MF 1200 buying guide

Posted by Chris Graham on 19th January 2022

Jonathan Whitlam takes a look at the impressive MF 1200 and wonders whether, despite its size, it was actually too little, too late?

In its day, the MF 1200 was a superb tractor, despite its often-mentioned failings of not enough power and a rather weak three-point linkage.

Massey-Harris had been one of the first tractor manufacturers to offer a four-wheel-drive tractor, after introducing the General Purpose during the 1930s with its four, equal-size driving wheels. Designed more for row crop work than out-and-out tractive ability, the General Purpose proved to be somewhat ahead of its time and, as a result, never really achieved its full potential.

In 1971, Massey Ferguson launched a four-wheel-drive tractor in the shape of the 1500; a large, articulated-steer machine powered by a Caterpillar V8 diesel engine producing 152hp. This was quickly followed by the even larger 1800, with 180hp under its bonnet, also courtesy of a CAT V8 motor.

NEW DESIGNS

Designed and built in North America, these two new behemoths were also the first Massey Ferguson models to feature a new, ‘hard-nose’ radiator surround design, which would later be adopted across the board in new tractor designs launched during the rest of that decade. They were also the first to feature a cab designed as an integral part of the tractor, rather than just being an optional afterthought, and it was a pretty quiet and impressive one too.

However, these large machines were specifically designed to work in the wide-open fields of North America, and were never officially sold into Britain or Europe – mind you, with an average weight of eight tons, it’s probably not that surprising that they never made it across the Atlantic.

However, MF hadn’t forgotten its European markets, and a scaled-down version was designed alongside the 1500 and 1800 models. It was the 1200 and, although it shared many features with its larger siblings, it was very different under the skin. It wasn’t built in North America, either, with Massey Ferguson choosing to produce the 1200 in Manchester.

The Massey Ferguson 1200, launched at the end of 1971, was unlike any other British tractor on the market at that time. With pivot-steering and true four-wheel-drive it was aimed at those with large farms and/or big contracts.

THE MF 1200

Although pivot-steer agricultural tractors weren’t a completely new idea in early 1970s Britain, there was no British-built articulated tractor in production at that time. Previously there had been the Doe Triple D, the 130 and the 150, but these had basically been two tractors joined together. The only true pivot-steer tractor produced in the UK had been the Matbro Mastiff, introduced in 1962 and based on the Fordson Super Major, with a six-cylinder engine replacing the original power plant. Despite a Mark II version appearing later in the 1960s, this tractor was never a huge commercial success.

Fast-forward a decade and Massey Ferguson had high hopes that its own, British-built articulated tractor would prove to be a more enduring model as it began to arrive on British and European farms during 1972, following its UK launch at London’s Royal Smithfield Show in December 1971.

The first prototypes had been built in North America and trials followed in the UK. Externally, the 1200 followed pretty closely to the design parameters already set by the larger 1500 and 1800 models, with the same type of ‘hard-nosed’ bonnet, complete with side-mounted air intake stalk and pre-cleaner element, as well as the very square-looking cab.

The pivot point itself was also of similar design but, at the rear, an integrated three-point hitch was developed to enable the more versatile use of implements that was required on this side of the pond. The result was a very purposeful looking tractor with equal-size wheels and plenty of ground clearance, making it ideal for the heaviest and toughest jobs that European farms could throw at it.

It would have been natural, perhaps, to build the 1200 at either Coventry or Beauvais, in France. Instead, and probably sensibly given its heavy construction machinery experience, the job was given to the Massey Ferguson industrial machinery factory at Barton Dock Road, in Manchester. After all, the actual chassis of this new machine was very different to that used on any of the then-current 100 Series models, with its heavier and more industrial-style design.

