Ferguson 35 buyer’s guide

Posted by Chris Graham on 17th June 2020

Mark Channell’s essential Ferguson 35 buyer’s guide, providing practical hints and tips on all the vital areas, for would-be owners.

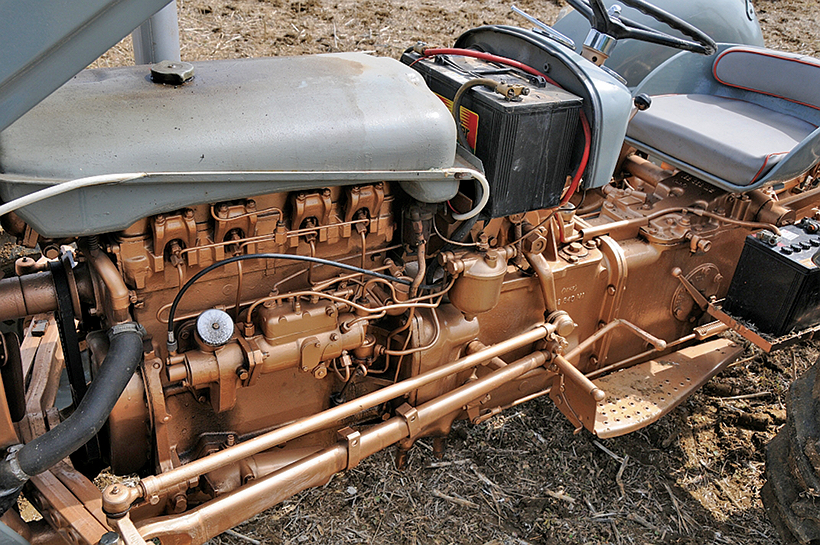

Buyer’s guide: Ferguson 35: A fine example of a diesel-powered Ferguson 35, owned by Bob Newton.

I usually start my buyers’ guides with a bit of a history lesson. Every classic Massey Ferguson model can be traced backwards through its ‘DNA’. In evolutionary terms, it’s fair to say that the FE 35 (Ferguson, England, 35hp), was launched in the equivalent period where tractors had just begun to walk upright, but were still scraping their hairy knuckles along the ground!

What I’m trying to say is that, before the FE 35, Ferguson’s only previous model range was the TE-20. Initially available from October 1956, the Ferguson 35 was launched into a market full of customers with almost impossibly high expectations. By 1956, the TE-20 had been produced for some 10 years or so and had, quite literally, revolutionised farming throughout the developed world. With a wide range of implements to complement these hugely capable tractors, Harry Ferguson had skilfully created an entire system of mechanised farming.

The problem that faced Ferguson’s design engineers must have been extremely daunting. Times were changing, the TE-20 was getting on in years but customers were sold on – indeed, embedded in – the entire Ferguson system. The engineers would need to come up with a new machine that retained the same vital statistics in terms of wheelbase and link arm geometry provided on the previous TE-20 models, which would render the TE-20’s implements ‘backwardly compatible’ yet innovate in other areas to ensure Ferguson’s market dominance continued.

Initially sold with a blend of Ferguson grey tinwork and a striking gold skid unit this tractor is, unsurprisingly, now better known to us all as the ‘Grey & Gold’, or ‘Copper Belly’ for those living to the west of the Irish Sea. After just one full year of production, the FE 35 would be given the MF re-branding treatment to become the more common red and grey farm tractor.

It’s unclear when Massey Ferguson ceased to call the 35 the FE 35, but research has led me to believe it was soon after the change to the three-cylinder Perkins diesel engine, as product information from the time introduced the 3-A-152-engined model as the ‘FE 35 Tractor with New Engine’. For this reason alone, this buyers’ guide will be based on the FE 35 produced from its initial launch in 1956, to the point in November 1959, when the three-cylinder Perkins engine replaced the Standard Motor Company’s four-cylinder 23C unit.

Model variants

The FE 35 was offered in both ‘standard’ and ‘De Luxe’ variants. While the standard model offered little in the way of driver comfort and controls, the more popular De Luxe version delivered additional benefits of ownership, such as a cushion seat (over the standard’s TE-20-style metal pan), a tractormeter, a dual clutch (over the standard’s single-plate affair) and a luxury footrest assembly.

An FE 35 vineyard model, owned by Mike Thorne.

