public.

The two-axle tractive unit coupled to the front of a container; a two-axle bogie unit was coupled to its rear. As a way of transporting an 8ft wide, 40ft long shipping container, the configuration lowered the centre of gravity, which in turn enhanced stability.

To put the Bison’s novelty into context, it anticipated the introduction of ISO intermodal containers that, four years later, became the universal standard for shipping and road transport.

Whereas there is no evidence that the Bison concept ever moved under its own power, Ford’s Big Red was fully operable and extensively tested.

Big Red’s driver sat at a central console. Crew accommodation included a loo. It carried fuel sufficient for a non-stop haul of 600 miles.

Ford Big Red was also conceived with container transportation in mind. Its overall spec was framed around the ability to operate at 85 tons gross, hauling two trailers non-stop for 600 miles at an average speed of 70mph. Commensurate with this, fuel capacity was 280 US gallons.

Tyres were Firestone, 12-22.5s on the front axle and wide-tread 18-19.5/16-ply on the tandem drive axles and trailers.

With a central driving console, Big Red’s 13ft high, aero-style cab had over 6ft of standing headroom. It had living accommodation for a crew of two – including a loo.

The Ford’s turbine engine was designated the ‘705’. It was believed to have been a spinoff from a gas turbine development contract Ford was working on for the US military. Delivering 560shp at 3,080rpm at the output shaft and with a 955- to 1,620-lb.ft torque range, it weighed less than one and a half tons. Departing from other gas turbines focused on automotive use, it incorporated a two-stage supercharging compressor system for intake air.

Like the GM Bison, design of Ford Motor Company’s 1964 Big Red was influenced by the impending container revolution – and the higher speed, long distance haulage advantages made possible by America’s new and expanding Interstate superhighways.

While Big Red was abandoned, Ford did not stop experimenting: at the 1968 Commercial Motor Show, Ford of Britain exhibited a standard cab-over-engine US Ford W-1000 fitted with a 375bhp gas turbine.

Preceded by two standard production Chevrolet trucks with their engines swapped for gas turbines, in 1966, GM rolled out its Chevrolet Turbo Titan III semi-trailer tractor. This time round, engineering and operational practicalities overruled styling studio dreaming.

The 280shp, 875-ft.lb torque GT-309 gas turbine was same type as the Bison concept’s ‘normal running’ main engine. This time round, the spec didn’t include the 1964 concept 700shp auxiliary booster engine.

Although visually less extreme than Ford’s Big Red, it was an impressive piece of kit. The steel and glass reinforced plastic cab and integral side fairings featured twin jet fighter inspired air intake ducts. The cab did feature one radical indulgence. Steering control was by two side-by-side wheels, each with a knob so – hands-on all the time, thanks to the truck’s Allison six-speed automatic transmission.

Mack toyed with gas turbines for ten years from the early 1970s. This included installing 550-shp units in a Cruise-Liner cabover and a bonneted Super-Liner. Besides testing in North America, they toured the UK and mainland Europe.

Double-drive bogie tyres were big singles. With a box trailer, grossed weight was just under 40 tons. Trials are believed to have included coast-to-coast test hauls.

With no gain in efficiency and a gas turbine engine’s inherent problem of slow throttle response, like every other attempt to engineer a gas turbine powered truck, the Titan III was canned.

Although the highest profile US gas turbine truck development projects came from General Motors and Ford (in those days the world’s two biggest vehicle manufacturers), the first known gas turbine powered trucks had Boeing engines.

The Mack Cruise-Liner displays its twin intake stacks and shielded exhaust. The exhaust of prototype gas turbine tucks was hot enough to burn the foliage of overhanging trees.

In 1950, Boeing approached its Seattle neighbour Kenworth and proposed testing one of its 175shp gas turbines in truck. As well as weighing over a ton less than the similar output of the diesel that normally powered the Kenworth, the gas turbine occupied over 80 percent less space in the truck’s engine compartment. So – easy to see the carrot of less engine weight and more load capacity.

