Fordson Model F buying guide

Posted by Chris Graham on 11th December 2020

Chris Graham digs into the Fordson Model F’s background, to discover more about buying and owning one of these mass-produced marvels.

Iron wheels were fitted as standard throughout the Fordson Model F’s 11-year production run. However, it was possible to order an Industrial version that featured solid, rubber tyres.

The Fordson Model F is a momentous machine in many respects. For a start, it was the first tractor to be mass-produced, and then sold at an affordable price to farmers around the world. But, perhaps more fundamentally, it triggered an agricultural revolution. The Model F, and the huge numbers in which it was made, was instrumental in the introduction of a new era in farming – the mechanised age.

Henry Ford had a long-held ambition to ease the lot of the over-worked farm labourer. His success with the Model T – which brought the reality of owning a motor car to the masses – allowed him to experiment with successive, Model T-based vehicles, in a bid to create a machine that could be used on the land, for agricultural purposes. He wanted to see combustion engine-powered machines replace horses on farms and, eventually, that’s exactly what happened.

Core business

However, with the core of Ford’s business then being the production of road cars and light commercials, Henry was encouraged to set-up a subsidiary operation to further his tractor-making ambitions. He did this with his son, Edsel, and called it Henry Ford & Son Inc. (can you see where the ‘Fordson’ name came from?). The new operation had its first, serious tractor prototypes ready in 1916.

Being a relative lightweight, the Fordson Model F suffered with a nasty tendency to rear up if an implement being towed hit an obstacle. This sometimes caused the tractor to flip, injuring or killing the driver. Ford’s solution was to beef-up and extend the rear mudguards much lower so that, should the front start to lift, the bottoms of the mudguards would impact the ground and halt the rise. This late, 1927 model features tapered rear wings, to facilitate better turning when towing.

Of course, at this time on the other side of the Atlantic, World War 1 was raging in Europe, and Great Britain was facing ever-growing food shortages due to its dependence on imports. In 1917, the British government devised a plan to boost home production by ploughing-up great swathes of the nation’s pastureland, and turning it over to crop and vegetable production.

However, the war effort meant that the number of both farm labourers and horses left on the home front was worryingly low. In short, the nation’s agricultural workforce was seriously depleted, which posed a major problem.

Useful contacts

Fortunately, Percival Perry, who was both the chief executive of Ford in Great Britain, and involved with the government’s drive to bolster home-grown food production, was ideally placed to advise on the problem. He knew of Henry Ford’s tractor production ambitions, and suggested to the government that these machines could provide the answer to both the labour and horsepower shortage.

The Model F remains perfectly usable for a bit of ploughing, cultivation work or log-cutting. This 1926 example, despite its ‘working clothes’ appearance, has been completely rebuilt.

The idea met with approval, a couple of the prototype tractors were shipped to Great Britain for trials and everyone was very impressed. The machines were found to be effective, easy to operate and reliable, so negotiations began. Henry Ford offered his full co-operation, and made his factory in Cork, southern Ireland, available for tractor production. He also sent his production guru, Charles Sorensen, to run the facility, under the control of the British government’s Ministry of Munitions (MoM).

Then, following a change in wartime production priorities, the British government asked Henry Ford if he could produce a batch of 6,000 ‘MoM’ tractors at his plant in Dearborn, close to Detroit, in Michigan, and then ship them across the Atlantic. He agreed, Sorensen returned to the USA to oversee things there, and production began. Unfortunately, initial progress was slower than expected.

A slow start

By the end of 1917, only 254 had been built, although production really ramped-up the following year, which ended with just over 34,000 having been made. The 6,000 order for Great Britain was completed by April, 1918, and it was at some point during this period that the ‘Model F’ name became established, simply because ‘F’ was the vehicle’s factory designation at the Dearborn plant.