A vineyard model was offered on 5×15 and 9×24 tyres, once again in standard and De Luxe versions. The same also applied to an Industrial model that was fully road legal, sporting a horn, mirrors and a twin braking system with a handbrake. Road lights, a radiator grille guard, a front-mounted bumper and mudguards were offered on these models as optional, fitted extras.

Another one of Mike’s tractors at the Coldridge Collection, this time it’s a well-restored FE 35 Industrial.

Engine options

There were two basic engines available for the FE 35. A 2,186.5cc spark-ignition engine was offered with the three fuelling options of straight petrol, petrol/TVO and lamp oil. All three of these engines are referred to as the ‘87mm engine’ in MF parts books (the bore size).

In addition to the trio above, there’s the somewhat notorious, four-cylinder, 2,258cc Standard-built 23C diesel engine. Horsepower figures for the spark engines were quoted as 37hp for the straight petrol, 30hp for the TVO option and a fairly frugal 29hp for the lamp oil-fuelled unit. The diesel was rated at 37hp.

It would be fair to say that the most popular engines were the TVO option and, of course, the diesel, so finding straight petrol or lamp-oil versions now would be something of a rarity.

Spark-ignition engines are, in my opinion, the better motors to have as they offer fairly hassle-free ownership when serviced and set up properly. Obvious things to check when appraising a tractor are the plugs, plug leads, distributor cap and points, one or all of which will probably be responsible for poor starting and running.

The engine’s front crank seal is situated in the front of the timing cover, and can be prone to a little weeping, especially on tractors that have been exposed to the elements for long periods of time. These engines sport a rubber lip seal and pre-date the rope seals used in the later Perkins engine.

Water pump bearings can also be problematic, once again due, more than anything, to age. Check for dribbles from behind the pulley once the engine has reached full operating temperature, but never put your fingers near the fan with the engine running.

Throttle butterfly wear can be present on machines achieving high working hours, with the spindle wearing its hole to an egg shape. The carburettor features an adjustable main jet on a thumb wheel which can (and should) be tweaked to find the optimum fuel/air mixture. These engines do run hot when raced, which is perfectly normal, provided the water temperature remains within the green on the gauge.

It’s also worth checking (on all engine types) for frost damage. Dip the oil to check for water ingress, and look in the radiator for oil in the water. Water coming from the exhaust pipe also spells bad news.

I called the 23C four-cylinder diesel engine notorious earlier as, sadly, the notoriety this engine has gained over the years is one of a poor starter, especially from cold. The main problem is that the engine has only one heater plug situated in the inlet manifold and, being an indirect-injection engine, it can be very difficult to fire up, especially from cold.

The Standard Motor Company-built 23C diesel engine has gained a reputation as a poor-starter but, with all components in good order, there’s no reason why it shouldn’t start well.

It’s worth noting that this engine was also fitted to the Allis Chalmers ED-40 and, with a glow plug provided for each of the four cylinders, it started a treat! I’ve heard lots of stories over the years about how to improve the starting of a four-cylinder FE 35 diesel, but the fact of the matter is that, if your engine has plenty of compression and shows little signs of wear, the timing has been ‘tweaked to perfection’, the valve clearances have been gapped correctly and the single glow plug is working, then you should be problem-free!

Look out for excessive breathing or black smoking on this engine, which will indicate an overhaul is about due – or even overdue in the case of heavy-smokers. Rear main oil seal leaks can be detected by drips around the bell housing, but you’ll be less likely to find a leaking rear main seal on this engine than on a later rope seal three-cylinder model.