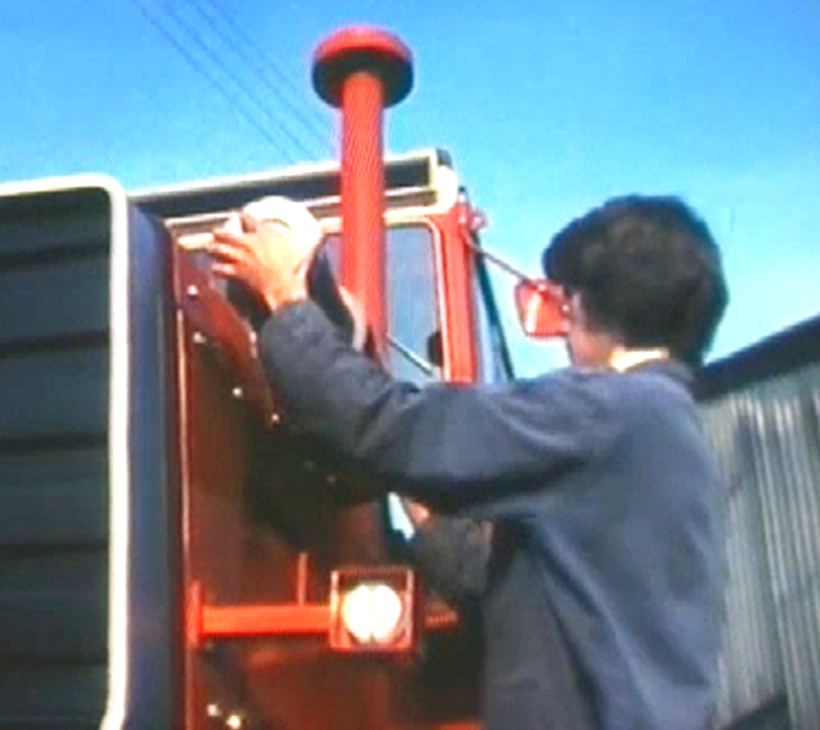

The pre-cleaner air filter was located on the opposite side of the bonnet from the exhaust stack, and was externally mounted, below the air intake pipe. This made accessibility for servicing extremely straightforward (Pic: AGCO)

A TURNING POINT

The central pivot of the 1200 allowed for very tight turns when turning on the headland of fields; much tighter than was possible with competitive four-wheel-drive machines such as those County and Roadless equal-size-wheel models. All four wheels on the 1200 were fixed, with a powerful hydraulic ram turning the machine around its central pivot point, with the engine and cab on the front half allowing the driver to face forwards at all times, while the rear wheels always followed in the tracks of the fronts.

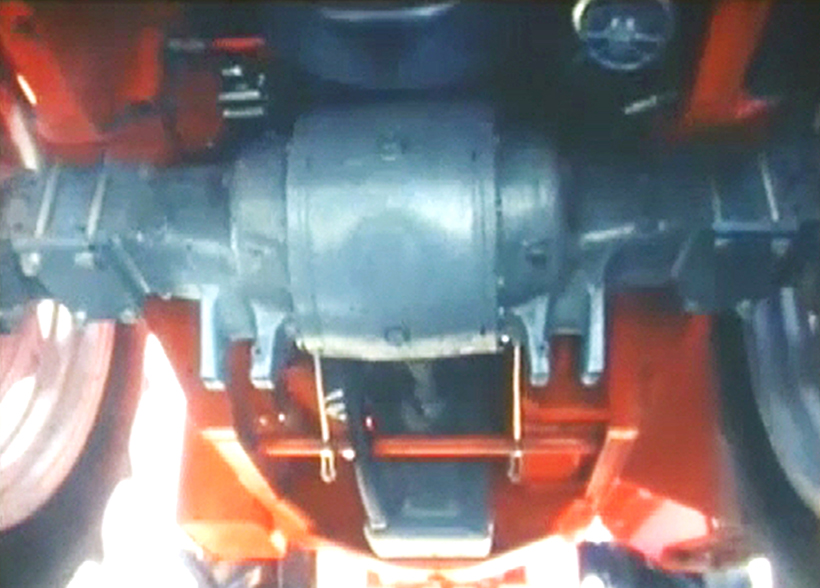

The same axle design was employed both front and rear, using the same assembly as found on the larger, MF two-wheel-drive tractors, such as the 188, resulting in the differential lock working on both axles. The articulated design also allowed for the front and rear wheels to tilt independently of each other when moving over very rough ground.

