The Scammell Contractor remembered

Posted by Chris Graham on 31st January 2020

Bob Tuck takes a personal look back at one of Watford’s finest, the Scammell Contractor, and discovers it actually proved far more versatile than its bigger crew-cab offspring.

When Scammell offered its new 4×4 Mountaineer – and later, the 6×6 Constructor – they utilised the cab which Bedford had first used on its ‘O’ Type models

It was like a breath of fresh air. To this young ‘wagon nut’ in far-off Geordie Land, the first fleeting look – in the eagerly-awaited weekly arrival of Commercial Motor – at the newly-announced Scammell Contractor just blew my socks off. As a big fan of almost anything with a Scammell badge on the front (although that passion was never really transferred to the three wheel Scarabs, even though British Rail’s Consett station was a big user of them), I could hardly believe what the production team in distant Watford had done in creating such a dreamy looking heavyweight!

In truth, I was still getting used to the early ‘60s Michelotti cabs on Scammell’s general haulage models of Handyman, Trunker and Routeman. Of course, the industry had never seen anything like these finned, ‘cheese grater’-type cabs, although my biggest problem was in knowing how to pronounce – never mind spell – the name of this classy Italian designer.

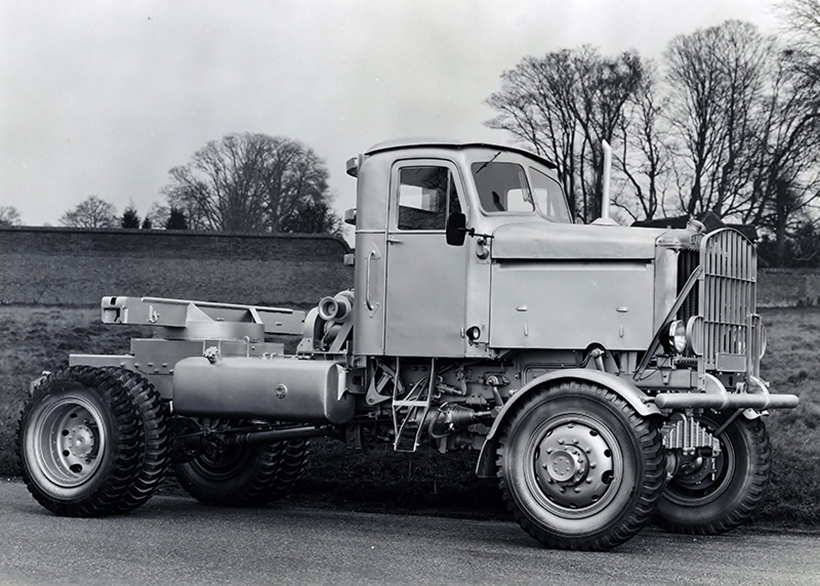

This is a mock-up of the Contractor seen in Scammell’s Experimental shop

But this ‘Crinklie’ was forgotten about once I’d seen the new Contractor. I’d always been a big fan of the so-called LAD cab and, for Scammell to take this and blend it into something so big then, wow! Yes, this new 6×4 was my favourite model of all time – well right up until the subsequent announcement of the crew cab version of this big tractor, a year or two later. Well, when you see the two motors side-by-side, you can’t really blame me for jumping ship. But, more than 50 years later, I’d like to apologise for such a move and, at the same time, try and right some of the many misconceptions I seemed to have reached about this cracking ‘little’ Scammell. Because, really, it had a lot more versatility (and sales) going for it than its bigger, four-door counterpart.

LAD and S

But, before we have a good look at the Contractor, let’s take a moment to consider the cab it was to be fitted with as standard. If you follow Scammell (don’t we all?), then you’ll realise they didn’t really prioritise the driver’s compartment that much. To that end, historically, they were quite keen on recycling other folks’ hand-me-downs, and first did this in the late ‘40s and early ‘50s. When they were launching the 4×4 Mountaineer, and then the 6×6 Constructor, the cab for these monsters was, in essence, from the diminutive ‘O’ Series Bedford – honest.