Clutch and gearbox

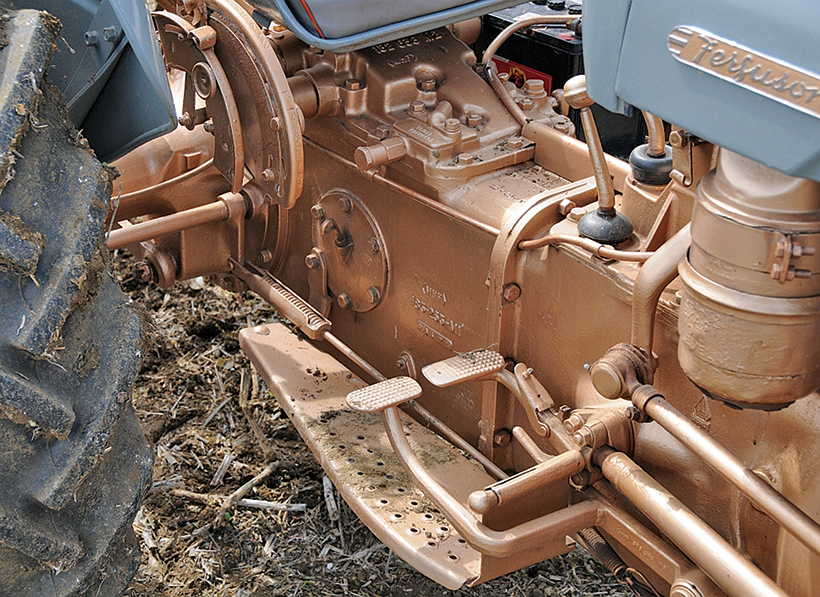

The FE 35 was the first Ferguson tractor to be offered with a dual clutch system. A main plate provided the drive connection for the engine and gearbox and the smaller, secondary plate breaking the drive for the PTO and hydraulic pump.

Check for usable service life by raising the pedal with the engine running (in gear) to observe the bite point. If this is high up the pedal, and a little pedal free play is evident, then the clutch is almost certainly due for replacement. The PTO shaft should engage and disengage with little or no complaining, with the pedal down as far as it will go. If you can’t stop the shaft spinning by a full dip of the pedal and the main drive seems to be OK, it could just be a matter of adjustment, which can be made with a feeler gauge from the underside of the bell housing.

It’s also worth noting that wear on the clutch pedal can be used as a good indicator of operating hours on machines with stopped clocks or, in the case of the standard model, no clock! If the clutch pedal is as thin as a super model’s waist, or as smooth as a baby’s bum, then it’s a safe bet that your potential new tractor has racked up some serious hours.

Splitting an FE 35 is really not a big deal, and can be done in the home workshop. So, if you’re even a tad handy and own some Swarfega, then don’t let a worn-out clutch put you off making a purchase!

The gearbox on an FE 35 can only be described as a robust affair. In a move away from the single-stick ’box of the TE-20, Ferguson engineers provided the FE 35 with a two-stick arrangement. The main lever controls the three forward speeds and a single reverse, while the smaller lever provides both a low and high ratio, with a neutral safety start position in the centre.

Thanks to Ferguson over-engineering this ’box, you’ll be hard-pushed to find a poor example. That said, check for broken teeth by driving the machine in all gears and both ranges. Remove the dipstick in the right-hand side cover (behind your right foot) to check for water ingress, which can be possible due to the rubber gaiters perishing and allowing the rainwater to run down the levers and into the gearbox.

Check the dipstick for signs of water ingress in the back end oil.

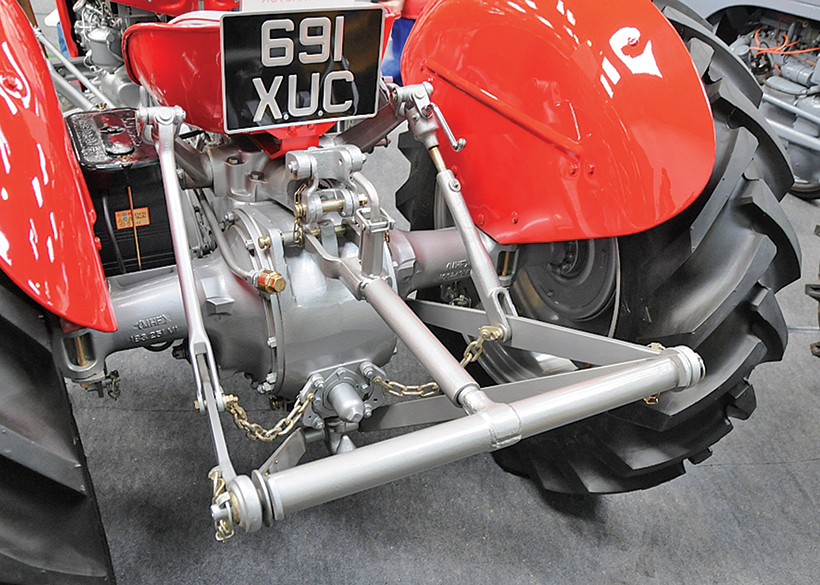

Hydraulics, PTO and linkage

In a move away from the TE-20’s engine speed PTO, the Ferguson engineers provided the FE 35 with both engine and ground speed outputs. The latter turns the shaft in proportion to the forward travel of the tractor. This new feature was to prove popular for implements such as the side-delivery rake and power-driven trailers.