The 318-litre fuel tank was mounted high up behind the cab, which not only kept it out of harm’s way, but also helped stop the filler neck from getting coated in dust and dirt. Two large, easy-to-remove panels on either side of the bonnet provided access for routine engine maintenance, and a small flap on the top of the bonnet concealed the radiator coolant filling point. With the dry element air pre-cleaner mounted to the side of the bonnet, maintenance was an easy job requiring nothing more than the undoing of a couple of wingnuts.

The battery was housed under the cab, on the offside, with a swinging door giving easy access. Overall, the amount of attention to detail lavished on the 1200’s layout at the design stage, resulted in a very user-friendly tractor that was easy to live with, service and maintain.

The independent power take-off was of the 1,000rpm type, allowing for the operation of heavy-duty implements such as power harrows, forage harvesters and rotavators; these being the types of equipment that the 1200 was really intended to be used with.

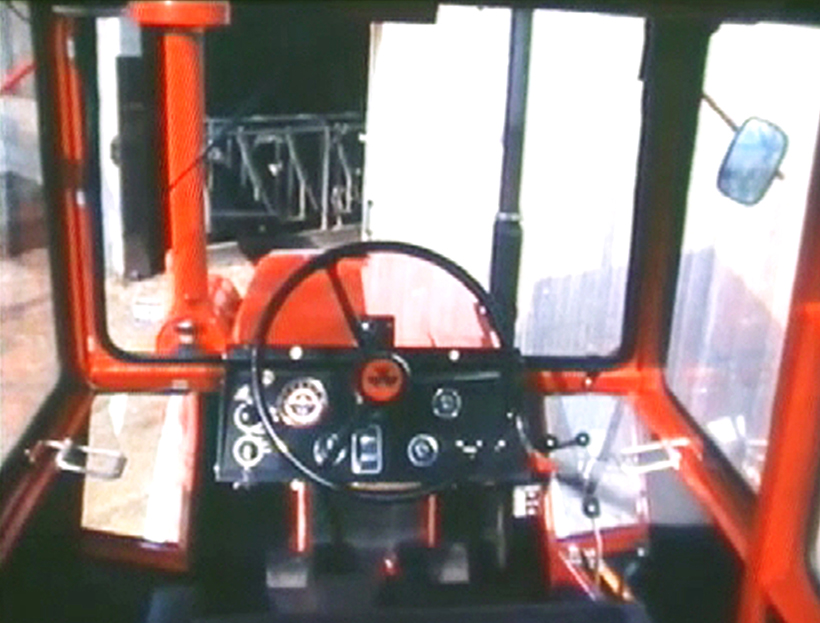

The 1200’s cab was a very well-designed space that was integral to the whole design of the tractor. It sat on rubber mounts to isolate it from vibration, and was well insulated, too. (Pic: AGCO)

POWER LIMITATIONS

Despite its similar appearance to the 1500 and 1800, under the skin, the 1200 was a very different beast. Power came from a Perkins A6.354 six-cylinder diesel engine of 5.8-litre capacity that produced 105hp at 2,400rpm; pretty modest compared to the output of the larger models’ V8s. But, here in Britain at that time, tractors of around 100hp were regarded as the most powerful necessary.