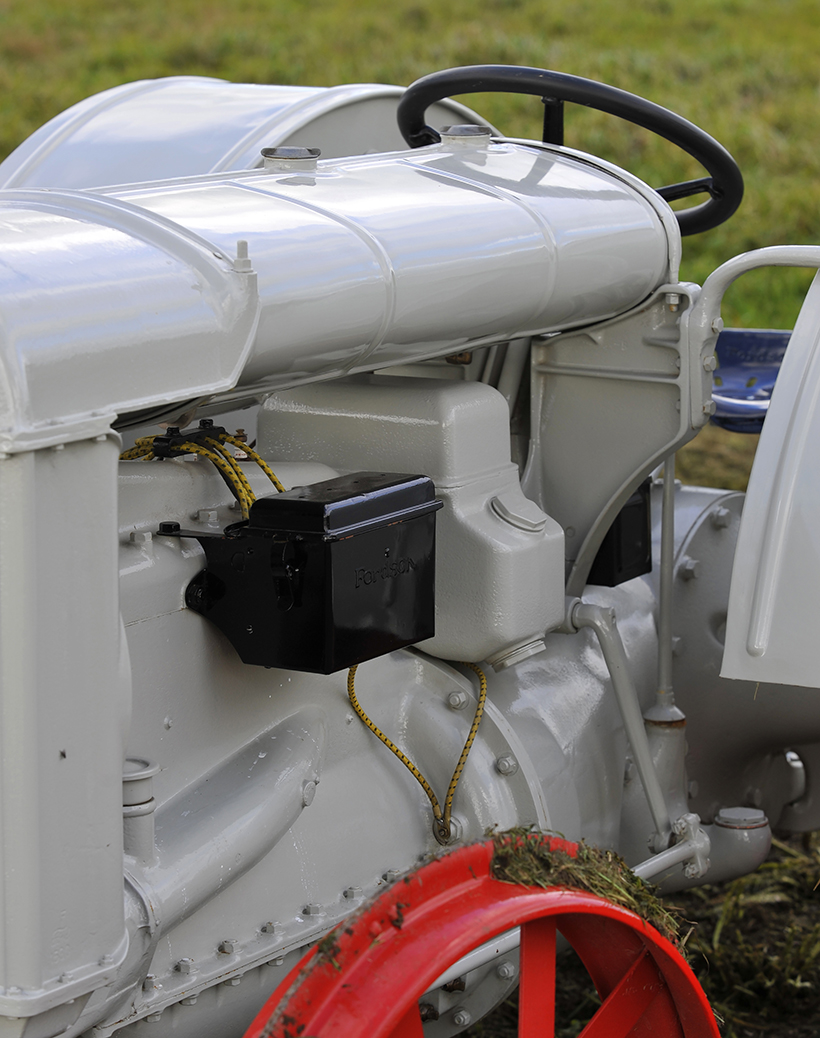

From 1920 onwards, a Ford-made four-cylinder engine replaced the original Hercules unit. Both produced 20hp. The black box on the side of the engine contains the four trembler coils.

Rather ironically, WW1 ended later that same year, so the rush to get the new machinery into service came a little bit too late. Nevertheless, a legend had been born, and the agricultural world would never be the same again. Ford’s Cork plant produced the first of the Irish Model Fs in July 1919, but it wasn’t to last there for much more than two years.

Market changes and political problems led to the closure of the Irish factory in 1922, with just over 7,500 having been made there. After that, all Fordson Model F production was switched to Ford’s Rouge factory, in another part of Dearborn. This facility was to become the largest, integrated factory in the world in 1928 which, coincidentally, was the year that Model F production ended, with some three-quarters of a million examples of this game-changing tractor having rolled from the production line.

Model F overview

The early Model F was powered by a Hercules, 4.1-litre, four-cylinder engine, producing 20hp. This was changed, in 1920, to a very similar, Ford-produced version, with the same power output. Both were designed to be started on petrol, then switched over to cheaper kerosene once the engine had warmed.

Model F controls are rudimentary. There’s a clutch/brake pedal on the right-hand side, a spindly gear stick on the left, an ignition advance/retard control on the bulkhead and a throttle lever immediately beneath the steering wheel.

Intake air was initially cleaned by a water bath before entering the Holley carburettor, but a switch to a more effective oil cleaner followed. The ignition system was similar to that used on the Model T car, with flywheel-mounted magneto and trembler coils.

The engine was linked to the rear axle by a three-speed transmission (with one reverse gear), delivering a top speed of just over 6mph. There were no brakes, with internal, mechanical friction considered sufficient to stop the tractor when the clutch pedal was depressed.

By cleverly bolting the engine block, transmission and rear axle directly together to provide and inherently strong structure, there was no requirement for a heavy chassis frame, which saved money and simplified the manufacturing process.

The extended, anti-tipping mudguards on the Model F incorporate a pair of handy tool boxes, one on each side. This 1926 machine has the normal, squared-off ends, which could inhibit turning when towing.

The Model F ran on fabricated steel, spoked and cleated rear wheels, initially with 12 spokes, then 14. The front wheels were available in a fabricated steel, 10-spoke design or, later, a five-spoke, cast iron version.

Buying one

To get some practical, experienced-based insight into buying and owning a Fordson Model F, I took a trip to Somerset to consult Fordson expert, Nick Bryne. He owns a couple of late Fs, one of which has been restored to a high standard and the other which, although completely rebuilt, lives on in its unpainted, ‘working clothes’.

Chatting with Nick, it quickly became apparent that buying a Model F is about taking an opportunity when one presents itself; getting a tractor and then moving forwards from there. It’s not a process over which you can afford to be too picky, unless you have lots of money to throw at the job.

“Probably the biggest problem when buying is knowing what you’re actually getting,” he explained. “With all these machines now being at least 92 years old, every one will have had so much done to it over the years, as things got broken or became worn out, that finding a complete, all-original machine is, in most cases, the stuff of dreams.

“Things like fuel tanks, manifolds, wheels and even cylinder heads may all have been changed, together with countless other mechanical parts, as the tractor was serviced, repaired and restored by successive owners. So recognising what’s original and what’s not can be quite a challenge. This is why I say that, given that genuine originality is a pipedream with the Model F, most buyers will be better off buying a machine, accepting that lots will be wrong about it, then deciding what to do with it from then on.”