The output shaft on an FE 35 is 13/8in, a quarter-inch increase over the previous TE’s 11/8in. Both power take-off options are selected via a single lever mounted on the left-hand side cover, under the driver’s seat. The rubber seal on this lever can be replaced with relative ease if wetting is present.

The FE 35’s hydraulics are powered by Ferguson’s famous four-piston Scotch yoke pump. For the first time in its history, Ferguson provided the FE 35 with both draft control, for soil-engaging implements, and a new position control for mounted implements. Both levers can be found on the single quadrant with the outer lever being draft and the inner providing position control.

Removal of the blanking plate on the top cover provides direct access to the hydraulic pump’s stack pipe. If the plate is replaced by a selector valve, it’s possible to work remote cylinders, such as those fitted to loaders or front-mounted sugar beet hoes.

It’s worth noting here that, in the absence of the constant pumping command fitted to later MF tractor models, it’s only possible to power the tipping trailer pipe on tractors fitted with a trailer hitch ‘T-bar’ assembly. Without the presence of the T-bar restricting maximum lift on the system, the link arms hit the fully-raised position, and automatically cancel the pump.

With the T-bar pick-up hitch present, you will be able to fully pressurise the hydraulic pump.

Hydraulic pressure on all FE 35 model variants is quoted in literature to be 2,500psi, with a respectable oil flow rate just shy of four gallons per minute.

It’s pretty difficult to test your potential new tractor without the T-bar fitted, as it’s not possible to fully pressurise the pump without it. Put the tractor into lift and check for a nice smooth movement as the arms rise. If the arms fall sharply with the engine off, wear will be present in the lift piston.

You can expect the arms to drop slowly, which is nothing to worry about. Putting a heavy implement may give a false reading of hydraulic health if the draft spring is out of adjustment, as the weight pulling on the top link could cancel the lift. In short, you can test a T-bar-equipped model with a pressure gauge through the trailer pipe, but a tractor missing this part will be harder to appraise.

Stand to the rear of the machine and lift the link arms manually to check for wear in the various linkages and pins. Like the clutch pedal trick, this is always a good indicator of a tractor’s working hours. Tractors used continuously on scraper duties will be more likely to suffer from worn link arm mounting pins at the tractor end. These pins are sealed by a taper into the casting, which can only be accessed from the inside. If oil is issuing from this area, make a thorough check to make sure the casting hasn’t been worn into an oval shape, as little can be done once this has been allowed to happen without some ‘major surgery’ or even a new casting.

Finally, check for wear in the cross shaft’s bushes, once again especially on machines used for scraping.

Brakes

The FE 35 won’t win any awards for best braking but, with a little TLC, most tractors can be made sufficiently safe to drive on the public highway. The most likely cause of ineffective brakes will be oil contamination of the system, caused by leaking half shaft seals.

Check for wetness on the brake’s back plate and down the inside of the rear wheel dish. Replacing the half-shaft seals and bearings is a specialist job requiring the use of a press and specialist tools, as is adjusting the bearing end float by means of shimming. Rock the tractor’s rear wheels and listen for a knock which, if present, will indicate wear in this area.

With the exception of the industrial variants, the parking brake is a ratchet and pawl system on the foot pedal.

Front axle and steering

The front axle set-up on an FE 35 is similar in part to that of the previous TE-20 model, with a swept axle supported by a pair of radius arms mounting back to the tractor, behind the engine. Check for play on the ball and socket joint of the radius rod, which can be relieved somewhat by taking a few thou off the mounting socket where it bolts to the tractor, but don’t tell anyone I told you to do that!

The ‘new’ front axle used a malleable iron, heavy-duty support that was bolted to the cylinder block and sump.

The pivot pin is a dry, non-greaseable affair and, to this end, can wear. As the axle is curved, it exerts its force in a twisting motion to the axle. For this reason, wear usually manifests itself at the rear of the pin support web situated directly in front of the crankshaft pulley. This will probably only be an issue on tractors that have previously been fitted with a loader.

If your tractor has lights (or holes) on the top of the bonnet in a Mickey Mouse pose, then it’s a safe bet that it’s been on a loader at some stage in its life.

The steering box on an FE 35 is far superior than that of a TE-20, with its recirculating ball mechanism serving to reduce feedback or shock-load for the steering wheel over rough ground and minimising the risk of broken thumbs as a result.