In practice, the 1200 soon proved that its power output was usually up to the job as it had been designed as a true 4WD machine and had been well-conceived from the outset. Plenty of thought had been given to vital factors such as correct weight distribution and the tractor’s ability to get all the available power down to the ground. The design ensured that more weight was positioned over the front axle, allowing for more tractive effort, while the weight of any mounted implements, and the pull of them in the soil, added weight to the rear axle. This tractor may have been a ‘mini-artic’, but the same principles of balance and maximum traction applied as with its larger, North American cousins.

However, as time passed, the 1200 started to lag behind other manufacturers’ offerings in the power stakes although, in the early 1970s, it was certainly powerful enough for most operators. With an official rating of 105hp, most advertising material stated a slightly inflated maximum of 110 horses. This led to Opico, and a few other manufacturers, introducing an aftermarket, turbocharger kit for the 1200, which boosted the power available by more than 10hp and made some of the promotional claims more attainable.

TRIED AND TRUSTED

In a sense, the 1200 made use of many components already available in the MF parts bin. This was the case with the standard transmission chosen, which was the eight forward by two reverse gearbox as standard. Alternatively, customers could opt for the Multi-Power, 12 forward by four reverse unit at extra cost option, but both transmissions were well proven from use on other MF models, and performed well in this application.

A top speed of over 17mph seems very sedate nowadays, but was actually pretty run-of-the-mill for most tractors of the time, and the prospect of driving this pivot-steered beast any quicker probably wouldn’t have appealed to many, anyway!

A rear view of this superbly-restored example shows the three-point linkage located on the rear half of the tractor. The lower links were extendable, and a 1,000rpm power take-off was also fitted.

The gearbox was controlled by two levers positioned down to the right of the driver’s seat, while the Multi-Power lever was mounted up on the console, under the steering wheel.

IN THE CAB

At first glance, the cab looks very simple and perhaps even a little spartan but, when launched, this was probably one of the best units around. It offered the driver plenty of room, lots of comfort, good visibility and a quiet environment. Massey Ferguson was justifiably proud of the result, and made great play of the fact that it was ‘a cab designed by drivers, for drivers’.

Safety cab legislation had only been introduced in the UK in 1970, and the 1200’s cab met all the requirements to keep the operator safe in the event of a roll-over accident. The strong vertical pillars – three on each side – were more than capable of taking the weight of the tractor if it flipped, without too much deformation. Moreover, the sound insulation inside was well ahead of the official legislation that came into force in 1976.

The use of rubber mounts to isolate the cab from the rest of the tractor, and plenty of effective insulation material, ensured that both vibration and noise were impressively controlled, delivering a driving experience that was at least five years ahead of its time.

Built to provide a flat floor, hydro-mechanical controls were used to take all the effort out of steering, braking and the other repetitive jobs that came with everyday tractor driving. Climate control was also fitted as standard to keep the driver either warm in winter or cool in summer, with the controls for the system mounted up in the cab roof, above the steering wheel.

