Ford 9N/2N buying guide

Posted by Chris Graham on 15th February 2022

Peter Smith looks at the history and development of the Ford 9N/2N, and offers advice for those interested in these influential tractors.

Ford 9N/2N prices start from a little over £1,000 for a ‘project tractor’, but expect to pay upwards of £2,500 for one that will drive away. However, top quality, aluminium-bonnet examples can make £40,000 ($55,000) at auction in the USA.

The Ford 9N was a product of the partnership between Harry Ferguson and Henry Ford. When Ferguson became disheartened with the David Brown Company and the Ferguson Brown tractor, he went looking for a new business partner to build his tractors with.

In October 1938, Harry Ferguson arrived in the US. He took with him a Ferguson brown tractor and a selection of machinery that included two ploughs, a ridger and a cultivator. A meeting was set up by the Sherman Brothers between Harry Ferguson and Henry Ford at Dearborn, where Ford was sufficiently impressed with Ferguson’s machine to enter into an agreement with him, which later became known as the ‘Handshake Agreement’.

A gentleman’s agreement

The Handshake Agreement was quite simple; Ford would manufacture the tractor and would finance its manufacture. Ferguson would buy tractors from Ford and distribute them, firstly through The Ferguson-Sherman Manufacturing Corporation and, when that arrangement ended in 1942, tractors continued being distributed by Harry Ferguson Incorporated. The agreement also stated that either party could cancel the agreement for any reason, at any time, with notice.

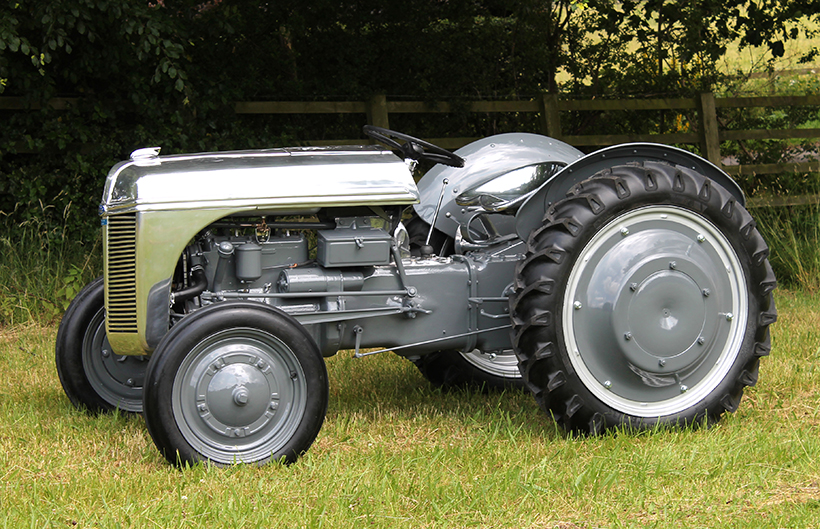

This is a Ford 9N with Funk six-cylinder conversion, owned by Steve Watts.

The agreement also allowed Ferguson sole rights to supply implements, and Ford loaned Ferguson money for his start-up costs. It appeared that Mr Ferguson had the upper hand in the deal.

Ford engineers immediately started work on the new tractor, which would be known as the 9N – ‘9’ because production started in 1939, and ‘N’ because that letter was Ford’s tractor code.

By April 1st, 1939, the first sample tractor was completed and, by June 5th that same year, tractor production had started. On June 29th, 1939, the new model was officially launched to the press, which meant that Ford and Ferguson had achieved the impossible; they’d designed and produced a radically different tractor in just seven months!

While both parties claim credit for the design, it’s most likely that Ford engineers contributed the larger percentage of the work involved. This was probably because the Ford engineers had access to the parts already in the Ford parts bin, although there’s no mistaking that the stand-out feature of the new design was the Ferguson Draft Control System.