Check for lift in the steering wheel, which can be adjusted out but requires the removal of the wheel, which can be troublesome and will certainly require the use of a three-legged puller.

Leaking boxes can be easily repaired and should not pose much of a problem to fix. As the ball joints are greaseable, they should provide plenty of service life if kept well lubricated by the previous owner.

Tinwork

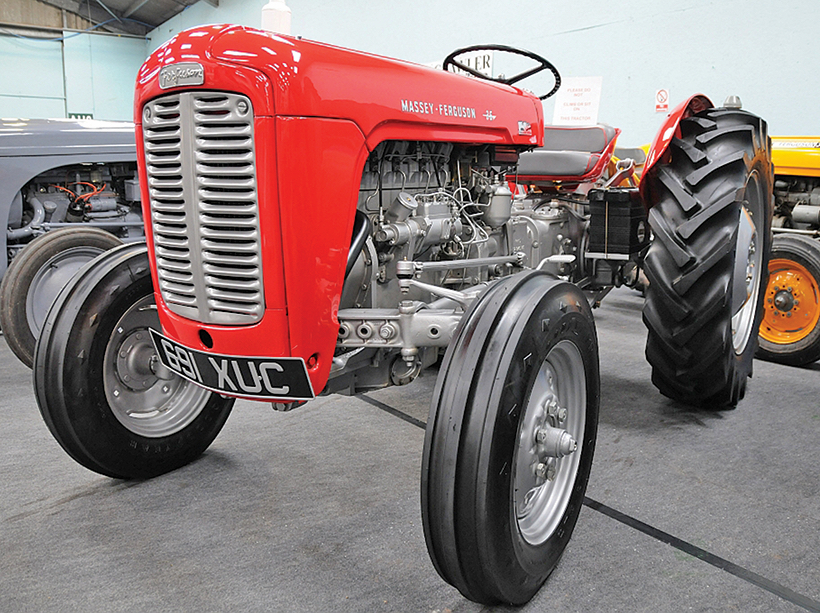

It’s worth noting here that the bonnet of an FE 35 is different to that of the later MF 35 models. FE bonnets have a flush-mounted service hatch (operated by push buttons), opening to reveal the water and fuel filling points.

Grey & Gold FE 35s have a cast, gold-coloured Ferguson badge on the front and sides of the bonnet.

The front grille is removable to reveal the radiator for cleaning. Bonnet badges for the grey and gold tractor are both side- and front-mounted, with the word ‘Ferguson’ cast into a gold-backed badge. Early red and grey models sport just the ‘Ferguson’ badge to the front of the bonnet, in a chromed finish. The side badges were deleted and replaced by the new (at this time) Ferguson system logo. Later FEs in red will have the triple triangle logo proudly mounted to the front, top edge.

The first batch of red and Flint Grey FE 35s have a silver-coloured cast Ferguson bonnet badge to the front of the bonnet only. Side badges were deleted in favour of the Ferguson System logo transfer.

Dents can be a pain to remove and fill if you’re planning a concours restoration, and look out for rotten chin panels where mud has been allowed to build up. Fenders pre-date the mandatory safety improvements, and will be the shell-type that doesn’t extend down to join the footboards. Although the skins can be prone to rot out at the bottoms, the frames will usually be intact, and can be reused on new skins, which are widely available.

Some models will have been retro-fitted with an aftermarket safety kit, which will most likely also include an additional guard to the bonnet around the fan area.

Paint colours for an FE 35 are Light Grey and Gold for the early model and MF red and Flint Grey metallic for the later variants. It’s my belief that the introduction of the three-cylinder 35 sparked the launch of the later-type red and Stoneleigh Grey models. As always, I’d be pleased to hear if anyone knows differently.

A fine example of an FE 35 seen at Tractor World Spring, in 2010.

Electrical system

There’s not a lot to report here. The diesel-powered FE 35 had twin, six-volt batteries wired to produce a 12-volt system. One battery is housed on the front of the left-hand trumpet housing, with the other in the usual place, just forward of the dash panel on this model. The spark-ignition engines all have one 12-volt battery, once again in front of the dash panel.

The De Luxe model was fitted with a tractormeter as standard.

Charging to this positive-earth system is provided by a dynamo on all model variants. With few gauges, there’s little to go wrong. If the tractormeter/rev counter is not functioning, it could well be the angle-drive gearbox that’s situated near the injector pump on the 23C diesel engine.