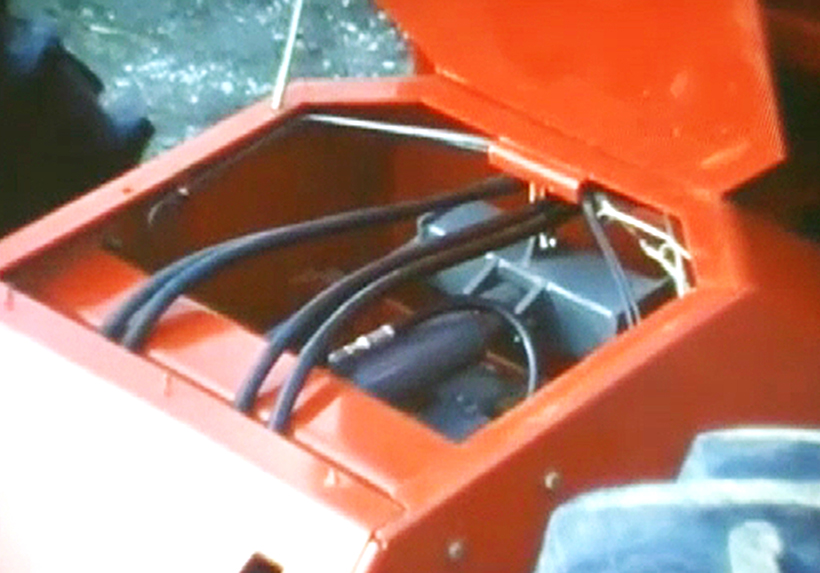

The cover of the rear section (behind the cab) could be lifted to gain access to the ram that raised and lowered the three-point linkage. (Pic: AGCO)

The large and comfortable driving seat was fully adjustable so that the operator could find the perfect position and I’m sure that, overall, the 1200 would have been a complete revelation to drivers used to operating, say, a canvas safety cab-equipped MF 165!

HYDRAULICS AND HITCH

A three-point hitch was standard on the 1200, which was an improvement over the American offerings at that time, which usually only came with a drawbar. A hydraulic ram, neatly housed in the rear half of the tractor between the rear wheels, gave more power to lift heavier implements quickly and smoothly. Quick-release couplings gave instant hydraulic power to those implements requiring external services, and made connecting and un-connecting an easy task.

The hydraulic system on the 1200 was pretty comprehensive, with several standard functions giving draft control, position control and response control as well as pressure control and external services. The maximum pump flow was 8.6l/min, while the auxiliary hydraulic system provided two rates of independent oil flow, with a maximum flow rate of 34.6l/m. An optional, high-flow system was also available, delivering an impressive 72.7l/min flow rate.

In keeping with the ‘bin of bits’ philosophy that had been adopted while designing the 1200, its three-point linkage was sourced from the then-current 185 and 188 models being built at the factory in Coventry (among other plants around the world). This seemed a great idea in principle, but would lead to one of the biggest problems that owners of the 1200 ever experienced.

With more power than the 185/188, the 1200 was soon putting more stress on these components, and this was made dramatically worse by the fact that the 1200 was actively sold as a big tractor able to cope with the biggest and heaviest implements. This may have been true of the rest of the tractor, but when users continually used the tractor with big, wide and heavy cultivators and other implements, the cracks began to show – quite literally – as the 100 Series-derived rear linkage began to fall apart under the strain.

A six-furrow Ransomes conventional, semi-mounted plough is a good match to the Massey Ferguson 1200. This late example of the tractor is showing signs of rust, especially on the cab roof, but, mechanically, it was in very fine fettle (Pic: Kim Parks)

END OF THE ROAD

By 1979, the 1200 had really begun to show its age. The design was still sound overall, but the size of implements had grown to such an extent that the poor 1200 was struggling, not only in the three-point linkage area, but also in the power stakes. Many conventional tractors had already overtaken the big MF, in terms of power.

In 1975, the North American 1500 had become the 1505 while the 1800 had, likewise, evolved into the 1805 with several major improvements, including an increase of engine power, improved power take-off and also the option of a three-point hitch. This increased versatility led to a few sales for these models in the UK and Europe. The 1200, however, continued on as before, falling ever further behind the rest of the pack.

It wasn’t until 1979 that the 1200 was finally replaced, with Massey Ferguson introducing the very similar 1250 to succeed it. This new model featured a new variant of the engine originally fitted to the 1200 – the newly-developed Perkins A6.354.4, which featured a new block and redesigned cylinder head, and resulted in a maximum output of 112hp.

The gearbox was an improved version of the 12-forward-and-four-reverse unit, and was similar to that used in the French-built MF 595. The 1250 also shared that model’s braking system. The whole steering system received a major upgrade, the hydrostatic system providing a tight, 3.62m turning circle. The rear hydraulic system also received an upgrade, and it was claimed that the 1250 was able to lift 28% more than the 1200. The same monocoque cab was used on the 1250 as on the 1200, and remained remarkably effective, despite its age.