Of course, it’s not as if would-be buyers will be spoilt for choice, anyway. Classified sections are hardly groaning at the seams with Model Fs, but there’s usually a handful for sale at any one time. Nick says that quite a few machines are still trickling in from America, but adds that very few of these are great examples.

“Imported Fs can be found with a weird assortment of non-original parts fitted, including things like chain-driven magnetos and exhaust manifolds cobbled together from bits of old water pipe. Such changes would have been made out of necessity back in the day, when it was essential that farmers kept their tractors running and productive.

There’s something very special about a 90-year-old Model F in its working clothes. Lights were never available; Nick Bryne fitted this period unit simply because he fancied doing so!

Mechanical matters

The mechanical side of the Model F is relatively straightforward but, in terms of DIY friendliness, everything depends on your own ability and workshop experience. There are specialists around who can help, of course, but there’s always a price to pay for that.

Nick says: “The engines are essentially tough and reliable units, but one must never forget their age. Things are bound to be worn, and the way everything’s been serviced, maintained and/or repaired over the years, will be a big factor in determining how much time and money will need to be spent.

“There are plenty of people who are just happy to see such elderly machines running and working, and who are prepared to be rather more forgiving on the component accuracy front, as a result. As far as I’m concerned, though, accuracy is important, and I like to have my tractors as close to original as possible. As always, though, it’s each to their own.”

So, the bottom line appears to be that would-be buyers should go into Model F ownership with their eyes wide open, and expecting things to be a bit of a mechanical jumble. Everything is repairable, though, so there’s nothing that with patience, tenacity and a bit of cash, can’t be sorted out.

As far as the market’s concerned, things are somewhat polarised concerning the Model F. Nick says: “I think that an increasing number of people simply look upon the Model F as a very old Fordson that’s likely to cause them problems and be difficult to start. Consequently, lots are put off the idea of ownership. The metal, cleated wheels can be similarly off-putting and, inevitably, some regard these as nothing more than lawn-wreckers, that make the tractor harder to transport and show, and restrict its usability.

“On the plus side, these engines needn’t be difficult to start if they’re properly set-up, and the steel wheels aren’t a problem if you take care, make allowances and have a bit of space to play with.” There’s no question that the Model F is a machine of its time, and its time was a very, very long while ago. So, it’s no good expecting one of these tractors to be as easy and predicable to live with as something from the 1970s or ‘80s.”

However, if you approach ownership with an appreciation for the pivotal role the Model F played in agricultural development, its ground-breaking engineering and the sheer history that every survivor now carries with it, you won’t be disappointed. I think that it’s incredible to be able to buy a working machine that, despite being nearly 100 years old, doesn’t need to be molly-coddled or wrapped in cotton wool like a precious museum piece. So, be in no doubt that these tough little survivors remain perfectly capable of getting out there and mixing it in the mud, and loving every minute of it!

Owner’s view: Nick Bryne

“I never thought that I’d own a Model F; I’d written-off the idea thinking they were just too rare and difficult to sort out, due to their age. But then the import market started to pick up and I got a call from Martin at Yeovil-based Cox & Turner Engineering.

“He knew that I was interested in the model, and said that he’d just got a 1927 restoration project in from America that he thought would suit me. It wasn’t complete, or a runner, but I took it on, nevertheless. That was about 15 years ago

“It was a long job getting it sorted and into the condition you see today. It took a lot of research and patience to locate the many missing parts. My ‘working clothes’ F is a 1926 model, which is fitted with the un-tapered mudguards.

“Contrary to what many people believe, I often find the Model F easier to start than my Model Ns, but I think that’s because the engines have been properly restored and set-up. Down-at-heal examples with dodgy ignition systems – worn-out trembler coils and tired flywheel magnets – will inevitably be more of a struggle to get going!

“I have no plans to bring my unpainted F up to ‘as new’ condition as I like it just the way it is. I’ve taken both machines to shows in the past, and the painted one has won me a prize or two, which was very satisfying.”

What to pay?

Prices really are all over the place for the Fordson Model F, with early, USA-built examples available for under £1,000. The Irish-built machines command slightly higher prices than equivalent American-made versions, with the entry level for one of these being about £2,000. Mid-range Fs can cost anything between £3,000 and £6,000 while, at the top of the tree, you should expect to pay £9,000 to £12,000 for a smart, fully-operational example.

Fordson Model F specs

| Engine | Hercules/Ford four-cylinder |

| Max power | 20hp |

| Displacement | 4,100cc (251.3cu in) |

| Bore/Stroke | 4x5in (102x127mm) |

| Rated speed | 1,000rpm |

| Transmission | 3 fwd, 1 rev, constant mesh |

| Weight | 1,342kg (2,920lb) |

| Produced | 1917-1928 |

For a money-0saving subscription to Ford & Fordson Tractors magazine, simply click here