Wheels, tyres and extras

Pressed-steel PAVT (power adjusted, variable track) wheels were offered as an option on later models, and would make a rare find on an FE 35 tractor. Standard wheels were offered as 10×28 or 11×28, with the basic model having ‘skinny’ fronts of 4.00×19 and the De Luxe sporting the more common 6.00×16, all in pressed steel.

The FE 35 is a lovely tractor from every angle. This example is fitted with 6.00-16 front tyres and 11.2-28 rears.

Optional extras also make a nice find, and will add value to any potential purchase. Look out for the T-bar-style pick-up hitch, which will nearly always be bundled with the trailer tipping pipe. Stabilisers (for the lower links) will be fairly common, but belt pulleys are becoming rarer, as are tractor jacks, which provided the tractor with the ability to raise itself clear of the ground using its own hydraulic linkage. Genuine engine covers are as rare as hen’s teeth!

Final words

The FE 35 is a no-frills, basic, fun tractor to use, enjoy and work on. Owning an FE 35 puts you back before the days of Multi-Power, iPTO, Pressure Control, locking differentials and even safety-shell fenders. With the growing interest in these historic machines, parts have become increasingly available, and at reasonable prices.

With so many models having been made, there will also be lots of choice, so appraise your tractor well before making a commitment. The later, three-cylinder diesel MF 35s tend to command higher prices than the FE 35s, which is another good reason for joining the FE owners club.

| Specification: Ferguson 35 | ||||

| Petrol | Diesel | TVO | Lamp Oil | |

| Cylinders | 4 | 4 | 4 | 4 |

| Bore | 87mm | 84.14mm | 87mm | 87mm |

| Stroke | 92mm | 101.6mm | 92mm | 92mm |

| Displacement | 2,186.5cc | 2,258cc | 2,186.5cc | 2,186.5cc |

| Valves | Overhead high-lift type | |||

| Compression ratio | 6:1 or 6.6:1 | 20:1 with no decompressor | 5:1 | 4.3:1 |

| Brake horsepower | 37hp | 37hp | 30hp | 29hp |

| Fuel tank capacity | 10 gal | 9 gal | 1 gal petrol,

9 gal TVO |

1 gal petrol

9 gal LO |

| Engine sump | 12 pints | |||

| Transmission | 6.6 gals | |||

| Cooling system | 15 pints | |||

| Length | 117in | |||

| Height | 54in | |||

| Weight | 2,940lb | 3,150lb | 2,940lb | 2,940lb |

| Ground clearance | 12¼in | |||

| Wheelbase | 72in | |||

| Turning circle | 16ft (using brakes) | |||

| Gears | 6 fwd, 2 rev | |||

Note: Data taken from Ferguson 35 launch brochure, dated July 1956.

| Massey Ferguson list prices: November 1957 | |||

| £ | s | d | |

| De Luxe petrol | £524 | 5 | 0 |

| Basic petrol | £491 | 0 | 0 |

| De Luxe diesel | £624 | 15 | 0 |

| Basic diesel | £586 | 0 | 0 |

| De Luxe vaporising oil | £534 | 5 | 0 |

| Basic vaporising oil | £505 | 5 | 0 |

| Serial numbers: FE 35 | ||||

| Year | From | To | No. made* | Notes |

| 1956 | 1001 | 9225 | 8,224 | Starts October 1956 |

| 1957 | 9226 | 74655 | 65,429 | End of grey & gold to October 1957 |

| 1957 | 74656 | 79552 | 4,896 | Red & Flint Grey tractor starts November 1957 |

| 1958 | 79553 | 125067 | 45,514 | |

| 1959 | 125068 | 166595 | 41,527 | Last 23C approx. November 1959, first A3.152 from 166596 – year ends 171470 |

| Total of FE 35s produced* | 165,590 | |||

Source: MF

* Assuming no gaps in serial number data

| Serial number prefixes: all models | |

| Chassis/skid unit type | |

| Normal width model | S |

| Vineyard model | V |

| Industrial | J |

| High clear | C |

| Engine type | |

| Petrol engine | G |

| Petrol (High altitude) | H |

| Four-cylinder diesel (23C) | D |

| TVO | K |

| Lamp oil | L |

| Three-Cylinder diesel | N |

| Butane Gas | B |

| Clutch type | |

| Single plate | F |

| Dual plate | N |

For a money-saving subscription to Tractor & Machinery magazine, simply click here

Previous Post

Silage-making secrets from the 1960s

Next Post

Beautifully-restored Ferguson Mark 1 trailer