Sadly, comparatively few 1250s were produced, with the final example rolling off the production line in 1982. By then it was, in many ways, out of date. Massey Ferguson had introduced the conventional-layout 2000 Series in 1979, offering more power and the option of four-wheel-drive in a rigid chassis.

A worm’s eye view underneath the MF 1200, showing how the front axle was basically the same as the rear axle used on the Massey Ferguson 185 and 188 models.

If only the 1250 had been introduced earlier it might well have sold a lot better. As it was, the 1250 would prove to be not only the last Massey Ferguson articulated tractor to be built in Europe, but also the last articulated design to be built in Britain – full stop!

BUYING A 1200

The 1200 is no different to any other tractor when looking at a prospective purchase and as always, overall condition is key. If you’re lucky enough to find an immaculate, low-hours example, then you shouldn’t go far wrong. Most likely, though, you’ll be looking at tractors that have done a great deal of work in their lifetime so, unless you have lots of spare cash to spend on getting it back into good condition, it’s best to avoid any really rusty, run-down examples.

Check the engine and driveline as you would any tractor, to make sure that everything works as it should, and that there are no obvious leaks or severe corrosion. Check the axles for wear and leaks, and make sure that the linkage and PTO work properly.

As I’ve already mentioned, the 1200 was mostly put together using already tried and trusted components from the Massey Ferguson parts bin, so the engine, transmission, axles and rear linkage all use components that are pretty much readily available. However, it’s very important to check the 1200’s unique points, such as the pivot joint, which should be in at least reasonable condition, without too much wear on the shafts that transfer power to the rear axle and power take-off. Also, the joint itself mustn’t be showing signs of excessive wear.

The cab should also be carefully inspected. Check that it’s not rusting excessively, as doing anything more than a simple patch repair can be difficult on a safety cab such as this, bearing in mind it was designed as an integral part of the machine and, therefore, any work that needs to be carried out on it must be done to a very high standard. Find more than a few rusted holes and, once again, it’s probably best to walk away.

Awaiting sale at an auction, this 1200 has lost many parts, including the bonnet side panels and glass from the cab. Although it will take time and money to restore an example like this, as long as the engine and drivetrain are in good order and the corrosion on the cab isn’t too far gone, it could be a good prospect for renovation.

AN ANOMALY THAT WORKED

The Massey Ferguson was a large and powerful machine that, at the same time, wasn’t so big that it was too heavy or clumsy. It also offered all the benefits of articulated steering and true four-wheel-drive.

In its day, the 1200 was a superb tractor, despite its often-mentioned failings of not enough power and a rather weak three-point linkage. Many have had enjoyed very long working lives (even to this day, in some cases), and many others have now been preserved as a fitting tribute to this unique ‘mini-artic’.

While the MF 1200 might not have benefitted from the glamour and awesomeness associated with those huge, 400-500hp articulated tractors that started appearing as the 1970s drew to a close, it was a solid machine, nonetheless. In many ways, it and the 1250 that followed it, were perfect for the type of work they’d been designed to undertake. Many who operated these models regarded them as the ultimate in usable tractor power at a time when most farmers and contractors were still working with conventional, two-wheel-drive machines delivering 70-80hp.

Today, the sight of a Massey Ferguson 1200 hard at work remains an impressive one, and provides a fitting testament to the design team that worked so hard to see its innovative idea transformed into a genuinely capable, working machine.

MF 1200 SPECIFICATION

| Engine | Perkins A6.354, six-cylinder, 5.8-litre naturally-aspirated |

| Power | 105hp |

| Transmission | 8×2 standard or 12×4 Multi-Power (optional) |

| PTO | 1,000rpm at 2,216rpm, independent, 91.2hp |

| Hitch | Category II, extending links, 3,402kg lift capacity |

| Weight | 5,157kg |

For a money-saving subscription to Classic Massey & Ferguson Enthusiast magazine, simply click HERE