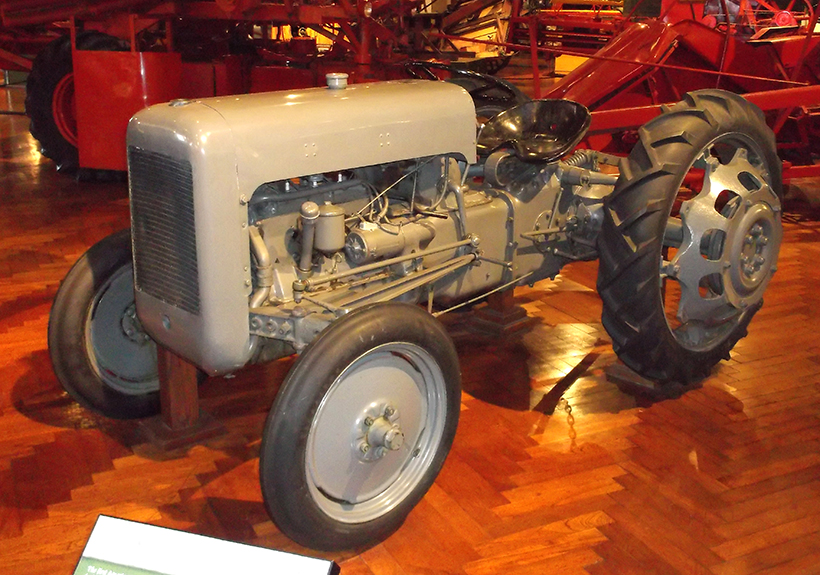

A 1940 9N in original condition, owned by Edwin Hughes.

This was revolutionary for its day, and gave Ford a unique selling point. Indeed, it’s safe to say that the 9N is probably the only tractor from the 1930s that you could buy today, and still fit a brand-new topper without any major modification!

Notable features

Other notable features included the tractor’s high power-to-weight ratio, its centre PTO and the adjustable front axle. These were all features that made the new tractor stand out from the crowd.

Production was slow at first but, by October ’39, Ford was producing 2,036 tractors a month. Production grew and grew until the outbreak of war began to starve the Ford Corporation of its raw materials and, in 1942, the tractor was re-designed and re-named the 2N.

Basically the same machine, the 2N was stripped of all critical materials and, to enable production to continue, it was turned out on steel wheels, magneto ignition, without a battery and with an aluminium radiator. In later years, when supplies were returned to some normality, the 2N was fitted with all the luxuries that the 9N had, which made a late 2N and an original 9N, almost identical.

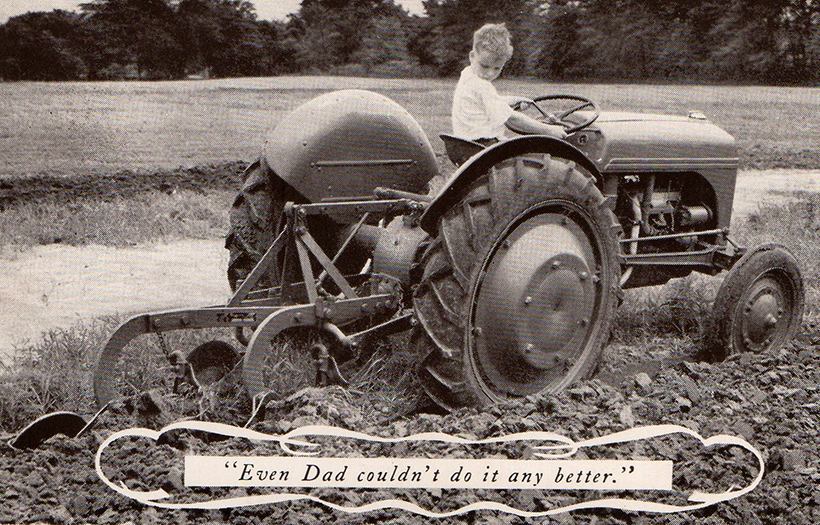

This early publicity shot illustrates the fact that Ford claimed the 9N tractor was so easy to drive that a child could do it!

During the war years, raw materials were rationed, and Ford’s factory was forced to run well below capacity. So, as one way of trying to boost production, Ford decided to create a much-modified 2N, to create a tug version that it could sell to the military. These vehicles were designated BNO-25 and BNO-40 (Bureau of Naval Ordnance).

Production of the 9N and later the 2N finished in 1947, when production of the Ford 8N tractor started. The 8N was a Ford tractor with no allegiance to Ferguson in any way, even though it still used an improved version to the three-point draft control system that incorporated position control; something that Ferguson didn’t offer until 1954.

The 8N tractor – and the use of the Draft Hydraulic System by Ford – led to a lengthy court case between Ford and Ferguson, which eventually resulted in Ferguson winning $9,250,000 in payment of royalties on patented devices used by Ford after the break-up.

Here’s a 9N with a rare, half-track conversion.

Buying a 9N/2N

The 9N was designed at a critical time for farming in the US. Farmers had just endured the effects of the great depression plus those in Texas, Oklahoma, New Mexico, Colorado and Kansas had also lived through the ‘dust bowl’ drought. These two disasters had a massively detrimental effect on US farming as a whole for most of the 1930s, and exhausted farm incomes. So, any new tractor being launched into an economic environment that challenging had to be both economical and affordable.