Testing was conducted in Kenworth’s normal domain, the mountainous US West Coast, and in Canada and Mexico. The conditions proved unsuited to a type of engine that works best running at a constant speed.

The Kenworth experiment was followed in 1953 by the Chrysler T55, a 2.5-ton US Army 6×6 cargo truck. A 175shp Boeing unit replaced the T55 prototype’s original Continental AO-402 piston engine. The Boeing weighed under 250-lb – massively less than 704-lb of the 188shp Continental. The T55 project also fell by the wayside.

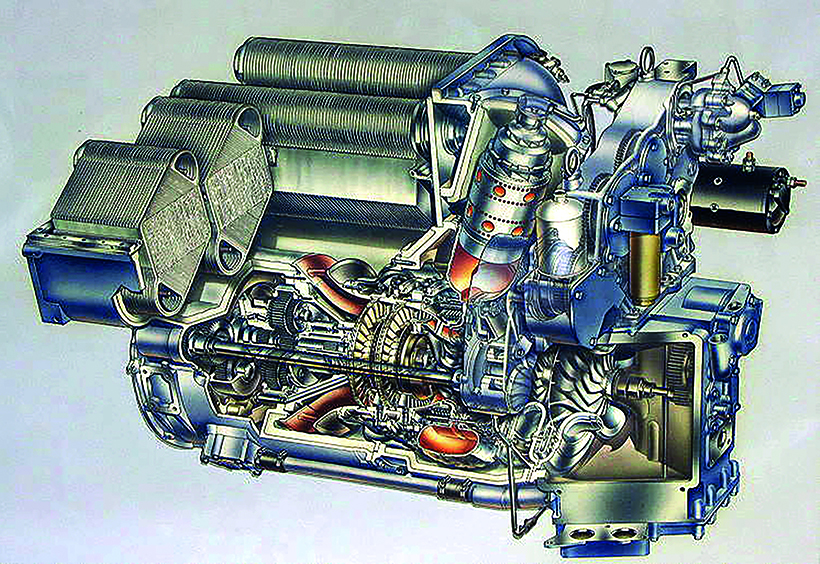

Mack’s Garrett AiResearch/KHD GT601 gas turbine. The intake ducts are rear left, the heat exchanger is front left, the combustion chamber is at an angle in the centre, the output shaft runs left from lower right impeller.

In 1965, Freightliner got the bug, and installed a Boeing gas turbine producing around 500shp in a standard two-axle cabover tractor. Named Turboliner, it was tested over a four-year period. Further tractors were trialled by two legendary West Coast hauliers, Consolidated Freightways (Freightliner’s parent) and PIE/Pacific Intermountain Express.

Between 1970 and 1973, Freightliner built nine Turboliner IIs, one powered by a Ford gas turbine, the others by 300/325shp GT-404 units made by General Motors’ Detroit Diesel Allison division. The one-ton weight saving proved insufficient to justify full scale production. In the mid-1970s, Allison units of up to 500shp tested in other vehicle types also proved gas turbines were non-starters for automotive use.

Just for the record, in 1961, Boeing supplied three 500shp industrial units to American La France for fire trucks – but in 1968 quit its small gas turbines sideline to concentrate resources on developing the 747 ‘Jumbo Jet’ and other aircraft.

Taking advantage of its ownership of the Solar industrial gas turbine business, in 1968 International Harvester trialled a 300shp unit in is a cabover 3-axle semi-trailer tractor. IH had no more success than its rivals.

In 1972, Mack, US gas turbine engine builder Garrett AiResearch and Magirus parent Klöckner-Humboldt-Deutz, collaborated on the development of gas turbines in the 450-/650shp range specifically for heavy trucks. During 1979-80, a bonneted ‘West Coast’ Mack was tested with a 550shp GT601 unit. Like other gas turbines, it could run on diesel, kerosene or bioethanol (plant-derived alcohol). This was followed by installing GT601s in a Cruise-Liner cabover and a bonneted Super-Liner. Both had tandem-drive bogies and standard Maxitorque transmission. They did a showboating tour of the UK and mainland Europe, followed by intensive long-haul testing in the US until 1986. After years and countless miles of investment, the partners proved to themselves gas turbines could not match the all-round performance and economics of state-of-the-art turbo charged diesels.