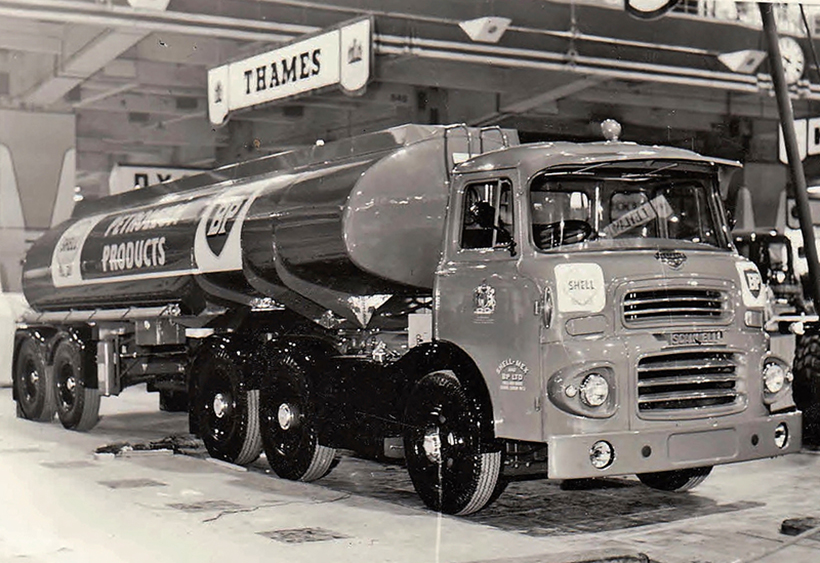

Scammell first used a version of the LAD cab on its experimental Trunker which was exhibited at the Commercial Vehicle Show in 1960

So, no surprise that, 10-15 years later, they pounced on the LAD cab at a time when L, A and D were actually thinking of replacing it. Technically, Leyland had called this the ‘Vista-Vue’ cab when it first adorned the late-‘50s version of the Comet four-wheeler range. However, when Albion and Dodge took versions of the same cab for their new models, the LAD name was coined – and it seems to have stuck.

This. however, is the first wrong I’d like to try and right because, of course, Scammell made use of the same cab shell with the ‘new’ Contractor. Nobody seems to have acknowledged this, so I think from now on this cab should be referred to as the LADS. In fairness, as Scammell was still using the cab more than 10-15 years later, there’s even merit in its initial being used at the start – SLAD. It even has a good ring to it!

Actually, meticulous Scammell historian devotees like John Fadelle and Geoff Clarke, will insist that I draw attention to how the Contractor wasn’t the first Scammell model to use the LAD cab. The first, ‘classy’ version of the Trunker did, of course, sport a true, Albion-style of this cab. And while this motors brilliant mechanical concept didn’t reach full-scale production, it’s still a motor that anyone with engineering love in their DNA enjoys talking about.

This is the cab and chassis Contractor which was first exhibited at the 1964 Commercial Vehicle Show

The downside to talking to a knowledgeable engineer is that they can passionately converse in a different language to most people, and so be difficult to understand. However, what they’ll probably tell you is that the LADS cab – and perhaps most steel/tin-made products of the time – did suffer with quality control issues. Consequently, they’d be afflicted with tin worm/bad corrosion – especially if they were operated in places like the UK. which tended to spray profusions of salt on the roads during the winter months. The bottom line was that the cab could be the soft spot of a motor that could literally last forever – and that’s no exaggeration.

But what that longevity attribute (for the chassis and rest of the vehicle) meant was that some ‘small cab’ Contractor operators had to adapt replacements for this weakest link of a cab. Which, to the observer who enjoys looking for oddballs, was like regularly finding the Holy Grail.

Super Hippo replacement

When the Contractor was first launched in ‘64, I naturally thought it was just a progression/replacement of the big Scammell that had gone before – the late ‘50s Super Constructor. However, with that one assumption, I actually picked up two misconceptions. The first blooper was that I thought it replaced the big 6×6 ‘Super’, and that it wasn’t until about 20 years later that Scammell man, Frank Bone, put me straight about that. In fact, the ‘go anywhere/do almost anything’ Super Constructor did stay in modest production until the 1980s, primarily for the specialist export market. During that life, it did pick up the use of the striking Motor Panels cab, which was used on the Crusader, so that may have contributed to me fogging assumptions – although I’m really only scratching round for an excuse.

The small cab Contractor was initially designed to replace Leyland’s ageing bonneted Super Hippo. During the ‘50s, this model was Leyland’s strongest truck and saw service all round the world. In April ’60, this example – owned by the Australian Department of Supply – is seen moving the core part of an RAAF Dakota which was heading for service in the Antarctic

However, it wasn’t until I recently re-read part of John Fadelle’s account of the Scammell story, that I realised how much I’d been in the dark about the true origins of the Contractor. As John points out, this Scammell was first designed and created at the behest of its Leyland parent, which was actually searching for a replacement/update of its bonneted Super Hippo model. This first saw light of day in the late ‘40s/early ‘50s so – at 10 years old – it was getting a bit long in the tooth and overdue for an update. It was primarily a model built for export, although some memorable, early UK examples were the drilling rigs which I think were operated by ICI.