This low cost of the 9N ($585), and the rapid pace at which it had been designed and put into production, left little time for testing, so the early examples suffered from many issues. However, most of these were successfully ironed-out thanks to an ongoing program of continual design modification. With this in mind, it’s difficult to find an original tractor that hasn’t received some updated parts.

The first 650 or so 9Ns that rolled off the production line were fitted with an aluminium bonnet. This was used in part because of the rapid design time, but also because Ford couldn’t get steel bonnets pressed in time, so the decision was taken to use cast aluminium panels instead, simply to get production started.

This Ford 9N crane conversion was spotted in a Wisconsin junkyard, awaiting rescue and restoration.

Ford sent an aluminium-bonneted tractor to the 1939 World’s Fair in New York and, for the display, the bonnet was polished to a high shine to make it stand out. Today, collectors still polish their aluminium bonnets to replicate that early show tractor. Unfortunately, the aluminium bonnet was quite weak, and prone to cracking, so few have survived, but these are probably the tractor of choice for the collector.

Which version?

Determining which 9N/2N tractor you may be looking at isn’t always straightforward. The tractor serial number is the engine number stamped on the left of the block. If the engine has been changed, then the chances are that the original serial number will have gone. ‘9N’ part numbers were used continually if a part never changed; the number never changed and 2N tractors have a ‘9N’ prefix on the serial number. I’ve included a guide to the major changes, to help you recognise which tractor you’re looking at.

The engine used in the 9N was the petrol-powered four-cylinder 120CU (approximately 1,966cc) side-valve design, that had been developed by the Ford Motor Company. As a cost-saving measure, it shared parts with the car engines that Ford was making at the time.

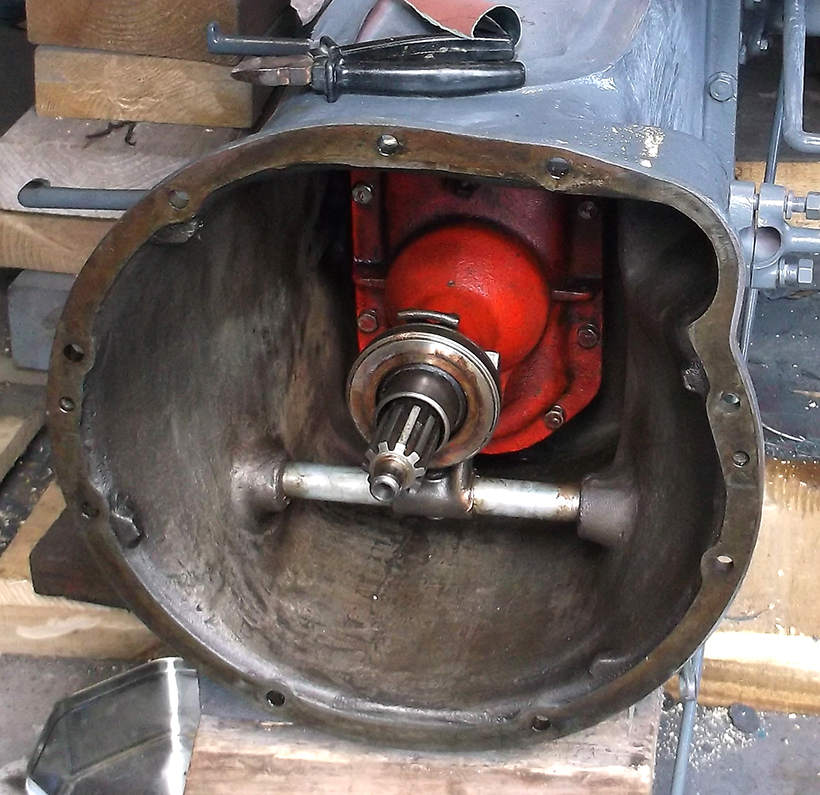

A dismantled gearbox showing the Hi-Lo conversion; a popular modification that boosted the practicality of the 9N’s standard transmission.

A kerosene-powered version was available with a Holley vaporiser on it, and this was designated as a ‘NAN’ tractor. These were mainly for export to Europe, and were extremely rare on the home market. To keep up with the latest developments, the tractor was fitted with an electric start, distributor ignition, an oil filter and a silenced exhaust system.