Autocar, the heavy-duty truck division of the former White group, ran an experimental cab-over-engine tractor in 1967. The gas turbine, a 600shp industrial unit, was provided by Orenda, the one-time Canadian jet engine builder owned by the UK’s former Hawker Siddeley Group.

The ultimate in gas turbine engined wheeled transport was the Overland Train MkII, built by electric wheel drive earthmover specialist RG LeTourneau. Rolling out of LeT’s Longview, Texas plant in 1962 on 54 rubber tyres, each 10ft in diameter and 4ft wide, it was built for the US Army and tested on its vast Yuma, Arizona proving grounds.

Grossing 421-tons and 572ft long, the outfit comprised the control car, two four-wheeled power cars plus ten 13.6-ton load capacity four-wheeled cargo cars. One of the cargo cars was equipped as a tanker, satisfying the outfit’s thirst for fuel.

Freightliner probably trailed more gas turbine development trucks than any other manufacturer. They were run by its parent, Consolidated Freightways, and one-time haulage giant PIE/Pacific Intermountain Express. Well, you can’t say they didn’t try.

Power was supplied by a total of four fixed-shaft, constant speed, Solar 10MC industrial gas turbine units driving direct-coupled AC-DC generators. These were derived from a gas turbine power plant developed for the US Navy for high-speed boat propulsion. The gas turbine generator in the six-wheeled, 44ft long, 16.5ft wide, 20.3ft front control car was used as an auxiliary. The main gas turbine generator sets, producing a combined 4,800shp, were installed in the two power cars at the tail end of the train. Although the other units of the Overland Train were scrapped in the 1970s, the control car survives and is on static display at the US Army’s Yuma Proving Grounds Heritage Centre.

The Solar gas turbine business had been acquired by International Harvester in 1960. In 1968, International rolled out its experimental 300shp Solar-engined TurboStar cabover tractor testbed. But a more flexible engine requiring a five-speed rather than a ten-speed transmission, weight saving, good reliability and other attributes were insufficient to justify commercial production.

Sold by IH to Caterpillar in 1981, today Solar manufactures gas turbines with from 1,000 to 30,000 horsepower for electricity generation and other industrial applications.

Late to the party and oblivious to the negative results of the extended testing of gas turbine trucks in the US, in 1973-74, Leyland rose to the challenge and trialled a fleet of six 6×4 tractor units.

LeTourneau’s US Army Overland Train MkII of 1962 sported Solar gas turbines with a combined 4,800shp. They drove generators, which fed the electric traction motors in the hub of each of its 54 rubber-tyred wheels.

Incorporating a ceramic heat exchanger to reduce fuel consumption, the engine was a development of Rover’s work a decade previously on automotive gas turbines. (Despite abandoning road vehicle applications, until becoming part of the Leyland Group in 1967, Rover had success building gas turbines for a variety of industrial and other applications – including duty as an on-board auxiliary power unit in aircraft).

Output of the Leyland was 350shp, consistent with the 8-10shp per ton envisaged at the time for future trucks grossing 38-/40-tons. With its sights on exports, Leyland speculated that a gas turbine would be superior to a diesel for rigs running at a steady speed over long hauls in Australia and elsewhere.

The Overland Train’s radar-equipped control car had space-shuttle-like living accommodation. It is coupled here to the two power cars.

Inevitably, Leyland’s engineering team was unable to overcome the issues that defeated their counterparts in the US. Notwithstanding its failure, Leyland Group top management gave the gas turbine truck project a positive PR spin, using it as evidence of commitment to forward-looking R&D. But polish a stone – and it’s still a stone.

This article is from the latest issue of Heritage Commercials magazine, and you can get a money-saving subscription simply by clicking HERE