I suppose, in modern day parlance, the Super Hippo wasn’t too strong, and its potential end user would certainly be happy with the Contractor replacement. But, as well as filling that requirement from the new model, Scammell also had a plan that would make its new 6×4 of interest to all manner of customers – in all parts of the world.

Any spec you like

It isn’t rocket science but, if you can offer a huge wealth of choices to a vehicle’s specification, then you’re bound to interest a bigger potential customer base. The downside is that this ‘everyone can be different’ result doesn’t lend itself to a mass production line but, seeing that Scammell was aiming for the discerning specialist operator, this variety of choice with the new Contractor didn’t bother them.

The Contractor was built and used in many configurations. Although it was originally intended as a tractor unit, it was to be sold and operated as a rigid 6×4 dump truck when grossing up to 60 tons – and yes, on just three axles!

To go under the bonnet, you could have a choice of eight different engines – three were Cummins, three were variations on the Rolls-Royce 12.17 power pack and then there were a couple of absolute monsters. The Leyland EN902 was actually a creation of Albion Motors and, with 15.2 litres of capacity, had started life as a rail-car engine. Scammell had used it in the Super Constructor, but it wasn’t without its problems.

The largest engine choice by far was the AEC AV1100N, which was a massive 17.75 litres. Being naturally-aspirated (rather than super-charged or turbo-charged), this power pack produced 300bhp at 1,900rpm. It’s not known how many Contractors went out with this engine, but the late Glynne Rees (one of Scammell’s versatile field engineers) told me he accumulated many hours repairing of one of these models in service in Austria.

There was a choice of Leyland, Fuller or Self-Changing Gears (semi-automatic) gearbox but, of course, the strength of the Contractor was generally built into the chassis and rear bogie. Getting the overall gearing right for the back end drive wheels was where Scammell had first shown its expertise, way back in 1929, when it unveiled the first vehicle capable of transporting a 100-ton load – all on its own. Yes, that first 100-tonner was initially powered by a four-cylinder petrol engine pushing out a lowly 86bhp but, Scammell geared the vehicle in such a way that it could move such a phenomenal weight (albeit at a fairly slow speed).

Generally speaking, a transmission is either built for strength or for speed. And in that respect, the Scammell rear axle ratios varied from the highest speed – 6.058 – to the lowest, 14.36: 1. The choice was yours.

One of the last of the LADS Contractors to be built was HBB 775W, which was new to the Tyneside-based heavy engineering concern of CA Parsons, in April 1981

Horses for courses

Although the 240-ton gross Contractor was in time to be the massive flagship of many of the big names on the UK heavy haulage scene, the earliest, lighter examples were soon making their mark in places like Israel. John Fadelle tells us that, historically, Leyland had a very strong hold in this market, and the company felt the Super Hippo replacement (the small cab Contractor) would sell very well out there. But, with other USA concerns like Mack also wanting to make inroads with their bonneted offerings, Leyland/Scammell had to be quick off the mark.

It was a strange time in Israel in those days. John explained that the Government there was offering a strong cash incentive if road hauliers bought a certain spec of heavy-duty vehicle, which could be requisitioned and used if the country went to war. So, although a new Contractor would be bought with, say, general or timber haulage in mind, the operator actually ordered the type of vehicle that could also be used as a battle tank transporter. And it was to be in this latter field that the Contractor was to become a shining star.

With Leyland being so well known in Israel, the Contractors supplied to this country were badged as Leyland Contractors. This actually helped when the marketing guys sold similar 6x4s into nearby Jordan. The fact that these motors were badged as Scammells, meant that the Contractor avoided what was known as the politics of an Arab boycott.

Seen on test in the UK, this is the type of Contractor artic tank transporter which was used in Israel

John tells us that the first two prototypes sent to Israel were geared for a top speed of 50mph, although were only rated for 54 tons gross train weight. That, of course, is a laughable weight limit for a big/small Scammell, and operators soon began testing the new model in the prescribed manner of overloading it until it broke! The Contractor took lots of abuse in its stride and, being made from a kit of possible parts, the end result was a motor that could turn itself into a master of many operations.

South Africa was a big market in the 1960s, although all Contractors destined for there were sent out in kit form. They even had locally-made cabs fitted as part of the build, and John recalls that the big 1100 AEC engine was a favoured choice. The one quirk to this power pack was that it was a bit longer than the others, so the locally-made bonnet was 7in longer than the traditional LADS one fitted at Watford.