The engine was a robust unit for the era with few problems, but early engines were cast without core plugs and with very thin wall thickness. This led to a large number of early tractors suffering from cracked blocks. The coil and distributor system were located in an unusual position, just above the bottom pulley. This makes setting the points rather difficult. The correct procedure is to remove the distributor and set it up using a special tool, but care must be taken when reinstalling it, as the drive will only fit one way, and incorrect installation will cause damage.

Liner variation

Another strange quirk of the engine is that there are two sizes of cylinder liners. Both have an identical bore, but the wall thickness varies (0.040 and 0.090). I can only assume that if a block didn’t pass the grade at 0.040, it would be re-bored to use thicker liners. This makes pre-ordering parts difficult, as you can only tell the liner thickness by stripping the engine.

The front axle was completely new at the time, and offered variable track width. The front hubs were quite large and the bearings were oil-lubricated. Look out for leaking oil seals. The centre pin on early models didn’t have an end plate, and was held in position with a pinch bolt. Always check these pins haven’t slid out, as they’re not as reliable as later pins.

A prototype 9N at the Ford museum.

Generally, as with most of the 9N, the front axle was strengthened with time, so always check for cracks, especially around early hubs. The 9N was fitted with single-rib front tyres and finding these nowadays is difficult. But some specialist tyre companies do still offer them.

The 9N was fitted with a basic, three-speed gearbox. This soon led to a host of aftermarket options offered by several companies. Most of these specialists would offer another small gearbox that would fit into the original bell housing, behind the clutch assembly. They would offer an overdrive, underdrive or both over- and under-drive gears. This would also have the effect of altering the PTO ratio, and would give a high or low PTO gear as well. These conversions can easily be spotted by the extra gearstick that’s usually drilled through the bell housing.

Axle issues

As with the rest of the tractor, early rear axles were quite weak, so upgrades soon started to appear. Typically, this took the form of riveted centres fitted to the half shafts, to stop them from cracking.

The tractor was fitted with independent foot brakes that assisted with tight turns. Manoeuvrability was one of the features that Harry Ferguson was very keen to promote, and several of his sales demonstrations were based around this practical aspect. On later models, the left-hand brake pedal had a crank cast into it. As the left foot is operating the clutch, the crank allows the driver to reach and apply the brake by hand.

The 9N was powered by a four-cylinder petrol engine that produced a fraction over 23hp.

Buyers must always check the condition of the rear axle seals carefully. These are prone to leaking after so many years, and will allow oil to escape out onto the brake shoes, resulting in brake failure.

In their home country many Ford 9N and 2N tractors are still in regular use mowing grass, and as general, yard tractors. With this in mind, there’s a plentiful supply of aftermarket parts. Unfortunately, UK suppliers have been slower to stock early Ford parts, and only a few specialists offer anything suitable here and, often, that’s as an import service. Caution here, NAN models were mainly destined for the European markets and so have been largely overlooked by the US parts suppliers. This makes the few parts that differ between the N and the NAN model much harder to find.

The Ford 9N/2N tractor will always be known as the forerunner of the Ferguson TE-20 range. With this in mind, most Ferguson machines and equipment will fit the Ford tractor, and many were even designed in the Ford era. This makes the 9N/2N a useful little tractor that’s a little more individual than the little grey Ferguson.

What to pay?

Ford 9N/2N prices start from a little over £1,000 for a ‘project tractor’, but expect to pay upwards of £2,500 for one that will drive away. ‘NAN’ versions usually command a slightly higher value as buyers usually prefer a UK-supplied tractor, and there were far fewer NAN versions built.

This Ford BNO25 tug, based on a modified version of the 2N, was photographed at The Old Timer Tractor Rally in 2021.

A good, restored, show-quality tractor will command around £6,000. Of course, the 9N and 2N models are very similar, and prices reflect this, but look out for very clean, unrestored examples, especially early 2Ns with steel wheels and magneto ignition. Also, period six-cylinder and eight-cylinder conversions seem to sell at a premium.

At the other end of the price scale, top quality, aluminium-bonnet examples can make £40,000 ($55,000) at auction in the USA.

Technical specifications

| Production period | 1939-1942 |

| Produced at | Dearborn, Michigan, USA |

| Engine: | Ford four-cylinder, liquid-cooled, petrol, four-stroke, 1,961cc (120cu/in) |

| Bore/stroke | 81mm x 95mm |

| Compression ratio | 6.0:1 |

| Max. power | 23.1hp |

| Transmission | Three-speed |

| Dimensions | Length: 2,920mm (115in)

Width: 1,620mm (63.8in) Wheelbase: 1,770mm (69.7in) |

| Weight | 1,315kg (2,900lb) |

For a money-saving subscription to Ford & Fordson Tractors magazine, simply click HERE