The Australian scene at the time is recalled for its very modest axle loading limits, although there seemed no limit to how many trailers could be hauled. Thus, the Peko Mines Contractor road-trains could gross up to 170 tons, when three drawbar trailers were in tow. In this case, the Contractor was run in a sort of rigid dump-truck form, with the weight of the load acting as ballast to give traction. John recalls the engine of choice for this work had evolved to be the much-loved 14-litre Cummins NT335. And this power pack became the engine of choice for most of the subsequent Contractor sales, both in the UK and abroad.

With Australia demanding modest axle loadings, this Australian cattle-haulier added a fourth axle to this Contractor chassis. It also hauled two or perhaps three drawbar trailers

Extending life

The truck market can be a fickle place to try and make a living, although the Contractor was to enjoy a good 10-15 years before the competition (from both Europe and the USA) began eating into its market dominance. But at such an age, the Contractor was still as good as ever and, in some respects, it’s in this phase of its extended life that it really shone the brightest. At the outset, I mentioned how the cab could be its weakest point (both in terms of size and corrosion potential) but, of course, it’s an easy enough matter just to replace the cab.

Exponent extraordinaire of getting more from an ageing Contractor is, of course, Heanor Haulage’s Peter Searson. It’s arguable that his ‘Fantastic Four’ was actually an improvement on the Scammell product. Changing the engine and gearbox was always possible through the Watford maker, although the HHT use of the Volvo F88 cab allowed more space for crew and sleeping accommodation – something the old LADS cab never really offered.

Peter Searson’s Heanor Haulage HHT was the most famous exponent of what the small cab Contractor could have looked like. Peter Noble spotted HHT 004 on the Wilderness Road in Middlesbrough, during August ’83 hauling this hefty lump of rope. (Photo: Peter Noble)

Another variation on cab fitment was shown by Allan Sime of Dundee-based Newtyle Commercials. When he bought the 125-ton Contractor XGG 785J in 1990, the original cab was shot. The artic tractor unit was new to the Glasgow-based civil engineering company of Limmer & Trinidad but, because it had seen extended service on the Shetland Isles, rust soon formed in the cab. No problem for the versatile Mr Sime, though, who discovered a cab from the Bedford TM would certainly be an ideal match. And, 30 years on, this Contractor/TM combo is still in one piece, of course.

XGG 785J was given a TM cab by Allan Sime of Dundee-based Newtyle Commercials back in 1990. Thirty years later, this rather special combo was seen in David Crouch’s yard, awaiting its next owner. But still a big pussy cat to drive!

I say ‘of course’ because Scammell’s Contractor could last as long as you wanted, even though it went out of production in the early 1980s, when Scammell launched the S24 and S26. True, it could become old-fashioned and dated – and, yes, getting spares could become a problem, but not so much of a problem that a good engineer worth his salt couldn’t get round. No fly-by-wire or other miscellany of electronics to fret about in a motor devised almost 60 years ago, in a time when your senses were all you needed to appreciate how the motor was doing.

In fairness, not too many Contractors have been saved for preservation. But, as David Crouch explained, this is merely a reflection of how the model is perhaps a shade too slow to be used on the 2020 main road network. But, if you want say 100 tons – or more – moving on site, then an aged Contractor (that’s worth little on the books) could still do the job just as well as a modern-day ‘Super Truck’ which, of course, could cost you £250,000 if bought new.

John Fadelle tells us that something like 1,200 Contractors were actually built – which includes the six fabulous Mark 2s. And he reckons that less than 5% (no more than 60) would have been made with the huge, four-door crew cab. “It was no good for the export market,” he tells us, “because its wooden cab would have been eaten away by termites.” The small cab-version never had that problem to withstand.

Looks can be deceptive, of course, and yours truly still thinks that the Watford-built crew cab 240-tonner still oozes more presence than its LADS counterpart. However, once you dig under the skin of what are, in essence, two identical Watford heart beats, it’s the original ‘little’ creation that has championed the Scammell cause right across the globe. And for that, Scammell fans have every right in feeling extremely proud.

It’s hard to believe, but less than 5% of the 1,200 Contractors built had the large, four-door crew cab. Although these three look the same, they’re all slightly different. NAJ 103P (centre) is a Watford-built Mark 1, while DBO 661V (right) is one of only six Mark 2 Contractors which Scammell made. YVN 308T had its cab built by Plaxton’s, the bus and coach body builder from Scarborough. This Scammell started life as TPY 675H but, after years of hard work, Sunters decided on a total rebuild, which prompted a new registration (Photo: Bob Tuck)

To subscribe to Heritage Commercials, click here

‘